1. Introduction

The built environment consists of human-made buildings and infrastructures such as commercial and residential buildings, bridges, roads, tunnels, storage tanks, and pipelines. These structures must be routinely inspected and monitored both during and after construction. The structure is monitored and assessed through regular inspections performed by different stakeholders including owners, project managers, architects, engineers, contractors, sub-contractors, end users, and facility managers [

1]. Irrespective of who is performing the inspection, manual inspection is a time-consuming process and adds to the project cost [

2]. Manual inspection is also characterized by a high degree of variability in the quality of assessment and subjectivity [

3,

4].

Some inspection tasks are difficult for humans to perform due to inaccessibility, e.g., confined spaces such as inside air-conditioning ducts [

5,

6], water-filled pipelines and tunnels [

7], offshore structures [

8], and small spaces in walls [

9]. Some situations might be hazardous for humans, such as inspection at heights [

10], structures subjected to natural disasters [

11], or a bridge deck [

12]. Different inspection and monitoring activities differ in their requirements and face different challenges. Therefore, not all types of inspection can be performed by the same robot.

Robots have been used in building and infrastructure projects in many ways—e.g., for concrete production, automated brickwork, steel welding, concrete distribution, steel reinforcement positioning, concrete finishing, tile placement, fireproof coating, painting, earthmoving, material handling, and road maintenance [

13]. Robots with many different locomotion types and sensors have been used for the inspection of the built environment [

3]. Some examples are unmanned aerial vehicles (UAV), unmanned ground vehicles (UGV), marine vehicles, wall-climbing robots, and cable-crawling robots, among others. Robotic inspection provides a safer alternative to manual inspection [

14,

15]. Automated robotic inspection improves the frequency of inspections and reduces subjectivity in detecting errors [

16,

17,

18].

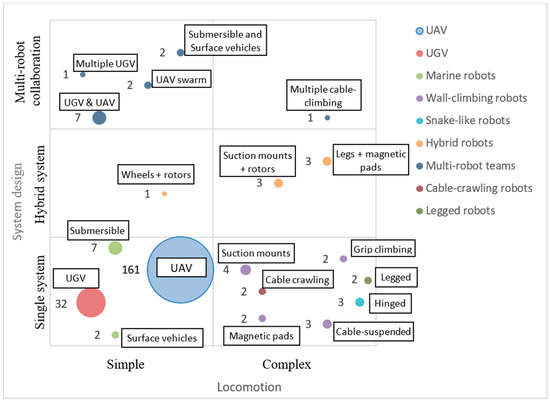

Figure 1 shows the types of robots identified. The numbers in the figure denote the number of papers reporting the use of that type of robot. Most researchers used UAVs, and because of their ability to reach places that humans cannot, they are found to be useful tools for many inspection applications [

30,

31]. They provide valuable support to quickly and safely access exterior facades of high-rise buildings and hard-to-reach places of bridge decks [

32]. The second-most-common type of robot found to be used is the UGV. Unlike UAVs, which offer small payload capacities, ground-based robots such as wheeled robots offer much higher payload capacities and are useful tools in the longer inspection of buildings [

3].

Figure 1. Types of robots used in literature.

Some researchers used multiple types of robots in collaboration, e.g., a UAV with a ground robot [

33,

34]. Other researchers developed custom hybrid robots with more than one locomotion system [

20,

35,

36,

37]. These hybrid robots provide better reach and are more versatile than simple robots. For example—a wheeled robot with a rotor attached developed by Lee et al. [

20] can jump around obstacles and inspect both the interior and exterior of a building.

2. Unmanned Aerial Vehicle (UAV)

UAVs are by far the most commonly used type of robot for inspection and monitoring of the built environment, as found in the literature. According to Association for Unmanned Vehicle Systems International (AUVSI), the market for UAVs is estimated to be $11.3 billion in the U.S. alone, which will grow to $140 billion in the next 10 years [

38]. Examples of commercial UAVs used in research are DJI Phantom 3 [

39], DJI Phantom 4 [

40], Parrot AR.Drone 2.0 [

41], DJI M600 Pro [

42], DJI Matrice 100 [

43], FlyTop FlyNovex [

44], DJI Mavic Mini [

45], DJI Mavic Pro [

46], and Tarot FY680 [

47]. The use of UAVs, also known as drones, started in military operations; however, they are now increasingly being used in the construction and maintenance of civil infrastructures for inspection and monitoring [

30,

48,

49]. Their versatility and low operating and maintenance costs make them appealing to a wide range of sectors, including construction [

50,

51]. UAVs are a preferred tool for data collection because of their maneuverability and higher angles of measurement [

52,

53]. They are also very lightweight and take little time to set up. They can reach places where it is difficult to reach for humans [

51,

54,

55]. UAVs can also undertake at-height inspections isolating humans from fall hazards [

56,

57]. UAVs are also faster than human inspectors [

58]. High-rise towers with glass facades often get damaged after extreme weather events. These facades need to be inspected before re-occupancy of the building is allowed [

59]. Due to their speed, UAVs can provide accurate information much faster and more frequently than humans [

58,

60]. UAVs can thereby reduce the cost and risk of inspection of the built environment [

61].

UAVs are classified into two categories—fixed-wing and rotary-wing UAVs. While fixed-wing UAVs are faster, they cannot hover or take-off vertically. Rotary-wing UAVs can take off vertically from any location, eliminating the need for a horizontal plane on which to gain speed [

62]. The most popular rotary-wing UAV is a quadrotor with four rotors [

63]. They are agile and can hover in one place. They are, however, slower and have a shorter range [

62]. As a result, rotary-wing UAVs are better suited for building applications. However, fixed-wing UAVs can be useful in long, linear infrastructure projects such as highways and railways. A relatively rare UAV type is a lighter-than-air-platform; examples are balloons and kites [

64,

65]. These systems are substantially slower and have very little wind resistance.

Typically, UAVs carry digital cameras as payloads to capture visual data from the site [

66,

67]. They can also carry other equipment, such as thermal cameras [

68,

69]. However, images or videos captured from UAVs can be noisy and require post-processing [

66]. The design and payload of the UAV may vary based on the desired application [

70]. The common use of UAVs in building inspections is to collect visual data by utilizing their onboard cameras [

15,

71]. UAVs are also commonly used for bridge and powerline inspections, because of the high risk of fall accidents in the manual inspection of bridges [

72,

73]. Lyu et al. [

74] identified the following requirements for a UAV system for building inspection:

-

UAVs can hover anywhere to take photos.

-

UAVs can zoom in and focus on a small region of interest.

-

UAV operation should be simple, and the operator can get started without professional training.

-

UAVs should have a long enough flight time to improve operational efficiency.

-

UAVs should be capable of autonomous flight.

-

UAVs should be small enough for transportation and maintenance.

A UAV can be operated either remotely or autonomously and also fly over difficult-to-access areas [

75]. Researchers [

72] have found that for large linear infrastructure projects, and with manual control of the UAV, frequent turning and climbing maneuvers can be exhausting for the UAV pilot. The quality of the images captured by UAVs also depends on the pilot’s performance [

76]. This motivated the development of autonomous trajectory planning for UAVs [

77,

78]. Active collision avoidance for UAVs is required to avoid accidents on sites due to their use, and it is more complicated than that for autonomous ground vehicles [

79]. Shared autonomy has also been developed, in which humans provide higher-level goals to the UAV, but lower-level control, such as keeping a safe distance from the building and avoiding objects, is conducted autonomously [

80]. Shared autonomy reduces the cognitive load on the human operator while still utilizing their experience and expertise [

80].

Although UAVs are efficient and versatile in an outdoor environment, they are of limited use in indoor situations because of visual obstructions [

81]. Another challenge for UAVs is that GPS signals used by outdoor autonomous UAVs may become unreliable in indoor settings [

82,

83]. Many UAVs use other sensors to aid in navigation, such as gyroscopes, magnetometers, barometers, SONAR, and inertial navigation systems [

65]. Vision-based localization and navigation have also been developed and tested [

84].

3. Unmanned Ground Vehicles (UGV)

UGVs, also known as rovers, are the simplest in the design of all the robots discussed herein. These robots work well on flat surfaces but perform poorly on cluttered surfaces [

85]. UGVs can be wheel-driven, using pneumatic wheels to move [

86], or crawler-mounted or tracked systems [

87]. Crawlers, which are also used in military tanks and heavy equipment, have better traction on slick or wet terrain. If the surface conditions are suitable, wheeled UGVs are the most efficient in terms of power consumption, cost, control, robustness, and speed [

85]. Owing to lower power consumption and longer runtime, UGVs can be used as human assistants for long inspection rounds [

88]. Some examples of commercially available UGVs used for research are the Clearpath Jackal [

89] and Clearpath Husky [

90].

Due to their low center of gravity, UGVs are the most stable and can carry large payloads. Some common payloads attached to UGVs in the built environment for inspection and monitoring purposes are (a) regular fixed cameras and stereo cameras for visual data collection [

90,

91]; (b) LiDAR and laser scanners for 3D data capture [

89,

91]; (c) mechanical arms for obstacle removal [

90]; (d) ground-penetrating RADAR (GPR), ultrasonic sensors, and infrared sensors for behind-wall and under-ground sensing [

92,

93,

94,

95]; (e) a graphics processing unit (GPU) for processing [

89]; and (f) IMU, GPS, and UWB sensors for localizing and navigation [

89,

96].

UGVs have been used in a variety of situations other than buildings due to their ease of design and operation. They have been used for the inspection of bridge decks [

89,

97], storage tanks [

98], HVAC ducts [

5], and even sewer and water pipelines [

99]. Owing to their adaptability, they can perform floor cleaning, wall construction, and wall painting in addition to inspection [

90]. They make an excellent test bed for algorithms and sensor design due to their ease of operation.

The low height of UGVs is also a disadvantage because it limits their reach in large halls or spaces with high ceilings. As a result, UGVs are also used in close collaboration with other robots, such as UAVs.

4. Wall-Climbing Robots

Wall-climbing robots are used for the inspections of building facades, windows, or external pipes. Manual inspection of exterior utilities on a high-rise building is performed by human inspectors supported on a temporary frame suspended from the roof of the structure, which poses a huge safety risk to the human inspector [

100]. A UAV can be the tool of choice for such applications because of its easy setup and flexibility. However, as discussed above, UAVs are susceptible to high winds and legal restrictions. Liu et al. [

100] developed a cable-suspended wall-climbing robot for the inspection of exterior pipelines. Such robots are much safer and can carry larger sensor payloads. They can also be used for the external inspection of large above-ground storage tanks [

101]. When supported by a single cable, as developed by [

100], the robot can only move in the vertical direction. However, horizontal motion can be added by supporting the robot with two cables suspended from two different horizontally-spaced points at the top of the structure [

101].

Other methods of wall-climbing include grip-climbing using mechanical actuators and springs to create gripping action [

102]. These robots do not require any pre-installed infrastructure to climb the vertical structure. However, they need surface protrusions to grip while climbing and are not suitable for smooth surfaces.

Magnetic climbing robots use electromagnets controlled by circuits to climb steel structures [

103]. The power needed to operate the magnets in these robots is very little compared to UAVs, and they can hold a position indefinitely [

103]. A similar robot was developed by [

104] with magnetic tracks. The robot was designed to inspect the interior of large steel storage tanks. Magnetic climbers are susceptible to losing traction from the surface due to dust or unevenness, which can be dangerous [

105]. Therefore, both grip-climbing and magnetic-climbing robots are limited in their use for special types of surfaces.

Owing to the need for dedicated infrastructure or a special type of surface in the previously mentioned wall-climbing robots, researchers have also developed suction-mounts that can stick to a wider range of wall surface types. The Alicia robot was developed by [

106] as three circular suction mounts linked together by two arms. The mounts are sealed by special sealants to maintain negative pressure and develop strong adhesion with the wall surface. A similar design was seen in [

107]. Their robot Mantis was also designed as three suction modules joined by two links used for the inspection of window frames. When moving from one frame to another, one of the modules would detach and go over the frame followed by the other two modules one-by-one. Kouzehgar et al. [

107] acknowledged that cracked glass windows may create a dangerous situation for their robot; therefore, they also developed a crack-detection algorithm to avoid attaching to cracked surfaces. In contrast, the ROMERIN robot developed by [

108] used six inter-linked suction cups and turbines, instead of pumps, to create stronger air flow and negative air pressure. The use of many suction cups/mounts and high air-flow turbines provided the robot resilience against cracked surfaces [

108].

5. Cable-Crawling Robots

Cable-crawling robots have a niche area of application in the inspection of stay cables in cable-stayed and suspension bridges [

109]. These robots are different from the cable-suspended robots used for wall-climbing. These robots do not need additional infrastructure to navigate but crawl along the existing steel cables in bridges through the use of drive rollers [

110]. Although drones can also be used to safely inspect these bridge cables at high-altitudes, drones need to maintain a minimum safe distance to avoid collision [

109]. Images captured from a distance do not provide enough clarity to detect micro-cracks on the cable surface [

109]. Additionally, cable-crawling robots equipped with multiple cameras, as performed in [

109], can inspect the whole surface of the steel cables instead of only one side at a time.

A similar cable-crawling robot was also developed by [

110] in Japan for the inspection of the steel cables of suspension bridges. Their design was similar to [

109], yet slightly different. Their robot consisted of a base platform that crawled the main cables of the bridge connecting the support tower and a tethered camera module that was lowered from the base platform for the inspection of the hanging ropes. The actual inspection was carried out by the camera module suspended from the base platform, while the base platform provided horizontal locomotion along the bridge.

6. Marine Robots

Marine robots are used for the inspection of marine structures such as bridge piers, dam embankments, underwater pipes, and offshore structures. There are two types of marine robots found in the literature—(a) submersible robots, also known as unmanned underwater vehicles (UUVs) [

111] or autonomous underwater vehicles (AUVs) [

112]; and (b) unmanned surface vehicles (USV), sometimes called surface water platforms (SWPs) [

113]. Both USV and UUV are sometimes clubbed together under a single term of unmanned marine vehicles [

114].

Submersible robots, as the name suggests, can be fully submerged in water and can perform inspection under water. They are also sometimes referred to as underwater drones [

115]. Underwater inspection is conventionally performed by human divers, which is costly, labor-intensive, and unsafe [

116,

117]. With UUVs, positioning and navigating the robot is a huge challenge because most sensor and positioning techniques (GPS, fiducials, UWB, visual odometry, etc.) used on the ground are inviable underwater [

111]. Dead reckoning techniques using inertial navigation can be used for underwater navigation, but its accuracy deteriorates with time due to drift [

111]. Optic and acoustic systems are also used that measure distance from the reflected light or sound waves [

8]. However, inertial systems do not rely on information from outside and therefore are not affected by underwater rocks or marine life, as is the case with optic and acoustic systems [

8].

Unmanned surface vehicles, on the other hand, operate on the surface of a water body. They are low-cost devices that can facilitate safer inspection of marine structures. USVs are often designed as large devices so they are stable in rough waters, though small USVs have also been developed and tested. The use of waterproof cameras and other equipment is a crucial design consideration for USVs [

118]. Although USVs have been primarily used in military applications before, the construction industry can also benefit largely from their application. Bridge inspection is one of the largest areas where USV can be utilized because out of 575,000 bridges in the US, 85% of them span waterways [

119].

7. Hinged Microbots

Hinged microbots are made up of several tiny body sections hinged together. These robots imitate the movements of snakes or worms. Instead of wheels, they move by using multiple motored joints along their body. They can move by contracting and stretching their bodies like worms, or by sidewinding like snakes [

120]. Various propagation techniques for these robots have previously been investigated, such as piezoelectric, hydraulic, pneumatic, and electrical micro-actuators [

9]. Electrical micro-motors have been found to provide the best speed and power.

The main advantage of hinged microbots is that they are lighter and smaller in size than other types of robots [

9]. They are only a few cubic centimeters in size. As a result, they are appropriate for inspecting sewer, gas, water, or other pipes [

9,

120]. However, due to size limitations, they can only carry a limited amount of data-collection equipment. They are most often equipped with cameras on their heads [

120]. Pipeline inspection is also complicated by a limited and unreliable network. Owing to unreliable communication within pipelines, Paap et al. [

120] developed autonomous path-finding for their robot that can navigate sewer pipes even if there is no communication with the operator. With the advancement in machine learning techniques, Lakshmanan et al. [

121] created a path-planning method for their hinged microbot based on reinforcement learning that quickly finds the best path with the least energy requirement.

8. Legged Robots

Legged robots are relatively newer than other types of robots used for the inspection and monitoring of the built environment. They move using mechanical limbs controlled by multiple motors in each limb. Legged robots may have two legs (bipedal) [

122], four legs (quadrupeds) [

123], or even six legs (hexapods) [

124]. They have the adaptability and mobility to traverse various types of terrains, making them well-suited for construction sites [

123]. Numerous legged robots have been developed by NASA, MIT, IIT, ETH, Boston Dynamics, Ghost Robotics, ANYbotics, and Unitree [

125]. However, due to high technical complexity, very few have been used outside of a laboratory setting [

125]. Due to less availability of commercial legged robots in the market, the literature on these in the construction domain is also sparse. A major advantage of using legged robots over UGVs is that the former can traverse stairs, which facilitates multi-story inspections [

126].

9. Hybrid Robots

A hybrid class of robots uses more than one locomotion to navigate. These are a special type of robots that are developed for specific problems and are not commercially available in the market for general use. A simple hybrid robot is a wheeled robot with additional rotors on top as developed by [

20]. In such a robot, the wheels provide stability on a flat surface indoors whereas the rotors assist in inspection at height, obstacle avoidance, and floor change.

Another hybrid robot that was developed by [

127] adds rotors to wall-climbing robots. As discussed above, wall-climbing robots using suction or magnetic mounts can be useful for flat exterior surfaces. However, protrusions on the façade such as columns and mullions limit the maneuverability of wall-climbing robots. Rotors allow skipping over these protrusions easily without any additional infrastructure, such as cables, thereby extending the reach of wall-climbing robots. A similar robot developed by [

128] used wheels with adhesive coating. The rotors not only provided the vertical thrust but also horizontal thrust to maintain contact with the structure. The wall-sticking mechanism can also be provided through the use of electro-magnets as done by [

37]. Electro-magnets can be more stable against strong winds, however, may only work with steel structures and not with concrete or glass surfaces.

Another example of hybrid robot was provided by [

35] that consists of legs with magnetic padding. The magnetic legs cannot only climb steel elements for at-height inspections but can also walk over wall protrusions. The strong electro-magnets also provide some fall protection against high winds. However, glass and ceramic surfaces may not work with this type of robot. A similar robot with six magnetic legs was developed by [

129]. The robot matched a spider in appearance that climb walls for at-height inspection. Such complex robots require complex control systems and circuity to control the legs and their magnetism in tune with the walking motion, which is a separate research area.

10. Multi-Robot Systems

Researchers have also used teams of multiple robots of the same or different types for inspection and monitoring of the built environment. The robotic system developed by [

130] comprised two quadruped robots working in a “so-called” master-slave relationship. The master robot was responsible for mission planning, task allocation, and comprehensive report generation and carried a high-performance computing unit for these purposes. The slave or the secondary robot carried other payloads such as a thermal camera, robotic arm, and long-range Lidar along with a smaller computing unit for running local control algorithms. Such systems can carry larger payloads without the need for an over-size robotic platform. The primary focus of the research with multiple robots is the development of multi-robot collaboration strategies.

Another type of multi-robot system used by researchers is a team of Unmanned Aerial and unmanned ground vehicles. In the multi-robot system developed by [

33], the wheeled robot on the ground carried the sensors for mapping the environment while the UAV provided a wider view of the area from a higher vantage point for better path planning and navigation. A similar approach was undertaken by [

34,

131,

132], in which the UAV provided an initial scan of the area for the identification of obstacles and occlusions. Based on the initial scan by the UAV, the optimum scan locations were selected for the wheeled robot for higher-quality and longer scans.

Multi-UAV swarms have been used by Khaloo et al. [

133] and Mansouri et al. [

134] independently. Large infrastructure projects, such as gravity dams and linear transportation infrastructure, can be too large for a single UAV to inspect in a single mission and require mid-mission recharging. Utilizing multiple UAVs together may reduce the time for data collection while covering a large area. In studies related to multiple UAVs where each robot is inspecting a part of the target structure, the combine path planning and data fusion from multiple data sources become the primary research focus [

135]. This even applies to other multi-robot systems as well.

Finally, a team of underwater robots and USV has been independently developed by Ueda et al. [

136], Yang et al. [

137], and Shimono et al. [

113] for the underwater inspection of dams and bridge piers. In these studies, the USV provided horizontal navigation from the surface of the water body and lowered the submersible robot suspended by cables or winch for closer inspection under the water.

This entry is adapted from the peer-reviewed paper 10.3390/app13042304