| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Georgiana Gabriela Codina | + 4404 word(s) | 4404 | 2021-05-20 08:27:11 | | | |

| 2 | Peter Tang | Meta information modification | 4404 | 2021-05-21 10:35:23 | | |

Video Upload Options

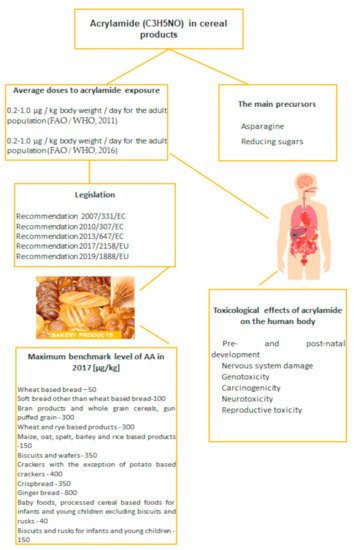

Acrylamide is a contaminant as defined in Council Regulation (EEC) No 315/93 and as such, it is considered a chemical hazard in the food chain. The toxicity of acrylamide has been acknowledged since 2002, among its toxicological effects on humans being neurotoxicity, genotoxicity, carcinogenicity, and reproductive toxicity. Acrylamide has been classified as carcinogenic in the 2A group, with human exposure leading to progressive degeneration of the peripheral and central nervous systems characterized by cognitive and motor abnormalities. Bakery products (bread, crispbread, cakes, batter, breakfast cereals, biscuits, pies, etc.) are some of the major sources of dietary acrylamide.

1. Introduction

2. Toxicological Effects of Acrylamide on the Human Body and Its Risks Represented by It Consumption

3. Legislative Rules on the Maximum Benchmark Levels of Acrylamide in Bakery Products

|

Food |

Benchmark Level 2013 [μg/kg] |

Benchmark Level 2017 [μg/kg] |

|---|---|---|

|

Soft bread |

||

|

Wheat based bread |

80 |

50 |

|

Soft bread other than wheat based bread |

150 |

100 |

|

Breakfast cereals (excl. porridge) |

||

|

Bran products and whole grain cereals, gun puffed grain |

400 |

300 |

|

Wheat and rye based products |

300 |

300 |

|

Maize, oat, spelt, barley and rice based products |

200 |

150 |

|

Biscuits and wafers |

500 |

350 |

|

Crackers with the exception of potato based crackers |

500 |

400 |

|

Crispbread |

450 |

350 |

|

Ginger bread |

1000 |

800 |

|

Baby foods, processed cereal based foods for infants and young children excluding biscuits and rusks |

50 |

40 |

|

Biscuits and rusks for infants and young children |

200 |

150 |

4. Methods to Reduce the Acrylamide Content in Bakery Products

References

- Nachi, I.; Fhoula, I.; Smida, I.; Taher, I.B.; Chouaibi, M.; Jaunbergs, J.; Hassouna, M. Assessment of lactic acid bacteria application for the reduction of acrylamide formation in bread. LWT 2018, 92, 435–441.

- Miśkiewicz, K.; Nebesny, E.; Rosicka-Kaczmarek, J.; Żyżelewicz, D.; Budryn, G. The effects of baking conditions on acrylamide content in shortcrust cookies with added freeze-dried aqueous rosemary extract. J. Food Sci. Technol. 2018, 55, 4184–4196.

- Miśkiewicz, K.; Rosicka-Kaczmarek, J.; Nebesny, E. Effects of chickpea protein on carbohydrate reactivity in acrylamide formation in low humidity model systems. Foods 2020, 9, 167.

- Mogol, B.A.; Gökmen, V. Mitigation of acrylamide and hydroxymethylfurfural in biscuits using a combined partial conventional baking and vacuum post-baking process: Preliminary study at the lab scale. Innov. Food Sci. Emerg. Technol. 2014, 26, 265–270.

- Keramat, J.; LeBail, A.; Prost, C.; Jafari, M. Acrylamide in baking products: A review article. Food Bioprocess Technol. 2011, 4, 530–543.

- Nematollahi, A.; Kamankesh, M.; Hosseini, H.; Ghasemi, J.; Hosseini-Esfahani, F.; Mohammadi, A.; Mousavi Khaneghah, A. Acrylamide content of collected food products from Tehran’s market: A risk assessment study. Environ. Sci. Pollut. Res. 2020, 27, 30558–30570.

- Abt, E.; Robin, L.P.; McGrath, S.; Srinivasan, J.; DiNovi, M.; Adachi, Y.; Chirtel, S. Acrylamide levels and dietary exposure from foods in the United States, an update based on 2011–2015 data. Food Addit. Contam. Part A 2019, 36, 1475–1490.

- Mesías, M.; Morales, F.J.; Delgado-Andrade, C. Acrylamide in biscuits commercialised in Spain: A view of the Spanish market from 2007 to 2019. Food Funct. 2019, 10, 6624–6632.

- Andačić, I.M.; Tot, A.; Ivešić, M.; Krivohlavek, A.; Thirumdas, R.; Barba, F.J.; Brnčić, S.R. Exposure of the Croatian adult population to acrylamide through bread and bakery products. Food Chem. 2020, 322, 126771.

- Mousavi Khaneghah, A.; Fakhri, Y.; Nematollahi, A.; Seilani, F.; Vasseghian, Y. The concentration of acrylamide in different food products: A global systematic review, meta-analysis, and meta-regression. Food Rev. Int. 2020, 2–19.

- Crawford, L.M.; Kahlon, T.S.; Chiu, M.C.M.; Wang, S.C.; Friedman, M. Acrylamide content of experimental and commercial flatbreads. J. Food Sci. 2019, 84, 659–666.

- Salimi, A.; Pashaei, R.; Bohlooli, S.; Vaghar-Moussavi, M.; Pourahmad, J. Analysis of the acrylamide in breads and evaluation of mitochondrial/lysosomal protective agents to reduce its toxicity in vitro model. Toxin Rev. 2020, 1–10.

- Schouten, M.A.; Tappi, S.; Romani, S. Acrylamide in coffee: Formation and possible mitigation strategies—A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 3807–3821.

- Schouten, M.A.; Genovese, J.; Tappi, S.; Di Francesco, A.; Baraldi, E.; Cortese, M.; Romani, S. Effect of innovative pre-treatments on the mitigation of acrylamide formation in potato chips. Innov. Food Sci. Emerg. Technol. 2020, 64, 102397.

- Žilić, S. Acrylamide formation in biscuits made of different wholegrain flours depending on their free asparagine content and baking conditions. Food Res. Int. 2020, 132, 109109.

- Cantrell, M.S.; McDougal, O.M. Biomedical rationale for acrylamide regulation and methods of detection. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2176–2205.

- Jeong, H.; Hwang, S.; Kwon, H. Survey for acrylamide in processed foods from Korean market and individual exposure estimation using a non-parametric probabilistic model. Food Addit. Contam. Part A 2020, 37, 916–930.

- Koszucka, A.; Nowak, A.; Nowak, I.; Motyl, I. Acrylamide in human diet, its metabolism, toxicity, inactivation and the associated European Union legal regulations in food industry. Crit. Rev. Food Sci. Nutr. 2020, 60, 1677–1692.

- Rifai, L.; Saleh, F.A. A review on acrylamide in food: Occurrence, toxicity, and mitigation strategies. Int. J. Toxicol. 2020, 39, 93–102.

- Mustafa, A.; Kamal-Eldin, A.; Petersson, E.; Andersson, R.; Åman, P. Effect of extraction pH on acrylamide content in fresh and stored rye crisp bread. J. Food Compos. Anal. 2008, 21, 351–355.

- Wang, S.; Yu, J.; Xin, Q.; Wang, S.; Copeland, L. Effects of starch damage and yeast fermentation on acrylamide formation in bread. Food Control 2017, 73, 230–236.

- Gerssena, A.; Boveea, T.; van Ginkela, L.; van Ierselb, M.; Hoogenbooma, R. Food and feed safety: Cases and approaches to identify the responsible toxins and toxicants. Food Control 2019, 98, 9–18.

- Vingborg Hedegaard, R.; Granby, K.; Frandsen, H.; Thygesen, J.; Skibsted, L. Acrylamide in bread. Effect of prooxidants and antioxidants. Eur. Food Res. Technol. 2008, 227, 519–525.

- Zhuang, H.; Zhang, T.; Liu, J.; Yuan, Y. Detection of acrylamide content in traditional Chinese food by high-performance liquid chromatography tandem mass spectrometry method. CyTA J. Food 2012, 10, 36–41.

- Curtis, T.; Halford, N. Reducing the acrylamide-forming potential of wheat. Food Energy Secur. 2016, 5, 153–164.

- Gökmen, V.; Açar, Ö.C.; Köksel, H.; Acar, J. Effects of dough formula and baking conditions on acrylamide and hydroxymethylfurfural formation in cookies. Food Chem. 2007, 104, 1136–1142.

- Ohm, J.B.; Simsek, S.; Mergoum, M. Variation of protein MWD parameters and their associations with free asparagine concentration and quality characteristics in hard red spring wheat. J. Cereal Sci. 2018, 79, 154–159.

- Huang, W.; Yu, S.; Zou, Q.; Tilley, M. Effects of frying conditions and yeast fermentation on the acrylamide content in you-tiao, a traditional Chinese, fried, twisted dough-roll. Food Res. Int. 2008, 41, 918–923.

- Bartkiene, E.; Jakobsone, I.; Juodeikiene, G.; Vidmantiene, D.; Pugajeva, I.; Bartkevics, V. Study on the reduction of acrylamide in mixed rye bread by fermentation with bacteriocin-like inhibitory substances producing lactic acid bacteria in combination with Aspergillus niger glucoamylase. Food Control 2013, 30, 35–40.

- Anese, M.; Quarta, B.; Peloux, L.; Calligaris, S. Effect of formulation on the capacity of l-asparaginase to minimize acrylamide formation in short dough biscuits. Food Res. Int. 2011, 44, 2837–2842.

- Michalak, J.; Czarnowska-Kujawska, M.; Klepacka, J.; Gujska, E. Effect of Microwave Heating on the Acrylamide Formation in Foods. Molecules 2020, 25, 4140.

- Gülcan, Ü.; Uslu, C.C.; Mutlu, C.; Arslan-Tontul, S.; Erbaş, M. Impact of inert and inhibitor baking atmosphere on HMF and acrylamide formation in bread. Food Chem. 2020, 332, 127434.

- Claus, A.; Weisz, G.M.; Kammerer, D.R.; Carle, R.; Schieber, A. A method for the determination of acrylamide in bakery products using ion trap LC-ESI-MS/MS. Mol. Nutr. Food Res. 2005, 49, 918–925.

- Mustafa, A.; Fink, M.; Kamal-Eldin, A.; Rosén, J.; Andersson, R.; Åman, P. Interaction effects of fermentation time and added asparagine and glycine on acrylamide content in yeast-leavened bread. Food Chem. 2009, 112, 767–774.

- Bråthen, E.; Knutsen, S.H. Effect of temperature and time on the formation of acrylamide in starch-based and cereal model systems, flat breads and bread. Food Chem. 2005, 92, 693–700.

- Matoso, V.; Bargi-Souza, P.; Ivanski, F.; Romano, M.A.; Romano, R.M. Acrylamide: A review about its toxic effects in the light of Developmental Origin of Health and Disease (DOHaD) concept. Food Chem. 2019, 283, 422–430.

- Mollakhalili-Meybodi, N.; Khorshidian, N.; Nematollahi, A.; Arab, M. Acrylamide in bread: A review on formation, health risk assessment, and determination by analytical techniques. Environ. Sci. Pollut. Res. 2021, 28, 15627–15645.

- Pundir, C.S.; Yadav, N.; Chhillar, A.K. Occurrence, synthesis, toxicity and detection methods for acrylamide determination in processed foods with special reference to biosensors: A review. Trends Food Sci. Technol. 2019, 85, 211–225.

- Sazesh, B. Quinoa as a wheat substitute to improve the textural properties and minimize the carcinogenic acrylamide content of the biscuit. J. Food Process. Preserv. 2020, 44, e14563.

- Duke, T.J.; Ruestow, P.S.; Marsh, G.M. The influence of demographic, physical, behavioral, and dietary factors on hemoglobin adducts levels of acrylamide and glycidamide in the general US population. Crit. Rev. Food Sci. Nutr. 2018, 58, 700–710.

- Nematollahi, A.; Kamankesh, M.; Hosseini, H.; Hadian, Z.; Ghasemi, J.; Mohammadi, A. Investigation and determination of acrylamide in 24 types of roasted nuts and seeds using microextraction method coupled with gas chromatography–mass spectrometry: Central composite design. J. Food Meas. Charact. 2020, 14, 1249–1260.

- Crawford, L.M.; Kahlon, T.S.; Wang, S.C.; Friedman, M. Acrylamide Content of Experimental Flatbreads Prepared from Potato, Quinoa, and Wheat Flours with Added Fruit and Vegetable Peels and Mushroom Powders. Foods 2019, 8, 228.

- Bignardi, C.; Cavazza, A.; Grimaldi, M.; Laganà, C.; Manzi, C.; Rinaldi, M.; Corradini, C. Acrylamide determination in baked potatoes by HPLC–MS: Effect of steam and correlation with colour indices. Eur. Food Res. Technol. 2019, 245, 2393–2400.

- Crawford, L.M.; Wang, S.C. Comparative study of four analytical methods for the routine determination of acrylamide in black ripe olives. J. Agric. Food Chem. 2019, 67, 12633–12641.

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Scientific opinion on acrylamide in food. EFSA J. 2015, 13, 4104.

- Kafouris, D.; Stavroulakis, G.; Christofidou, M.; Iakovou, X.; Christou, E.; Paikousis, L.; Yiannopoulos, S. Determination of acrylamide in food using a UPLC–MS/MS method: Results of the official control and dietary exposure assessment in Cyprus. Food Addit. Contam. Part A 2018, 35, 1928–1939.

- Roszko, M.Ł.; Szczepańska, M.; Szymczyk, K.; Rzepkowska, M. Dietary risk evaluation of acrylamide intake with bread in Poland, determined by two comparable cleanup procedures. Food Addit. Contam. Part B 2020, 13, 1–9.

- Esposito, F.; Velotto, S.; Rea, T.; Stasi, T.; Cirillo, T. Occurrence of Acrylamide in Italian Baked Products and Dietary Exposure Assessment. Molecules 2020, 25, 4156.

- Khezerolou, A.; Alizadeh-Sani, M.; Zolfaghari Firouzsalari, N.; Ehsani, A. Formation, properties, and reduction methods of acrylamide in foods: A review study. J. Nutr. Fasting Health 2018, 6, 52–59.

- Kopanska, M.; Muchacka, R.; Czech, J.; Batoryna, M.; Formicki, G. Acrylamide toxicity and cholinergic nervous system. J. Physiol. Pharmacol. 2018, 69, 847–858.

- Lambert, M.; Inthavong, C.; Hommet, F.; Leblanc, J.C.; Hulin, M.; Guérin, T. Levels of acrylamide in foods included in ‘the first French total diet study on infants and toddlers’. Food Chem. 2018, 240, 997–1004.

- Sawicka, B.; Mohammed, A.; Umachandran, K. Food safety of potato processed in the aspect of acrylamide risk. MOJ Food Process Technol. 2018, 6, 96–102.

- Stockmann, F.; Weber, E.A.; Schreiter, P.; Merkt, N.; Claupein, W.; Graeff-Hönninger, S. Impact of nitrogen and sulfur supply on the potential of acrylamide formation in organically and conventionally grown winter wheat. Agron. J. 2018, 8, 284.

- Sarion, C.; Dabija, A.; Oroian, M.; Negoiță, M.; Codină, G.G. Evaluation of acrylamide levels in cereal products from the Romanian market during the 2017 and 2018 period. EuroBiotech J. 2020, 4, 127–133.

- JECFA 2005. Joint FAO/WHO Expert Committee on Food Additives. Available online: (accessed on 18 March 2021).

- Negoiță, M.; Culețu, A. Application of an Accurate and Validated Method for Identification and Quantification of Acrylamide in Bread, Biscuits and Other Bakery Products Using GC-MS/MS System. J. Braz. Chem. Soc. 2016, 27, 1782–1791.

- Manson, J.; Brabec, M.J.; Buelke-Sam, J.; Carlson, G.P.; Chapin, R.E.; Favor, J.B.; Fischer, L.J.; Hattis, D.; Lees, P.S.; Perreault-Darney, S.; et al. NTP-CERHR expert panel report on the reproductive and developmental toxicity of acrylamide. Birth Defects Res. B Dev. Reprod. Toxicol. 2005, 74, 17–113.

- Claeys, W.; De Meulenaer, B.; Huyghebaert, A.; Scippo, M.-L.; Hoet, P.; Matthys, C. Reassessment of the acrylamide risk: Belgium as a case-study. Food Control 2016, 59, 628–635.

- Sarion, C.; Dabija, A.; Codină, G.G. Assessment of acrylamide content in some foodstuffs on the Romania market. Sci. Bull. Ser. F Biotechnol. 2020, 24, 62–68.

- Negoiță, M.; Adascalului, A.; Iorga, E.; Catana, L.; Catana, M.; Belc, N. Internal validation of the method for determination of acrylamide in bread by gas chromatography tandem mass spectrometry. Rev. Chim. 2015, 66, 464–471.

- JECFA. Evaluation of Certain Food Additives and Contaminants. 72nd Report of the Joint FAO/Who Expert Committee on Food Additive; WHO Press: Geneva, Switzerland, 2011.

- Jouquand, C.; Niquet-Léridon, C.; Jacolot, P.; Petit, N.; Marier, D.; Gadonna-Widehem, P. Effects of Maillard Reaction products on sensory and nutritional qualities of the traditional French baguette. J. Food Sci. 2018, 83, 2424–2431.

- Zhang, L.; Xu, Y.; Li, Y.; Bao, T.; Gowd, V.; Chen, W. Protective property of mulberry digest against oxidative stress–A potential approach to ameliorate dietary acrylamide-induced cytotoxicity. Food Chem. 2017, 230, 306–315.

- Nematollahi, A.; Kamankesh, M.; Hosseini, H.; Ghasemi, J.; Hosseini-Esfahani, F.; Mohammadi, A. Investigation and determination of acrylamide in the main group of cereal products using advanced microextraction method coupled with gas chromatography-mass spectrometry. J. Cereal Sci. 2019, 87, 157–164.

- Svensson, K.; Abramsson, L.; Becker, W.; Glynn, A.; Hellenäs, K.E.; Lind, Y.; Rosen, J. Dietary intake of acrylamide in Sweden. Food Chem. Toxicol. 2003, 41, 1581–1586.

- Şenyuva, H.Z.; Gökmen, V. Study of acrylamide in coffee using an improved liquid chromatography mass spectrometry method: Investigation of colour changes and acrylamide formation in coffee during roasting. Food Addit. Contam. 2005, 22, 214–220.

- EU European Commission Recommendation of 3 May 2007 on the Monitoring of Acrylamide Levels in Food (2007/331/EC), L 123/33, 12.5.2007. 2007. Available online: (accessed on 18 March 2021).

- Arámbula-Villa, G.; Flores-Casamayor, V.; Velés-Medina, J.J.; Salazar, R. Mitigating effect of calcium and magnesium on acrylamide formation in tortilla chips. Cereal Chem. 2018, 95, 94–97.

- Lindsay, R.C.; Jang, S. Model systems for evaluating factors affecting acrylamide formation in deep fried foods. In Chemistry and Safety of Acrylamide in Food; Springer: Boston, MA, USA, 2005; pp. 329–341.

- Saraji, M.; Javadian, S. Single-drop microextraction combined with gas chromatography-electron capture detection for the determination of acrylamide in food samples. Food Chem. 2019, 274, 55–60.

- Norouzi, E.; Kamankesh, M.; Mohammadi, A.; Attaran, A. Acrylamide in bread samples: Determining using ultrasonic-assisted extraction and microextraction method followed by gas chromatography-mass spectrometry. J. Cereal Sci. 2018, 79, 1–5.

- Alyousef, H.A.; Wang, H.; Al-Hajj, N.Q.; Koko, M. Determination of acrylamide levels in selected commercial and traditional foods in Syria. Trop. J. Pharm. Res. 2016, 15, 1275–1281.

- Raffan, S.; Halford, N.G. Acrylamide in food: Progress in and prospects for genetic and agronomic solutions. Ann. Appl. Biol. 2019, 175, 259–281.

- Eriksson, M.; Giovannini, S.; Ghosh, R.K. Is there a need for greater integration and shift in policy to tackle food waste? Insights from a review of European Union legislations. SN Appl. Sci. 2020, 2, 1347.

- Commission Decision (2007/333/EC) Laying Down the Methods of Sampling and Analysis for the Official Control of the Levels of Lead, Cadmium, Mercury, Inorganic Tin, 3-MCPD and Benzo(A)-Pyrene in Foodstuffs. Available online: (accessed on 18 March 2021).

- European Food Safety Authority. Update on acrylamide levels in food from monitoring years 2007 to 2010. EFSA J. 2012, 10, 2938.

- European Food Safety Authority. Results on the monitoring of acrylamide levels in food. EFSA J. 2009, 7, RN-285.

- FoodDrinkEurope (FDE). Acrylamide Toolbox. 2013. Available online: (accessed on 15 March 2021).

- Wen, C.; Shi, X.; Wang, Z.; Gao, W.; Jiang, L.; Xiao, Q.; Liu, X.; Deng, F. Effects of metal ions on formation of acrylamide and 5-hydroxymethylfurfural in asparagine–glucose model system. Int. J. Food Sci. Technol. 2016, 51, 279–285.

- EU European Commission Recommendation of 8 November 2013 on Investigations into the Levels of Acrylamide in Food (2013/647/EU). Available online: (accessed on 18 March 2021).

- EU European Commission Regulation of 20 November 2017 Establishing Mitigation Measures and Benchmark Levels for the Reduction of the Presence of Acrylamide in Food (2017/2158). Available online: (accessed on 12 January 2020).

- EFSA. Scientific opinion on the risks for public health related to the presence of furan and methylfurans in food. EFSA J. 2017, 15, 5005.

- EU European Commission Recommendation of 7 November 2019 on the Monitoring of the Presence of Acrylamide in Certain Foods (2019/1888/EU). Commission Recommendation. Available online: (accessed on 18 March 2021).

- EFSA CONTAM Panel (EFSA Panel on Contaminants in the Food Chain). Opinion of the Scientific Panel on Contaminants in Food Chain. EFSA J. 2005, 225, 1–27.

- FDE. Food Drink Europe Acrylamide Toolbox 2019. Available online: (accessed on 15 March 2021).

- Nguyen, H.T.; Van Boekel, M.A.J.S. Acrylamide and 5-hydroxymethylfurfural formation during biscuit baking. Part II: Effect of the ratio of reducing sugars and asparagine. Food Chem. 2017, 230, 14–23.

- Suman, M.; Generotti, S.; Cirlini, M.; Dall’Asta, C. Acrylamide Reduction Strategy in Combination with Deoxynivalenol Mitigation in Industrial Biscuits Production. Toxins 2019, 11, 499.

- Codex Alimentarius. Code of Practice for the Reduction of Acrylamide in Foods. CAC/RCP. 2009. Available online: (accessed on 20 December 2019).

- Mildner-Szkudlarz, S.; Różańska, M.; Piechowska, P.; Waśkiewicz, A.; Zawirska-Wojtasiak, R. Effects of polyphenols on volatile profile and acrylamide formation in a model wheat bread system. Food Chem. 2019, 297, 125008.

- Khorshidian, N.; Yousefi, M.; Shadnoush, M.; Siadat, S.D.; Mohammadi, M.; Mortazavian, A.M. Using probiotics for mitigation of acrylamide in food products: A mini review. Curr. Opin. Food Sci. 2020, 32, 67–75.