Modern society relies heavily on plastic packaging. It protects food, extends shelf life, reduces transportation losses, and supports global supply chains. Yet the very properties that make plastics useful—durability, resistance to moisture, and low cost—also make them persistent pollutants in ecosystems. Microplastics are now found in soil, oceans, and even human bodies. As a result, scientists and engineers are actively searching for alternatives that are not only functional but also biodegradable, renewable, and environmentally compatible.

A recent study published in MDPI Processes entitled "Heat-Sealing Process for Chañar Brea Gum Films" explores exactly this connection between material properties, processing methods, and sustainability by investigating chañar brea gum as a potential biodegradable and heat-sealable packaging material. The research does not simply ask whether this natural gum can form films, but how its molecular structure, thermal behavior, mechanical performance, and barrier properties interact—and how these relationships ultimately shape its practical usability in packaging applications.

1. What is Chañar Brea Gum?

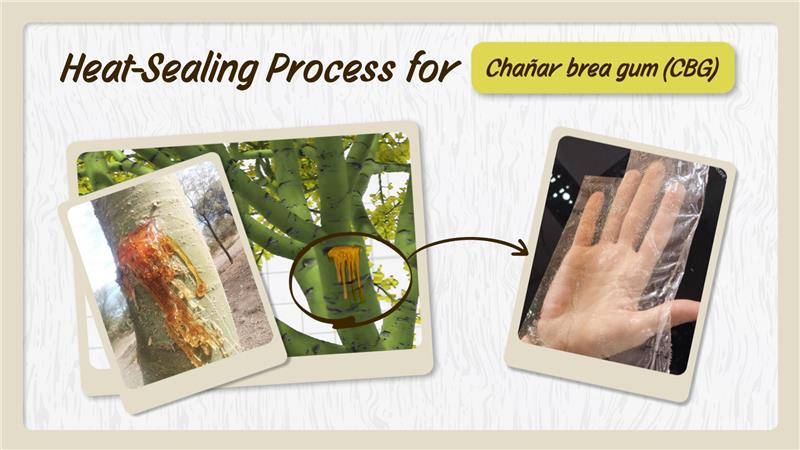

Chañar brea gum is a natural exudate obtained from the Chañar brea tree (Parkinsonia praecox, also known as Cercidium praecox or “palo verde”). This tree thrives in the Chaco forest of Argentina, a semi-arid region where vegetation has adapted to withstand high temperatures and limited water availability.

The gum is collected either from intentional superficial cuts or from naturally occurring wounds on the trunk and branches. Production is typically highest during spring and summer, when sap flow is most active. After harvesting, the raw gum undergoes purification: it is dissolved in water, filtered to remove impurities, and then dried and milled into a fine powder suitable for material processing.

This purification step is essential, as natural gums often contain bark particles, dust, or microbial residues that could otherwise compromise film quality and consistency.

2. From Gum to Packaging Film

To transform chañar brea gum into a functional packaging material, the purified powder was dissolved in distilled water to form a viscous solution. A plasticizer—commonly glycerol—was then added to improve flexibility and reduce brittleness; without this step, the resulting film tends to be rigid and prone to cracking.

In the study, this solution was cast into a thin layer and dried under controlled conditions to form a film. In their experimental design, the researchers treated variables such as gum concentration, plasticizer content, and relative humidity during drying as critical parameters, since these factors influence film thickness, mechanical performance, and barrier properties.

Close control of these processing conditions is therefore important for tailoring the properties of the final material.

3. Heat Sealing: Making Functional Packages

Beyond simply forming films, the researchers examined whether chañar brea gum could be applied in practical packaging applications. By applying heat and pressure, they successfully bonded layers of 10% chañar brea gum film to form a rectangular container (18 × 12 cm).

Because chañar brea gum behaves as a hydrocolloid, precise control of temperature and sealing time was required during heat sealing. Excessive heat could degrade the material, whereas insufficient heat would result in incomplete or weak bonding.

To investigate sealing behavior in more detail, additional experiments were conducted on smaller strips (2 × 10 cm) oriented horizontally and vertically, and a joint determination method was applied to analyze bonding performance.

4. A Comprehensive Materials Study

Rather than focusing on a single property, the study took a holistic approach to characterizing chañar brea gum films. The researchers employed a suite of analytical techniques, including:

-

Proximate analysis to determine composition.

-

Fourier Transform Infrared Spectroscopy (FTIR) to examine molecular structure.

-

Differential Scanning Calorimetry (DSC) to analyze thermal transitions.

-

Thermogravimetric Analysis (TGA–DTG) to assess thermal stability.

-

X-ray Diffraction (XRD) to investigate molecular arrangement.

In addition, mechanical testing was used to evaluate strength and flexibility, while measurements of antioxidant capacity, water vapor permeability, water sorption, and biodegradability were conducted to assess functional performance. By integrating these results, the study sought to clarify how molecular structure, composition, thermal behavior, and mechanical properties interact—and how these factors ultimately govern heat sealability.

5. What the Results Revealed

The findings demonstrate several notable characteristics of chañar brea gum films:

-

Thermal stability: Thermogravimetric analysis showed that the material remained stable up to approximately 200 °C, with an onset of melting behavior near 152.48 °C, suggesting compatibility with typical food packaging processing conditions.

-

Structural consistency: X-ray diffraction indicated similar interstrand spacing in the polymer network for untreated CBG (4.88 nm) and heat-treated CBG-H (4.66 nm), reflecting overall structural consistency.

-

Microstructure: Scanning electron microscopy of heat-sealed joints revealed rounded surface features, and cross-sectional imaging showed a homogeneous internal structure with minimal gaps—both indicative of strong bonding.

-

Barrier performance: Water vapor permeability decreased markedly from roughly 1.7 g·mm/m²·day·kPa for untreated films to 0.37 g·mm/m²·day·kPa after heat treatment, demonstrating improved moisture barrier performance.

-

Mechanical properties: Mechanical testing showed that Young’s modulus decreased from about 132 MPa to 96.5 MPa after heat treatment, indicating a modest increase in flexibility—an advantageous change for packaging applications.

-

Heat sealability: The ability to form reliable seals was quantified at approximately 656 N/m, a competitive value for biodegradable films.

-

Biodegradability: Most notably, biodegradability testing indicated that the material degraded fully in about four days under the study conditions, underscoring its environmental compatibility.

Overall, heat treatment tended to enhance barrier properties while slightly reducing stiffness, highlighting a favorable trade-off for practical packaging use.

6. Why This Matters for Sustainable Packaging

Conventional plastics can persist in the environment for decades or even centuries. In contrast, the biodegradable nature of chañar brea gum films means they break down rapidly under natural conditions, significantly reducing long-term ecological impact.

Because the material is plant-derived, biodegradable, and potentially edible, it could be particularly valuable for food packaging applications, reducing reliance on synthetic coatings or chemical additives. Its ability to be heat-sealed also suggests compatibility with existing industrial packaging processes, which could make large-scale adoption more feasible.

7. Challenges, Future Directions, and Overall Significance

Despite its promise, several challenges remain before chañar brea gum films can be widely commercialized. Scaling up sustainable gum production, ensuring consistent film quality across batches, evaluating long-term storage stability, and assessing cost competitiveness compared with conventional plastics are all important issues that require further investigation. Nevertheless, the current study provides a robust scientific foundation for future development and optimization by clarifying how processing conditions, material structure, and performance are interrelated in this novel biopolymer-based film.

Overall, this research demonstrates that chañar brea gum is more than a natural tree exudate: it is a functional material with real potential for sustainable packaging. By systematically examining its thermal, mechanical, barrier, and heat-sealing properties, the study offers valuable insights for the design of next-generation biodegradable packaging systems. As industries continue to seek alternatives to conventional plastics, materials such as chañar brea gum represent an important step toward a more sustainable and circular packaging future.

For more information about topic, you can view the online video entitled "Heat-Sealing Process for Chañar Brea Gum Films".