Non-Biodegradable Polymeric Matrices

ABS is one of the most common materials in FDM filaments [53]: It is quite easy to print, exhibits adequate mechanical properties and toughness [7], high melt strength [4] and durability [19]. On the other hand, since ABS is not classifiable as a commodity, there is margin to decrease cost by adding cheap natural fibers [54]. In the last three years quite a good number of authors have investigated the effect of compounding bio-based fillers in ABS filaments [4,7,18,19,20,55]. From Table 2, it can be seen that ABS formulations are generally simple, with additives other than biofiller being only coupling [7,55] and toughening agents [4,7].

In order to decrease material cost even further, a limited group of researchers investigated polyolefins, such as PE and PP, which are true low cost commodities. In the pursuit of plastic waste reduction, pre-consumer PP waste was considered in [8,44], while for obtaining a more environmentally friendly material, bio-polyethylene (bioPE) was studied in [6,13]. This material is derived from vegetable feedstocks (e.g., sugar cane, sugar beet and wheat grain) and is chemically identical to petroleum based PE.

With polyolefins, the biggest issue comes from the printing process, as the mechanical properties of the melts are quite low. As described previously, this is typical of semicrystalline polymers and is due to the high difference between the polymer processing temperature, which obviously must exceed the crystal melting temperature, and their glass transition temperature. To limit these problems, in [8,44] a filament spooling machine was used to achieve good tolerance, as well as a 5 mm thick PP sheet retrofitted onto the print bed to improve adhesion. On the other hand, for these materials the effect of natural fibers becomes very interesting: Melt properties increase, thus improving self-sustaining characteristics during printing. Moreover, shrinkage and warpage effects decrease, but the poor adhesion between the polar fibers and the non-polar polyolefin matrix makes the addition of an appropriate coupling agent necessary (Table 2).

A last non-biodegradable biocomposite for FDM is thermoplastic polyurethane (TPU) [56]. TPU is interesting because of its versatility in terms of a wide range of mechanical properties, good abrasion resistance and low density [57]. However, cost is higher than other thermoplastics, therefore natural fibers can be helpful in making TPU more exploitable. Concerning additives, different types of coupling agents were analyzed in [56].

Biodegradable Polymeric Matrices

As the price of 3D printers drops every year, FDM becomes accessible to a growing number of people and this may increase the quantity of waste that is not properly disposed of or recycled at the end of life cycle. This is the main driving force for the development of filaments that are made of biodegradable or compostable materials [58].

PLA is the front-runner in the biodegradable plastics market, with the best availability and the most attractive cost vs. mechanical properties ratio [59]. Its production is relatively easy: It can be synthesized by condensation polymerization directly from lactic acid or from lactide ring opening, which are compounds that can be derived from fermentation of carbohydrate sources such as corn starch, sugarcane or tapioca [60]. Although it may possess a regular structure that would lead to a semicrystalline polymer, the most common commercial grades are almost completely amorphous glassy polymers.

The use of neat PLA in FDM 3D printing increases every year. It does not emit any unpleasant smell during the printing process and allows us to obtain components with reasonable tolerance [38]. The close connection between PLA and FDM has been established in the biomedical field, in particular in tissue engineering scaffold production. Here PLA can favor cell adhesion and proliferation, thus constituting a positive environment from a biological and mechanical point of view [61].

PLA biodegradation is due to hydrolysis: Water diffuses first into the amorphous domains and induces de-esterification. Degradation then proceeds also into the crystalline regions causing a drastic decay in the mechanical properties followed by complete dissolution of the material. On the other hand, as degradation is strongly accelerated by temperature, hydrolysis can be unwillingly activated during processing. Reaction kinetics is further accelerated by acidic environment, and as the degradation products lower pH, PLA hydrolysis is an autocatalytic process [36], thus it proceeds very quickly. PLA filled with natural fibers such as wood, hemp, kenaf and flax processed using standard technologies has already been studied [27,59,62,63]. Filler quantity and different fiber chemical treatments have a positive effect on stiffness and strength [27,28,64]. This however is closely linked to the compounding process, taking into account that natural fibers are highly hygroscopic. For these reasons, processing of natural fiber filled PLA is complex and requires appropriate feedstock drying and storage.

Although there are quite a few studies on PLA-based biocomposites in FDM, the challenges brought by the material coupled to the ones coming from the processing method have forced a “trial and error” procedure. Interestingly, the available literature that does not make use of commercial filaments is significant [3,9,17,21,23,38,39,45,46,48,49,65,66,67,68], but has appeared only recently and the effects of processing parameters, additives formulation, patterning and geometrical features are not yet deeply explored. As can be seen from Table 3, plasticizers [21,45,48], toughening agents [39,65] and compatibilizers [39] have been studied.

Besides PLA, other biodegradable polyesters were also considered in the literature, such as poly-(ε-caprolactone) (PCL) [16], poly-(hydroxyalkanoates) (PHA) [5] and their blends with PLA [12,20]. The growing interest towards biodegradable polymers filled with natural fibers is confirmed by the availability in the commercial filament market of biocomposite wood/PLA filaments, such as “Bamboo fill” and “Woodfill” (ColorFabb Company) and “Laywoo” (CC Products), which are listed in Table 4.

Mechanical Properties

Components produced through FDM have mechanical properties that are heavily dependent on printing architecture. For this reason, filament properties after compounding should be evaluated before introducing the numerous processing variables of 3D printing. Tensile, flexural, compressive and impact properties of 3D printed samples will be considered next and separately from each other, to allow for more significant comparison. In all published papers the specimens were shaped according to standards that are valid for materials in bulk. Despite this may seem inappropriate at first, one should consider that no specific standard for 3D printed parts exists.

Filaments

In the scientific literature a few researchers have dealt with the tensile characterization of filaments. Harakeke and hemp fiber filled PP was studied in [8,44] and was shown that both strength and stiffness increase with natural fiber content. Harakeke had a stronger effect than hemp, leading to a tensile strength increase of about 50% for a harakeke loading of about 30 wt %, while stiffness more than doubled.

The situation is quite different for PLA: 10 wt % wood flour filling led to a very small increase in strength [23], but it decreased remarkably at higher wood content. Interestingly, this could not be ascribed to PLA hygrothermal degradation, as the authors were careful in drying raw materials before processing. A similar situation was also found in cocoa shell waste (CSW) filled PCL [16] and in commercial wood/PLA filaments [69].

In order to explain this discrepancy, the chemical nature of the matrix may not be the only issue to consider. In fact, as reported in Table 2 and Table 3, the polyolefin filaments had a diameter greater than 2.4 mm, thus were significantly thicker than the polyester ones, whose diameter was 1.75 mm. Although this last size is the one that is most commonly required by 3D printers, it may not allow an adequate wetting of the fibers at high percentages of filler. Secondly, despite the similar fiber content (i.e., around 40 wt %) in both filaments, this is close to the maximum fiber loading for PLA, while polyolefins can accept wood filling up to 70 wt %. Notice also that the negative effect of biofiller is independent of filler geometry. In fact, Depuydt [48] et al. analyzed PLA filled with flax and bamboo fibers as a function of the length over diameter ratio (L/D) of the reinforcement. Despite their results showed that the L/D ratio had an important influence on stiffness (longer fibers increase it by 215%), it did not have the same influence on strength, and anyway the properties of neat PLA were much higher. The same authors evaluated the effects of two different plasticizers, finding no relevant influence and completed filament characterization with a verification of porosity reduction induced by vacuum drying at the end of compounding.

Concerning the effects of fiber treatment, Filgueira et al. [49] evaluated the strength of filaments based on PLA filled with thermomechanical pulp fibers (TMP), subjected to two different enzymatic modifications, namely laccase-assisted grafting (LG) and laccase-mediated grafting (OG). The OG-modified composites yielded the highest strength among all filaments, probably because of a better interfacial adhesion between TMP and PLA. On the other hand, strength of all other biocomposites was lower than that of neat PLA, and this was justified on the basis of filament porosity, which was confirmed by electron microscopy analysis.

3D Printed Components

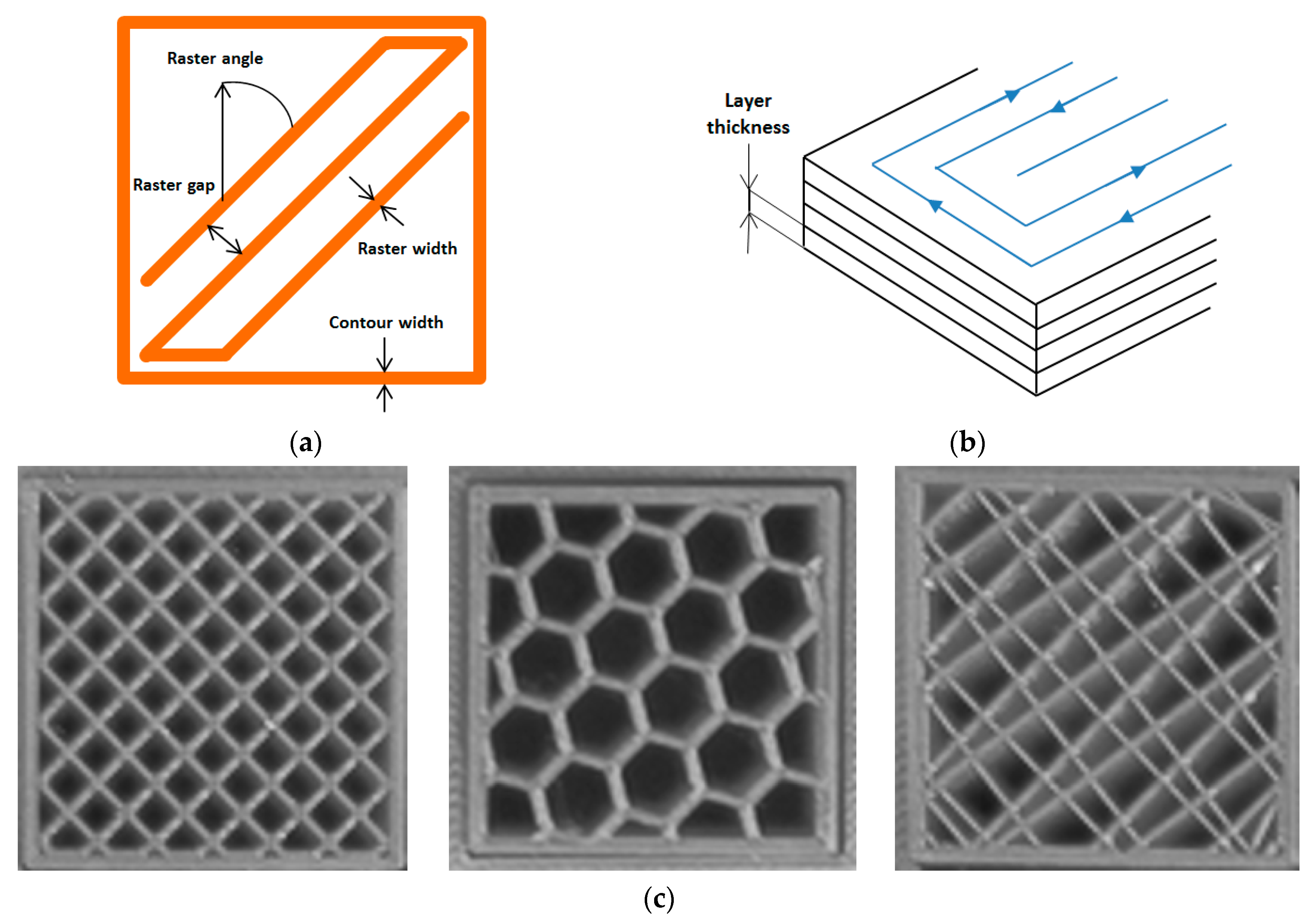

The mechanical properties of 3D printed parts depend also on a wide range of structural and printing parameters. These actually define a structure within the part, which is deeply connected with the material in making the properties of the printed component. These may change considerably even if only a single parameter is modified [70,71]. This is already known in the case of FDM of unfilled materials, as the mechanical properties are strongly influenced by the infill geometry of the specimen. The situation is even more complicated in the case of a composite, i.e., an intrinsically inhomogeneous and anisotropic material. This strong connection between structure, material and the final mechanical properties is still at the core of current research interests and needs further understanding.

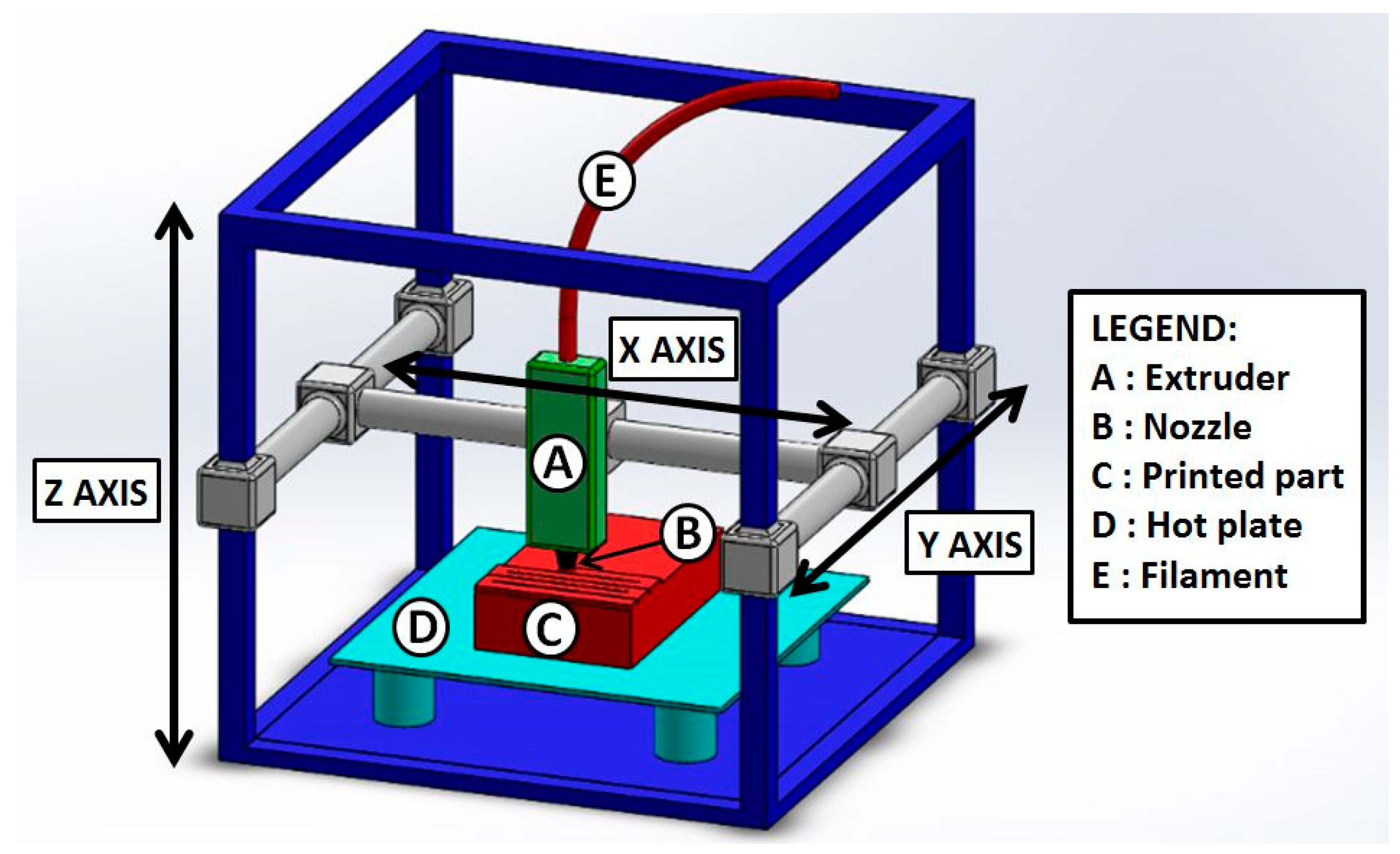

The most frequently reported printing parameters are listed in Table 5. It can be seen that the most common nozzle diameter is 0.4 mm, albeit greater nozzles are also comprehensibly employed in the case of filled materials, up to 1.5 mm. The layer height is also centered around 0.2–0.3 mm, while the extrusion speed rate is more variable, ranging from 15 up to 100 mm/s. The extrusion temperature is always relatively high, i.e., greater than 180 °C, except for one paper, in which PCL was used, while the bed temperature is in the range 40–110 °C. For the reader’s convenience, also the commercial names of the 3D printers that have been used in the papers analyzed in this review are reported in Table 5, together with the bibliographic reference.

Table 5. 3D printing FDM parameters.

| Nozzle Diameter (mm) | Extrusion Temperature (°C) | Bed Temperature (°C) | Extrusion Speed Rate (mm/s) | Layer Height (mm) | 3D-printer | Ref. |

|---|---|---|---|---|---|---|

| 0.4 | 220 | 70 | 90 | 0.34 | MakerBot-Replicator 2 | [3] |

| 0.5 | 230 | 110 | 50 | / | LulzBot TAZ | [4] |

| 0.75 | 190 | 40 | 25 | 0.3 | MakerGear™ V2 | [5] |

| 0.4 | 210 | / | 15 | / | Ultimaker Original | [6] |

| / | 210 | / | / | / | da Vinci 1.0 | [7] |

| 1.5 | 230 | / | / | 1 | Diamond Age | [8] |

| 0.4 | 210 | / | / | / | Self-assembled | [9] |

| 0.4 | 210 | 70 | 18 | / | Prusa i3-Rework | [12] |

| / | 180–200 | / | / | / | Prusa i3 | [13] |

| 0.6 | 120 | / | 50 | 0.3 | Prusa i3-Hephestos | [16] |

| / | 190–195 | / | 30–50 | / | / | [17] |

| / | 230-245 | 70 | 21 | 0.2 | Easy3DMaker | [18] |

| 1 | 250 | 100 | / | 0.2 | Printrbot Simple Metal | [19] |

| / | 220–275 | 60–90 | 30–40 | 0.4 | CreatBot DX-3D | [20] |

| / | 220 | / | / | / | MakerBot-Replicator 2 | [21] |

| / | 210 | 80 | 60–100 | / | Blade 1 | [22] |

| 0.4 | 230–275 | / | 30 | 0.19 | Zortrax M200 | [23] |

| 0.4 | 200–230 | 50 | 30 | / | Creator Pro-Flashforge | [24] |

| / | 205 | / | 20 | 0.1 | Zmorph 2.0 | [38] |

| / | / | / | / | / | MR300 | [39] |

| 1 | 230 | / | 50 | / | / | [44] |

| 0.8 | 230 | 60 | 30 | 0.4 | MakerBot-Replicator 2 | [45] |

| 0.4 | 230–275 | / | 30 | 0.19 | Zortrax M200 | [46] |

| / | / | / | / | 0.8 | / | [47] |

| 0.4 | 210 | / | 15 | / | Ultimaker Original | [49] |

| 0.4 | 200 | 80 | / | 0.05–0.3 | Zaxe | [52] |

| 0.5 | / | / | / | / | Leapfrog Creatr | [55] |

| / | 185 | / | / | / | MR300 | [56] |

| 0.5 | 180 | / | / | 0.1 | / | [65] |

| 0.4 | / | / | / | / | Accucraft | [66] |

| 0.6 | 200 | 50 | 40 | 0.1 | / | [67] |

| 1 | / | 110 | / | / | Diamond age | [68] |

| 0.5 | 188 | 50 | 60 | 0.4 | Profi3Dmaker | [69] |

| / | 215 | / | 60 | 0.2 | MakerBot-Replicator 5 | [72] |

| / | 230 | 70 | 90 | / | MakerBot-Replicator 2 | [73] |

| 0.4 | 200 | 80 | / | / | Zaxe | [74] |

| 0.4 | 200 | 60 | 30 | 0.3 | Open source, 605 S model | [75] |

4.2.1. Tensile Properties

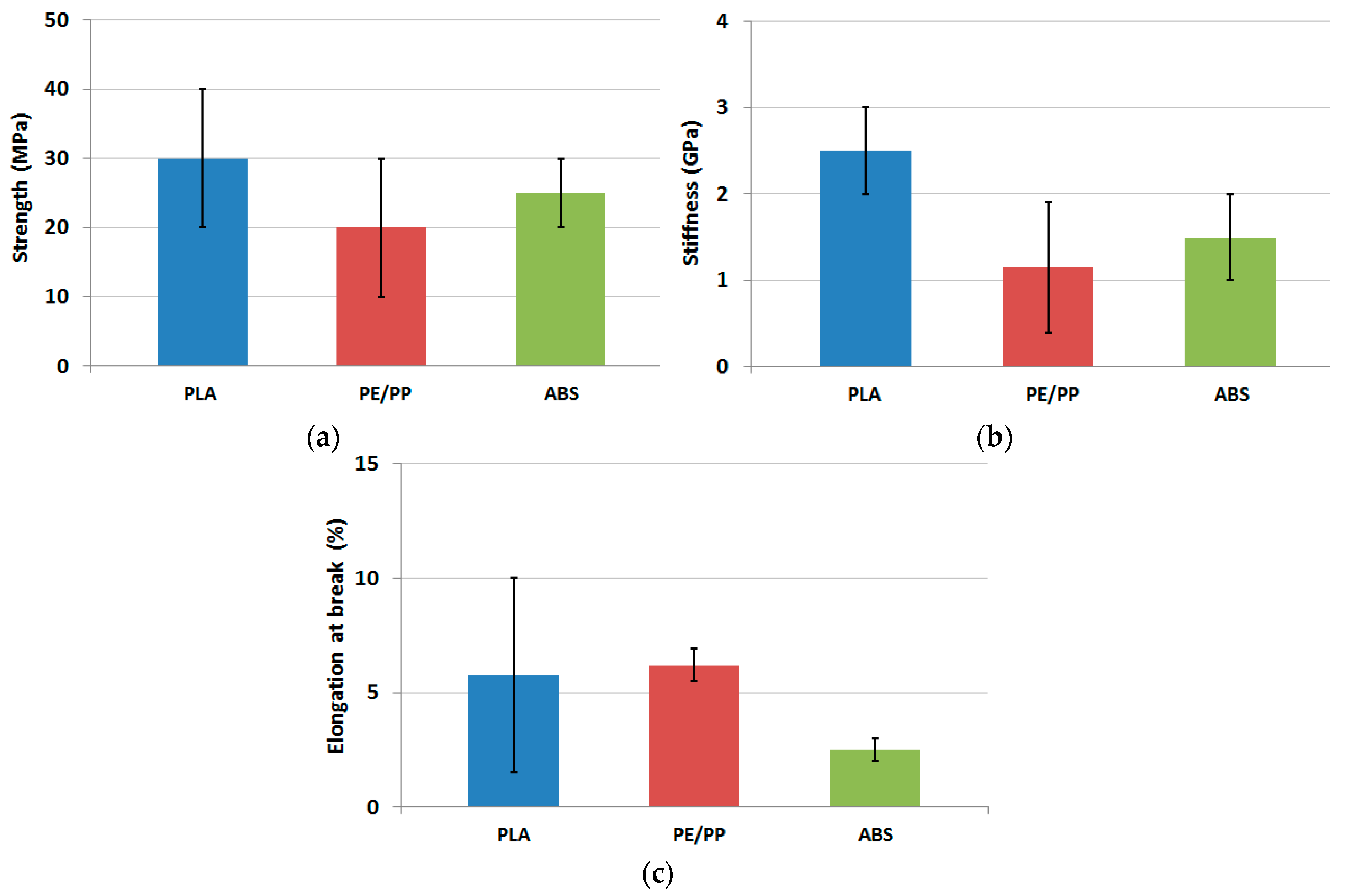

From Table 3 it is evident that the majority of the papers concerned with the tensile properties of FDM printed biocomposites dealt with PLA-based filaments [3,9,12,21,22,24,38,39,45,49,67,68,69,72,73,74]. These possess average tensile strength ranging from 20 up to 40 MPa, Young’s moduli between 2 and 3 GPa and elongation at break between 1.5% and 10%. The biocomposites based on ABS are the second class of materials [4,18,19,55]: Their properties range between 20 and 30 MPa for strength, 1 and 2 GPa for stiffness and 2%–3% for elongation at break. The third class is polyolefin-based biocomposites [8,13,44], which have strength around 20 MPa, Young’s moduli from 0.5 up to 2 GPa and elongation at break of about 5%. Strength, stiffness and elongation at break for these materials are reported in Figure 3. Only one paper investigated a TPU based composite [56], whose properties are similar to the other biocomposites, with the notable exception of elongation at break, which exceeds 300% at 40 wt % wood flour content.

Figure 3. Average tensile properties of 3D printed samples for different polymeric matrices: (a) Strength; (b) stiffness and (c) elongation at break.

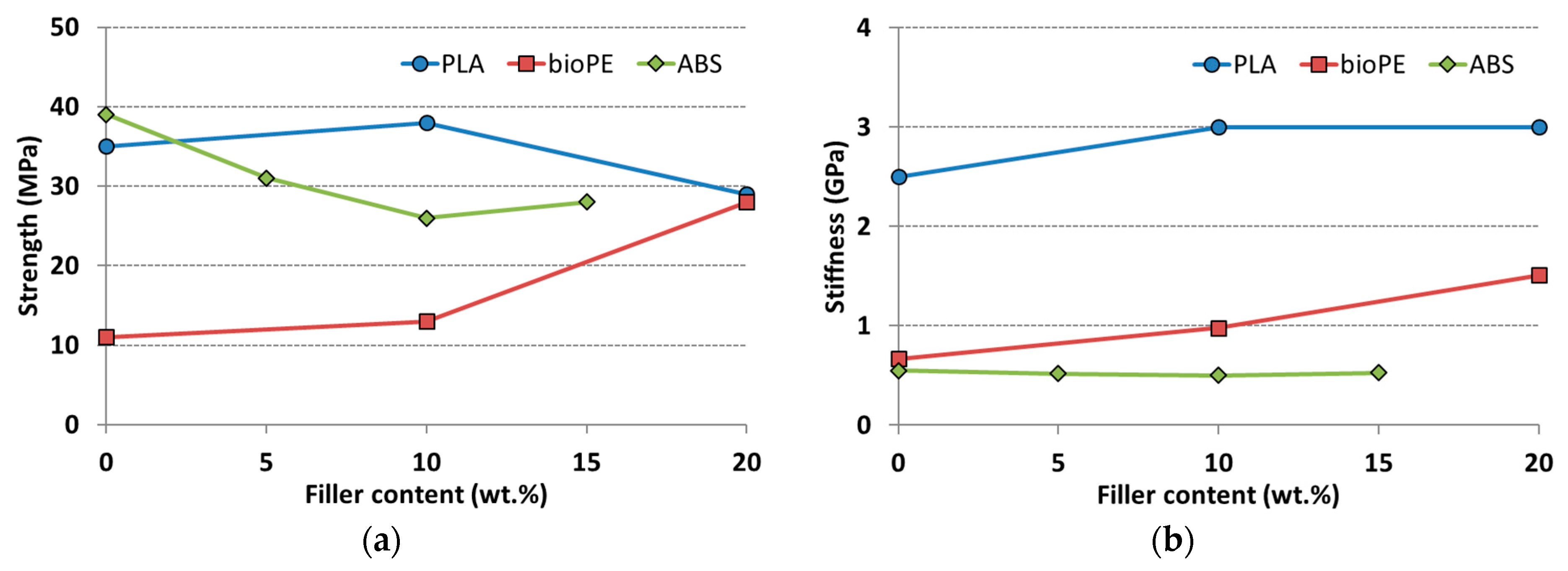

Comparing unfilled printed specimens with reinforced ones, it can be often concluded that natural fibers have a negative influence on strength [3,4,9,18,19,38,39,56,67,68,69,73], while stiffness either increases slightly [8,13,18,19,44,68] or remains constant [3,38], as shown in Figure 4. The detrimental effect on strength is present in all materials, except for the polyolefins, where values increase with fiber content [8,13,44]. Analogously as filament properties, polyolefins do seem to benefit from natural fiber filling, irrespective of filler geometry: Indeed, TMP/PP biocomposite specimens increase their mechanical properties also with biofiller in the form of short chips, more similar to particles than to fibers [13].

Figure 4. Mechanical properties of hemp/PLA [68], TMP/bioPE [13] and rice husk/ABS [19] as a function of biofiller content: (a) Strength and (b) stiffness.

The effect of additives other than biofillers has been studied only by a few authors [4,21,39,56]. Toughening agents, such as TPU on PLA/wood [39] or nitrile rubber on ABS [4], seem to improve strength, especially when coupled to compatibilizers. Notice, though, that strength of the composite remains lower anyway than that of the neat matrix. Xie et al. [21] evaluated the effect of two different plasticizers and their combination in different percentages and found that adding 4 wt % of tributyl citrate increased both strength and elongation at break. Bi et al. [56] tested different modifiers on wood/TPU composites, and found that it is possible to improve the interfacial adhesion between TPU and wood fibers with diphenylmethyl propane diisocyanate (MDI) and compensated the excessive flexibility with the addition of EPDM grafted with maleic anhydride (EPDM-g-MAH) as compatibilizer. Chemical treatments can also be used to enhance the properties of biocomposites [27,28]: Higher properties in sugarcane bagasse fiber (SBF) filled PLA are reported, in which SBF was treated sequentially with alkaline and acidic solutions [67].

Several authors have explored the effects that processing parameters have on the properties of the biocomposites [24,38,69,73,74]. On the basis of a design of experiment (DoE) methodology, Dong et al. [73] determined that the number of layers is the parameter that mostly affects the tensile properties, and verified this finding in the case of unfilled PLA and wood/PLA systems. The effect of the printing layer thickness was studied in [74] for a commercial wood/PLA, yielding the best results with a 0.05 mm layer thickness (i.e., the minimum tested value) and this was explained due to reduced porosity. Again for the wood/PLA system the negative effects of high processing temperature were investigated in [24]: At temperatures higher than 200 °C, strength decreased by 10%, while stiffness dropped by 5%. The infill density is also a very important parameter, as reported in [69], for pure PLA and two commercial wood/PLA filaments. As expected, infill density increased the mechanical properties for all materials, but more effectively for pure PLA than for the composites. Instead, nozzle diameter (0.2 mm up to 0.4 mm) was studied in [38], with 0.4 mm providing maximum elongation at break and strength but lower stiffness. Sample width can have a strong effect on tensile properties [12], and this is related to the percentage of overlap, and hence porosity, of the samples. Patterning has a significant effect [12,19,67], in that specimens printed following a longitudinal toolpath are much stiffer and stronger than the ones printed following other directions [12], due to poor interfilament adhesion [67]. Interestingly, though, increasing the filler content had a particularly negative effect for the 45° raster angle specimens, while the Young’s modulus for the 0° angle remained almost constant at any percentage of filler [19]. Environmental conditions can also modify the behavior of wood/PLA FDM printed samples [12]. In hygroscopic saturated conditions stiffness and strength were reduced by about 12.5% and 25%, respectively.

In an interesting group of papers, the tensile properties of 3D printed biocomposite specimens were compared to those of samples obtained by processing the same materials through injection molding [13,18] and compression molding [38,45]. Stiffness and strength of 3D printed specimens were similar to compression molded ones, but much less than injection molded samples. This may be clearly justified on the basis of the lower forming pressure of compression molding with respect to injection molding, but this conclusion cannot be considered completely exhaustive, as too few results are present in the literature, thus further investigations are necessary.

Hinchcliffe et al. [72] and Matsuzaki et al. [22] investigated continuous natural fiber reinforcement on 3D printed specimens in the form of an I-beam and a plate, respectively. The stress-strain behavior studied in [72] demonstrated that prestressed flax fibers strands increased the ultimate strength and stiffness of the samples, while jute fibers did not induce a significant improvement over the unreinforced specimens. Instead, in [22] the modulus and strength of jute reinforced plate specimens were +157% and +134%, respectively, compared with PLA specimens, but the 3D printer that was used did not allow fiber pre-tensioning.

Compressive Properties

Compressive properties of FDM printed natural fibers reinforced thermoplastics were studied only in three articles, i.e., [24,55,75]. The range of average values of strength goes from 15 MPa for ABS based composites up to 30 MPa for those based on PLA. Compressive failure is primarily determined by localized buckling of the outside layers, as reported for all materials studied in [55]. The same type of failure was observed in [24], where the effect of printing temperature on strength was evaluated for a commercial wood/PLA filament. For compressive properties the effect of a temperature increase seems to be beneficial, as there is an improvement by 15% in strength in going from 200 °C up to 230 °C. Tao et al. [75] evaluated the influence of infill geometry using a commercial wood/PLA filament. This study compared the performance of different 3D printed cellular structures depending on the geometry of the cell cavities (circular, square and voronoi), indicating that square geometry is the most rigid, but the authors pointed out that square paths are inherently easier to print successfully. The influence of the deposed line width was also evaluated, with greater line width creating higher porosity, thus lower properties.

Flexural Properties

Almost all of the literature that studied the flexural properties of biocomposites in FDM used PLA as the matrix [24,39,46,66,67,72,73,74] with only one exception, i.e., [19], in which ABS was used. Flexural properties were always measured through the three-point bending method and ranged between 30 and 60 MPa for strength and between 2 and 4 GPa for stiffness.

In analogy with tensile properties, flexural strength rapidly decreases with the filler content [19,39,67], while the situation is different for stiffness. Here, the literature explored only the range from 0 wt % up to 15 wt % filler content, finding that the Young’s modulus increases by about 20% or more [19,67].

The effect of additives was studied only in [39], where different toughening agents were evaluated (Table 3). In keeping with tensile properties, the addition of TPU seemed to be the best choice to increase strength. The authors also studied the effects of two different coupling agents, but these failed to improve strength. Fiber chemical treatment is beneficial also in the case of flexural properties [67].

FDM process parameters were investigated only in three papers [24,73,74]. The number of layers was found to be more effective than infill density and layer thickness [73]. Interestingly, though, unlike tensile properties, this effect was found to be more significant in the case of composites rather than the neat matrix. Ayrilmis et al. [74] investigated the effect of printing layer thickness on the bending properties of a commercial wood/PLA filament, finding significant improvement at minimal thicknesses because of reduced porosity. The effect of extrusion temperature on wood/PLA composite was studied in [24]: This parameter can be critical during the printing phase because both natural fibers and PLA can suffer from thermal degradation. Stiffness appeared to decrease with printing temperature, while strength seemed to remain about constant.

In addition to material and processing variables, also environmental parameters can influence flexural properties. Kariz et al. [46] evaluated the behavior of wood/PLA samples in different humidity conditions (i.e., 33%, 65% and 87%), finding that stiffness of the wood filled composites strongly decreased with moisture content.

Impact Properties

Adding natural fibers to an unfilled thermoplastic polymer processed with standard technologies normally reduces its impact properties [76], since filler introduces defects and stress intensity regions that may embrittle the material, even if chemical bonds between fibers and matrix are adequate. In the published literature concerning impact properties of FDM, only wood/PLA biocomposites have been evaluated. Accordingly, it was found that toughness always decreased when adding natural fibers or particles [69] and this was particularly significant when compared with unfilled PLA [39,65,73].

The effect of toughening agents was studied in [39,65]. In particular, Guo et al. [39] concluded that TPU is more effective than PCL and metallocene-based poly(ethylene-octene) elastomer (POE). POE was studied also in [65] and was found to improve impact properties in such a way that a 15 wt % content was sufficient to recover the impact strength of neat PLA. Coupling agents are studied only in [39], where it is reported that the combined effect of an appropriate compatibilizer with a toughening agent is effective.

Only two papers have studied the influence of processing parameters on impact properties. Increasing the number of layers had no effects on wood/PLA biocomposites, in spite of being advantageous in neat PLA [73], while the infill density (from 23% up to 55%) had a positive effect on commercial wood/PLA [69].

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Part B 2018, 143, 172–196.

- Wahab, M.S.; Wagiman, A.; Ibrahim, M. Development of wood-based composites material for 3D printing process. Mech. Mat. 2013, 315, 987–991.

- Tisserat, B.; Liu, Z.; Finkenstadt, V.; Lewandowski, B.; Ott, S.; Reifschneider, L. 3D printing biocomposites. Plast. Res. Online (SPE) 2015, 1–3, 10.2417/spepro.005690.

- Nguyen, N.A.; Bowland, C.C.; Naskar, A.K.; A general method to improve 3D-printability and inter-layer adhesion in lignin-based composites. Mater. Today 2018, 12, 138–152.

- Vaidya, A.A.; Collet, C.; Gaugler, M.; Lloyd-Jones, G. Integrating softwood biorefinery lignin into polyhydroxybutyrate composites and application in 3D printing. Today Commun. 2019, 19, 286–296.

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. 3D Printable filaments made of biobased polyethylene biocomposites. Polymers 2018, 10, 314.

- Kuo, C.C.; Liu, L.C.; Teng, W.F.; Chang, H.Y.; Chien, F.M.; Liao, S.J.; Kuo, W.F.; Chen, C.M. Preparation of starch/acrylonitrile-butadiene-styrene copolymers (ABS) biomass alloys and their feasible evaluation for 3D printing application. Part B 2016, 86, 36–39.

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the mechanical properties of fused deposition modelling natural fiber recycled polypropylene composites. Compos. Sci. 2017, 1, 7.

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and application of wood flour-filled polylactic acid composite filament for 3D printing. Materials 2017, 10, 339.

- Kariz, M.; Sernek, M.; Kuzman, M.K. Use of wood powder and adhesive as a mixture for 3D printing. J. Wood Prod. 2016, 74, 123–126.

- Pitt, K.; Lopez-Botello, O.; Lafferty, A.D.; Todd, I.; Mumtaz, K. Investigation into the material properties of wooden composite structures with in-situ fibre reinforcement using additive manufacturing. Sci. Technol. 2017, 138, 32–39.

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Des. 2016, 96, 106–114.

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Part B 2018, 153, 70–77.

- Henke, K.; Treml, S. Wood based bulk material in 3D printing processes for applications in construction. J. Wood Prod. 2013, 71, 139–141.

- D'Amora, U.; D'Este, M.; Eglin, D.; Safari, F.; Sprecher, M.C.; Gloria, A.; De Santis, R.; Alini, M.; Ambrosio, L. Collagen density gradient on three‐dimensional printed poly(ε‐caprolactone) scaffolds for interface tissue engineering. Tissue Eng. Regen. Med. 2018, 12, 321–329.

- Tran, T.N.; Bayer, I.S.; Heredia-Guerrero, J.A.; Frugone, M.; Lagomarsino, M.; Maggio, F.; Athanassiou, A. Cocoa shell waste biofilaments for 3D printing applications. Mater. Eng. 2017, 302, 1700219

- Zhao, D.; Cai, X.; Shou, G.; Gu, Y.; Wang, P. Study on the preparation of bamboo plastic composite intend for additive manufacturing. Key Eng. Mater. 2016, 667, 250–258.

- Šafka, J.; Ackermann, M.; Bobek, J.; Seidl, M.; Habr, J.; Behalek, L. Use of composite materials for FDM 3D print technology. Sci. Forum 2016, 862, 174–181.

- Osman, M.A.; Atia, M.R.A. Investigation of ABS-rice straw composite feedstock filament for FDM. Rapid Prototyp. J. 2018, 24, 1067–1075.

- Pop, M.A.; Croitoru, C.; Bedő, T.; Geaman, V.; Radomir, I.; Cosnita, M.; Zaharia, S.M.; Chicos, L.A.; Milosan, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. Appl. Polym. Sci. 2019, 47382

- Xie, G.; Zhang, Y.; Lin, W. Plasticizer combinations and performance of wood flour—poly(lactic acid) 3D printing filaments. BioResource 2017, 12, 6736–6748.

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Rep. 2016, 6, 23058.

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Today Commun. 2018, 14, 135-140.

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused deposition modeling. Polymers 2018, 10, 976.

- Mazzanti, V.; Mollica, F.; El Kissi, N. Rheological and mechanical characterization of polypropylene-based wood plastic composites. Compos. 2015, 37, 3460–3473.

- Barczewski, M.; Mysiukiewicz, O.; Kloziński, A. Complex modification effect of linseed cake as an agricultural waste filler used in high density polyethylene composites. Iran Polym. J. 2018, 27, 677–

- Mazzanti, V.; Pariante, R.; Bonanno, A.; Ruiz de Ballesteros, O.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Sci. Technol. 2019, 180, 51–59.

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Gloaguen, V.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Part A 2008, 39, 514–522.

- Yi, S.; Xu, S.; Fang, Y.; Wang, H.; Wang, Q. Effects of matrix modification on the mechanical properties of wood–polypropylene composites. Polymers 2017, 9, 712.

- Bledzki, A.; Faruk, O. Wood fibre reinforced polypropylene composites: Effect of fibre geometry and coupling agent on physico-mechanical properties. Compos. Mater. 2003, 10, 365–379.

- Valente, M.; Tirillò, J.; Quitadamo, A.; Santulli, C. Paper fiber filled polymer. Mechanical evaluation and interfaces modification. Part B 2017, 110, 520–529.

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Part B 2013, 44, 120–127.

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the sound absorption performance of sustainable thermal insulation materials: Natural hemp fibres. Acoust. 2019, 150, 279–289.

- Bouafif, H.; Koubaa, A.; Perre´, P.; Cloutier, A.; Riedl, B. Wood particle/high-density polyethylene composites: thermal sensitivity and nucleating ability of wood particles. Appl. Polym. Sci. 2009, 113, 593–600.

- Mazzanti, V.; Mollica, F. In-process measurements of flow characteristics of wood plastic composites. Polym. Environ. 2017, 25, 1044–1050.

- Elsawy, M.A.; Kim, K.H.; Park, J.W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Sust. Energ. Rev. 2017, 79, 1346–1352.

- van den Oever, M.J.A.; Beck, B.; Müssig, J. Agrofibre reinforced poly-(lactic acid) composites: Effect of moisture on degradation and mechanical properties. Part A 2010, 41, 1628–1635.

- Gkartzou, E.; Koumoulos, E.P.; Charitidis, C.A. Production and 3D printing processing of bio-based thermoplastic filament. Manufacturing Rev. 2017, 4, 2016020.

- Guo, R.; Ren,Z.; Bi, H.; Song, Y.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly(lactic acid) composites fabricated with fused deposition modeling. Polym. J. 2018, 107, 34–45.

- Gardan, J.; Roucoules, L. 3D printing device for numerical control machine and wood deposition. Julien Gardan Int. J. Eng. Res. App. 2014, 4, 123–131.

- Wimmer, R.; Steyrer, B.; Woess, J.; Koddenberg, T.; Mundigler, N. 3D Printing and wood. Pro Ligno 2015, 11, 144–149.

- Gardan, J.; Nguyen, D.C.; Roucoules, L.; Montay, G. Characterization of wood filament in additive deposition to study the mechanical behavior of reconstituted wood products. Eng. Fibers Fabr. 2016, 11, 56–63.

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.T. Liquid deposition modeling: a promising approach for 3D printing of wood. J. Wood Wood Prod. 2018, 76, 797–799.

- Stoof, D.; Pickering, K. Sustainable composite fused deposition modelling filament using recycled pre-consumer polypropylene. Part B 2018, 135, 110–118.

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork–PLA composite filaments for fused deposition modelling. Sci. Technol. 2018, 168, 230–237.

- Kariz, M.; Sernek, M.; Kuzman, M.K. Effect of humidity on 3D-printed specimens from wood-PLA filaments. Wood Res. 2018, 63, 917–922.

- Correa, D.; Papadopoulou, A.; Guberan, C.; Jhaveri,N.; Reichert, S.; Menges, A.; Tibbits, S. 3D-Printed wood: Programming hygroscopic material transformations. 3D Print. Addit. Manuf. 2015, 2, 106–118.

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Van Vuure, A.W. Production and characterization of bamboo and flax fiber reinforced polylactic acid filaments for fused deposition modeling (FDM). Compos. 2019, 40, 1951–1963.

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly-(lactic acid) for 3D printing. ACS Sustainable Chem. Eng. 2017, 5, 9338−9346.

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Part B 2017, 110, 442–458.

- Rauwendaal, C.J. Analysis and experimental evaluation of twin screw extruders. Eng. Sci. 1981, 21, 1092–1100.

- Ayrilmis, N. Effect of layer thickness on surface properties of 3D printed materials produced from wood flour/PLA filament. Test. 2018, 71, 163–166.

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Phys. Prototyp. 2017, 12, 47–59.

- Dunne, R.; Desai, D.; Sadiku, R. Material characterization of blended sisal-kenaf composites with an ABS matrix. Acoust. 2017, 125, 184–193.

- Girdis, J.; Gaudion, L.; Proust, G.; Loschke, S.; Dong, A. Rethinking timber: Investigation into the use of waste macadamia nut shells for additive manufacturing. JOM 2017, 69, 575–579.

- Bi, H.; Ren, Z.; Guo, R.; Xu, M.; Song, Y. Fabrication of flexible wood flour/thermoplastic polyurethane elastomer composites using fused deposition molding. Crops Prod. 2018, 122, 76–84.

- Bates, S.R.G.; Farrow, I.R.; Trask, R.S. 3D printed polyurethane honeycombs for repeated tailored energy absorption. Des. 2016, 112, 172–183.

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the use of recycled or biodegradable filaments for sustainability of 3D printing. Des. Manuf. 2017, 68, 776–785.

- Mazzanti, V.; Mollica, F. Rheological behavior of wood flour filled poly-(lactic acid): Temperature and concentration dependence. Compos. 2019, 40, E169–E176.

- Grossman, R.F.; Nwabunma, D. Poly(lactic acid): Synthesis, Structures, properties, Processing, and Applications, 1st ed.; John Wiley & Sons: Hoboken, New Jersey, USA,

- Hsu, S.H.; Yen, H.J.; Tseng, C.S.; Cheng, C.S.; Tsai, C.L. Evaluation of the growth of chondrocytes and osteoblasts seeded into precision scaffolds fabricated by fused deposition manufacturing. Biomed. Mat. Res. Part B 2007, 80, 519–527.

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mater. 2008, 40, 446–452.

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Sci. Technol. 2003, 63, 1317–1324.

- Huber, T.; Müssig, J. Fibre matrix adhesion of natural fibres cotton, flax and hemp in polymeric matrices analyzed with the single fibre fragmentation test. Interfaces 2008, 15, 335–349.

- Zhang, Q.; Cai, H.; Zhang, A.; Lin, X.; Yi, W.; Xhang, J. Effects of lubricant and toughening agent on the fluidity and toughness of poplar powder-reinforced polylactic acid 3D printing materials. Polymers 2018, 10, 932.

- Mangat, A.S.; Singh, S.; Gupta, M.; Sharma, R. Experimental investigations on natural fiber embedded additive manufacturing-based biodegradable structures for biomedical applications. Rapid Prototyp. J. 2018, 24, 1221–1234.

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three‐dimensional printing of poly(lactic acid) bio‐based composites with sugarcane bagasse fiber: Effect of printing orientation on tensile performance. Adv. Technol. 2019, 30, 910–922.

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. Compos. Sci. 2017, 1, 8.

- Martikka, O.; Kärki, T.; Wu, Q. Mechanical properties of 3D-printed wood-plastic composites. Key Eng. Mater. 2018, 777, 499–

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modelling ABS. Rapid Prototyp. 2002, 8, 248–257.

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Des. 2017, 124, 143–157.

- Hinchcliffe, S.A.; Hess, K.M.; Srubar III, W.V. Experimental and theoretical investigation of prestressed natural fiber-reinforced polylactic acid (PLA) composite materials. Part B 2016, 95, 346–354.

- Dong, Y.; Milentis, J.; Pramanik, A. Additive manufacturing of mechanical testing samples based on virgin poly(lactic acid) (PLA) and PLA/wood fibre composites. Manuf. 2018, 6, 71–82.

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kuzman, M.K. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. Adv. Manuf. Technol. (in press).

- Tao, Y.; Pan, L.; Liu, D.; Li, P. A case study: Mechanical modeling optimization of cellular structure fabricated using wood flour-filled polylactic acid composites with fused deposition modelling. Struct. 2019, 216, 360–365.

- Fortini, A.; Mazzanti, V. Combined effect of water uptake and temperature on wood polymer composites. Appl. Polym. Sci. 2018, 46674.

- Migneault, S., Koubaa, A., Erchiqui, F., Chaala, A., Englund, K., Wolcott, M.P. Effects of processing methods and fiber size on the structure and properties of wood-plastic composites. Part A 2009, 40, 80–85.

- Hung, K.C., Yeh, H., Yang, P.C., Wu, T.L., Xu, J.W., Wu, J.H. Characterization of Wood-Plastic composites made with different lignocellulosic materials that vary in their morphology, chemical composition and thermal stability. Polymers 2017, 9, 726–736.

- Mazzanti, V., Mollica, F. Pressure dependent wall slip of wood flour filled polymer melts. Non-Newtonian Fluid Mech. 2017, 247, 178–187.

- Ahmed, I., Shariff, M.S., Zeeshan, M.S.I., Prasanth, S. Troubleshooting for FDM technology J. Res. Appl. Sci. Engng. Tech. 2018, 6, 986–990.