| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Volodymyr Gnatyuk | + 7956 word(s) | 7956 | 2021-06-03 05:13:44 |

Video Upload Options

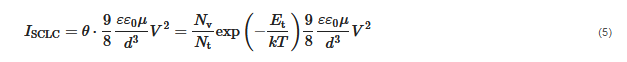

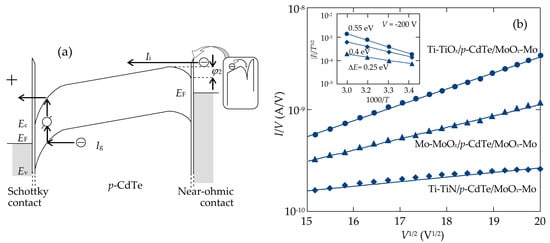

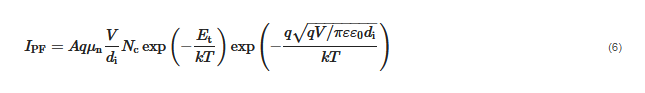

Different contact materials and optimization of techniques of their depositions expand the possibilities to obtain high performance room temperature CdTe-based X/γ-ray detectors. The heterostructures with ohmic (MoOx) and Schottky (MoOx, TiOx, TiN, and In) contacts, created by DC reactive magnetron sputtering and vacuum thermal evaporation, as well as In/CdTe/Au diodes with a p-n junction, formed by laser-induced doping, have been developed and investigated. Depending on the surface pre-treatment of semi-insulating p-CdTe crystals, the deposition of a MoOx film formed either ohmic or Schottky contacts. Based on the calculations and I-V characteristics of the Mo-MoOx/p-CdTe/MoOx-Mo, In/p-CdTe/MoOx-Mo, Ti-TiOx/p-CdTe/MoOx-Mo, and Ti-TiN/p-CdTe/MoOx-Mo Schottky-diode detectors, the current transport processes were described in the models of the carrier generation–recombination within the space-charge region (SCR) at low bias, and space-charge limited current incorporating the Poole–Frenkel effect at higher voltages, respectively. The energies of generation–recombination centers, density of trapping centers, and effective carrier lifetimes were determined. Nanosecond laser irradiation of the In electrode, pre-deposited on the p-CdTe crystals, resulted in extending the voltage range, corresponding to the carrier generation–recombination in the SCR in the I-V characteristics of the In/CdTe/Au diodes. Such In/CdTe/Au p-n junction diode detectors demonstrated high energy resolutions (7%@59.5 keV, 4%@122 keV, and 1.6%@662 keV).

Article pdf

1. Introduction

2. Capabilities of CdTe-Based X/γ-ray Detectors with MoOx Ohmic Contacts

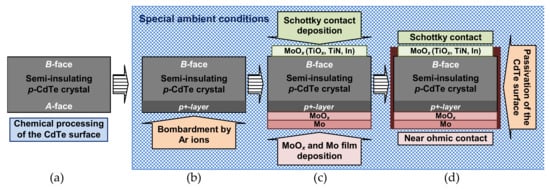

2.1. Fabrication of CdTe-Based Detectors with MoOx Ohmic Contacts

2.1.1. Molybdenum Oxide as a Prospective Material for Ohmic Contact Formation

2.1.2. Schottky Contact Formation

2.2. Electrical Characteristics of CdTe-Based Detectors with MoOx Ohmic Contacts

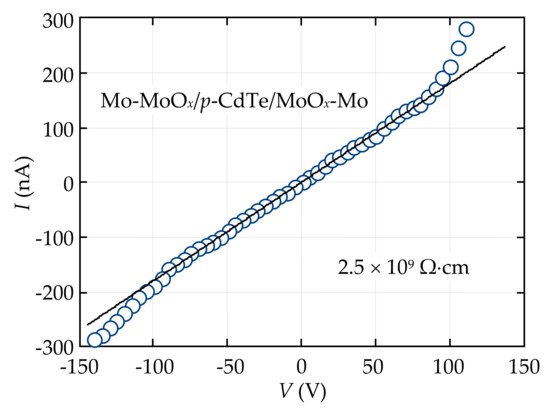

2.2.1. I-V Characteristics of the Heterostructures with MoOx Ohmic Contacts

2.2.2. Features of the Heterostructures with MoOx Ohmic Contacts at Higher Bias

- Capabilities of CdTe-Based X/γ-Ray Detectors with an In Contact Treated by Laser Pulse Radiation

4.1. Laser-Assisted Formation of In/CdTe/Au Diode Structures

4.1.1. Techniques of CdTe Crystal Surface Processing and Electrical Contact Formation

Prior to the formation of electrical contacts and electrode deposition, detector-grade (111) oriented CdTe single-crystal wafers were subjected to preliminary chemical surface processing for cleaning and removing of a disordered surface layer which was generally formed after mechanical polishing and storage of semiconductor crystals [53,54]. The CdTe samples were cleaned in acetone and methanol, then etched in a polishing 3–5% bromine–methanol solution, and finally were thoroughly rinsed with pure methanol. The polished and cleaned samples were dried in an argon flow before applying the next technological procedures of electrical contact formation and laser-induced doping.

The techniques of the fabrication of the In/CdTe/Au diodes with a p-n junction are shown in Figure 7. After the preliminary surface processing, the CdTe crystals were subjected to low temperature (~70–90 °C) annealing in a vacuum chamber at low pressure (< 0.6 mPa) for 1.5–2 h prior to before the metal contact deposition to remove a thin (~0.03 nm) Te film which was generally formed on the semiconductor surface during etching in bromine-containing solutions and then oxidized in air [53,54]. Then, an In film was evaporated on the CdTe(111)B crystal surface without heating of the samples (Figure 7a). The whole surface area of the CdTe crystal pre-coated with an In film was entirely and uniformly irradiated with nanosecond laser pulses at room temperature (Figure 7b). It was shown that distilled water environment was the optimal ambient condition for such treatment [55]. A KrF excimer laser, emitting single pulses with a wavelength of 248 nm and duration of 20 ns, was a pulsed radiation source. The incident laser pulse energy density was varied in a wide range both below and above the CdTe melting threshold [28]. A glass diffuser, homogenizer, and lens were used to provide uniform and controlled laser irradiation of the In/CdTe samples. The time and energy parameters of laser pulses were monitored during irradiation. The deposited In film was relatively thick (0.3–0.5 µm) and it was not completely evaporated under laser irradiation, thus the film served both as an n-type dopant source and electrical contact (electrode) after laser-induced doping (Figure 7c,d).

The second electrode was formed on the opposite side of the samples, i.e., on the CdTe(111)A surface by vacuum thermal evaporation of an Au film (0.3–0.5 µm) (Figure 7d). Both the In and Au electrodes were formed as 4 × 4 mm2 squares and centered on the Te- and Cd-terminated surfaces (5 × 5 mm2) of the sample, respectively. The deposition velocity and thickness of the electrodes (In and Au films) were controlled by the voltage applied to the evaporating metal source and monitored with an XTC thin film deposition controller. After laser irradiation of the In/CdTe structure from the In-coated side and prior to the Au electrode deposition, the sample was subjected to chemical passivation in an aqueous H2O2 solution, and then was rinsed with methanol (Figure 7d). Such procedure was employed to minimize lateral leakage currents, create the appropriate surface states at the CdTe(111)A side, and stabilize electrical characteristics of the In/CdTe/Au diode structure.

Figure 7. Schematic illustration of the fabrication procedures of In/CdTe/Au diode detectors using the laser irradiation technique: (a) chemical surface processing of the crystal and thermal vacuum deposition of an In electrode (dopant film) on the CdTe(111)B surface; (b) irradiation of the In/CdTe structure with nanosecond laser pulses; (c) laser-induced shock wave solid-phase doping of the p-CdTe surface region by In atoms (donors) and formation of a p-n junction; (d) chemical passivation of the crystal surfaces and thermal vacuum deposition of an Au electrode on the CdTe(111)A surface.

4.1.2. Mechanisms of Laser Action on the In/CdTe Structure and p-n Junction Formation

The use of a relatively thick In electrode (0.3–0.5 µm), which also served as an dopant film, made it possible to ensure laser-induced doping without heating the underlying bulk In region and CdTe crystal that avoided a heat-induced deterioration of the structure and properties of the semiconductor. Despite the fact that absorption of laser radiation occurred in a thin (tens of nanometers) In surface layer, the thin semiconductor region under the In/CdTe interface was heavily doped with In atoms [55,56]. It was supposed that In/CdTe/Au diode structures with an In doped CdTe nano-layer and built-in p-n junction were obtained as a result of laser-stimulated modification of the defect structure and solid-phase doping in the deep-seated CdTe region.

Figure 7c illustrates the laser pulse action on the In/CdTe structure that was accompanied with superfast heating, melting, and evaporation of a thin (in order of the radiation absorption depth) In surface layer. The temperature of the laser-induced plasma (evaporated In and overheated environment medium, i.e., water) could reach 1000 °C and higher at laser pulse energy densities used in the experiment (80–130 mJ/cm2). Rapid expansion of the laser-heated In surface region and plasma recoil momentum resulted in generation of high-amplitude stress waves which were transformed to a high pressure shock wave [57]. Laser-induced stress and shock waves propagated through the In film and entered the CdTe crystal involving In dopant atoms [55,56]. Laser-stimulated penetration of high-concentration In dopants into the thin semiconductor region near the In-CdTe interface was due to essential elastic stress gradients, generation of stress and shock waves, and superfast diffusion of In atoms due to barodiffusion [56]. Despite high temperatures of the In electrode surface during laser irradiation, underlying deeper layers remained almost unheated because the deposited In film was much thicker than the laser-heated In surface region; therefore, the temperature in the bulk of In and particularly in CdTe did not significantly increased. This provided optimal conditions for solid-phase doping of a thin CdTe layer owing to rapid mass transport of the In impurity and transformation of the semiconductor point defect structure near the In/CdTe interface as a result of shock wave action and barodiffusion [56].

The fabricated In/CdTe/Au diode detectors were considered as complex metal-semiconductor multi-layered structures consisting of the following layers: In electrode, In/n-CdTe ohmic contact, low-resistivity highly doped n-CdTe:In layer, abrupt p-n junction, bulk part of semi-insulating p-CdTe, Au/p-CdTe near-ohmic contact and Au electrode (Figure 7d). Laser-induced doping of semi-insulating Cl-compensated p-like CdTe crystals was due to the modification of the point-defect system of the semiconductor [28,55]. Detector-grade high-resistivity CdTe:Cl semiconductor contains a large number of intrinsic and impurity point defects, in particular, VCd and Cli, ClTe and other substitutional impurities in Te sites [3–7]. The point defects are generally aggregated as complexes (VCd–ClTe), (VCd–2ClTe) or (VCd–Cli) [6,7]. In detector-grade CdTe:Cl or CdTe:In crystals, complex acceptor defects called A-centers ((VCd–ClTe) and (VCd–InCd)) are typically formed that results in p-type conductivity of the semiconductors and, moreover, spontaneous formation of compensating acceptors (VCd–InCd) is the general problem in n-type doping of CdTe with an In impurity [6,58].

The main advantage of the modification of the CdTe structure and properties during laser irradiation of the crystals pre-coated with a relatively thick In film, was the action of an induced shock wave that could be considered as a stream of phonons scattered by point and extended defects of the crystalline structure. Such action resulted in the dissociation of defect complexes, barodiffusion of impurities and dopants, desorption, and segregation of interstitial atoms, etc. [28,55–57]. In the case of nanosecond laser irradiation of the In/CdTe structures, In dopant atoms, implicated by laser-induced stress and shock waves, penetrated into the CdTe region near the metal-semiconductor interface [28,55]. Laser stimulated processes of barodiffusion and migration of In atoms at VCd and then super-fast “freezing” of a large number of donor point defects (InCd, Cdi, and ClCd) without formation of compensating acceptor complexes (VCd–X), in particular A-centers like (VCd–ClTe) and (VCd–InCd), ensured solid-phase high In doping of a thin CdTe layer near the In/CdTe interface and formation of an abrupt p-n junction [28,55,56].

4.2. Electrical Characteristics of In/CdTe/Au Diode Structures Fabricated by Laser Irradiation

The In/CdTe/Au diode structures with a p-n junction, formed by laser irradiation of the In electrode, were examined by electrical measurements and then samples with low reverse dark currents were selected for testing them as X/γ-ray radiation detectors. Reverse current flowed when the In contact (near the p-n junction) was biased positively with respect to the Au contact (quasi-ohmic). Figure 8 shows the typical I‑V characteristics of the In/CdTe/Au samples fabricated without laser irradiation of the In electrode (a) and with irradiation by nanosecond pulses of a KrF excimer laser with energy densities of ~90 J/cm2 (b) and ~110 J/cm2 (c). The I‑V characteristics of the In/CdTe/Au diodes, measured in dark conditions at room temperature, showed excellent rectifying properties, especially taking into account the fact that CdTe crystals used for detector fabrication were semi-insulating (Figure 8).

In the case of unirradiated In/CdTe/Au samples with just deposited In and Au electrodes (Figure 8a), the rectification was due to a high Schottky barrier at the In/CdTe interface that was typical for an In electrical contact and semi-insulating p-like CdTe and this was widely used for fabrication of Schottky diode detectors [5–10,14]. Moreover, the rectification significantly increased after laser irradiation of the In/CdTe structure (Figure 8b,c). As discussed in the section above, it resulted from laser-induced doping of the thin CdTe region under the In/CdTe interface with an In donor dopant and formation of a shallow and abrupt p-n junction according to the doping mechanisms investigated earlier [28,55,56]. As seen, laser irradiation of the In/CdTe structure from the In electrode side remarkably shifted the I‑V characteristic forward branch toward lower voltages (forward current increased) and reduced reverse current compared with the unirradiated In/CdTe/Au sample (Figure 8). From a practical point of view, it is important to note that the reverse current of the In/CdTe/Au p-n junction diodes reduced by more than 250 times due to laser treatment of the In electrode (Figure 8c).

Figure 8. I‑V characteristics of the In/CdTe/Au diode structures in semi-logarithmic coordinates (a) before and (b,c) after irradiation from the In electrode side by nanosecond pulses of a KrF excimer laser with energy densities of (b) 90 J/cm2 and (c) 120 J/cm2.

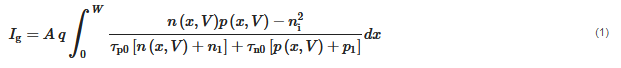

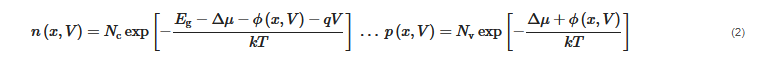

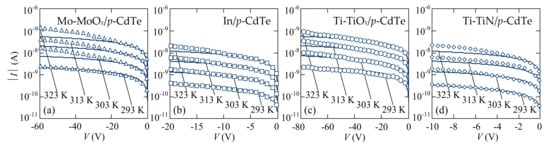

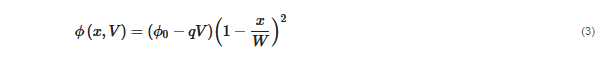

Figure 9 presents a comparison of the calculation results using Equations (1)–(4) (solid lines) and experimental data (symbols). It should be emphasized that the calculations were performed at the concentration of uncompensated acceptors N = Na–Nd = 5 × 1010 сm−3 as it corresponded to CdTe single crystals produced by Acrorad and the ionization energy of the generation–recombination center was accepted as Et = 0.67 eV [20–26]. The computed results exhibited that the lifetimes tn0 of electrons and holes tp0 were such critical parameters determining the reverse current values in the I‑V characteristics.

As mentioned in the section above, the laser-generated stress and shock waves penetrated into the semiconductor region near the In/CdTe interface, implicating In atoms and introducing them as a dopant into the crystal lattice, that decreased the concentration of vacancies in that region. In particular, Cd vacancies were partly filled by the nearest accidental impurities, mainly by In dopant atoms [28,55]. In atoms, substituting Cd atoms, acted as donors [6,58]. So, the impact of laser irradiation increased the effective lifetimes of charge carriers in the depleted region, reduced the generation rate, and thus decreased the reverse dark current of In/CdTe/Au p-n junction detectors.

Figure 9. Comparison of the experimental (symbols) and calculated according to the Sah–Noyce–Shockley theory (solid lines) results of the reverse dark I‑V characteristics of the In/CdTe/Au diode structures before (circles) and after (triangles and squares) irradiation from the In electrode side by nanosecond pulses of a KrF excimer laser with energy densities of 90 J/cm2 (triangles) and 120 J/cm2 (squares).

As seen from Figure 9, the Sah–Noyce–Shockley theory describes well the reverse dark current in the unirradiated In/CdTe/Au diode only in the voltage range of 0 V < |V| < 5 V (circles). The sections of the plots, where the experimental results coincide with calculations, expand in In/CdTe/Au diode structures formed by laser irradiation. In particular, the generation current prevails in the In/CdTe/Au diode after laser treatment with energy density of 90 J/cm2 in the voltage range of 0 V < |V| < 10 V (triangles), whereas laser irradiation with energy density of 120 J/cm2 leads to an increase in the voltage range, corresponding to the generation current, up to ~ −15 V (squares) (Figure 9).

- Spectroscopic Characteristics of CdTe-Based X/γ-Ray Detectors

The spectroscopic performance, including the energy resolutions of the fabricated CdTe-based detectors, was examined using 241Am (59.5 keV), 57Co (122 keV), and 137Cs (662 keV) isotopes as X/γ-ray radiation sources as well as employing a portable spectrometer ANS-MNT004-GTK produced by ANSeeN, Inc. or standard laboratory equipment (a charge-sensitive preamplifier 5102 BS produced by Clear Pulse Co., Ltd. (Tokyo, Japan), coupled to a multichannel analyzer MCA7600 produced by Seiko EG&G Co., Ltd. (Tokyo, Japan), etc.) in the case of investigation of the In/CdTeAu p-n junction diode detectors. The spectroscopic measurements were carried out at room temperature. The electrodes (quasi-ohmic contact) deposited on the CdTe(111)A surface (Cd-terminated) were biased negatively for all the tested detectors.

The energy resolution of the developed detectors was determined by the fabrication techniques and materials selected for the electrical contact formation as well as was depended on the applied bias voltage. The voltage dependences of the energy resolution (FWHM) slightly differed for CdTe-based detectors created by the same techniques, but under different conditions. It can be explained by the decreasing of the misfit strains at the interface between the thin contact film and bulk crystal. In particular, for the Mo-MoOx/р-CdTe/MoOx-Mo, Ti-TiOx/р-CdTe/MoOx-Mo, Ti-TiN/р-CdTe/MoOx-Mo, and In/р-CdTe/MoOx-Mo structures the misfit strain was determined by well-known ratio [59] and equals to 14%, 29%, 34%, and 18%, respectively. Another reason for differences in the energy resolutions could be due to different surface states at the CdTe crystal surfaces when electrical contacts were deposited [21–25]. The optimal bias voltages were found for each detector with MoOx contacts at which the energy resolution and detection efficiency reached the best values.

In Table 1, the energy resolution values for the 59.5 keV and 662 keV peaks in the spectra of 241Am and 137Cs isotopes are respectively presented for the detectors with different contact materials at different combinations of applied bias voltages. For the CdTe-based structures with the same electrical contacts, the energy resolutions varied from the detector to detector by ~25%. At lower bias voltages, the energy resolution degraded due to insufficient field strength to collect photogenerated charge carriers and at higher voltages, deterioration in the energy resolution was due to excessive dark current in the detectors. Some of the reasons for such features of the detectors was the effect of the CdTe crystal defect structure and misfit strains in the transition layer at the electrical contact-bulk semiconductor interface. Here, the results for the best performance of the detectors with one MoOx contact and the second one made from different materials are presented.

Table 1. Energy resolutions of the CdTe-based detectors with different contact materials, measured at different bias voltages for two X/γ-ray radiation sources.

|

X/γ-Ray Source |

Anode/CdTe/Cathode |

Bias Voltage (V) |

FWHM (%) |

|

241Am |

Mo-MoOx/р-CdTe/MoOx-Mo |

−80 |

6 |

|

Ti-TiOx/р-CdTe/MoOx-Mo |

−100 |

>20 |

|

|

Ti-TiN/р-CdTe/MoOx-Mo |

−80 |

11 |

|

|

In/р-CdTe/MoOx-Mo |

−100 |

>25 |

|

|

137Cs |

Mo-MoOx/р-CdTe/MoOx-Mo |

−100 |

7.9 |

|

Ti-TiOx/р-CdTe/MoOx-Mo |

−100 |

9 |

|

|

Ti-TiN/р-CdTe/MoOx-Mo |

−100 |

10.1 |

|

|

In/р-CdTe/MoOx-Mo |

−120 |

5.1 |

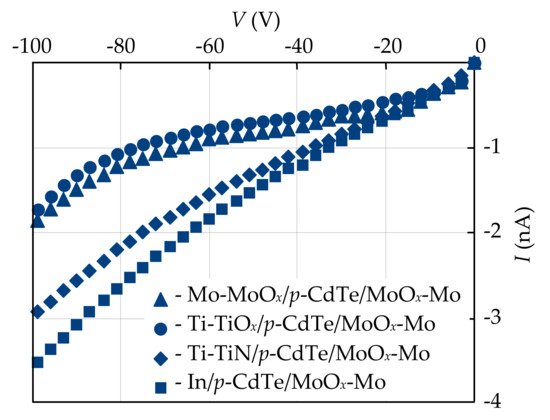

The energy resolution and efficiency of the fabricated CdTe-based detectors depended on the applied bias voltage (Figures 10 and 11). Figure 10 shows the spectra of a 137Cs (662 keV) isotope with the best values of FWHM, measured by the fabricated heterostructures with different electrical contacts at the optimal bias voltages. As seen, the highest resolution (the lowest value of FWHM = 5.1%) was obtained for the In/р-CdTe/MoOx-Mo Schottky-diode detector at V = −120 V (Figure 10b). However, the energy resolution deteriorated (FWHM rose) with increasing bias voltage that was due to a sharp increase in the dark (leakage) current of the diode (Figure 4b).

Figure 10. Room temperature spectra of a 137Cs (662 keV) isotope taken with the (a) Mo-MoOx/р-CdTe/MoOx-Mo, (b) In/р-CdTe/MoOx-Mo, (c) Ti-TiOx/р-CdTe/MoOx-Mo, and (d) Ti-TiN/р-CdTe/MoOx-Mo Schottky-diode detectors.

The techniques developed for the modification of the surface state of semi-insulating p-like CdTe crystals and electrical contact formation, using nanosecond pulse laser irradiation, resulted in the optimization of the detector fabrication technology that made it possible to obtain In/CdTe/Au diode-type X/γ-ray sensors with higher detection efficiency and energy resolution in comparison with the Mo-MoOx/р-CdTe/MoOx-Mo, In/р-CdTe/MoOx-Mo, Ti-TiOx/р-CdTe/MoOx-Mo, and Ti-TiN/р-CdTe/MoOx-Mo Schottky-diode detectors, which we also elaborated, fabricated and investigated. However, CdTe-based detectors with molybdenum oxide ohmic contacts and titanium oxide, titanium nitride, and indium Schottky contacts have shown promise and it is possible to achieve better performance by modification and optimization of the technology procedures of CdTe crystal surface preparation and electrode deposition techniques using different contact materials [21–25,35–40].

Figure 11. Effect of the bias voltage applied to the Mo-MoOx/р-CdTe/MoOx-Mo (triangles), In/р-CdTe/MoOx-Mo (squares), Ti-TiOx/р-CdTe/MoOx-Mo (circles), and Ti-TiN/р-CdTe/MoOx-Mo (diamonds) Schottky-diode detectors on the energy resolution (FWHM) of the 662 keV photopeak in the room temperature 137Cs isotope spectra.

Due to creating the appropriate conditions for photogenerated charge carrier collection, lowering the reverse dark (leakage) current in the In/CdTe/Au p-n junction diode detectors and thus increasing detecting ability and decreasing electrical noises in the detectors, the spectra of 241Am, 57Co, and 137Cs isotopes with quite high energy resolutions were obtained (Figure 12). There was also found a certain optimal bias voltage range for each In/CdTe/Au p-n junction detector that provided higher numbers of counts (better detection efficiency), lower FWHM values for the isotope spectrum photopeaks (higher energy resolution), and true peak channel positions (Figure 12).

Figure 12. Room temperature spectra of (a) 241Am (59.5 keV), (b) 57Co (122 keV), and (c) 137Cs (662 keV) isotopes at different bias voltages (−200 V, −250 V, and −300 V) taken with the In/CdTe/Au p-n junction detector, fabricated by laser radiation of the In electrode.

Table 2 presents the data on the energy resolutions of the In/CdTe/Au p-n detector calculated for the emission spectra of three isotopes measured at different bias voltages (Figure 12). As seen, the best FWHM values were obtained in the spectra taken at V = −200 V. A quite symmetrical shape of the prominent lines of 59.5 keV, 122 keV, and 662 keV in the spectra of 241Am, 122Co and 137Cs isotopes, respectively, for all the applied bias voltages evidences that the full charge collection was complete even at the lowest bias voltage V = −200 V (Figure 12). The broad shoulder at the low-energy side from the 662 keV line (c) was attributed to Compton scattering of γ-rays [7–10].

Table 2. Energy resolutions of the In/CdTe/Au p-n junction detector, fabricated by laser radiation of the In electrode, measured at different bias voltages for three X/γ-ray radiation sources.

|

X-Ray Source |

Bias Voltage (V) |

||

|

−200 |

−250 |

−300 |

|

|

FWHM (%) |

|||

|

241Am (59.5 keV) |

7.5 |

9.04 |

14.72 |

|

57Co (122 keV) |

4.79 |

5.62 |

6.19 |

|

137Cs (662 keV) |

1.6 |

2.1 |

2.7 |

An increase in bias voltage (V = −250 V and V = −300 V) resulted in deterioration of the spectra: the number of counts decreased (a–c), the FWHM values increased (a–c) and the peak channel positions for the 59.5 keV (a) and 662 keV (c) lines were shifted toward the lower-energy side (Figure 12). Such distortion in the isotope spectra with rising bias voltages was attributed to an increase in the total reverse current, i.e., photocurrent (charge packet) and leakage current (mainly due to lateral currents because no any guard ring was used in the experiments).

The features of the CdTe-based X/γ-ray detectors with different contact materials were studied in details earlier [18–34]. The capabilities of the developed detectors to operate for long time without deterioration of their functional parameters were shown and analyzed. However, further improvement of spectroscopic properties of CdTe-based detectors can be achieved by the optimal choice of contact materials, pre-treatment procedures of the semiconductor crystal surfaces, and corresponding techniques of electrode deposition.

- Conclusions

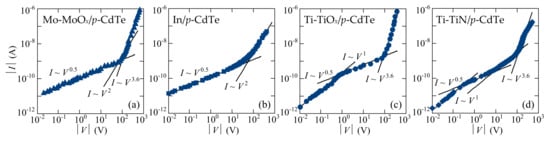

Based on the developed efficient techniques of semiconductor crystal surface processing and electrode deposition, X/γ-ray detectors with different contact materials were fabricated using the same detector-grade p-like CdTe produced by Acrorad Co. The heterostructures with ohmic (MoOx) and Schottky-type (MoOx, TiOx, TiN, and In) contacts, created by DC reactive magnetron sputtering and vacuum thermal evaporation, were characterized by electrical and spectroscopic measurements. It was shown the possibility of the application of molybdenum oxide thin films, as an ohmic or Schottky contacts to semi-insulating p-CdTe crystals, depending on pre-treatment of their surfaces. The fabricated Mo-MoOx/р-CdTe/MoOx-Mo, In/р-CdTe/MoOx-Mo, Ti-TiOx/р-CdTe/MoOx-Mo, and Ti-TiN/р-CdTe/MoOx-Mo Schottky-diode detectors showed high rectification properties with quite low reverse dark currents and were sensitive to X/γ-ray radiation with moderate energy resolutions (5–20%@59.5 keV, 5–10%@662 keV). The comparative analysis of the I‑V characteristics of the developed heterostructures in the framework of the well-known theoretical models allowed us to determine the dominant mechanisms of charge carrier transport and reasons limiting the efficiency and energy resolution of the heterostructure-based X/γ-ray detectors. The charge transport mechanisms, dominating in the heterostructures at certain bias voltage ranges, were attributed to the generation–recombination in the SCR at low bias voltages, SCLC at higher voltages, and the Poole–Frenkel emission at the highest applied biases. The last effect limited the use of the developed Schottky-diode heterostructures as X/γ-ray detectors at high bias voltages.

Higher energy resolutions (7–15%@59.5 keV, 4–6%@122 keV, and 1.6–3%@662 keV) were obtained by the developed In/CdTe/Au diode detectors with a p-n junction formed by laser-induced doping of a thin CdTe surface layer with In atoms (donors). This was realized by irradiation of the p-CdTe crystals pre-coated with an In dopant film with nanosecond laser pulses. The analysis of the I‑V characteristics of the In/CdTe/Au structures evidenced that laser irradiation of the In electrode increased the bias voltage range corresponding to the charge transport mechanism of the carrier generation–recombination in the SCR.