Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hilton DEETH | + 2429 word(s) | 2429 | 2021-07-06 05:29:01 | | | |

| 2 | Peter Tang | Meta information modification | 2429 | 2021-07-16 10:40:49 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Deeth, H. Extended Shelf-Life Milk Thermal Processing. Encyclopedia. Available online: https://encyclopedia.pub/entry/12113 (accessed on 07 February 2026).

Deeth H. Extended Shelf-Life Milk Thermal Processing. Encyclopedia. Available at: https://encyclopedia.pub/entry/12113. Accessed February 07, 2026.

Deeth, Hilton. "Extended Shelf-Life Milk Thermal Processing" Encyclopedia, https://encyclopedia.pub/entry/12113 (accessed February 07, 2026).

Deeth, H. (2021, July 15). Extended Shelf-Life Milk Thermal Processing. In Encyclopedia. https://encyclopedia.pub/entry/12113

Deeth, Hilton. "Extended Shelf-Life Milk Thermal Processing." Encyclopedia. Web. 15 July, 2021.

Copy Citation

Extended shelf-life (ESL) or ultra-pasteurized milk is produced by thermal processing using conditions between those used for traditional high-temperature, short-time (HTST) pasteurization and those used for ultra-high-temperature (UHT) sterilization.

extended shelf-life

ESL milk

psychrotrophic spore-formers

B*-value

β-lactoglobulin denaturation

1. Introduction

Extended shelf-life (ESL) milk has gained substantial market share in many countries [1]. It has a refrigerated shelf-life of 21–45 days with some manufacturers claiming a shelf-life of up to 90 days. It is produced by two principal technologies: (1) Thermal processing using more severe conditions than pasteurization but less severe than ultra-high-temperature (UHT) processing; and (2) Non-thermal processes such as microfiltration [2] and bactofugation [3], usually combined with a final thermal pasteurization treatment to meet regulatory requirements.

2. Heating Methods

The heating systems used for ESL processing are of two major types, direct and indirect. In direct systems, heating occurs through direct contact between steam and the product and in indirect systems the heat is transferred to the product from steam or hot water through a stainless steel barrier in a heat exchanger. These systems are described in numerous publications, e.g., [4][5][6][7].

3. Microbiological Considerations

There are two major aspects to be considered when optimizing the conditions for producing ESL milk, microbiological and sensory. Ideally, ESL milk should not show any microbial growth during refrigerated storage. However, this is generally not the case because of several factors.

The microbiological issues can be divided into those related to the bactericidal nature of the heating conditions and those associated with post-processing contamination. The relative importance of these for the shelf-life of ESL milk depends on whether the milk is packaged aseptically or under very clean, but not aseptic, conditions. The nature of the heating conditions and storage temperature are the only factors relevant to the microbiology of aseptically packaged milk, while post-processing contamination together with the heating and storage conditions is important for ESL milks not packaged aseptically. Since ESL milk is usually not packaged under aseptic conditions, the bacteria in such ESL milk include spore-forming bacteria whose spores are not destroyed by the heating process, as well as spore-forming and non-spore-forming bacteria entering the milk after processing.

A further consideration that can affect ESL milk is the bacteriological quality of the raw milk. Because of the logarithmic reduction of bacterial counts by heat, the higher the bacterial count in the raw milk, the higher will be the residual count in the heated milk. Also, if psychrotrophic bacteria such as Pseudomonads are allowed to grow in the raw milk and produce heat-resistant proteases, bitter flavors can develop in the ESL milk during storage. As a rule of thumb, the total count in the raw milk should not exceed 105 CFU/mL.

4. Optimizing the Flavor of ESL Milk

As well as the microbiological aspects, the chemical effect of the heat process also needs to be considered. The main chemical effect of concern is the production of flavor volatiles, which impart a heated or cooked flavor to the milk. The ideal ESL milk should have a flavor similar to that of pasteurized milk, that is, a very low level of heated or cooked flavor. Fortunately this is possible, although in practice the heating conditions for this to occur are seldom optimized.

At this point it is necessary to reiterate an essential difference between the kinetics of bacterial destruction and those of chemical reactions. Heating at high temperatures for short holding times favors high levels of bacterial destruction, while heating at lower temperatures for longer holding times result in high levels of chemical change. This is illustrated in a comparison of UHT processing, which typically occurs at ~140 °C for a few seconds, and in-container sterilization, which uses temperatures of 110–120 °C for 10–20 min. Both processes have a similar bactericidal effect but much more chemical change occurs in the in-container sterilized milk, as evidenced by a brownish color and a distinct cooked flavor. Similarly for ESL processing for a particular bactericidal effect, i.e., the same F0 or B*, combinations of higher temperatures for short times produce less chemical change than combinations of lower temperatures for longer times. This was illustrated by Rysstad and Kolstad [1] with a direct and an indirect process having equal bactericidal effects (i.e., the same B* or F0) (135 °C for 0.5 s and 127 °C for 1 s, respectively); the indirect process causes much more chemical change, as measured by denaturation of β-Lg, than the direct process (details below).

The chemical effect of a heat process can be assessed in several ways using the kinetics of various chemical reactions. A commonly used chemical index is C*, which is based on the kinetics of destruction of the vitamin thiamine. A C* of 1 is equivalent to a 3% destruction of thiamine and is the recommended upper limit for UHT milk. Another measure is the percentage denaturation of the whey protein, β-Lg. This is arguably a better measure than C* for ESL milk as the denaturation is accompanied by the formation of volatile sulfur compounds, which are largely responsible for the heated or cooked flavor of heat-treated milk.

Mayer et al. [8] investigated the levels of undenatured β-Lg in commercial milk samples, including 71 ESL, obtained from retail outlets in Austria. Only 45% of the ESL milk samples analyzed had β-Lg contents of >1800 mg/L milk, a proposed limit for ESL milk [1]. (Note: an undenatured β-Lg content of 1800 mg/L represents 45–50% denaturation.) A further 55% of the analyzed ESL milk samples had low undenatured β-Lg levels, <500 mg/L, equivalent to >85% denaturation). This spread of data reflects the fact that there are no specified conditions for ESL processing.

Rysstad and Kolstad [1] reported 13.6% denaturation of β-Lg in Pure-Lac ESL milk processed at 135 °C for 0.5 s. They compared this with an indirect heating system of equal F0-value with a nominal temperature–time condition of 127 °C for 1 s, which had 83.5% denaturation. Huijs et al. [9] reported ~20–25% denaturation of β-Lg in milk treated with Innovative Steam Injection (ISI) heating at 150–180 °C for <0.1 s.

Cooked/sulfurous flavor begins to be noticed in heated milks when denaturation of β-Lg reaches ~60% [10]. Therefore, appropriate heating conditions should be chosen in order to minimize denaturation of β-Lg and avoid development of this flavor. Therefore, the recommended level of 1800 mg/L of undenatured β-Lg [1] (45–50% denaturation) is reasonable. A percentage denaturation of 50% is proposed here as the upper limit for ESL milk. It is recognized, however, that only the undenatured level is measured and the level in the raw milk from which the ESL milk is produced is seldom known. For that reason, a level of 1600–1800 mg/mL is suggested, assuming a level of β-Lg in raw milk of 3200–3600 mg/mL. An alternative measure is the undenatured whey protein index (WPNI), which is commonly used to indicate the severity of the pre-heating process in the manufacture of skim milk powder [11]. ESL milk fits into the medium-heat range and it is proposed that the level in ESL milk should be 3.75–4.0 mg/g of dry matter. WPNI correlates very well (negatively) with denaturation of β-Lg [12].

Another chemical measure of heat load is furosine, which is a measure of the first stage of the Maillard reaction between lactose and protein-bound lysine. Lorenzen et al. [13] reported the level of furosine in commercial thermally processed ESL milk in Germany, Austria, and Switzerland to be 11.1–22.6 mg/100 g protein, while Mayer et al. [8] analyzed 71 ESL milk in Austria and found that only 45% had furosine levels <40 mg/100 g protein, a recommended upper limit. According to these authors, “good” ESL milk had a furosine level of 11.6 mg/100 g protein, while “bad” ESL milk had 71.3 mg/100 g protein. Gallman [14] reported an average furosine level for ESL milk of 20 mg/100 g protein but suggested that it should be possible to achieve <12 mg/100 g protein (and >1800 mg/L of undenatured β-Lg).

Lactulose, which is not present in raw milk, is formed from lactose during heating and is arguably the best chemical index of heat treatment [4] (pp. 198–200). It has been used for ESL milk, with proposed values for good-quality milk of <30 mg/L [14] and <40 mg/L [15] being suggested. For reference, Pure-Lac milks were reported to have <40 mg/L [15] and commercial directly processed UHT milks have levels of ≥90 mg/L [4] (p. 199).

5. Optimizing ESL Heating Conditions

Unlike the temperature–time conditions for pasteurization, which are specified in most countries to be ≥72 °C for ≥15 s, there are generally no such specified conditions for ESL processing. The reported temperatures for producing ESL milk by thermal means alone vary from 90 to 145 °C. However, most ESL milk is processed at 120–130 °C, for holding times of a few seconds. In the USA, ESL milk, called “ultra-pasteurized milk,” is defined as being processed at ≥138 °C for ≥2 s. Packaging of ESL milk is commonly under ultra-clean conditions but can be aseptic [16].

Reported commercial processing conditions for ESL milk are mostly in the range 123–127 °C for 1–5 s [17][18][13][19][20][21]. Higher temperatures can also be used. As mentioned, U.S. regulations define the process of “ultra-pasteurization” as heating milk at ≥138 °C for ≥2 s. A heat treatment of 138 °C for 2 s may seem severe for ESL milk, but it is still a sub-UHT treatment with calculated F0, B*, and C* of 1.7 min, 0.4, and 0.12, respectively, for a steam infusion or steam injection system; corresponding UHT indices are ≥3 min, ≥1, and ≤1, respectively. Even higher temperatures for shorter times, up to 145 °C for <1 s, using the Pure-Lac system [1][15] and up to 180 °C for <0.1 s using the ISI system [9], have also been advocated. These higher-temperature treatments with very short holding times are still sub-UHT treatments in terms of their sporicidal effects, i.e., B* values are <1. ESL milks produced at lower temperatures are also marketed. In South Africa, ESL milk is processed at 94–100 °C [22]. This product is similar to the ESL milks discussed by Manji [23], involving processing by direct steam heating at 89–100 °C.

Several authors have reported the effects of different ESL temperature–time combinations on the shelf-life of the product. For example, Ranjith [24] showed that heating at <117.5 °C for 1 s was insufficient to prevent bacterial growth in cream during storage at 7 °C. He concluded that temperatures ≥120 °C were required for a shelf-life of 49 days at 7 °C. Blake et al. [25] found that treatments at ≤132 °C were insufficient to prevent growth during refrigerated storage but that heating at ≥134 °C for 4 s produced ESL milk with a long shelf-life. In both of these studies, the ESL milk was packaged aseptically.

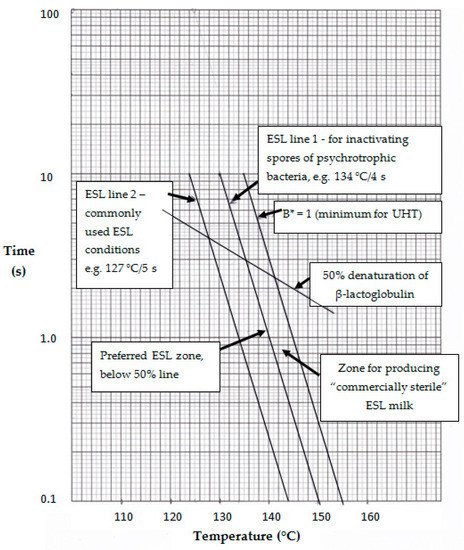

Based on the above discussion, it is apparent that the optimum heating conditions for producing ESL milk should be based on inactivating spores of psychrotrophic bacteria and minimizing cooked flavor. It is proposed that the former be based on the data of Blake et al. [25], which showed that treatment at ≥134 °C for 4 s was effective. This is in line with the conclusion of Bergere and Cerf [26] that milk processed at ≥134 °C should not contain B. cereus spores. A heat treatment 134 °C for 4 s would have a B* of 0.32 (and F0 of 1.33), considerably less than 1.0, the minimum for UHT processing [4]. This is shown in Figure 1 by “ESL line 1,” which joins points with a B* of 0.32 and is to the left of the B* = 1 line. The slope of the line is based on the assumption that the z-value for psychrotrophic spore inactivation is the same as for inactivation of thermophilic spores, i.e., ~10. This is a reasonable assumption given the wide range of z-values reported for B. cereus spores [27][26][28][29][30]. It is therefore proposed that the B* for ESL processing should be >0.3.

Figure 1. Temperature–time combinations for producing extended shelf life (ESL) and ultra-high-temperature (UHT) processed milk. Points along lines have equal effectiveness in either inactivating bacterial spores or causing 50% denaturation of β-lactoglobulin.

As proposed in Section 4, the heat input for ESL milk processing should be less than that which would theoretically cause ~50% denaturation of β-Lg (according to the kinetics reported by Lyster [31]. The temperature–time conditions to achieve 50% denaturation of β-Lg are shown by the line labeled thus in Figure 1. Hence, points along the ESL line 1 below the 50% β-Lg denaturation line (the 50% line) represent the best conditions for producing ESL milk to ensure the destruction of spores of psychrotrophic bacteria and cause minimal flavor change. “ESL line 2” in Figure 1 shows temperature–time conditions equivalent to 127 for 5 s, which is representative of the conditions commonly used for ESL milk production, and joins points with a B* of ~0.09. Clearly these conditions lie to the left of ESL line 1 and would not be expected to inactivate all psychrotrophic spores.

Points in the zone between ESL lines 1 and 2 and below the 50% line represent reasonable conditions for commercial production of ESL milk; the nearer the conditions are to ESL line 1, the more likely that spores of psychrotrophic spore-formers will be destroyed. Furthermore, points in this zone below the 50% line will have the freshest flavor. Points in the zone between ESL lines 1 and 2 and above the 50% line will have similar bactericidal effects to those below the 50% line but will have more cooked flavors.

Milk processed at temperature–time conditions in the zones between ESL line 1 and the B* = 1 line and below the 50% line will have the greatest bacterial stability, having B* values between 0.32 and 1 and little cooked flavor. In effect, such milk could be termed “commercially sterile” ESL milk. A commercially sterile product is defined as one in which no bacterial growth occurs under the normal conditions of storage; for ESL milk, this is under refrigeration, preferably at ≤4 °C. While this term is normally applied to UHT milk, it is also applicable to ESL milk processed to inactivate all spores of psychrotrophic bacteria, and packaged aseptically. Commercial sterility implies that not all packages of every batch will be devoid of bacteria that could grow and cause spoilage. Brody [32] suggested a target defect rate of ~1 in 10,000, the same as for UHT milk [4] (p. 329).

Commercially sterile ESL milk with an expected long shelf-life has an increased risk of developing bitterness. The native milk plasmin will not be inactivated under these heating conditions and, although it has low activity at low temperature, it is not inactive [33]. De Jong [34] showed that ISI-ESL milk, a commercially sterile ESL milk that had plasmin activity, did not develop bitterness during storage at 7 °C for up to 28 days. However, bitterness may develop during longer periods of storage. In addition to plasmin, residual bacterial proteases from growth of psychrotrophic bacteria in the raw milk before processing will be more likely to cause proteolysis, and hence bitterness, during long storage times (>30–40 days) than during shorter storage times. For both plasmin and bacterial proteases, maintenance of low temperature in the cold chain, preferably at ≤4 °C, is crucial. Fluctuations to higher temperatures will increase the risk of proteolysis and the development of bitterness. Further research is required to assess the risk of bitterness development in “commercially sterile” ESL milk, with long shelf-life, from proteolysis by plasmin and bacterial proteases.

References

- Rysstad, G.; Kolstad, J. Conference contribution: Extended shelf life milk-advances in technology. Int. J. Dairy Technol. 2006, 59, 85–96.

- Schmidt, V.S.J.; Kaufmann, V.; Kulozik, U.; Scherer, S.; Wenning, M. Microbial biodiversity, quality and shelf life of microfiltered and pasteurized extended shelf life (ESL) milk from Germany, Austria and Switzerland. Int. J. Food Microbiol. 2012, 154, 1–9.

- Khoza, S. Effect of Extended Shelf Life Milk Processing on the Bacterial Composition Associated with the Nozzles of Filling Machines. Master’s Thesis, University of Pretoria, Pretoria, South Africa, 2015.

- Deeth, H.C.; Lewis, M.J. High Temperature Processing of Milk and Milk Products; Wiley Blackwell: Oxford, UK, 2017; ISBN 978-1-118-46050-4.

- Burton, H. Ultra High Temperature Processing of Milk and Milk Products; Elsevier Applied Science Publishers: New York, NY, USA, 1988.

- Lewis, M.; Heppell, N. Continuous Thermal Processing of Foods: Pasteurization and UHT Sterilization; Aspen Publishers: Gaithersburg, MD, USA, 2000; ISBN 0-8342-1259-5.

- Datta, N.; Elliott, A.J.; Perkins, M.L.; Deeth, H.C. Ultra-high-temperature (UHT) treatment of milk: Comparison of direct and indirect modes of heating. Aust. J. Dairy Technol. 2002, 57, 211–227.

- Mayer, H.K.; Raba, B.; Meier, J.; Schmid, A. RP-HPLC analysis of furosine and acid-soluble β-lactoglobulin to assess the heat load of extended shelf life milk samples in Austria. Dairy Sci. Technol. 2010, 90, 413–428.

- Huijs, G.; van Asselt, A.; Verdurmen, R.; de Jong, P. High speed milk. Dairy Ind. Int. 2004, 69, 30–32.

- Gaafar, A.M.M. Investigation into the Cooked Flavor in Heat-Treated Milk. Ph.D. Thesis, University of Reading, Reading, UK, 1987.

- Oliveira, L.N.; Marinho, V.T.; Zamagno, M.V.; Lauro, M.A.; Barboza, J.A.N.; da Silva, P.H.F. Assessment of whey protein nitrogen index as an indicator of heat treatment for UHT milk and milk powder. J. Candido Tostes Dairy Inst. 2015, 70, 78–84.

- Anema, S.G.; Lloyd, R.J. Analysis of whey protein denaturation: A comparative study of alternative methods. Milchwissenschaft 1999, 54, 206–210.

- Lorenzen, P.C.; Clawin-Raedecker, I.; Einhoff, K.; Hammer, P.; Hartmann, R.; Hoffmann, W.; Martin, D.; Molkentin, J.; Walte, H.G.; Devrese, M. A survey of the quality of extended shelf life (ESL) milk in relation to HTST and UHT milk. Int. J. Dairy Technol. 2011, 64, 166–178.

- Gallmann, P.U. Possible quality improvements/benefits of extended shelf life (ESL) milk. In Proceedings of the Conference on Extended Shelf-Life Milk; International Dairy Federation: Brussels, Belgium, 2000.

- Fredsted, L.B.; Rysstad, G.; Eie, T. Pure-Lac™: The new milk with protected freshness and extended shelf life. In Heat Treatments and Alternative Methods; International Dairy Federation: Brussels, Belgium, 1996; Volume 9602, pp. 104–125. ISBN 92 9098 023 6.

- Kaufmann, V.; Scherer, S.; Kulozik, U. Procedures for the prolongation of the storability of consumable milk and its material changes: ESL milk. J. Verbraucherschutz Lebensm.-J. Consum. Prot. Food Saf. 2010, 5, 59–64.

- Mayr, R.; Gutser, K.; Busse, M.; Seiler, H. Indigenous aerobic spore-formers in high heat treated (127 °C, 5 s) German ESL (Extended Shelf-life) milk. Milchwissenschaft 2004, 59, 143–146.

- Mugadza, D.; Buys, E. Diversity of Spore Former and Non-Spore Former Bacteria in Extended Shelf-Life (ESL) Milk; South African Society of Dairy Technology Dairy Symposium: Capetown, South Africa, 2014.

- Vatne, K.B.; Castberg, H.B. Processing and packaging aspects of extended shelf life products. Aust. J. Dairy Technol. 1991, 46, 98–100.

- Kaufmann, V.; Kulozik, U. Processing factors influencing quality and stability of extended shelf life (ESL) milk. DMZ Lebensm. Milchmirtschaft 2008, 129, 28–30.

- MGT. ESL Systems. Extended Shelf Life Milk (Brochure). Available online: (accessed on 1 October 2017).

- Mugadza, D.T.; Buys, E.M. Spoilage Potential of Bacillus spp. & Paenibacillus spp. in Extended Shelf Life (ESL) Milk. In Proceedings of the SASDT 48th AGM & Symposium: Innovation and Cost Optimization, Cape St Francis, Eastern Cape, South Africa, 14–16 April 2015; Available online: (accessed on 1 October 2017).

- Manji, B. Regulatory perspectives to ESL products: North American situation. In Proceedings of the Conference on Extended Shelf-Life Milk; International Dairy Federation: Brussels, Belgium, 2000.

- Ranjith, H.M.P. High temperature pasteurization. In Proceedings of the Conference on Extended Shelf-Life Milk; International Dairy Federation: Brussels, Belgium, 2000.

- Blake, M.R.; Weimer, B.C.; McMahon, D.J.; Savello, P.A. Sensory and microbial quality of milk processed for extended shelf life by direct steam injection. J. Food Prot. 1995, 58, 1007–1013.

- Bergere, J.-L.; Cerf, O. Heat resistance of Bacillus cereus spores. In Bacillus cereus in Milk and Milk Products; International Dairy Federation: Brussels, Belgium, 1992; Volume 275, pp. 23–25.

- Dufrenne, J.; Bijwaard, M.; Te Giffel, M.; Beumer, R.; Notermans, S. Characteristics of some psychrotrophic Bacillus cereus isolates. Int. J. Food Microbiol. 1995, 27, 175–183.

- Stoeckel, M.; Westermann, A.C.; Atamer, Z.; Hinrichs, J. Thermal inactivation of Bacillus cereus spores in infant formula under shear conditions. Dairy Sci. Technol. 2013, 93, 163–175.

- Van Asselt, E.D.; Zwietering, M.H. A systematic approach to determine global thermal inactivation parameters for various food pathogens. Int. J. Food Microbiol. 2006, 107, 73–82.

- Hinrichs, J.; Atamer, Z. Sterilization of milk and other products. In Encyclopedia of Dairy Sciences, 2nd ed.; Fuquay, J.W., Fox, P.F., Eds.; McSweeney Academic Press: San Diego, CA, USA, 2011; Volume 2, pp. 714–724. ISBN 978-0-12-374402-9.

- Lyster, R.L.J. The denaturation of α-lactalbumin and β-lactoglobulin in heated milk. J. Dairy Res. 1970, 37, 233–243.

- Brody, A.L. Aseptic and extended-shelf-life packaging. Food Technol. 2006, 60, 66–68.

- Crudden, A.; Fox, F.; Kelly, A.L. Factors affecting the hydrolytic action of plasmin in milk. Int. Dairy J. 2005, 15, 305–313.

- De Jong, P. Thermal processing of milk. In Advanced Dairy Science and Technology; Britz, T.J., Robinson, R.K., Eds.; Blackwell Publishers Ltd.: Oxford, UK, 2008; pp. 1–34. ISBN 978-1-4051-3618-1.

More

Information

Subjects:

Food Science & Technology

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

13.8K

Revisions:

2 times

(View History)

Update Date:

16 Jul 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No