Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The recovery and recycling of textile waste is becoming urgent since textiles are generating more and more waste. In one year, about 92 million tons of textile waste are produced and the fashion industry accounts for 58 million tons of plastic waste per year. Several different synthetic fibres are used in textiles, thanks to their excellent processability and mechanical properties, but on the other hand, the difficulties linked to their end of life and the release of microplastics from them during washing is currently a cause of great concern.

- textile

- fibres

- polyamide

- enzymes

- sensors

1. The Current Situation Regarding Textile Products

Currently, textile production is constantly expanding by catering to fashion, style, and marketing needs as well as to increasingly competitive technical challenges. The prospect of innovation and development contrasts, however, with the pollution of the environment caused by this industrial activity. Between 1975 and 2018, the production of chemical and textile fibres nearly quadrupled, from 23.94 million tons to 105.6 million tons: a more than fourfold increase in about 40 years [1]. Concerns about the environmental impact of fibre production and subsequent disposal operations have grown in prominence as demand for fabrics has increased. Several recent studies show that the textile industry endangers freshwater and atmospheric micro-systems due to the use of industrially harmful and toxic chemicals during the manufacturing process, as well as the release of these chemicals.

Looking at waste, fashion industry accounts for 58 million tons of plastic waste per year, (ranked third after packaging and construction), 20% of global wastewater, and 10% of global/carbon emissions. It contributes to biodiversity loss, since 33% of the insecticide applied worldwide is used for tissue production. Unfortunately, only 1% of global clothes are recycled while 87% are incinerated or landfilled, due principally to the current exiguous development of recycling industrial chains [2][3][4]. It is necessary to transform the current linear economy, based on the taking, making and producing of waste, in a circular economy based on redesigning, reducing, reusing and recycling for zero waste [5][6][7]. Therefore, it is becoming urgent to organize a new productive model for making textile and fashion products based on a new eco-design production and at the same time to persuade consumers to make small and gradual behavioral changes [3][4][6].

The status of textile recycling and reuse in the world was surveyed by Lu and coworkers [8] in 2014. Their data showed that 10% of the fibre waste in China, 12–13% in Japan and 15% of the fibre waste in the US was reused or recycled. In Europe, Germany is one of the pioneer countries where as much as 66% of the projected textile fibre turnover is collected and recycled or reused according to a report from BVSE, the German federal organization for secondary raw materials and disposals [9]. More recently, a material flow analysis (MFA) was applied to quantify textile streams and recycling prospects in Europe [10]. The MFA estimated textile waste, energy and CO2eq emission streams in Europe and determined that Europe has generated an amount of 2526–2791 kt of textile waste in 2018. In a high separate collection rates (HSCR) scenario it is possible to collect 1894–2093 kt and to reduce landfilling to 1%. Textile recycling consumes 4079815–4509260 GJ of energy in the baseline scenario. In the HSCR, CO2eq emissions could be reduced from 2,419,261 t to 2,025,876 t (−16%). This research evidenced the essential role of textile recycling as a way to enlarge fibre and commodity lifespans and convert fast fashion into slow fashion. Similar considerations were expressed by Schumacher et al. [11], who additionally evidenced the need for harmonization of terminology, classifications, industry tools and standards to unify approaches and increase the interoperability of tools and resources. Moreover, a fundamental role can be played by broad, multidisciplinary and multi-stakeholder collaboration.

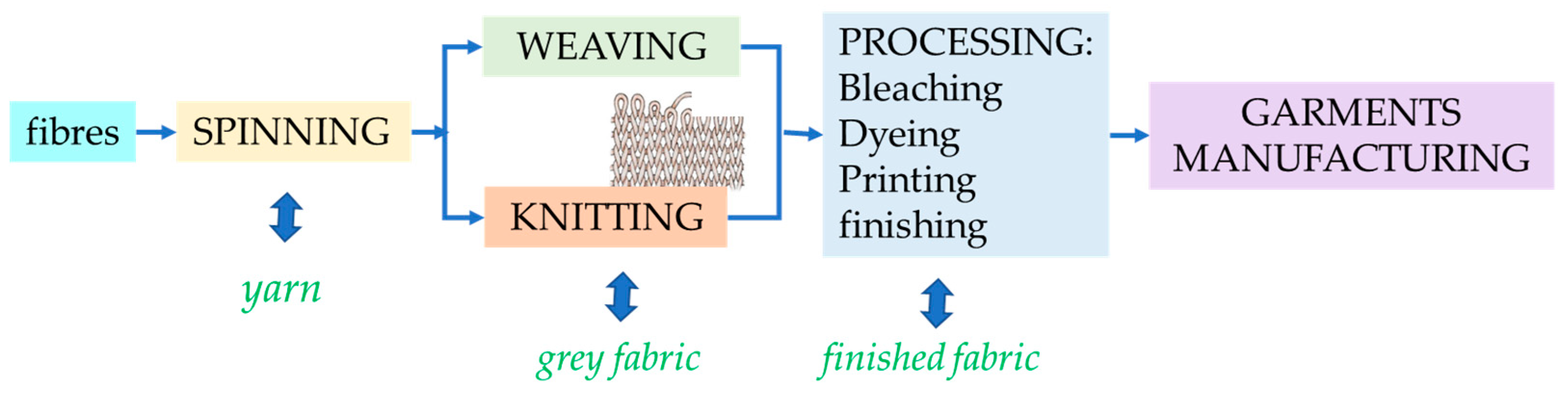

The manufacturing process of textiles consists of four primary stages: yarn production, fabric production, textile production and finishing treatment (Figure 1).

Figure 1. General scheme of textile production.

This type of industry deals with transforming raw materials (natural, artificial or synthetic fibres) into yarns and then fabrics, which are collected in reels and then commercialized. The raw material that reaches the textile industry is collected, instead, in large bales which are opened and then processed in the factory. In the textile factory, two fundamental operations are carried out: spinning and weaving. In the first phase, the fibres, first collected in bales, are washed and processed until yarns are obtained, possibly collected on a large reel. In the second phase, the textile fibre thread is then worked in other machines where it is woven with other threads to obtain the fabric [12]. In the case of natural fibres, which are short (with the exception of silk fibres that can reach 1 km of length) the fibre production is skipped. In the case of artificial and synthetic fibres, the extrusion of filaments can start from a polymer solution or polymer melt. At the end of this process, generally multifilament yarns are produced that can be used as such or successively texturized. Cutting these yarns allows staple fibres to be produced, so that the long-extruded filaments are transformed into short fibres.

In general, spinning is the set of operations that serve to transform textile fibres into a yarn, that is, a very long and resistant thread that is collected on a reel. The other important phase in the textile industry is weaving which allows the thread to become an actual fabric, to a cloth wound on reels [13]. The selection of yarns and the design of the fabric (woven or knitted) is fundamental to obtain the desired level of lightness, comfort and softness for the final textile product.

2. Sorting of Textiles: Techniques and Facilities

2.1. Sorting Methodologies

High volumes of textile materials are often incinerated and landfilled due to the lack of specific collection of post-consumer textile waste, difficulties in separating the discarded textiles and costs associated with their sorting [14]. Nonetheless, reusing and recycling of end-of-life textiles are still considered to be better choices when compared to incineration or landfilling [15]. Regardless of the recycling process to be followed (i.e., chemical, mechanical or physical), textiles must be sorted before according to their colour, fabric type or raw material, quality and style [16].

Textile waste sorting is often carried out manually. Even though this is feasible, the high costs, low speed, and lack of automatization associated with it makes its implementation not suitable for the processing of large volumes of materials [14]. Moreover, this method is prone to misclassifications since it depends on the material content listed on the product labels (might be faulty) and the expertise of the workers, who in turn experience high intensity and poor working conditions [15][17].

Other sorting methodologies can also be carried out, and these are divided into physical and chemical methods. Chemical methods (i.e., dissolution) are not usually considered for sorting waste textiles because they are destructive, hazardous and pollutant. On the other hand, physical methods include density and melting point measurements, among others [17]. In general terms, all the above-mentioned methods are expensive, time-consuming, and demand high training from the operator [18]. For this reason, a fast, non-destructive, and reliable method that is able to analyse large volumes of textile materials and can be implemented in-line is urgently needed for the waste textile recycling industry [15].

Some alternative physical methods have been explored during the last years to identify textile materials, such as the usage of radio frequency (RFID) tags that store information about the textile and could be read remotely. However, RFID tags being able to withstand several laundry cycles have not been developed yet. Furthermore, other methodologies based on the use of optical sensors have recently arisen. For example, colour sorting can be accomplished with the help of computer vision techniques based on an RGB camera [19][20][21]. RGB cameras are usually combined with infrared (IR) sensors to give further information about the textiles.

In this regard, Fourier-transform mid-infrared spectroscopy (FT-MIR) can be used to determine the material content of fabrics through the analysis of their spectral features that arise from the different molecular vibrations of the different textile components. For example, Riba et al. [14] classified textile samples based on synthetic (i.e., polyamide and polyester) and natural fibres (i.e., cotton, wool, and silk) by means of combining FT-MIR spectroscopy coupled to powerful mathematical recognition methods (such as principal component analysis, PCA). However, this technique cannot be implemented in-line and so is considered a complementary technique/extension to manual sorting [14][16].

2.2. The Advent of Near-Infrared Spectroscopy in Textile Sorting

Near-infrared spectroscopy (NIR) has gained a lot of popularity during the last decades because of its in-line and in-field capabilities (i.e., it performs real-time and non-destructive measurements). Therefore, a wide range of applications have been reported in the literature, such as in food science, agriculture, medicine, and the petrochemical industry, among others [22]. NIR spectroscopy (as FT-MIR spectroscopy) studies the energy transitions (i.e., absorptions) yielded by the interaction of the light (in this case the NIR region of 800 nm to 2500 nm) between vibrational energy states that are specific to every molecule, so a distinctive pattern can be obtained that can be thought of as a unique fingerprint (NIR spectroscopy is considered a fingerprinting technology). The NIR region displays broad bands with overlapping wavelengths that mainly provide information about NH, OH, and CH bonds, making this technique an optimal tool for the research of organic compounds [23][24].

Extensive literature can be found regarding the applications of NIR spectroscopy in textile sorting. In most of them, a portable NIR spectrometer working in diffuse reflectance mode is used and combined with powerful pattern recognition algorithms to sort and classify different textile materials (such as polyester, cotton, wool and polyamide, among others), reporting outstanding classification rates [14][15][16][17][18][22][25]. Such spectrometers offer the possibility of in-line implementation, but they rely on measurements performed on a single point of a sample, which could lead to misleading results when spectra are acquired from complex heterogeneous samples such as textile waste [26].

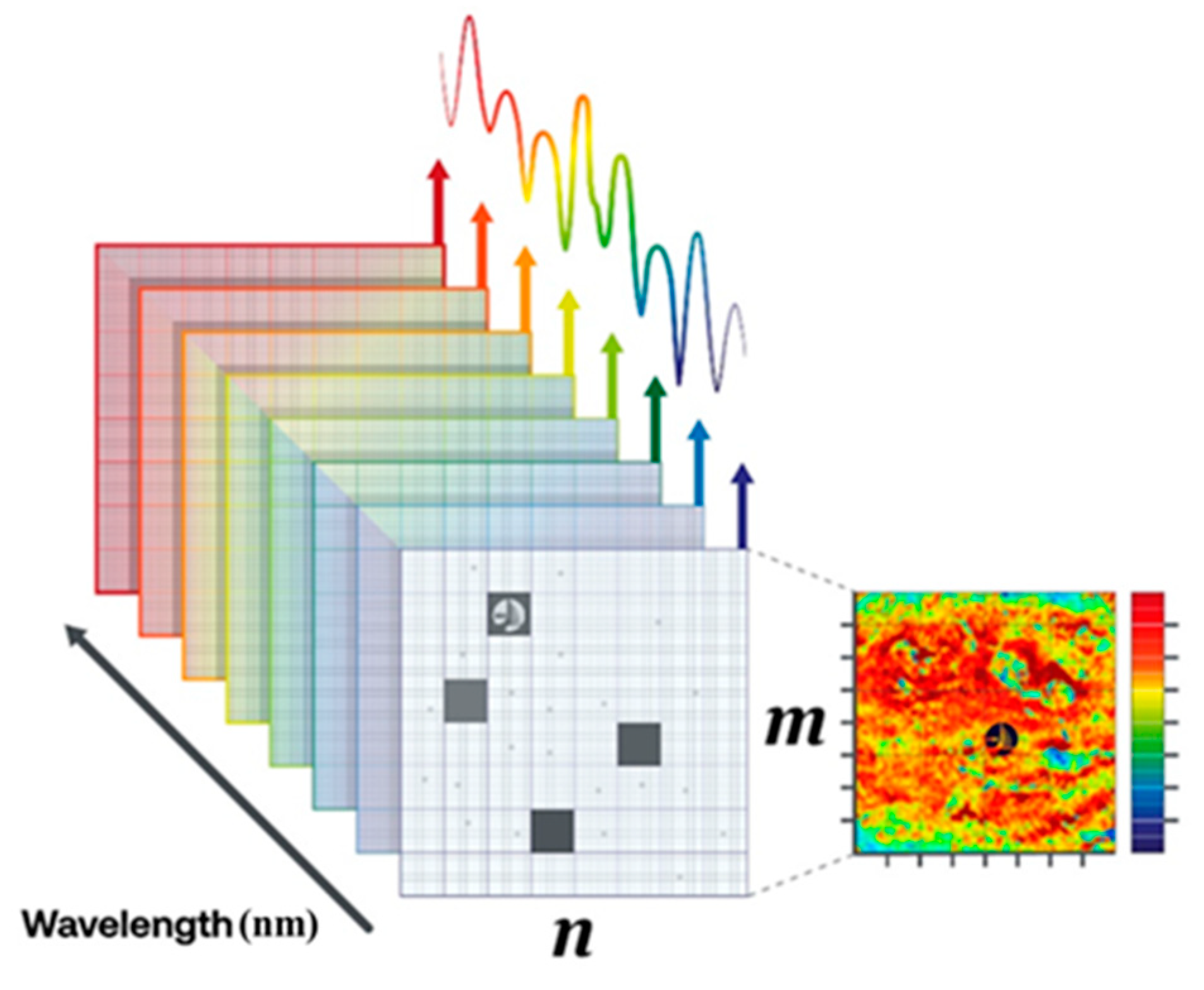

Hyperspectral imaging (HSI), which has been used for land observation remote sensing in satellites since the late 1960s, can provide both spectral and spatial information of the sample being tested; thus, heterogeneous samples are good candidates for this technology [27]. A hyperspectral image (also called hypercube) is a three-dimensional array that gathers two-dimensional spatial information (m × n pixels) and one-dimensional spectral information (spectra of n wavelengths; Figure 2). In other words, for each pixel a full spectrum is collected (spectral/chemical information) while for each m × n-plane an intensity map of a certain wavelength is obtained (spatial information) [28].

Figure 2. Graphic representation of a hyperspectral cube acquired with the industrial hyperspectral VISUM® HSI™. Each hyperplane (slide) of the cube corresponds to a spectral channel or wavelength The 2-D image on the right displays the average intensities for all the wavelengths (heat map; see the scale).

Successful results have also been reported on the use of HSI in the NIR range for textile applications. Jiang and Li [29] obtained classification results over 90% when using a SWIR HSI system for the identification of foreign matter in lint samples. Results on the classification of synthetic fibres (such as polyamide, polypropylene, etc.) using a SWIR HSI system and multivariate classification algorithms were reported by Blanch-Perez-del-Notario et al. [30] when using a low-cost mosaic based Visible-NIR (VNIR) HSI system. The VNIR range brings some advantages, since it offers higher spatial resolution, cheaper and more compact cameras than the traditional SWIR Range. Moreover, the VNIR range enables sorting of blue denim, a relevant component of textile waste, that could otherwise be difficult to distinguish by SWIR HSI systems [30].

The workflow process for an industrial throughput for conventional NIRS and HSI technologies at an industrial level is similar. Target waste is placed onto a conveyor belt in which the monitoring systems are placed (i.e., cameras, spectrometers, lights; usually above the conveyor) so spectral acquisitions can be acquired from the waste stream. Spectral measurements are then processed with chemometrics/machine learning models implemented into the monitoring system, providing the identification of the textiles that will be physically separated using sorting equipment.

Besides all the advantages of NIRS for material textile waste sorting applications, one of the main drawbacks is that NIR measurements usually only provide chemical information from the surface of materials due to the low penetration of IR radiation. Because of that, the inner part of materials cannot be properly assessed, yielding misclassifications in thicker materials [15][31]. All in all, optical-based sorting advancements coupled to chemometrics and artificial intelligence is increasingly improving the performance of recycling textiles, which will keep more materials in recycling loops and help pave the way towards a circular economy [32].

2.3. Industrial Applications of Sorting

A novel approach to the sorting and recovery of textile cuttings and scraps may be seen in some successful initiatives at the European level, such as:

-

sorting and preparing used textiles for recycling in the Amsterdam Area, “so that we become a hub for circular textiles and circular denim”, as alderman Marieke van Doorninck said [33];

-

sorting the post-consumer textiles by material into various fibre classes using optical identification technology developed by Lounais-Suomen Jätehuolto Oy (LSJH), a company owned by 17 municipalities in South-West Finland [34].

Within the framework of the EU directives, the European textile and clothing employers’ association, Euratex, is already working on five textile recycling hubs in five European countries, to up-cycle textile waste and scale up industrially the collecting, sorting, processing and recycling of pre-consumer and postconsumer materials. One of these hubs is to be installed in Prato (Italy), (not far from SPIN-PET company headquarters) with an annual collection capacity of 20,000 tons of wasted clothes and 14,000 tons of post-industrial textile scraps. A fibre-sorting unit for nearly 8000 tons/year capacity is included [35].

Finnish waste management company Lounais-Suomen Jätehuolto Oy (LSJH) will supply raw material to Infinited Fibre Company’s flagship plant from the full-scale textile waste refinement plant that is being prepared in the Turku region of Finland. LSJH’s plant will process all the end-of-life textiles of Finnish households in cooperation with other municipality-owned waste management companies. LSJH sorts the post-consumer textiles by material into various fibre classes using optical identification technology developed by LSJH and its partners. This ensures the quality of the raw material and the resulting fibre products [34].

This entry is adapted from the peer-reviewed paper 10.3390/macromol3020009

References

- Patti, A.; Acierno, D. Towards the Sustainability of the Plastic Industry through Biopolymers: Properties and Potential Applications to the Textiles World. Polymers 2022, 14, 692.

- Granskog, A.; Lee, L. The Fashion Industry Can Reduce Emissions across The Entire Valuechain, 2020 MacKinsey& Company Report, New York, USA. Available online: https://www.mckinsey.com/capabilities/sustainability/our-insights/sustainability-blog/the-fashion-industry-can-reduce-emissions-across-the-entire-value-chain (accessed on 10 February 2023).

- Sajn, N. Environmental Impact of the Textile and Clothing Industry, 2019. European Parliamentary Research Service, Bruxelles, Belgium. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2019/633143/EPRS_BRI(2019)633143_EN.pdf (accessed on 10 February 2023).

- Amed, I.; Berg, A.; Chandani, A.; Hedrich, A.; Jensen, J.E.; Straub, M. The State of Fashion 2022.BOF Report 2022, MacKinsey & Company. Available online: https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/state%20of%20fashion/2022/the-state-of-fashion-2022.pdf (accessed on 10 February 2023).

- EllenMacArthur Foundation. Available online: www.ellenmacarthurfoundation.org (accessed on 10 February 2023).

- Morganti, P.; Coltelli, M.B. An Introduction to The Circular Economy, 1st ed.; Nova Science Publishers: New York, NY, USA, 2021; pp. 9–51.

- Ellen MacArthur Foundation, Circular Business Models: Rethinking Business Models for a Thriving Fashion Industry. Available online: https://ellenmacarthurfoundation.org/fashion-business-models/overview (accessed on 10 February 2023).

- Lu, J.J.; Hamouda, H. Current Status of Fibre Waste Recycling and its Future. Adv. Mater. Res. 2014, 878, 122–131.

- Peterson, A. Towards Recycling of Textile Fibres. Master Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2015; pp. 8–18. Available online: https://odr.chalmers.se/bitstream/20.500.12380/218483/1/218483.pdf (accessed on 10 February 2023).

- Amicarelli, V.; Bux, C. Quantifying textile streams and recycling prospects in Europe by material flow analysis. Environ. Impact Assess. Rev. 2022, 97, 106878.

- Schumacher, K.A.; Forster, A.L. Textiles in a circular economy: An assessment of the current landscape, challenges, and opportunities in the United States. Front. Sustain. 2022, 3, 1038323.

- Uddin, F. Introductory Chapter: Textile Manufacturing Processes, IntechOpen, 2019. Available online: https://www.intechopen.com/chapters/68157 (accessed on 10 February 2023).

- Nawab, Y. (Ed.) Textile Engineering: An Introduction; De Gruyter: Berlin, Germany, 2016; pp. 172–184.

- Riba, J.R.; Cantero, R.; Canals, T.; Puig, R. Circular economy of post-consumer textile waste: Classification through infrared spectroscopy. J. Clean. Prod. 2020, 272, 123011.

- Cura, K.; Rintala, N.; Kamppuri, T.; Saarimäki, E.; Heikkilä, P. Textile recognition and sorting for recycling at an automated line using near infrared spectroscopy. Recycling 2021, 6, 11.

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Strategies of Recovery and Organic Recycling Used in Textile Waste Management. Int. J. Environ. Res. Public Health 2022, 19, 5859.

- Zhou, C.; Han, G.; Via, B.K.; Song, Y.; Gao, S.; Jiang, W. Rapid identification of fibres from different waste fabrics using the near-infrared spectroscopy technique. Text. Res. J. 2019, 89, 3610–3616.

- Liu, Z.; Li, W.; Wei, Z. Qualitative classification of waste textiles based on near infrared spectroscopy and the convolutional network. Text. Res. J. 2020, 90, 1057–1066.

- Daukantienė, V. Analysis of the sustainability aspects of fashion: A literature review. Text. Res. J. 2023, 93, 991–1002.

- Nørup, N.; Pihl, K.; Damgaard, A.; Scheutz, C. Development and testing of a sorting and quality assessment method for textile waste. Waste Manag. 2018, 79, 8–21.

- Kuo, C.J.; Kao, C.-Y.K. Self-organizing Map Network for Automatically Recognizing Color Texture Fabric Nature. Fibres Polym. 2007, 8, 174–180.

- Hu, J.; Yang, H.; Zhao, G.; Zhou, R. Research on Online Rapid Sorting Method of Waste Textiles Based on Near-Infrared Spectroscopy and Generative Adversity Network. Comput. Intell. Neurosci. 2022, 2022, 1–8.

- Penner, M.H. Basic Principles of Spectroscopy. In Food Analysis, 5th ed.; Nilesen, S.S., Ed.; Springer: New York, NY, USA, 2017; pp. 79–88.

- Dufour, É. Principles of Infrared Spectroscopy. In Infrared Spectroscopy for Food Quality Analysis and Control; Sun, D.W., Ed.; Academicc Press: Cambridge, MA, USA, 2009; pp. 3–27.

- Li, W.; Wei, Z.; Liu, Z.; Du, Y.; Zheng, J.; Wang, H.; Zhang, S. Qualitative identification of waste textiles based on near-infrared spectroscopy and the back propagation artificial neural network. Text. Res. J. 2021, 91, 2459–2467.

- Mäkelä, M.; Geladi, P. Hyperspectral near infrared imaging quantifies the heterogeneity of carbon materials. Sci. Rep. 2018, 8, 10442.

- Zhang, M.; Li, C.; Yang, F. Classification of foreign matter embedded inside cotton lint using short wave infrared (SWIR) hyperspectral transmittance imaging. Comput. Electron. Agric. 2017, 139, 75–90.

- Ma, J.; Sun, D.W.; Pu, H.; Cheng, J.H.; Wei, Q. Advanced Techniques for Hyperspectral Imaging in the Food Industry: Principles and Recent Applications. Annu. Rev. Food Sci. Technol. 2019, 10, 197–220.

- Jiang, Y.; Li, C. MRMR-based feature selection for classification of cotton foreign matter using hyperspectral imaging. Comput. Electron. Agric. 2015, 119, 191–200.

- Blanch-Perez-del-Notario, C.; Saeys, W.; Lambrechts, A. Hyperspectral imaging for textile sorting in the visible-near infrared range. J. Spectr. Imaging 2019, 8, 1–11.

- Rosales, A.; Mc Nerney, O. Sensing Technology. In Resource Efficiency of Processing Plants; Amancio-Filho, S.T., Blaga, L.-A., Eds.; Wiley: Hoboken, NJ, USA, 2018; pp. 129–157.

- Kroell, N.; Chen, X.; Greiff, K.; Feil, A. Optical sensors and machine learning algorithms in sensor-based material flow characterization for mechanical recycling processes: A systematic literature review. Waste Manag. 2022, 149, 259–290.

- Sommer, S. What Is the Amsterdam ‘Denim Deal’ All about? 2020, The Spinoff Modern Matters. Available online: https://www.the-spin-off.com/news/stories/Sustainability-What-is-the-Amsterdam-Denim-Deal-all-about-15643 (accessed on 13 February 2023).

- Lounais-Suomen Jätehuolto’. Post-Consumer Textile Recycling. Available online: https://poistotekstiili.lsjh.fi/en/home/ (accessed on 10 February 2023).

- Comune di Prato, Hub del Riciclo Tessile, La Presentazione in Consiglio Comunale. 2022. Available online: https://comunicati.comune.prato.it/generali/?action=dettaglio&comunicato=14202200000360 (accessed on 10 February 2023).

This entry is offline, you can click here to edit this entry!