1. Solid Waste in the Southern Cities of Jordan

In addition to 0.040 kilo-tons of natural wood, about 0.100 kilo-tons of straw and sawdust are produced each year in the southern cities of Jordan, which include Karak, Ma’an, Tafilah, and Aqaba. While these quantities are significant, they do not pose problems for the region, as these materials can be used as animal food (straw) and/or heating sources (wood and sawdust). The optimal C/N ratio for conventional treatment methods, such as anaerobic digestion, is approximately 20–30 according to the literature. At low C/N ratios, ammonium (NH

4) is produced during the biodegradation process

[1]. Al Momani et al.

[1] conclude that the experimental chemical analysis of these solids shows that the C/N ratio of straw, sawdust, wood, and cattle produced in this region is approximately 34, 33.5, 33, and 24, respectively. Furthermore, the chemical oxygen demand (COD) of straw, sawdust, wood, and cattle was found to be almost 450, 380, 380, and 240, respectively, while the biological oxygen demand (BOD) of straw, sawdust, wood, and cattle was approximately 435, 366, 370, and 189 (mg/L), respectively. The biodegradability index of straw, sawdust, wood, and cattle was found to be 0.97, 0.96, 0.97, and 0.79 (mg/L), respectively

[1].

1.1. Animal Manure

In 2005, there were more than 2.4 million sheep, 72,000 cows, and 40 million chickens spread across Jordan’s governorates

[2], while approximately 62.59 million animal heads were reported in Jordan in 2019

[3]. In 2013, Al-Hamamre et al.

[4] conducted a survey that investigated the national distribution of animal farms (including goats, sheep, and cattle). They found that northern governorates possessed the highest concentration of animal farms at 36.5%, followed by middle and southern governorates at 34.1% and 29.4%, respectively. The total animal waste from these farms was found to be 2114.09 kilotons/year

[4]. Between 2014–2019, the total obtainable amount of livestock manure was estimated to be 10,909.6 kilo-tons. Goats and sheep contribute the most to the amount of animal manure at 26.4%, as illustrated in

Table 1, these date are calculated and analyzed depend on the data collected from various references. However, in some local villages, animal manure is used as soil fertilizer by disposing of them in open and uncovered areas, where it is washed into the soil by rain

[4]. However, this application of animal manure can potentially cause environmental issues such as surface and groundwater pollution

[5]. Abu-Ashour et al.

[2] showed that the overall BOD content of Jordan’s animal waste was 200 kilo-tons per year, while Al-Hamamre et al.

[4] showed that the animal manure had calorific values ranging between 13.50–17.80 MJ/kg. The quantity of animal manure that could be converted into energy was found to be 1255.5 kilo-tons, which possesses an energy content of nearly 18.45 PJ (18.45 × 10

15 J)

[4], especially since poultry has a high energy content (54.6%). In contrast, sheep and goats have a proportional energy content of 25.9%, while cattle, camels, and horses and donkeys have proportional energy contents of 18.73%, 0.47%, and 0.33%, respectively

[4].

Table 1. Number of livestock, approximated generation of waste, and energy output for the years 2014–2019

[3][6][7][8].

1.2. Municipal Solid Waste (MSW)

MSW refers to waste produced by households, businesses, and industries, and includes plastic, glass, textiles, metal, and biodegradable materials such as paper

[4]. Solid waste management is considered to be a complicated procedure, especially in developing nations

[9][10]. MSW is a crucial component of GHG reduction action plans and strategies worldwide

[10] and accounts for nearly 10% of overall emissions in Jordan

[11]. Approximately 1960 kilo-tons of MSW were reported in 2011

[12], and approximately 2700 kilo-tons were reported in 2014. The growth rate of MSW has been estimated at 3% per year

[4]. Consequently, Jordan was expected to generate 2500 kilo-tons of MSW by 2015

[12]. However, the actual amount of MSW produced in 2015 was 3460 kilo-tons

[11]. Hatamleh et al.

[13] reported that, in 2020, Jordan generates 2077.215 kilo-tons of MSW/year, with a per capita waste creation rate of 0.9 kg/day in metropolitan areas. Al-Hamamre et al.

[4] found that, in 2012, Jordan’s MSW was comprised of 50% organic material, 16% plastic, 15% cardboard and paper, and 19% miscellaneous types. The estimated waste generation for rural areas and urban zones was reported as 0.6 and 0.9 kg per day per capita, respectively

[4]. Al-Hamamre et al.

[4] concluded that the MSW has an energy content of about 11.49 MJ/kg. In Jordan, MSW is disposed of in landfills, the largest of which, Al-Ghabawi, is located in Amman. Approximately 84% of the waste disposed of in this landfill is total solid (TS) waste, representing 58% of Jordan’s total TS waste by volume

[4]. Nearly half of Jordan’s MSW is disposed of in this landfill

[11], followed by the Akeedar landfill, which is located next to the Mafraq governorate’s main road. Akeedar is Jordan’s second-largest landfill, with an area of 0.806 km

2. In total, 45% of the waste processed at Akeedar is TS waste, representing 9.2% of national TS waste by volume. Only 20% of the solid waste in Irbid city is transferred to landfills

[4]. Fast-growing cities, such as Irbid, face significant challenges in collecting and handling solid waste. This is due to significant changes in the city’s demographics, especially since Irbid hosts many Syrian refugees

[13]. In Aqaba, a 120,000 m

2 landfill can be found around 17–20 km from the city center. It receives almost 0.080–0.120 kilo-tons of MSW per day, with trenching being the primary method of dealing with the waste disposed of in this landfill. This method entails depositing solid waste in an excavated area without a bottom liner. When the excavated area has been depleted, the solid waste is covered by soil.

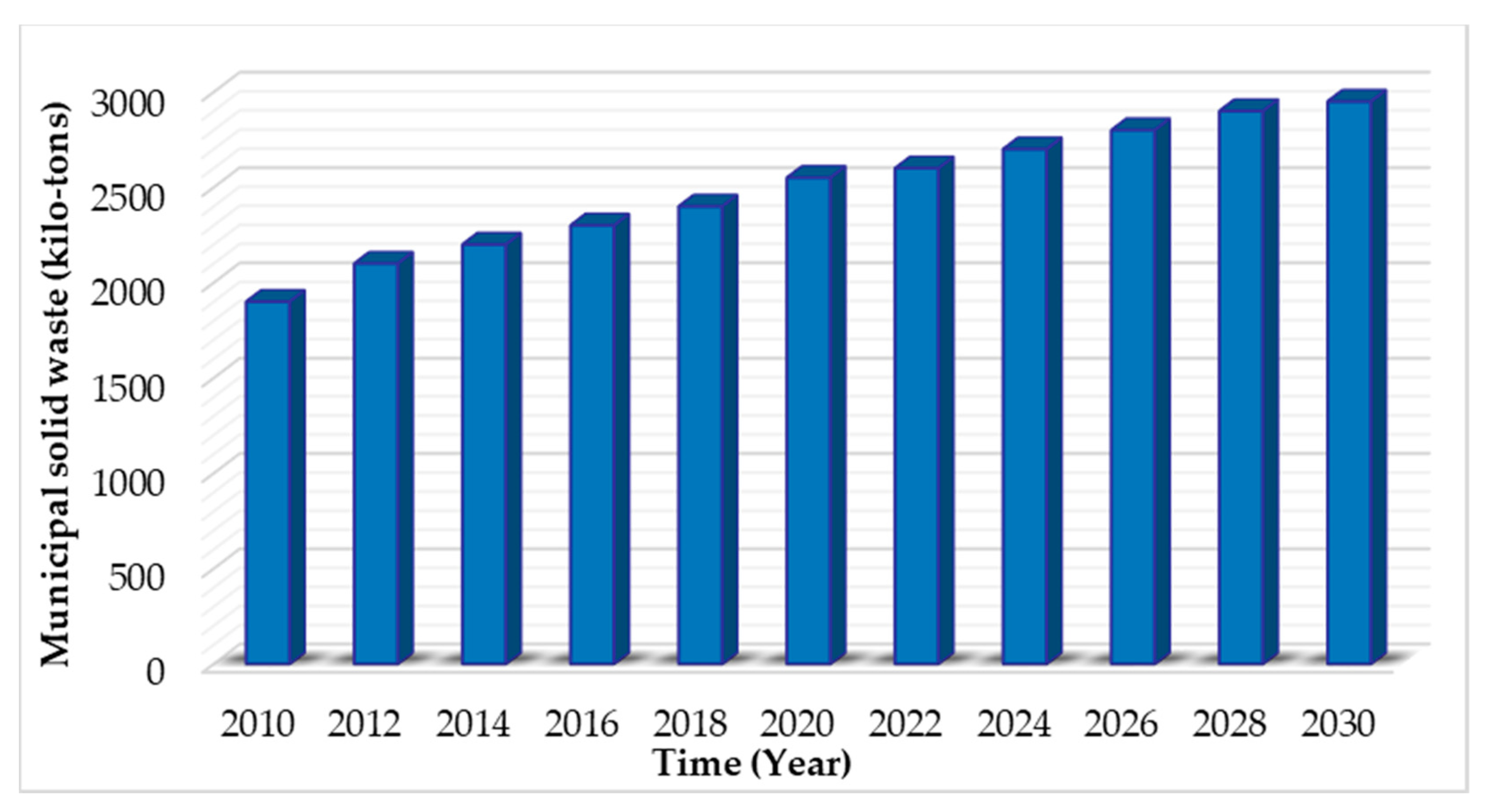

Figure 1 shows a 20-year projection of the generation of MSW (2010–2030)

[4]. Abu Hajar et al.

[11] concluded that, if the MSW management industry continues to develop at its current rate, net GHG emissions will climb to 5698 Gg CO

2-eq by 2025, accounting for 14.5% of GHG emissions in Jordan. The Jordan 2025 vision set a goal of reducing solid waste disposed of in landfills or dumpsites by 33%, replacing this method of waste disposal by anaerobic digestion, composting, and incineration

[11]. This would allow the organic material of MSW to be transformed into electricity and heat or a more adaptable power source such as gaseous or liquid fuels via thermochemical and biochemical processing methods. Waste-to-energy (WtE) projects operate by incinerating waste; the heat obtained is transformed into energy. Consequently, most projects continue to utilize this technology even in the present day

[4]. Jordan has twenty-three wastewater treatment plants

[12] that have a total daily average flow rate of approximately 216,412 m

3/d. This number is expected to grow to 237 MCM/year by 2020. Annually, treatment plants produce 2 MCM of sewage sludge; this massive amount of sewage sludge can be used to generate biogas

[12].

Figure 1. The projected amount of municipal solid waste in 20 years (2010–2030)

[4].

2. Agricultural Residues in Jordan

Even if water is available, most of Jordan’s soil is unsuitable for agriculture. Only 6% of Jordan’s territory is arable. In recent years, only 15% of Jordan’s geographical area received more than 200 mm of total annual rainfall, which is the bare minimum needed for rain-fed farming. Only 4.5% of Jordan’s land is currently being cultivated, and a majority of these cultivated areas are heavily reliant on irrigation. The total quantity of energy crops that could have been grown on 10%, 20%, and 30% of arable land in the southern cities of Jordan was calculated. It was found that it was possible to cultivate 30,000 km

2 of energy crop farms using 10% of the arable land in southern cities. This amount of energy crop production is capable of meeting the region’s energy demands

[1].

2.1. Vegetable Residue

In Jordan, vegetables are the primary crop cultivated on irrigated land. Most of Jordan’s vegetable production is located in the Jordan valley (irrigable lands), as well as some areas in northern and central Jordan that experience high annual rainfall of 400–600 mm per year

[4]. Al Momani et al.

[1] estimated the proportion of agricultural land in Jordan to be only 11.29% in 2011. Furthermore, 9.61% of the total agricultural land area required irrigation, which necessitates a controlled flooding system. Al-Hamamre et al.

[12] found that Jordan produced approximately 997.25 kilo-tons of vegetable residues in 2011, representing an energy content of 7.954 PJ (in dry base); this would have accounted for 2.48% of Jordan’s total primary energy consumption in 2011. Thus, these residues would have made a significant contribution to Jordan’s energy sector

[12]. Between 2014–2019, the average annual tomato dry waste was 106.8 kilo-tons. Tomato dry waste was found to have a moisture content of 80–90%, a calorific value of 6 MJ/kg, and the potential energy in the residue was calculated to be 160.2 TJ using an energy availability factor of 0.25. Similarly, the average annual potato dry waste was found to be 0.0488 kilo-tons with a moisture content of 55–65%, a calorific value of 6 MJ/kg, and the potential energy within the residue was found to be 73.1 TJ at an energy availability factor of 0.25 (

Table 2). These data are collected from different research papers and reports, presented, and calculated the data of vegetables biomass. Note that the quantity of residue was approximated using the available and previously reported ratios

[3][8][14][15]. Tomatoes occupy the greatest proportion of vegetable waste products in Jordan

[12]. About 33–40% of fresh tomatoes eventually end up as bio-waste

[16]. The majority of this waste is in the form of tomato skins and seeds

[17] generated through the industrial process of tomato ketchup, salsa, and paste

[17][18][19]. It is thus possible to obtain alkyd resins and biofuels from tomato residues

[16]. The energy content in residues is similar for most vegetable products (approximately 6 MJ/kg). Jordan considers vegetable residues to have a low energy availability factor of 0.25. Most vegetable waste is lost or burnt at farms due to collection difficulties, and a substantial portion of it is used as fertilizer and animal feed

[12].

Table 2. The significant vegetables grown in Jordan between 2014 and 2019, the approximate average residues generated, and their energy possibilities

[3][8][14][15].

2.2. Fruit Residues

In total, 917.9 kilo-tons of fruit were produced in Jordan in 2019. The olive is the most important fruit in Jordan and is cultivated over an area of 107 kilo-hectares

[4]. Olive groves account for roughly 73% of Jordan’s overall tree-planted agricultural area

[20]. These figures show that olive oil production is one of the country’s most crucial agri-business sectors. Half of Jordan’s olive trees are grown in northern Jordan

[20], which has irrigated lands, while the other half is grown in the western mountains, with rain-fed lands. There are an estimated 17 million olive trees in Jordan, with a growth rate of about 1 million trees per year

[4]. Al-Hamamre et al.

[12] found that the quantity of dehydrated olive cake made as a byproduct in olive extraction plants can be estimated, assuming that olive cake accounts for 35–45% of the mass of an olive fruit and that 60–70% of this amount can be acquired as dry olive cake. Based on these assumptions, 100 kg of olive fruit can generate about 26 kg of dry olive cake

[12]. Abu-Ashour et al.

[2] found that around 27.0 kilo-tons of olive waste were generated in 2005, with a waste collection efficiency of 70%. The overall heating value of these wastes was calculated to be 6600 million MJ or 157 ktoe. This amount would account for 84% of Jordan’s domestic crude oil and natural gas output

[2]. Al-Hamamre et al.

[4] reported that Jordan produced 34.268 kilo-tons of olive cake in 2011. The measured calorific value and ash content of this residue was found to be 24.5 MJ/kg and less than 3.27%, respectively. In 2010 and 2011, the average price of olive cake would have been around USD 84.5 per ton, i.e., the 34.268 kilo-tons of olive cake produced in Jordan would have been worth USD 2.9 million and represented a total energy of approximately 0.84 PJ. The second most commonly produced group of fruits in Jordan are citrus fruits (e.g., grapefruit, lemon, and orange), cultivated over 6.882 hectares, accounting for 25.3% of total Jordanian fruit production. Citrus fruit farms are mainly located in northern Ghour and central Jordan (irrigated lands)

[4]. Between 2014–2019, the average annual mass of residue generated by citrus fruits and olives was reported to be 207.4 kilo-tons and 344.9 kilo-tons, respectively. These residues had calorific values of 13.0 MJ/kg and 15.2 MJ/kg, respectively, and the potential energy of these residues was calculated to be as 674.1 and 3931.9 TJ using energy availability factors of 0.25 and 0.75, respectively. Overall, the total amount of fruit residue produced was estimated to be 940.3 kilo-tons/year with a total energy content of 13,439.3 TJ. Using the average energy availability factor of most fruit residues (0.25), the total potential energy that can be derived from fruit residue was estimated to be 5981.1 TJ, with olive and citrus fruit residues accounting for 65.7% and 11.3% of total potential energy, as illustrated in

Table 3.

Table 3 presented the vegetable biomass in Jordan, which are collected from different research references and reports that help in calculation and presented the residual data.

Table 3. The major fruits grown in Jordan between 2014 and 2019, the approximate average residues generated, and their energy possibilities

[3][8][14][21][22].

2.3. Field Crop Residues

Wheat is the primary rain-fed field crop cultivated by local farmers and Bedouins in areas with <350 mm of rainfall. According to the records collected by the Jordanian commerce ministry, Jordan imports more than 96% of its wheat requirements, with domestic production barely meeting around 4% of the nation’s needs

[23]. Between 2014–2019, the average annual dry waste generation of wheat, barley, and maize was reported to be 52.1 kilo-tons, 41.8 kilo-tons, and 10 kilo-tons, respectively, with a moisture content of 10–20% for wheat and barley and 11–22% for maize. The calorific values of wheat, barley, and maize were found to be 17.39 MJ/kg, 18.60 MJ/kg, and 17.39 MJ/kg, respectively, and the total potential energy from these residues were found to be 226.6 TJ, 194.3 TJ, and 43.6 TJ, respectively, based on an energy availability factor of 0.25, as illustrated in

Table 4, which collected from different references and calculated based on that. It should be noted that the residues from these crops (such as leaves, husks, and straw stalks) are mainly reported at harvest time

[4]. Al-Hamamre et al.

[4] concluded that nearly 117.2 kilo-tons of agricultural residues are available for use in Jordan, representing resources with an energy content ranging from 14.65–18.60 MJ/kg. The total energy content of crop residues in Jordan is estimated to be 519.8 TJ

[4]. Al Momani et al.

[1] found that utilizing 10% of arable land in southern cities of Jordan for the cultivation of energy crops with a yield of 3, 5, and 10 tons of TS waste can provide 2.2 Mtoe, 4.6 Mtoe, and 9.0 Mtoe, respectively. Furthermore, utilizing 30% of arable land for the cultivation of energy crops with a yield of 3, 5, and 10 tons of TS waste can provide 7.3 Mtoe, 13.2 Mtoe, and 28.0 Mtoe, respectively, assuming a biomass conversion efficiency of 100%. However, it should be noted that these values must be recalculated after the initial phase of any biogas projects, as not all biomasses can be converted to biogas (the biomass conversion efficiency generally does not exceed 80%). These low quantities of obtainable energy may have a significant effect on Jordan’s ability to supply crude oil and natural gas

[1].

Table 4. The major farming crops grown in Jordan between 2014 and 2019, the approximate average residues generated, and their energy possibilities

[3][8][14][22].

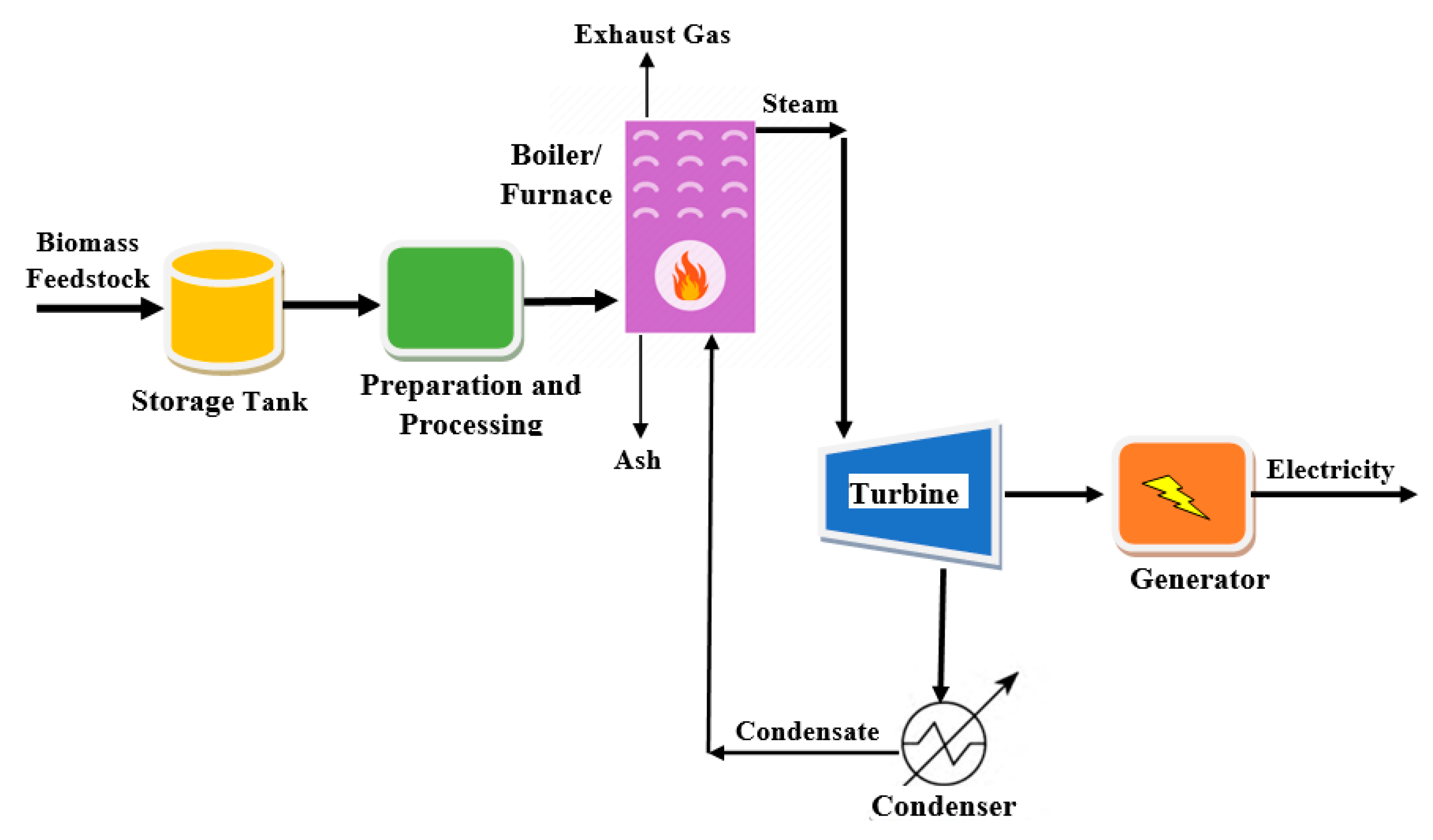

3. Electricity Generation from Biomass

The use of biomass for electricity production is becoming increasingly popular, and biomass is a readily available source of energy in rural areas. Furthermore, it is less harmful to the environment than energy derived from fossil fuels. It is thus considered to be an excellent source of electrical power and can be harnessed by the direct combustion of residues and/or the anaerobic digestion of animal manure

[24]. In direct combustion methods, biomass feedstocks are fired with available air/oxygen to generate heat. This heat can be used to generate steam in a boiler, which is subsequently used to power a steam turbine attached to a generator to produce electricity.

Figure 2 depicts a typical setup for biomass energy production

[4]. Al-Hamamre et al.

[12] found that the cumulative theoretically available thermal energy that can be obtained from Jordan’s biomass resources, assuming a conversion rate of 0.7, was 32.63 PJ, which is equivalent to nearly 20.1% of the total electricity consumption in Jordan in 2011 (nearly 10.2% of the nation’s primary power consumption). Taking an appropriate energy availability factor into account, the expected power that can be generated by biomass was 1210.5 GWh or 8.95% of total electricity usage in 2011, and the proportion of MSW within that energy is 7.3%

[12]. Sagani et al.

[25] found that this would result in a net positive annual electricity generation. The utilization of biomass would also reduce the need for fossil fuels, reduce CO

2 emissions, and have a positive social impact by creating new jobs for locals and increasing their potential earnings. In addition, the internal rate of return (IRR) of this venture was found to be relatively high

[4]. Al-Hamamre et al.

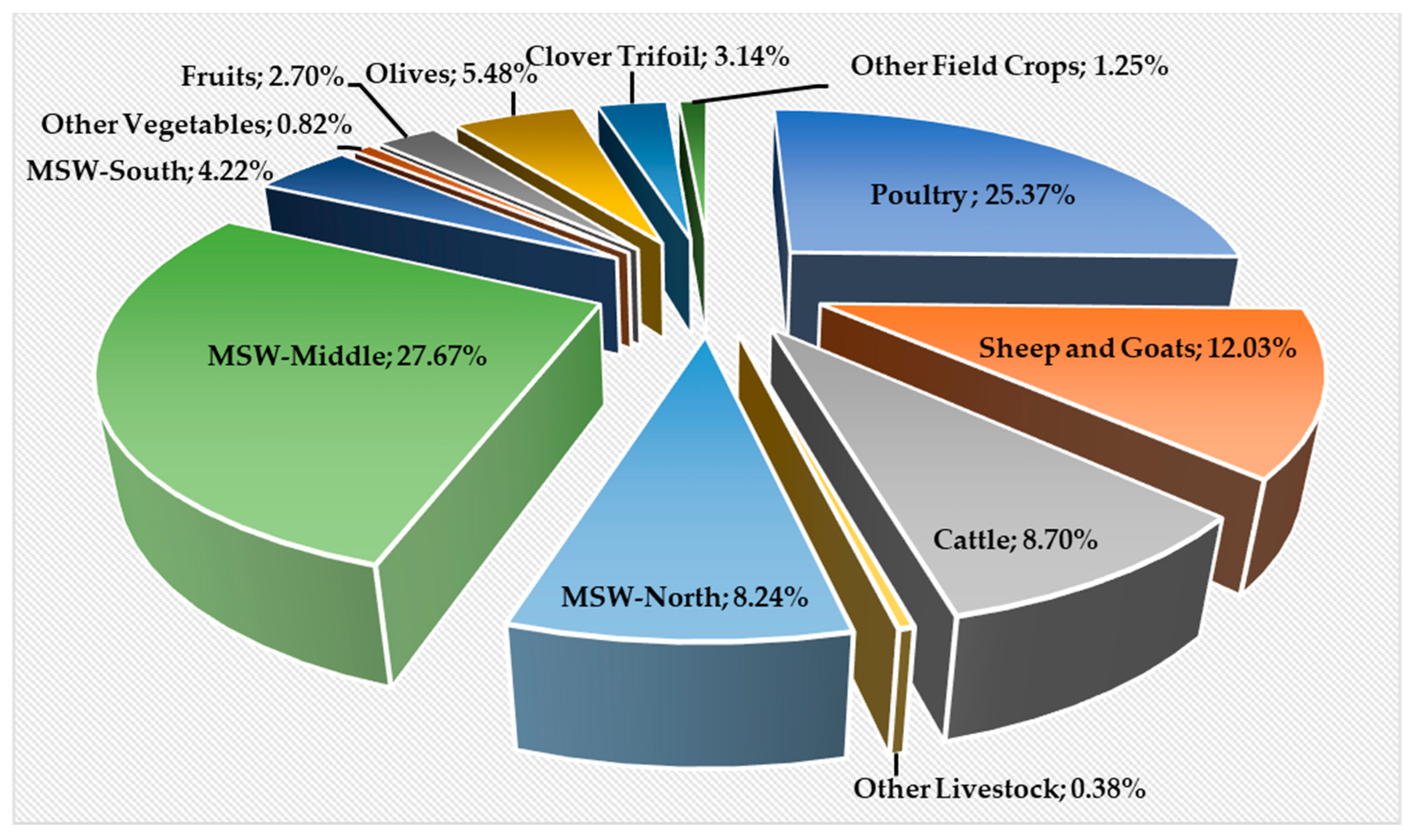

[4] concluded that the direct combustion of different biomass resources could provide Jordan with 2316.7 GWh of electricity, with relative contributions of 46.48%, 40.13%, and 13.39% for animal waste, MSW, and agricultural residue, respectively (

Figure 3).

Figure 2. The layout of a biomass electricity generating system (direct combustion/steam turbine).

Figure 3. The contribution of significant biomass resources to energy production via direct biomass combustion in Jordan.

This entry is adapted from the peer-reviewed paper 10.3390/su15075879