| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Behrooz Abbasi | + 6981 word(s) | 6981 | 2021-04-23 03:57:00 | | | |

| 2 | Lily Guo | Meta information modification | 6981 | 2021-05-07 03:23:38 | | |

Video Upload Options

Respirable coal mine dust (RCMD) exposure is associated with black lung and silicosis diseases in underground miners. Although only RCMD mass and silica concentrations are regulated, it is possible that particle size, surface area, and other chemical constituents also contribute to its adverse health effects. This review summarizes measurement technologies for RCMD mass concentrations, morphology, size distributions, and chemical compositions, with examples from published efforts where these methods have been applied. Some state-of-the-art technologies presented in this paper have not been certified as intrinsically safe, and caution should be exerted for their use in explosive environments. RCMD mass concentrations are most often obtained by filter sampling followed by gravimetric analysis, but recent requirements for real-time monitoring by continuous personal dust monitors (CPDM) enable quicker exposure risk assessments. Emerging low-cost photometers provide an opportunity for a wider deployment of real-time exposure assessment. Particle size distributions can be determined by microscopy, cascade impactors, aerodynamic spectrometers, optical particle counters, and electrical mobility analyzers, each with unique advantages and limitations. Different filter media are required to collect integrated samples over working shifts for comprehensive chemical analysis. Teflon membrane filters are used for mass by gravimetry, elements by energy dispersive X-ray fluorescence, rare-earth elements by inductively coupled plasma-mass spectrometry and mineralogy by X-ray diffraction. Quartz fiber filters are analyzed for organic, elemental, and brown carbon by thermal/optical methods and non-polar organics by thermal desorption-gas chromatography-mass spectrometry. Polycarbonate-membrane filters are analyzed for morphology and elements by scanning electron microscopy (SEM) with energy dispersive X-ray, and quartz content by Fourier-transform infrared spectroscopy and Raman spectroscopy.

1. Introduction

2. RCMD Mass Measurement Methods

| Method | Description | Limitations and Challenges |

|---|---|---|

| Gravimetric sampler | Constant-flow sampling through a particle size-selective cyclone (e.g., Dorr–Oliver) onto a filter cartridge by a personal sampling pump The filter is submitted to gravimetric analysis and optionally for chemical analysis in the laboratory Reference method Relatively low cost |

Ensuring that the cyclone assembly stays upright Labor intensive Low time resolution Data are not immediately available |

| Continuous personal dust monitor (CPDM) | A TEOM (tapered-element oscillating microbalance) obtains near real-time, gravimetric-equivalent measurement of RCMD mass concentrations Filter can be used for limited laboratory analysis Near real-time measurement (30-min average) Regulatory requirement Relatively independent of aerosol optical, physical, and chemical properties |

High cost Size and weight are burdensome Regulatory requirement to report data to MSHA Potential evaporation losses |

| Photometer | Inferred mass concentration based on aerosol light scattering intensity Low cost Lightweight Fast response (~1 s) |

Scattering-mass relationship varies with particle refractive index, shape, size distribution, density, and relative humidity Field calibration is needed |

3. RCMD Particle Size Characterization

| Technique | Advantages | Disadvantages |

|---|---|---|

| Optical Microscopy Size range > 1µm |

Visual size and morphology evaluation | Time consuming; not suitable for submicron particles; potential observational bias and errors |

| SEM Size range: ~0.01–10 µm |

Morphology and size analysis; elemental characteristics; wide particle size range | Laboratory measurement; needs sample pre-preparation; slow and costly; may not be representative as a small fraction of particles are analyzed |

| Cascade Impactor Size range: ~0.01–10 µm |

Wide aerodynamic diameter range; size segregated mass concentration and chemical composition; can be used for personal sampling; mechanically rugged | Ex situ analysis; long sampling duration to collect sufficient mass; particle bounce may cause bias; non-uniform deposition |

| ELPI Size range: 0.006–10 µm |

In situ real-time aerodynamic size distribution; wide size and concentration ranges | Particle bouncing; blow-off from substrates; overloading of substrates; low size resolution; charging efficiency uncertainty |

| APS Size range: 0.5–20 µm |

In situ real-time aerodynamic size distributions; high size resolution; easy operation | Not suitable for particles <0.5 µm; density-dependent non-Stokesian correction; liquid particle deformation and losses; low concentration limit |

| AAC Size range: 0.025–>5 µm |

In situ aerodynamic size distributions; high size resolution; high transmission efficiency | Relatively slow scans (~2 min); fast rotating components; still under development/perfection |

| OPC Size range: ~0.3–10 µm |

In situ real-time optical size distribution; compact and portable size; relatively low cost | Low concentration limit; dependence on particle shape and composition; non-monotonic dependence of light scattering on particle size |

| SMPS Size range: ~0.003–1 µm |

In situ near real-time mobility size distribution; high size resolution and accuracy for submicron particles | Relatively slow scans; not suitable for >1 µm; limitation of using radioactive neutralizers |

| EEPS/FMPS/DMS Size range: 0.006–0.6 µm for EEPS and FMPS; 0.005–2.5 µm for DMS |

In situ real-time mobility size distribution; high time resolution; suitable for rapidly changing aerosols | Lower size resolution than SMPS; dependence of charging efficiency on particle morphology |

3.1. Microscopic Imaging

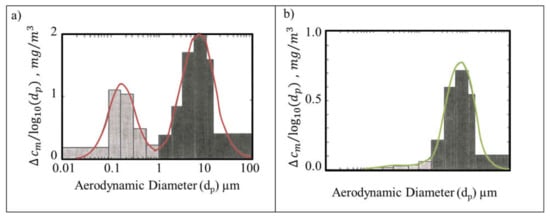

3.2. Aerodynamic Particle Sizing

3.2.1. Cascade Impactors

3.2.2. Electrical Low Pressure Impactor (ELPI)

3.2.3. Aerodynamic Particle Sizer (APS)

3.2.4. Aerodynamic Aerosol Classifier (AAC)

3.3. Optical Particle Sizing

3.4. Electrical Mobility Particle Sizing

3.5. Evaluation for Size Distribution Measurements in Mines

4. Summary

References

- Castranova, V.; Vallyathan, V. Silicosis and coal workers’ pneumoconiosis. Environ. Health Perspect. 2000, 108, 675–684.

- Halldin, C.N.; Wolfe, A.L.; Laney, A.S. Comparative respiratory morbidity of former and current US coal miners. Am. J. Public Health 2015, 105, 2576–2577.

- Centers for Disease Control and Prevention. Coal Workers’ Health Surveillance Program—Data Query System; NIOSH: Morgantown, WV, USA, 2016.

- Antao, V.C.; Petsonk, E.L.; Attfield, M.D. Advanced Cases of Coal Workers’ Pneumoconiosis—Two Counties, Virginia, 2006. JAMA 2006, 296, 2085.

- Fitzhugh, P.; Margach, E. Department of Health and Human Services Coal mine dust exposures and associated health outcomes- A review. In Coal Mine Dust: Health Reviews and Key Studies (with accompanying CD); Nova Science Publishers Inc: Hauppauge, NY, USA, 2013; pp. 25–67. ISBN 9781624170973.

- Laney, A.S.; Petsonk, E.L.; Attfield, M.D. Pneumoconiosis among underground bituminous coal miners in the United States: Is silicosis becoming more frequent? Occup. Environ. Med. 2010, 67, 652–656.

- Blackley, D.J.; Reynolds, L.E.; Short, C.; Carson, R.; Storey, E.; Halldin, C.N.; Laney, A.S. Progressive massive fibrosis in coal miners from 3 clinics in Virginia. JAMA 2018, 319, 500–501.

- Blackley, D.J.; Crum, J.B.; Halldin, C.N.; Storey, E.; Laney, A.S. Resurgence of progressive massive fibrosis in coal miners — Eastern Kentucky, 2016. Morb. Mortal. Wkly. Rep. 2016, 65, 1385–1389.

- Laney, A.S.; Petsonk, E.L.; Hale, J.M.; Wolfe, A.L.; Attfield, M.D. Potential determinants of coal workers’ pneumoconiosis, advanced pneumoconiosis, and progressive massive fibrosis among underground coal miners in the United States, 2005-2009. Am. J. Public Health 2012, 102, 2005–2009.

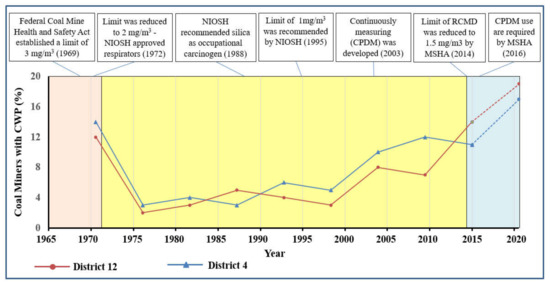

- Suarthana, E.; Laney, A.S.; Storey, E.; Hale, J.M.; Attfield, M.D. Coal workers’ pneumoconiosis in the United States: Regional differences 40 years after implementation of the 1969 Federal Coal Mine Health and Safety Act. Occup. Environ. Med. 2011, 68, 908–913.

- Department of Health and Human Services Coal Mine Dust Exposures and Associated Health Outcomes: A Review of Information Published Since 1995; National Institute for Occupational Safety and Health (NIOSH): Morgantown, WV, USA, 2011; Volume 64.

- MSHA Lowering Miners’ Exposure to Respirable Coal Mine Dust, Including Continuous Personal Dust Monitors. Fed. Regist. 2014, 79, 24814–24994.

- U.S. EPA National ambient air quality standards for particulate matter: Proposed rule. Fed. Regist. 2012, 77, 38890–39055.

- Madl, A.K.; Donovan, E.P.; Gaffney, S.H.; McKinley, M.A.; Moody, E.C.; Henshaw, J.L.; Paustenbach, D.J. State-of-the-science review of the occupational health hazards of crystalline silica in abrasive blasting operations and related requirements for respiratory protection. J. Toxicol. Environ. Health. B. Crit. Rev. 2008, 11, 548–608.

- Vincent, J. Particle size-selective sampling for particulate air contaminants; American Conference of Governmental Industrial Hygienists (ACGIH): Cincinnati, OH, USA, 1999; ISBN 978-1882417308.

- Johann-Essex, V.; Keles, C.; Sarver, E. A Computer-Controlled SEM-EDX Routine for Characterizing Respirable Coal Mine Dust. Minerals 2017, 7, 15.

- Kelly, F.J.; Fussell, J.C. Size, source and chemical composition as determinants of toxicity attributable to ambient particulate matter. Atmos. Environ. 2012, 60, 504–526.

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An emerging discipline evolving from studies of ultrafine particles. Environ. Health Perspect. 2005, 113, 823–839.

- Riediker, M.; Zink, D.; Kreyling, W.; Oberdörster, G.; Elder, A.; Graham, U.; Lynch, I.; Duschl, A.; Ichihara, G.; Ichihara, S.; et al. Particle toxicology and health - where are we? Part. Fibre Toxicol. 2019, 16, 19.

- Gautam, M.; Sreenath, A. Performance of a respirable multi-inlet cyclone sampler. J. Aerosol Sci. 1997, 28, 1265–1281.

- Vincent, J.H. Health-related aerosol measurement: A review of existing sampling criteria and proposals for new ones. J. Environ. Monit. 2005, 7, 1037–1053.

- National Academies of Sciences, Engineering, and Medicine (NASEM). Monitoring and Sampling Approaches to Assess Underground Coal Mine Dust Exposures; National Academies Press: Washington, DC, USA, 2018.

- Li, Q.; Wang, K.; Zheng, Y.; Ruan, M.; Mei, X.; Lin, B. Experimental research of particle size and size dispersity on the explosibility characteristics of coal dust. Powder Technol. 2016, 292, 290–297.

- Birch, M.E.; Noll, J.D. Submicrometer elemental carbon as a selective measure of diesel particulate matter in coal mines. J. Environ. Monit. 2004, 6, 799–806.

- Burkhart, J.E.; McCawley, M.A.; Wheeler, R.W. Particle Size Distributions in Underground Coal Mines. Am. Ind. Hyg. Assoc. J. 1987, 48, 122–126.

- Mine Safety and Health Administration (MSHA). 30 CFR Part 74: Coal Mine Dust Sampling Devices, Federal Register; U.S. Department of Labor: Washington, DC, USA, 2016.

- Bartley, D.L.; Chen, C.C.; Song, R.; Fischbach, T.J. Respirable Aerosol Sampler Performance Testing. Am. Ind. Hyg. Assoc. J. 1994, 55, 1036–1046.

- Watson, J.G.; Chow, J.C.; Shah, J.J.; Pace, T.G. The effect of sampling inlets on the PM10 and PM15 to TSP concentration ratios. J. Air Pollut. Control Assoc. 1983, 33, 114–119.

- Page, S.J.; Volkwein, J.C. A revised conversion factor relating respirable dust concentrations measured by 10 mm Dorr-Oliver nylon cyclones operated at 1.7 and 2.0 L min−1. J. Environ. Monit. 2009, 11, 684.

- Watson, J.G.; Tropp, R.J.; Kohl, S.D.; Wang, X.L.; Chow, J.C. Filter processing and gravimetric analysis for suspended particulate matter samples. Aerosol Sci. Eng. 2017, 1, 193–205.

- Blachman, M.W.; Lippmann, M. Performance Characteristics of the Multicyclone Aerosol Sampler. Am. Ind. Hyg. Assoc. J. 1974, 35, 311–326.

- Kar, K.; Gautam, M. Orientation Bias of the Isolated 10-mm Nylon Cyclone at Low Stream Velocity. Am. Ind. Hyg. Assoc. J. 1995, 56, 1090–1098.

- Tsai, C.-J.; Shiau, H.-G.; Lin, K.-C.; Shih, T.-S. Effect of deposited particles and particle charge on the penetration of small sampling cyclones. J. Aerosol Sci. 1999, 30, 313–323.

- Thermo Fisher Scientific. Personal Dust Monitor (Model PDM3700) Instruction Manual; Thermo Fisher Scientific: Franklin, MA, USA, 2016.

- Patashnick, H.; Rupprecht, E.G. Continuous PM-10 Measurements Using the Tapered Element Oscillating Microbalance. J. Air Waste Manag.. Assoc. 1991, 41, 1079–1083.

- Maynard, A.D.; Kenny, L.C. Performance assessment of three personal cyclone models, using an Aerodynamic Particle Sizer. J. Aerosol Sci. 1995, 26, 671–684.

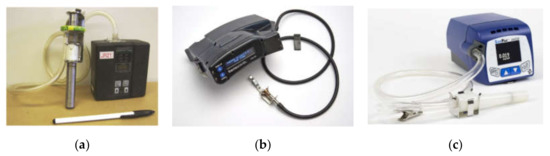

- Volkwein, J.C.; Vinson, R.P.; McWilliams, L.J.; Tuchman, D.P.; Mischler, S.E. Mining Publication: Performance of a New Personal Respirable Dust Monitor for Mine Use, Report of Investigations 9663; National Institute for Occupational Safety and Health (NIOSH): Pittsburgh, PA, USA, 2004.

- Chow, J.C.; Fairley, D.; Watson, J.G.; de Mandel, R.; Fujita, E.M.; Lowenthal, D.H.; Lu, Z.; Frazier, C.A.; Long, G.; Cordova, J. Source apportionment of wintertime PM10 at San Jose, CA. J. Environ. Eng 1995, 21, 378–387.

- Volkwein, J.C.; Vinson, R.P.; Page, S.J.; McWilliams, L.J.; Joy, G.J.; Mischler, S.E.; Tuchman, D.P. Report of investigations (National Institute for Occupational Safety and Health. In Laboratory and Field Performance of a Continuously Measuring Personal Respirable Dust Monitor; Department of Healthy and Human Services: Cincinnati, OH, USA, 2006.

- Page, S.J.; Volkwein, J.C.; Vinson, R.P.; Joy, G.J.; Mischler, S.E.; Tuchman, D.P.; McWilliams, L.J. Equivalency of a personal dust monitor to the current United States coal mine respirable dust sampler. J. Environ. Monit. 2008, 10, 96–101.

- Halterman, A.; Sousan, S.; Peters, T.M. Comparison of Respirable Mass Concentrations Measured by a Personal Dust Monitor and a Personal DataRAM to Gravimetric Measurements. Ann. Work Expo. Heal. 2017, 62, 62–71.

- Thorpe, A.; Walsh, P.T. Direct-Reading Inhalable Dust Monitoring—An Assessment of Current Measurement Methods. Ann. Occup. Hyg. 2013, 57, 824–841.

- Noll, J.; Volkwein, J.; Janisko, S.; Patts, L. Portable instruments for measuring tailpipe diesel particulate in underground mines. Min. Eng. 2013, 65, 42–49.

- Bulpitt, S.; Price, M. The composition of PM10 as collected by a conventional TEOM, a modified TEOM and a Partisol gravimetric monitor at a kerbside site in the North East of England. Environ. Monit. Assess. 2006, 121, 479–489.

- Nosratabadi, A.R.; Graff, P.; Karlsson, H.; Ljungman, A.; Leanderson, P. Use of TEOM monitors for continuous long-term sampling of ambient particles for analysis of constituents and biological effects. Air Qual. Atmos. Heal. 2019, 12, 161–171.

- Patts, J.R.; Tuchman, D.P.; Rubinstein, E.N.; Cauda, E.G.; Cecala, A.B. Performance Comparison of Real-Time Light Scattering Dust Monitors Across Dust Types and Humidity Levels. Min. Met. Explor. 2019, 36, 741–749.

- Pui, D.Y.H. Direct-reading instrumentation for workplace aerosol measurements. A review. Analyst 1996, 121, 1215.

- Thorpe, A. Assessment of Personal Direct-Reading Dust Monitors for the Measurement of Airborne Inhalable Dust. Ann. Occup. Hyg. 2007, 51, 97–112.

- Wang, X.L.; Chancellor, G.; Evenstad, J.; Farnsworth, J.E.; Hase, A.; Olson, G.M.; Sreenath, A.; Agarwal, J.K. A Novel Optical Instrument for Estimating Size Segregated Aerosol Mass Concentration in Real Time. Aerosol Sci. Technol. 2009, 43, 939–950.

- Hagler, G.S.W.; Solomon, P.A.; Hunt, S.W. New Technology for Low-Cost, Real-Time Air Monitoring; Air and Waste Management Association’s Magazine for Environmental Managers; Air & Waste Management Association: Pittsburgh, PA, USA, 2014.

- Morawska, L.; Thai, P.K.; Liu, X.; Asumadu-Sakyi, A.; Ayoko, G.; Bartonova, A.; Bedini, A.; Chai, F.; Christensen, B.; Dunbabin, M.; et al. Applications of low-cost sensing technologies for air quality monitoring and exposure assessment: How far have they gone? Environ. Int. 2018, 116, 286–299.

- McMurry, P.H. A Review of Atmospheric Aerosol Measurement. Atmos. Environ. 2000, 34, 1959–1999.

- Giechaskiel, B.; Maricq, M.; Ntziachristos, L.; Dardiotis, C.; Wang, X.; Axmann, H.; Bergmann, A.; Schindler, W. Review of motor vehicle particulate emissions sampling and measurement: From smoke and filter mass to particle number. J. Aerosol Sci. 2014, 67, 48–86.

- Shamir, L.; Delaney, J.D.; Orlov, N.; Eckley, D.M.; Goldberg, I.G. Pattern recognition software and techniques for biological image analysis. PLoS Comput. Biol. 2010, 6, e1000974.

- Cartwright, J. Relationships between Mass and Number Concentrations of Respirable Airborne Dust in British Coal Mines: Part 1—Mass-Number Relationships for Coal-Dust Clouds. Ann. Occup. Hyg. 1965, 8, 193–206.

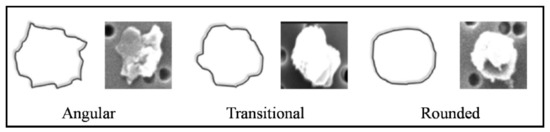

- Stein, F.; Corn, M. Shape factors of narrow size range samples of respirable coal mine dust. Powder Technol. 1975, 13, 133–141.

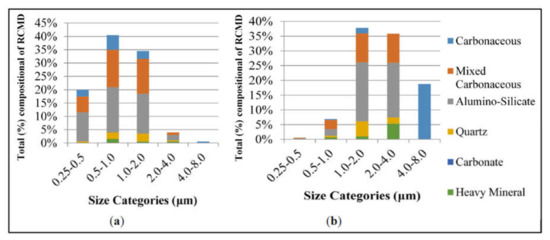

- Johann-essex, V.; Keles, C.; Rezaee, M.; Scaggs-witte, M.; Sarver, E. International Journal of Coal Geology Respirable coal mine dust characteristics in samples collected in central and northern Appalachia. Int. J. Coal Geol. 2017, 182, 85–93.

- Sellaro, R.; Sarver, E.; Baxter, D. A Standard Characterization Methodology for Respirable Coal Mine Dust Using SEM-EDX. Resources 2015, 939–957.

- Sarver, E.; Keles, C.; Rezaee, M. International Journal of Coal Geology Beyond conventional metrics: Comprehensive characterization of respirable coal mine dust. Int. J. Coal Geol. 2019, 207, 84–95.

- Powers, M.C. A New Roundness Scale for Sedimentary Particles. Sepm J. Sediment. Res. 1953, 23, 117–119.

- Arffman, A.; Kuuluvainen, H.; Harra, J.; Vuorinen, O.; Juuti, P.; Yli-Ojanperä, J.; Mäkelä, J.M.; Keskinen, J. The critical velocity of rebound determined for sub-micron silver particles with a variable nozzle area impactor. J. Aerosol Sci. 2015, 86, 32–43.

- Marple, V.A. History of Impactors—The First 110 Years. Aerosol Sci. Technol. 2004, 38, 247–292.

- Ramachandran, G.; Johnson, E.W.; Vincent, J.H. Inversion techniques for personal cascade impactor data. J. Aerosol Sci. 1996, 27, 1083–1097.

- Winklmayr, W.; Wang, H.-C.; John, W. Adaptation of the Twomey Algorithm to the Inversion of Cascade Impactor Data. Aerosol Sci. Technol. 1990, 13, 322–331.

- Potts, J.D.; McCawley, M.A.; Jankowski, R.A. Thoracic Dust Exposures on Longwall and Continuous Mining Sections. Appl. Occup. Environ. Hyg. 1990, 5, 440–447.

- Rubow, K.L.; Cantrell, B.K.; Marple, V.A. Measurement of coal dust and diesel exhaust aerosols in underground mines. In Proceedings of the 7th International Pneumoconioses Conference, Pittsburgh, PA, USA, 23–26 August 1988; pp. 23–26.

- Seixas, N.S.; Hewett, P.; Robins, T.G.; Haney, R. Variability of Particle Size-Specific Fractions of Personal Coal Mine Dust Exposures. Am. Ind. Hyg. Assoc. J. 1995, 56, 243–250.

- Rubow, K.L.; Marple, V.A.; Olin, J.; McCawley, M.A. A Personal Cascade Impactor Design, Evaluation and Calibration. AIHAJ 1987, 48, 532–538.

- Misra, C.; Singh, M.; Shen, S.; Sioutas, C.; Hall, P.M. Development and evaluation of a personal cascade impactor sampler (PCIS). J. Aerosol Sci. 2002, 33, 1027–1047.

- Chen, M.; Romay, F.J.; Marple, V.A. Design and evaluation of a low flow personal cascade impactor. Aerosol Sci. Technol. 2018, 52, 192–197.

- Marple, V.A.; Rubow, K.L.; Behm, S.M. A Microorifice Uniform Deposit Impactor (MOUDI): Description, Calibration, and Use. Aerosol Sci. Technol. 1991, 14, 434–446.

- Cantrell, B.K. Source apportionment analysis applied to mine dust aerosols: Coal dust and diesel emissions aerosol measurement. In Proceedings of the 3rd Mine Ventilation Symposium, University Park, PA, USA, 12–14 October 1987; Society of Mining Engineering: Littleton, CO, USA, 1987; pp. 495–501.

- Cantrell, B.K.; Volkwein, J.C. Mine Aerosol Measurement. In Aerosol Measurement: Principles, Techniques, and Applications; Baron, P.A., Willeke, K., Eds.; John Wiley & Sons, Inc.: New York, NY, USA, 2001; pp. 801–820.

- Chen, M.; Romay, F.J.; Li, L.; Naqwi, A.; Marple, V.A. A novel quartz crystal cascade impactor for real- time aerosol mass distribution measurement measurement. Aerosol Sci. Technol. 2016, 50, 971–983.

- Keskinen, J.; Pietarinen, K.; Lehtimäki, M. Electrical low pressure impactor. J. Aerosol Sci. 1992, 23, 353–360.

- Lemmetty, M.; Keskinen, J.; Marjamäki, M. The ELPI Response and Data Reduction II: Properties of Kernels and Data Inversion. Aerosol Sci. Technol. 2005, 39, 583–595.

- Marjamäki, M.; Lemmetty, M.; Keskinen, J. ELPI Response and Data Reduction I: Response Functions. Aerosol Sci. Technol. 2005, 39, 575–582.

- Saari, S.; Arffman, A.; Harra, J.; Rönkkö, T.; Keskinen, J. Performance evaluation of the HR-ELPI + inversion. Aerosol Sci. Technol. 2018, 52, 1037–1047.

- Moisio, M. Real time size distribution measurement of combustion aerosols. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 1999.

- Lehmann, U.; Niemelä, V.; Mohr, M. New Method for Time-Resolved Diesel Engine Exhaust Particle Mass Measurement. Environ. Sci. Technol. 2004, 38, 5704–5711.

- Maricq, M.M.; Szente, J.; Loos, M.; Vogt, R. Motor Vehicle PM Emissions Measurement at LEV III Levels. SAE Int. J. Engines 2011, 4, 597–609.

- Maricq, M.M. Monitoring Motor Vehicle PM Emissions: An Evaluation of Three Portable Low-Cost Aerosol Instruments. Aerosol Sci. Technol. 2013, 47, 564–573.

- Maricq, M.M.; Szente, J.J.; Harwell, A.L.; Loos, M.J. How well can aerosol instruments measure particulate mass and solid particle number in engine exhaust? Aerosol Sci. Technol. 2016, 50, 605–614.

- Jiang, J.; Kim, C.; Wang, X.; Stolzenburg, M.R.; Kaufman, S.L.; Qi, C.; Sem, G.J.; Sakurai, H.; Hama, N.; McMurry, P.H. Aerosol Charge Fractions Downstream of Six Bipolar Chargers: Effects of Ion Source, Source Activity, and Flowrate. Aerosol Sci. Technol. 2014, 48, 1207–1216.

- Wang, X.L.; Grose, M.A.; Caldow, R.; Osmondson, B.L.; Swanson, J.J.; Chow, J.C.; Watson, J.G.; Kittelson, D.B.; Li, Y.; Xue, J.; et al. Improvement of Engine Exhaust Particle Sizer (EEPS) size distribution measurement: II. Engine exhaust aerosols. J. Aerosol Sci. 2016, 92, 83–94.

- Järvinen, A.; Aitomaa, M.; Rostedt, A.; Keskinen, J.; Yli-Ojanperä, J. Calibration of the new electrical low pressure impactor (ELPI+). J. Aerosol Sci. 2014, 69, 150–159.

- Marjamäki, M.; Keskinen, J.; Chen, D.-R.; Pui, D.Y.H. Performance evaluation of the electrical low-pressure impactor (ELPI). J. Aerosol Sci. 2000, 31, 249–261.

- Bugarski, A.D.; Hummer, J.A.; Vanderslice, S.; Shahan, M.R. Characterization of Aerosols in an Underground Mine during a Longwall Move. Min. Met. Explor. 2020, 37, 1065–1078.

- Wilson, J.C.; Liu, B.Y.H. Aerodynamic particle size measurement by laser-doppler velocimetry. J. Aerosol Sci. 1980, 11, 139–150.

- Agarwal, J.K.; Remiarz, R.J.; Quant, F.R.; Sem, G.J. Real-time aerodynamic particle size analyzer. J. Aerosol Sci 1982, 13, 222–223.

- Baron, P.A. Calibration and Use of the Aerodynamic Particle Sizer (APS 3300). Aerosol Sci. Technol. 1986, 5, 55–67.

- Baron, P.A.; Mazumder, M.K.; Cheng, Y.-S.; Peters, T.M. Real-Time Techniques for Aerodynamic Size Measurement. Aerosol Meas. 2011, 36, 313–338.

- Ananth, G.; Wilson, J.C. Theoretical Analysis of the Performance of the TSI Aerodynamic Particle Sizer The Effect of Density on Response. Aerosol Sci. Technol. 1988, 9, 189–199.

- Rader, D.J.; Brockmann, J.E.; Ceman, D.L.; Lucero, D.A. A Method To Employ the Aerodynamic Particle Sizer Factory Calibration Under Different Operating Conditions. Aerosol Sci. Technol. 1990, 13, 514–521.

- Wang, H.C.; John, W. Particle Density Correction for the Aerodynamic Particle Sizer. Aerosol Sci. Technol. 1987, 6, 191–198.

- Baron, P.; Deye, G.J.; Martinez, A.B.; Jones, E.N.; Bennett, J.S. Size Shifts in Measurements of Droplets with the Aerodynamic Particle Sizer and the Aerosizer. Aerosol Sci. Technol. 2008, 42, 201–209.

- Bartley, D.L.; Martinez, A.B.; Baron, P.A.; Secker, D.R.; Hirst, E. Droplet Distortion in Accelerating Flow. J. Aerosol Sci. 2000, 31, 1447–1460.

- Volckens, J.; Peters, T.M. Counting and particle transmission efficiency of the aerodynamic particle sizer. J. Aerosol Sci. 2005, 36, 1400–1408.

- Chen, C.C.; Huang, S.H. Shift of Aerosol Penetration in Respirable Cyclone Samplers. Am. Ind. Hyg. Assoc. J. 1999, 60, 720–729.

- Kurth, L.M.; McCawley, M.; Hendryx, M.; Lusk, S. Atmospheric particulate matter size distribution and concentration in West Virginia coal mining and non-mining areas. J. Expo. Sci. Environ. Epidemiol. 2014, 24, 405–411.

- Peters, T.M. Use of the Aerodynamic Particle Sizer to Measure Ambient PM10–2.5: The Coarse Fraction of PM10. J. Air Waste Manag. Assoc. 2006, 56, 411–416.

- Reid, J.S.; Jonsson, H.H.; Maring, H.B.; Smirnov, A.; Savoie, D.L.; Cliff, S.S.; Reid, E.A.; Livingston, J.M.; Meier, M.M.; Dubovik, O.; et al. Comparison of size and morphological measurements of coarse mode dust particles from Africa. J. Geophys. Res. 2003, 108, 8593.

- Sioutas, C. Evaluation of the Measurement Performance of the Scanning Mobility Particle Sizer and Aerodynamic Particle Sizer. Aerosol Sci. Technol. 1999, 30, 84–92.

- DeCarlo, P.; Slowik, J.; Worsnop, D.; Davidovits, P.; Jimenez, J. Particle Morphology and Density Characterization by Combined Mobility and Aerodynamic Diameter Measurements. Part 1: Theory. Aerosol Sci. Technol. 2004, 38, 1185–1205.

- Park, K.; Dutcher, D.; Emery, M.; Pagels, J.; Sakurai, H.; Scheckman, J.; Qian, S.; Stolzenburg, M.R.; Wang, X.; Yang, J.; et al. Tandem Measurements of Aerosol Properties—A Review of Mobility Techniques with Extensions. Aerosol Sci. Technol. 2008, 42, 801–816.

- Stanier, C.O.; Khlystov, A.Y.; Pandis, S.N. Ambient aerosol size distributions and number concentrations measured during the Pittsburgh Air Quality Study (PAQS). Atmos. Environ. 2004, 38, 3275–3284.

- Saarikoski, S.; Teinilä, K.; Timonen, H.; Aurela, M.; Laaksovirta, T.; Reyes, F.; Vásques, Y.; Oyola, P.; Artaxo, P.; Pennanen, A.S.; et al. Particulate matter characteristics, dynamics, and sources in an underground mine. Aerosol Sci. Technol. 2018, 52, 114–122.

- Johnson, T.J.; Irwin, M.; Symonds, J.P.R.; Olfert, J.S.; Boies, A.M. Measuring aerosol size distributions with the aerodynamic aerosol classifier. Aerosol Sci. Technol. 2018, 52, 655–665.

- Tavakoli, F.; Olfert, J.S. An Instrument for the Classification of Aerosols by Particle Relaxation Time: Theoretical Models of the Aerodynamic Aerosol Classifier. Aerosol Sci. Technol. 2013, 47, 916–926.

- Tavakoli, F.; Olfert, J.S. Determination of particle mass, effective density, mass–mobility exponent, and dynamic shape factor using an aerodynamic aerosol classifier and a differential mobility analyzer in tandem. J. Aerosol Sci. 2014, 75, 35–42.

- International Organization for Standardization (ISO). ISO 21501-1:2009 Determination of Particle Size Distribution—Single Particle Light Interaction Methods—Part 1: Light Scattering Aerosol Spectrometer; ISO: Geneva, Switzerland, 2009.

- Sorensen, C.M.; Gebhart, J.; O’Hern, T.J.; Rader, D.J. Optical Measurement Techniques: Fundamentals and Applications. In Aerosol Measurement; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 269–312. ISBN 9781118001684.

- Pinnick, R.G.; Pendleton, J.D.; Videen, G. Response Characteristics of the Particle Measuring Systems Active Scattering Aerosol Spectrometer Probes. Aerosol Sci. Technol. 2000, 33, 334–352.

- Whitby, K.T.; Liu, B.Y.H. Generation of countable pulses by high concentrations of subcountable sized particles in the sensing volume of optical counters. J. Colloid Interface Sci. 1967, 25, 537–546.

- Whitby, K.T.; Willeke, K. Single particle optical counters: Principles and field use. In Aerosol Measurement; Lundgren, D.A., Lippmann, M., Harris, F.S., Clark, W.E., Marlow, W.H., Durham, M.D., Eds.; University Presses of Florida: Gainesville, FL, USA, 1979; pp. 145–182.

- Wang, X.; Zhou, H.; Arnott, W.P.; Meyer, M.E.; Taylor, S.; Firouzkouhi, H.; Moosmüller, H.; Chow, J.C.; Watson, J.G. Evaluation of gas and particle sensors for detecting spacecraft-relevant fire emissions. Fire Saf. J. 2020, 113, 102977.

- Liu, B.Y.H.; Marpple, V.A.; Whitby, K.T.; Barsic, N.J. Size Distribution Measurement of Airborne Coal Dust by Optical Particle Counters. Am. Ind. Hyg. Assoc. J. 1974, 35, 443–451.

- Whitby, K.T.; Vomela, R.A. Response of single particle optical counters to nonideal particles. Environ. Sci. Technol. 1967, 1, 801–814.

- Barone, T.L.; Hesse, E.; Seaman, C.E.; Baran, A.J.; Beck, T.W.; Harris, M.L.; Jaques, P.A.; Lee, T.; Mischler, S.E. Calibration of the cloud and aerosol spectrometer for coal dust composition and morphology. Adv. Powder Technol. 2019, 30, 1805–1814.

- Marple, V.A.; Rubow, K.L. Aerodynamic particle size calibration of optical particle counters. J. Aerosol Sci. 1976, 7, 425–433.

- Marple, V.A.; Rubow, K.L. A portable optical particle counter system for measuring dust aerosols. Am. Ind. Hyg. Assoc. J. 1978, 39, 210–218.

- Flagan, R.C. History of Electrical Aerosol Measurements. Aerosol Sci. Technol. 1998, 28, 301–380.

- Wang, S.C.; Flagan, R.C. Scanning Electrical Mobility Spectrometer. Aerosol Sci. Technol. 1990, 13, 230–240.

- Fuchs, N.A. On the stationary charge distribution on aerosol particles in a bipolar ionic atmosphere. Geofis. Pura E Appl. 1963, 56, 185–193.

- Wiedensohler, A. An approximation of the bipolar charge distribution for particles in the submicron size range. J. Aerosol Sci. 1988, 19, 387–389.

- Kallinger, P.; Steiner, G.; Szymanski, W.W. Characterization of four different bipolar charging devices for nanoparticle charge conditioning. J. Nanoparticle Res. 2012, 14, 944.

- Lee, H.M.; Soo Kim, C.; Shimada, M.; Okuyama, K. Bipolar diffusion charging for aerosol nanoparticle measurement using a soft X-ray charger. J. Aerosol Sci. 2005, 36, 813–829.

- Liu, B.Y.H.; Pui, D.Y.H. Equilibrium bipolar charge distribution of aerosols. J. Colloid Interface Sci. 1974, 49, 305–312.

- Liu, B.Y.H.; Pui, D.Y.H. Electrical neutralization of aerosols. J. Aerosol Sci. 1974, 5, 465–472.

- Knutson, E.O.; Whitby, K.T. Aerosol classification by electric mobility: Apparatus, theory, and applications. J. Aerosol Sci. 1975, 6, 443–451.

- McMurry, P.H. The History of Condensation Nucleus Counters. Aerosol Sci. Technol. 2000, 33, 297–322.

- Mai, H.; Flagan, R.C. Scanning DMA Data Analysis I. Classification Transfer Function. Aerosol Sci. Technol. 2018, 52, 1382–1399.

- Mai, H.; Kong, W.; Seinfeld, J.H.; Flagan, R.C. Scanning DMA data analysis II. Integrated DMA-CPC instrument response and data inversion. Aerosol Sci. Technol. 2018, 52, 1400–1414.

- Watson, J.G.; Chow, J.C.; Sodeman, D.A.; Lowenthal, D.H.; Chang, M.-C.O.; Park, K.; Wang, X.L. Comparison of four scanning mobility particle sizers at the Fresno Supersite. Particuology 2011, 9, 204–209.

- Brunelli, N.A.; Flagan, R.C.; Giapis, K.P. Radial Differential Mobility Analyzer for One Nanometer Particle Classification. Aerosol Sci. Technol. 2009, 43, 53–59.

- Cai, R.; Chen, D.-R.; Hao, J.; Jiang, J. A miniature cylindrical differential mobility analyzer for sub-3 nm particle sizing. J. Aerosol Sci. 2017, 106, 111–119.

- Franchin, A.; Downard, A.; Kangasluoma, J.; Nieminen, T.; Lehtipalo, K.; Steiner, G.; Manninen, H.E.; Petäjä, T.; Flagan, R.C.; Kulmala, M. A new high-transmission inlet for the Caltech nano-RDMA for size distribution measurements of sub-3nm ions at ambient concentrations. Atmos. Meas. Tech. 2016, 9, 2709–2720.

- Iida, K.; Stolzenburg, M.R.; McMurry, P.H. Effect of Working Fluid on Sub-2 nm Particle Detection with a Laminar Flow Ultrafine Condensation Particle Counter. Aerosol Sci. Technol. 2008, 43, 81–96.

- Jiang, J.; Chen, M.; Kuang, C.; Attoui, M.; McMurry, P.H. Electrical Mobility Spectrometer Using a Diethylene Glycol Condensation Particle Counter for Measurement of Aerosol Size Distributions Down to 1 nm. Aerosol Sci. Technol. 2011, 45, 510–521.

- Kangasluoma, J.; Cai, R.; Jiang, J.; Deng, C.; Stolzenburg, D.; Ahonen, L.R.; Chan, T.; Fu, Y.; Kim, C.; Laurila, T.M.; et al. Overview of measurements and current instrumentation for 1–10 nm aerosol particle number size distributions. J. Aerosol Sci. 2020, 148, 105584.

- Kuang, C.; Chen, M.; McMurry, P.H.; Wang, J. Modification of Laminar Flow Ultrafine Condensation Particle Counters for the Enhanced Detection of 1 nm Condensation Nuclei. Aerosol Sci. Technol. 2012, 46, 309–315.

- Stolzenburg, M.R.; Scheckman, J.H.T.; Attoui, M.; Han, H.-S.; McMurry, P.H. Characterization of the TSI model 3086 differential mobility analyzer for classifying aerosols down to 1 nm. Aerosol Sci. Technol. 2018, 52, 748–756.

- Enroth, J.; Kangasluoma, J.; Korhonen, F.; Hering, S.; Picard, D.; Lewis, G.; Attoui, M.; Petäjä, T. On the time response determination of condensation particle counters. Aerosol Sci. Technol. 2018, 52, 778–787.

- Fernandez de la Mora, J.; Perez-Lorenzo, L.J.; Arranz, G.; Amo-Gonzalez, M.; Burtscher, H. Fast high-resolution nanoDMA measurements with a 25 ms response time electrometer. Aerosol Sci. Technol. 2017, 51, 724–734.

- Shah, S.D.; Cocker, D.R. A Fast Scanning Mobility Particle Spectrometer for Monitoring Transient Particle Size Distributions. Aerosol Sci. Technol. 2005, 39, 519–526.

- Tröstl, J.; Tritscher, T.; Bischof, O.F.; Horn, H.-G.; Krinke, T.; Baltensperger, U.; Gysel, M. Fast and precise measurement in the sub-20nm size range using a Scanning Mobility Particle Sizer. J. Aerosol Sci. 2015, 87, 75–87.

- Amanatidis, S.; Kim, C.; Spielman, S.R.; Lewis, G.S.; Hering, S.V.; Flagan, R.C. The Spider DMA: A miniature radial differential mobility analyzer. Aerosol Sci. Technol. 2020, 54, 175–189.

- Hering, S.V.; Lewis, G.S.; Spielman, S.R.; Eiguren-Fernandez, A. A MAGIC concept for self-sustained, water-based, ultrafine particle counting. Aerosol Sci. Technol. 2019, 53, 63–72.

- Khlystov, A.; Stanier, C.; Pandis, S.N. An Algorithm for Combining Electrical Mobility and Aerodynamic Size Distributions Data when Measuring Ambient Aerosol Special Issue ofAerosol Science and Technologyon Findings from the Fine Particulate Matter Supersites Program. Aerosol Sci. Technol. 2004, 38, 229–238.

- Liu, J.; Jiang, J.; Zhang, Q.; Deng, J.; Hao, J. A spectrometer for measuring particle size distributions in the range of 3 nm to 10 μm. Front. Environ. Sci. Eng. 2016, 10, 63–72.

- Hand, J.L.; Kreidenweis, S.M. A New Method for Retrieving Particle Refractive Index and Effective Density from Aerosol Size Distribution Data. Aerosol Sci. Technol. 2002, 36, 1012–1026.

- Wang, X.L.; Watson, J.G.; Chow, J.C.; Gronstal, S.; Kohl, S.D. An efficient multipollutant system for measuring real-world emissions from stationary and mobile sources. Aerosol Air Qual. Res. 2012, 12, 145–160.

- Watson, J.G.; Chow, J.C.; Lowenthal, D.H.; Magliano, K.L. Estimating aerosol light scattering at the Fresno Supersite. Atmos. Environ. 2008, 42, 1186–1196.

- Woo, K.-S. Measurement of Atmospheric Aerosols: Size Distribution of Nanoparticles, Estimation of Distribution Moments and Control of Relative Humidity; University of Minnesota: Minneapolis, MN, USA, 2002.

- Skubacz, K.; Wojtecki, Ł.; Urban, P. Aerosol concentration and particle size distributions in underground excavations of a hard coal mine. Int. J. Occup. Saf. Erg. 2017, 23, 318–327.

- Saarikoski, S.; Salo, L.; Bloss, M.; Alanen, J.; Teinilä, K.; Reyes, F.; Vázquezuez, Y.; Keskinen, J.; Oyola, P.; Rönkkö, T.; et al. Sources and Characteristics of Particulate Matter at Five Locations in an Underground Mine. Aerosol Air Qual. Res. 2019, 9, 2613–2624.

- Biskos, G.; Reavell, K.; Collings, N. Description and Theoretical Analysis of a Differential Mobility Spectrometer. Aerosol Sci. Technol. 2005, 39, 527–541.

- Johnson, T.; Caldow, R.; Pöcher, A.; Mirme, A.; Kittelson, D. A New Electrical Mobility Particle Sizer Spectrometer for Engine Exhaust Particle Measurements; SAE International: Warrendale, PA, USA, 2004.

- Symonds, J.P.R.; Reavell, K.S.J.; Olfert, J.S.; Campbell, B.W.; Swift, S.J. Diesel soot mass calculation in real-time with a differential mobility spectrometer. J. Aerosol Sci. 2007, 38, 52–68.

- Wang, X.L.; Grose, M.A.; Avenido, A.; Stolzenburg, M.R.; Caldow, R.; Osmondson, B.L.; Chow, J.C.; Watson, J.G. Improvement of Engine Exhaust Particle Sizer (EEPS) size distribution measurement: I. Algorithm and Applications to Compact Aerosols. J. Aerosol Sci. 2016, 92, 95–108.

- Nakamura, K.; Oshikiri, T.; Ueno, K.; Wang, Y.; Kamata, Y.; Kotake, Y.; Misawa, H. Properties of Plasmon-Induced Photoelectric Conversion on a TiO2 /NiO p–n Junction with Au Nanoparticles. J. Phys. Chem. Lett. 2016, 7, 1004–1009.

- Reavell, K.; Hands, T.; Collings, N. A Fast Response Particulate Spectrometer for Combustion Aerosols. SAE Technical Paper2002-01-2714. Sae Trans. 2002, 111, 1338–1344.

- Bugarski, A.D.; Hummer, J.A. Contribution of various types and categories of diesel-powered vehicles to aerosols in an underground mine. J. Occup. Environ. Hyg. 2020, 17, 121–134.

- Bugarski, A.D.; Barone, T.L.; Hummer, J.A. Diesel and welding aerosols in an underground mine. Int. J. Min. Sci. Technol. 2020.