Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Biopolymers are an emerging class of novel materials with diverse applications and properties such as superior sustainability and tunability. Biopolymers pose another option for novel energy material applications. Biopolymers are biodegradable macromolecules composed of repeating units. Natural biopolymers are derived from living matter, such as proteins, polysaccharides, and nucleic acids.

- protein

- polysaccharide

- biopolymer

- battery

1. Introduction

Batteries and electric storage devices have become ubiquitous in human lives and can be found in cars, phones, and most portable devices. Population growth and increasing demand have propelled advancements to produce cleaner, smaller, and cheaper renewable energy sources [1]. The growing prevalence of implantable energy storage devices in biotechnology calls for increased stability and energy density to maximize the lifespan and minimize the size of the device [2]. Considering the array of uses in the human body (e.g., cochlear implants, implantable defibrillators, and drug delivery systems), an equally diverse array of batteries have been engineered to power these devices [2][3].

Lithium-ion batteries have been utilized extensively due to their high charge density, high coulombic efficiencies, and low self-discharge properties [4]. They are widespread amongst rechargeable portable devices, such as cellphones and computers, as well as electric vehicles [5]. Lithium-ion batteries are composed of a cathode, an anode, a separator, and an electrolyte [6]. The cathodes and anodes carry charge, the separator insulates both the electrodes from each other allowing Li+ ions to flow to each electrode, and the electrolyte carries ions [6][7]. Electrode compositions have been optimized to maximize energy density, as many electrodes contain lithium metal oxides with amounts of nickel, cobalt, and manganese, iron, or titanium [5][7]. Unfortunately, these electrodes suffer from poor electrical conductivity despite high energy density [7]. Furthermore, lithium-ion batteries are susceptible to hazardous failure due to electrochemical instability.

A new frontier in 2-dimensional allotropic materials allows for the development of novel electrode solutions. Two-dimensional materials such as graphene, transition metal dichalcogenides such as molybdenum disulfide (MoS2), and transition metal carbides such as titanium carbide (Ti3C2), enable rapid diffusion of ions, enhancing their effectiveness as electrodes for metal ion batteries [8]. For example, borophene is similar to graphene, but is created using the physical vapor deposition (PVD) technique, utilized by vaporizing boron so that it deposits onto a thin sheet of silver [9][10]. Despite naturally occurring as a metalloid, when boron is in a two-dimensional form as in borophene, it behaves as a highly conductive metal [10]. Borophene has been demonstrated to be an effective anode for lithium batteries without energy dispersion during the charge/discharge process, ensuring a quick charging time and long lifespan [10][11].

Biopolymers pose another option for novel energy material applications. Biopolymers are biodegradable macromolecules composed of repeating units. Natural biopolymers are derived from living matter, such as proteins, polysaccharides, and nucleic acids. Frequently utilized natural biopolymers include silk, hyaluronic acid, collagen, pectin, and gelatin [12][13][14]. Interestingly, their increase in demand stems from both a cost and toxicity standpoint as an alternative to petroleum-based plastics [15][16][17]. Specifically, the manufacturing, usage, and disposal of common plastics such as polystyrene (PS), polypropylene (PP), and polyethylene terephthalate (PETE) contribute to landfill consumptions, higher greenhouse gas emissions, and pollution among other negative effects [18][19]. Despite the significant established infrastructure and thus convenience of fossil-based plastics, biopolymers present a unique solution to enabling sustainability and biodegradability in materials [20][21]. They are further highlighted by their biocompatibility, low production cost, availability, and high control in fabrication [22]. Electronics typically struggle at their end-of-life due to improper disposal resulting in a health and environmental hazard from toxic leakages [23]. This lack of safe degradation originates from relatively stable bonds present in the material. For batteries, this includes potentially toxic elements such as lead, lithium, cadmium, among other metals [24]. Meanwhile, biopolymer-based electrical devices, previously synthesized from materials such as cellulose acetate, silk, chitosan, and pectin all exhibit the unique advantage of biodegradability from both mechanical breakdown and enzymatic cleavage of susceptible bonds via microorganisms [25]. These same functional groups can also promote the customization of biopolymers. For example, Lim et al. utilizes porous carbons with chitosan for lithium-ion batteries to increase efficiency of battery cycles [26]. In addition, biopolymers can demonstrate variable mechanical properties via control of elastic modulus, allowing higher densities of energy storage in previously incapable chemistries [27]. Many biopolymers further exhibit valuable electrical properties such as conductivity and ion conductance [28][29][30].

Based on the aforementioned advantages of biopolymers, many prior studies have focused on energy applications for supercapacitors, rechargeable batteries, solar cells, and fuel cells [31]. Supercapacitors are a promising alternative to traditional batteries; compared with normal capacitors, their higher capacitance allows them to be a potential large storage form for energy. Biopolymer research in this regard is focused on electrode materials with good conductivity, large surface area, and many active sites [32]. Several studies have focused on composite materials integrating graphene with biopolymers [32]. Combinations of this type include binary composites (e.g., graphene with polyindole [33]), tertiary composites (e.g., graphene, silicon dioxide, and polyaniline [34]), and quaternary composites (e.g., graphene, platinum, carbon nanotubes, and polyaniline [35]). Additionally, biopolymers are a promising possibility for innovation in rechargeable batteries. Polyethylene oxide-based lithium metal polymer batteries have improved flexibility and processability but currently, their lower ionic conductivity limits them in comparison with state-of-the-art lithium-ion batteries [36]. Other potential avenues for biopolymer-based rechargeable batteries include composite polymer electrolytes and hybrid inorganic-organic electrolytes [36]. Furthermore, biopolymers have also been found to be an exciting source for improvement in solar cells, specifically in the application of dye-sensitized solar cells. Dye-sensitized solar cells (DSSCs), relying on organic dyes for the conversion of light energy to electrical energy, are a cheaper, lighter alternative to conventional solar cells [37]. Polysaccharide biopolymers have been investigated as electrolytes for DSSCs, with examples including cellulose, agarose, chitosan, starch, carrageenan, with gelatin a non-polysaccharide electrolyte option [38]. Biopolymers have been explored in fuel cell applications as proton and ion exchange membranes. Nafion is a prominent proton exchange membrane currently; however, it faces limitations due to high costs and methanol crossover [39]. Cellulose, chitin, and alginate-based membranes offer lower monetary and environmental costs in comparison with nafion in proton exchange membranes with cellulose and chitin-based membranes showing more promise for anion exchange membrane options [40].

2. Biopolymer Materials

2.1. Silk

Silk is one of the oldest protein-based biopolymers harnessed by mankind, utilized for a variety of functions especially in the textile industry (Table 1) [41]. Silk is produced by silkworm (Bombyx mori), orb-weaver spiders, and numerous organisms of the order Lepidoptera as seen in Figure 1 [42]. The structure of silk directly correlates to its unique properties such as biocompatibility, biodegradability, mechanical strength, and precise control in fabrication [43]. Silk is a highly crystalline material, composed of repeating amino acid motifs in its primary structure and compact β sheet regions in its secondary structure [44]. Silk is further broken down into its unique variants, most notably silk I (with helices/coils) and silk II (with β sheets). The distinct crystal formations between silk I (monoclinic unit cell) and silk II (orthorhombic) result in a dimorphic crystalline structure that is a prerequisite for piezoelectric materials [45].

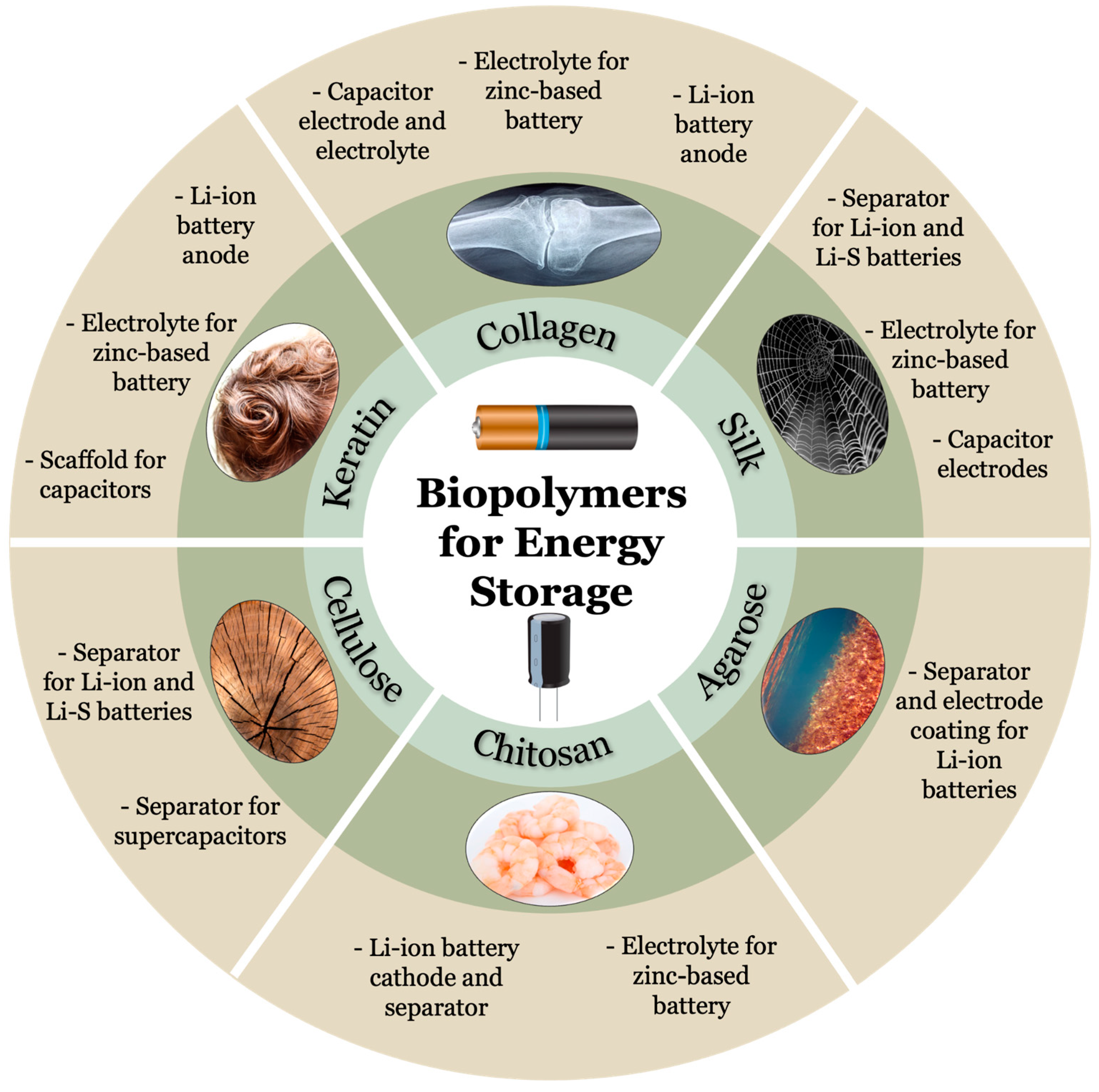

Figure 1. Source and applications for biopolymers commonly utilized for energy storage purposes such as batteries and capacitors. Keratin, collagen, and silk are protein-based biopolymers while cellulose, chitosan, and agarose are polysaccharide-based biopolymers. (Images of biopolymers were obtained with permission from pixabay.com, accessed on 1 December 2022).

2.2. Keratin

Keratin is a protein-based biopolymer known for its robust mechanical properties and self-assembling capability [46]. Keratins are classified as “hard”, stemming from the hair and “soft”, deriving from epithelial tissue. Hard keratins are typically associated with higher contents of the cysteine residue, yielding higher degrees of sulfur-based crosslinking [47]. Thus, as a fibrous protein, keratins are very stable polymers and insoluble. Furthermore, keratins are divided into α-keratins and β-keratins. α-keratins are found to be a tightly coiled right-handed helix with 3.6 amino acids per turn. This tertiary structure is established via hydrogen bonding in the side chains. Generally, α-keratin is the primary material in hair and wool among others. Meanwhile, β-keratins are found as pleated sheets, stabilized via hydrogen bonding between the carboxyl and amino groups in respective residues. β-keratin is usually located in reptiles and birds and is notoriously challenging to extract [48]. For energy applications, keratins are incredibly useful due to the presence of nitrogen atoms that enhance carbon activation for ion transport as well as inherent biopolymer properties such as biodegradability [49].

2.3. Collagen

Collagen is a protein-based polymer serving as the primary structural protein component in biological systems [50]. Collagen is known for its fibrous, hierarchical composition that ultimately yields a triple coil helix for the quaternary structure known as tropocollagen. These tropocollagens are then bundled to form collagen fibers. This novel polymer design provides collagen excellent mechanical properties including elasticity and strength [51]. Similar to previous polymers, collagen is rich in various atoms such as nitrogen, oxygen, and especially carbon. This translates into applications for doping in order to further induce electrochemical properties into biopolymers [52]. Interestingly, collagen for electrical applications is often sourced from leather waste, highlighting the importance of reusability in this search for more sustainable energy solutions [53].

2.4. Chitosan

Chitosan is a derivative of chitin, sourced from the exoskeleton of many insects, arthropods, shellfish, and even cell walls of fungi as portrayed in Figure 1 [54]. As a polysaccharide-based biopolymer, chitin’s structure is composed of β-1,4-glycosidic linked 2-acetamido-d-glucose and 2-amino-d-glucose units. Chitosan is formed by eliminating acetate through the chemical reaction of the previous polymer [55]. Notably, chitosan is seen as an evolutionary intermediate between cellulose and collagen [56]. However, unlike the latter examples, chitosan has a significantly higher percentage of nitrogen atoms, adding functionality as a chelating agent for electrical applications especially as additives within electrodes [57].

2.5. Cellulose

Cellulose, the most abundant biomaterial, is found mainly in plants, algae, and some species of bacteria [58]. Cellulose is a polymer fabricated of 1,4 covalent glycosidic bonded β-D glucose monomers and is insoluble despite its hydrophilic nature [59]. When synthesized in nature, cellulose is typically found as a structure of elementary fibrils which form microfibrils which then form macro cellulose fibers [60]. The cellulose fibers typically arrange as a semicrystalline structure in which regions of ordered chains are interrupted by amorphous regions. Four crystalline allomorphs of cellulose exist, cellulose I, II, III, IV. Cellulose I is fabrictaed of a mix of triclinic (Iα) and monoclinic (Iβ) structures and is obtained naturally [61]. Cellulose II, the most stable form of cellulose, can be obtained from cellulose I by regeneration or mercerization of cellulose I [62]. Cellulose III type I can be obtained from treatment of cellulose I and can be used to form cellulose IV type I; cellulose III type II is produced from cellulose II and can be utilized to form cellulose IV type II [62].

Cellulose can also be modified chemically to form cellulose derivatives with slightly distinct characteristics [63][64][65][66]. Cellulose acetate, produced by replacement of hydroxyl groups in glucose with acetyl groups, can be obtained from agricultural byproducts and does not require further chemical or mechanical treatment [62]. Carboxymethyl cellulose, derived from cellulose by hydroxyl group substitution for carboxymethyl group, is more soluble in water and other organic solvents and is effective for the formation of foams and aerogels [67]. This ease in modification in addition to chemical stability render cellulose a potent option for separators in energy storage options [68].

2.6. Agarose

Agarose, a linear biomass-derived polysaccharide, is composed of the repeating monomer units of agarobiose fabrictaed of β-D-galactose and α-3,6-lactose-L-galactose [69]. Agarose is typically obtained by extraction from seaweed as suggested in Figure 1 [70]. Characteristics of note are its hydrophilicity, chemical stability, and electrical neutrality [71]. Agarose may be insoluble in room temperature water, but can dissolve in ninety degree Celsius water, allowing for manipulation without harsh reagents [72]. The ether and hydroxyl functional groups aid in directing ion transfer. Agarose is gelated by self-assembly mainly due to hydrogen bond formation, resulting in a porous structure [73]. Such porosity enables agarose to be an ideal candidate for electrode materials.

Table 1. Overview of natural biopolymers as energy storage materials.

| Biopolymer | Natural Source | Characteristics | Applications |

|---|---|---|---|

| Silk | Silkworms, spiders [42] | Highly crystalline, biocompatible, biodegradable, high mechanical strength [43]. | Separator for lithium ion [74] and lithium sulfur batteries [75]. |

| Keratin | Hair, wool (α), reptiles (β) [48] | Stable, self-assembling, strong mechanical properties [47]. | Anode in lithium ion batteries [76], electrolyte in zinc-based batteries [77], scaffold in supercapacitors [78]. |

| Collagen | Leather waste [53] | Fibrous, excellent elasticity and strength [51]. | Anode in lithium ion batteries [79], electrolyte in zinc-based batteries [80], separator in supercapacitors [81], electrode in supercapacitors [82]. |

| Chitosan | Exoskeletons, fungi cell walls [54] | Biocompatible, biodegradable, functional as a chelating agent [57]. | Additive for cathode and separator in lithium sulfur batteries [83], electrolyte in zinc-based batteries [84]. |

| Cellulose | Plants, tunica, algae, bacteria [62] | High mechanical strength, high degrees of polymerization and crystallinity [64]. | Separator in supercapacitors [85] and lithium-ion batteries [86]. |

| Agarose | Seaweed [70] | Chemically stable, electrically neutral [71]. | Separator [87] and anode coating material [70] in lithium-ion batteries |

This entry is adapted from the peer-reviewed paper 10.3390/ijms24043975

References

- Chauhan, J.K.; Kumar, M.; Yadav, M.; Tiwari, T.; Srivastava, N. Effect of NaClO4 concentration on electrolytic behaviour of corn starch film for supercapacitor application. Ionics 2017, 23, 2943–2949.

- Zhang, T.; Li, Z.; Hou, W.; Yang, Y. Nanomaterials for implantable batteries to power cardiac devices. Mater. Today Nano 2020, 9, 100070.

- Wang, C.; Shi, Q.; Lee, C. Advanced Implantable Biomedical Devices Enabled by Triboelectric Nanogenerators. Nanomaterials 2022, 12, 1366.

- Kim, T.; Song, W.; Son, D.-Y.; Ono, L.K.; Qi, Y. Lithium-ion batteries: Outlook on present, future, and hybridized technologies. J. Mater. Chem. A 2019, 7, 2942–2964.

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. Etransportation 2019, 1, 100005.

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99.

- Fu, X.; Zhong, W.H. Biomaterials for high-energy lithium-based batteries: Strategies, challenges, and perspectives. Adv. Energy Mater. 2019, 9, 1901774.

- Zhang, X.; Hu, J.; Cheng, Y.; Yang, H.Y.; Yao, Y.; Yang, S.A. Borophene as an extremely high capacity electrode material for Li-ion and Na-ion batteries. Nanoscale 2016, 8, 15340–15347.

- Ranjan, P.; Lee, J.M.; Kumar, P.; Vinu, A. Borophene: New Sensation in Flatland. Adv. Mater. 2020, 32, e2000531.

- Tatullo, M.; Zavan, B.; Genovese, F.; Codispoti, B.; Makeeva, I.; Rengo, S.; Fortunato, L.; Spagnuolo, G. Borophene Is a Promising 2D Allotropic Material for Biomedical Devices. Appl. Sci. 2019, 9, 3446.

- Jiang, H.; Lu, Z.; Wu, M.; Ciucci, F.; Zhao, T. Borophene: A promising anode material offering high specific capacity and high rate capability for lithium-ion batteries. Nano Energy 2016, 23, 97–104.

- Wang, C.; Yokota, T.; Someya, T. Natural Biopolymer-Based Biocompatible Conductors for Stretchable Bioelectronics. Chem. Rev. 2021, 121, 2109–2146.

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer composites: A review. Int. J. Biobased Plast. 2021, 3, 40–84.

- Payne, G.F. Biopolymer-based materials: The nanoscale components and their hierarchical assembly. Curr. Opin. Chem. Biol. 2007, 11, 214–219.

- Mukherjee, T.; Kao, N. PLA Based Biopolymer Reinforced with Natural Fibre: A Review. J. Polym. Environ. 2011, 19, 714–725.

- Vieira, M.G.A.; da Silva, M.A.; dos Santos, L.O.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263.

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196.

- Ashok, K.; Babu, M.; Jula, V.; Mullai, N.K. Impact of used battery disposal in the environment. Linguistics Cult. Rev. 2021, 5, 1276–1286.

- Gironi, F.; Piemonte, V. Bioplastics and Petroleum-based Plastics: Strengths and Weaknesses. Energy Sources Part A Recover. Util. Environ. Eff. 2011, 33, 1949–1959.

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344.

- Kuruppalil, Z. Green plastics: An emerging alternative for petroleum-based plastics. Int. J. Eng. Res. Innov. 2011, 3, 59–64.

- Jian, M.; Zhang, Y.; Liu, Z. Natural Biopolymers for Flexible Sensing and Energy Devices. Chin. J. Polym. Sci. 2020, 38, 459–490.

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208.

- Winslow, K.M.; Laux, S.J.; Townsend, T.G. A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour. Conserv. Recycl. 2018, 129, 263–277.

- Li, X.; Ding, C.; Li, X.; Yang, H.; Liu, S.; Wang, X.; Zhang, L.; Sun, Q.; Liu, X.; Chen, J. Electronic biopolymers: From molecular engineering to functional devices. Chem. Eng. J. 2020, 397, 125499.

- Lim, W.-G.; Jo, C.; Lee, J.; Hwang, D.S. Simple modification with amine- and hydroxyl- group rich biopolymer on ordered mesoporous carbon/sulfur composite for lithium-sulfur batteries. Korean J. Chem. Eng. 2018, 35, 579–586.

- Liu, J.; Galpaya, D.G.D.; Yan, L.; Sun, M.; Lin, Z.; Yan, C.; Liang, C.; Zhang, S. Exploiting a robust biopolymer network binder for an ultrahigh-areal-capacity Li–S battery. Energy Environ. Sci. 2017, 10, 750–755.

- Finkenstadt, V.; Willett, J. Preparation and Characterization of Electroactive Biopolymers. Macromol. Symp. 2005, 227, 367–372.

- Shinwari, M.W.; Deen, M.J.; Starikov, E.B.; Cuniberti, G. Electrical Conductance in Biological Molecules. Adv. Funct. Mater. 2010, 20, 1865–1883.

- Variyam, A.R.; Agam, Y.; Paradisi, A.; Bortolotti, C.A.; Amdursky, N. Mixed ionic-electronic conductance across naphthalenediimide-functionalized biopolymer. J. Mater. Chem. C 2022, 10, 12444–12450.

- Lizundia, E.; Kundu, D. Advances in Natural Biopolymer-Based Electrolytes and Separators for Battery Applications. Adv. Funct. Mater. 2021, 31, 2005646.

- Okonkwo, P.; Collins, E.; Okonkwo, E. Application of biopolymer composites in super capacitor. In Biopolymer Composites in Electronics; Elsevier: Amsterdam, The Netherlands, 2017; pp. 487–503.

- Marriam, I.; Wang, Y.; Tebyetekerwa, M. Polyindole batteries and supercapacitors. Energy Storage Mater. 2020, 33, 336–359.

- Wang, H.; Liu, R.; Liu, X.; Wu, L.; Li, Y.; Zhang, X. Improved Electrochemical Performances of Graphene Hybrids Embedded with Silica as the Functional Connection Layer for Supercapacitors. J. Energy Storage 2021, 36, 102315.

- Golikand, A.N.; Bagherzadeh, M.; Shirazi, Z. Evaluation of the Polyaniline Based Nanocomposite Modified with Graphene Nanosheet, Carbon Nanotube, and Pt Nanoparticle as a Material for Supercapacitor. Electrochimica Acta 2017, 247, 116–124.

- Boaretto, N.; Meabe, L.; Martinez-Ibañez, M.; Armand, M.; Zhang, H. Review—Polymer Electrolytes for Rechargeable Batteries: From Nanocomposite to Nanohybrid. J. Electrochem. Soc. 2020, 167, 070524.

- Sharma, K.; Sharma, V.; Sharma, S.S. Dye-Sensitized Solar Cells: Fundamentals and Current Status. Nanoscale Res. Lett. 2018, 13, 1–46.

- Hasan, M.M.; Islam, D.; Rashid, T.U. Biopolymer-Based Electrolytes for Dye-Sensitized Solar Cells: A Critical Review. Energy Fuels 2020, 34, 15634–15671.

- Shaari, N.; Kamarudin, S. Chitosan and alginate types of bio-membrane in fuel cell application: An overview. J. Power Sources 2015, 289, 71–80.

- Samaniego, A.J.; Espiritu, R. Prospects on utilization of biopolymer materials for ion exchange membranes in fuel cells. Green Chem. Lett. Rev. 2022, 15, 253–275.

- Kundu, S.C.; Kundu, B.; Talukdar, S.; Bano, S.; Nayak, S.; Kundu, J.; Mandal, B.B.; Bhardwaj, N.; Botlagunta, M.; Dash, B.C.; et al. Nonmulberry silk biopolymers. Biopolymers 2012, 97, 455–467.

- Vepari, C.; Kaplan, D.L. Silk as a biomaterial. Prog. Polym. Sci. 2007, 32, 991–1007.

- Tao, H.; Kaplan, D.L.; Omenetto, F.G. Silk Materials—A Road to Sustainable High Technology. Adv. Mater. 2012, 24, 2824–2837.

- Altman, G.H.; Diaz, F.; Jakuba, C.; Calabro, T.; Horan, R.L.; Chen, J.; Lu, H.; Richmond, J.; Kaplan, D.L. Silk-based biomaterials. Biomaterials 2003, 24, 401–416.

- Sencadas, V.; Garvey, C.; Mudie, S.; Kirkensgaard, J.J.; Gouadec, G.; Hauser, S. Electroactive properties of electrospun silk fibroin for energy harvesting applications. Nano Energy 2019, 66, 104106.

- Feroz, S.; Muhammad, N.; Ratnayake, J.; Dias, G. Keratin-Based materials for biomedical applications. Bioact. Mater. 2020, 5, 496–509.

- Hill, P.; Brantley, H.; Van Dyke, M. Some properties of keratin biomaterials: Kerateines. Biomaterials 2010, 31, 585–593.

- Wang, B.; Yang, W.; McKittrick, J.; Meyers, M.A. Keratin: Structure, mechanical properties, occurrence in biological organisms, and efforts at bioinspiration. Prog. Mater. Sci. 2016, 76, 229–318.

- Sinha, P.; Yadav, A.; Tyagi, A.; Paik, P.; Yokoi, H.; Naskar, A.K.; Kuila, T.; Kar, K.K. Keratin-derived functional carbon with superior charge storage and transport for high-performance supercapacitors. Carbon 2020, 168, 419–438.

- Lo, S.; Fauzi, M. Current Update of Collagen Nanomaterials—Fabrication, Characterisation and Its Applications: A Review. Pharmaceutics 2021, 13, 316.

- Bazrafshan, Z.; Stylios, G.K. Spinnability of collagen as a biomimetic material: A review. Int. J. Biol. Macromol. 2019, 129, 693–705.

- Lei, J.; Zhou, J.; Li, J.; Wen, J.; Su, L.; Duan, T.; Zhu, W. Novel collagen waste derived Mn-doped nitrogen-containing carbon for supercapacitors. Electrochimica Acta 2018, 285, 292–300.

- Mekonnen, B.T.; Meiyazhagan, A.; Ragothaman, M.; Kalirajan, C.; Palanisamy, T. Bi-functional iron embedded carbon nanostructures from collagen waste for photocatalysis and Li-ion battery applications: A waste to wealth approach. J. Clean. Prod. 2019, 210, 190–199.

- Shukla, S.K.; Mishra, A.K.; Arotiba, O.A.; Mamba, B.B. Chitosan-based nanomaterials: A state-of-the-art review. Int. J. Biol. Macromol. 2013, 59, 46–58.

- Ravi Kumar, M.N.V. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27.

- Hou, J.; Aydemir, B.E.; Dumanli, A.G. Understanding the structural diversity of chitins as a versatile biomaterial. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379.

- Varma, A.J.; Deshpande, S.V.; Kennedy, J.F. Metal complexation by chitosan and its derivatives: A review. Carbohydr. Polym. 2004, 55, 77–93.

- Khan, F.; Ahmad, S.R. Polysaccharides and Their Derivatives for Versatile Tissue Engineering Application. Macromol. Biosci. 2013, 13, 395–421.

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896.

- Dassanayake, R.S.; Acharya, S.; Abidi, N. Biopolymer-Based Materials from Polysaccharides—Properties, Processing, Characterization and Sorption Applications. In Advanced Sorption Process Applications; Intech Open: London, UK, 2018.

- Wada, M.; Ike, M.; Tokuyasu, K. Enzymatic hydrolysis of cellulose I is greatly accelerated via its conversion to the cellulose II hydrate form. Polym. Degrad. Stab. 2010, 95, 543–548.

- Seddiqi, H.; Oliaei, E.; Honarkar, H.; Jin, J.; Geonzon, L.C.; Bacabac, R.G.; Klein-Nulend, J. Cellulose and its derivatives: Towards biomedical applications. Cellulose 2021, 28, 1893–1931.

- Martínez-Sanz, M.; Lopez-Rubio, A.; Lagaron, J.M. Optimization of the nanofabrication by acid hydrolysis of bacterial cellulose nanowhiskers. Carbohydr. Polym. 2011, 85, 228–236.

- Campano, C.; Balea, A.; Blanco, A.; Negro, C. Enhancement of the fermentation process and properties of bacterial cellulose: A review. Cellulose 2016, 23, 57–91.

- Rabemanolontsoa, H.; Saka, S. Comparative study on chemical composition of various biomass species. RSC Adv. 2013, 3, 3946–3956.

- Zhao, Y.; Li, J. Excellent chemical and material cellulose from tunicates: Diversity in cellulose production yield and chemical and morphological structures from different tunicate species. Cellulose 2014, 21, 3427–3441.

- Pettignano, A.; Charlot, A.; Fleury, E. Carboxyl-functionalized derivatives of carboxymethyl cellulose: Towards advanced biomedical applications. Polym. Rev. 2019, 59, 510–560.

- Liu, H.; Du, H.; Zheng, T.; Liu, K.; Ji, X.; Xu, T.; Zhang, X.; Si, C. Cellulose based composite foams and aerogels for advanced energy storage devices. Chem. Eng. J. 2021, 426, 130817.

- Merceron, T.K.; Murphy, S.V. Hydrogels for 3D bioprinting applications. In Essentials of 3D Biofabrication and Translation; Elsevier: Amsterdam, The Netherlands, 2015; pp. 249–270.

- Hwang, G.; Kim, J.-M.; Hong, D.; Kim, C.-K.; Choi, N.-S.; Lee, S.-Y.; Park, S. Multifunctional natural agarose as an alternative material for high-performance rechargeable lithium-ion batteries. Green Chem. 2016, 18, 2710–2716.

- Normand, V.; Lootens, D.L.; Amici, E.; Plucknett, K.P.; Aymard, P. New Insight into Agarose Gel Mechanical Properties. Biomacromolecules 2000, 1, 730–738.

- Hur, J.; Im, K.; Kim, S.W.; Kim, J.; Chung, D.-Y.; Kim, T.-H.; Jo, K.H.; Hahn, J.H.; Bao, Z.; Hwang, S.; et al. Polypyrrole/Agarose-Based Electronically Conductive and Reversibly Restorable Hydrogel. ACS Nano 2014, 8, 10066–10076.

- Xu, T.; Liu, K.; Sheng, N.; Zhang, M.; Liu, W.; Liu, H.; Dai, L.; Zhang, X.; Si, C.; Du, H.; et al. Biopolymer-based hydrogel electrolytes for advanced energy storage/conversion devices: Properties, applications, and perspectives. Energy Storage Mater. 2022, 48, 244–262.

- Hou, J.; Cao, C.; Idrees, F.; Ma, X. Hierarchical Porous Nitrogen-Doped Carbon Nanosheets Derived from Silk for Ultrahigh-Capacity Battery Anodes and Supercapacitors. ACS Nano 2015, 9, 2556–2564.

- Wu, K.; Hu, Y.; Cheng, Z.; Pan, P.; Jiang, L.; Mao, J.; Ni, C.; Gu, X.; Wang, Z. Carbonized regenerated silk nanofiber as multifunctional interlayer for high-performance lithium-sulfur batteries. J. Membr. Sci. 2019, 592, 117349.

- Thiyagarajan, G.B.; Shanmugam, V.; Wilhelm, M.; Mathur, S.; Moodakare, S.B.; Kumar, R. TiNb2O7-Keratin derived carbon nanocomposites as novel anode materials for high-capacity lithium-ion batteries. Open Ceram. 2021, 6, 100131.

- Shao, Y.; Zhao, J.; Hu, W.; Xia, Z.; Luo, J.; Zhou, Y.; Zhang, L.; Yang, X.; Ma, N.; Yang, D. Regulating Interfacial Ion Migration via Wool Keratin Mediated Biogel Electrolyte toward Robust Flexible Zn-Ion Batteries. Small 2022, 18, 2107163.

- Ramakrishnan, K.; Nithya, C.; Karvembu, R. High-Performance Sodium Ion Capacitor Based on MoO2@rGO Nanocomposite and Goat Hair Derived Carbon Electrodes. ACS Appl. Energy Mater. 2018, 1, 841–850.

- Odoom-Wubah, T.; Rubio, S.; Tirado, J.L.; Ortiz, G.F.; Akoi, B.J.; Huang, J.; Li, Q. Waste Pd/Fish-Collagen as anode for energy storage. Renew. Sustain. Energy Rev. 2020, 131, 109968.

- Zhou, J.; Li, Y.; Xie, L.; Xu, R.; Zhang, R.; Gao, M.; Tian, W.; Li, D.; Qiao, L.; Wang, T.; et al. Humidity-sensitive, shape-controllable, and transient zinc-ion batteries based on plasticizing gelatin-silk protein electrolytes. Mater. Today Energy 2021, 21, 100712.

- Lee, Y.-H.; Lee, Y.-F.; Chang, K.-H.; Hu, C.-C. Synthesis of N-doped carbon nanosheets from collagen for electrochemical energy storage/conversion systems. Electrochem. Commun. 2011, 13, 50–53.

- Xu, H.; Wang, Y.; Liao, X.; Shi, B. A collagen-based electrolyte-locked separator enables capacitor to have high safety and ionic conductivity. J. Energy Chem. 2020, 47, 324–332.

- Chen, Y.; Liu, N.; Shao, H.; Wang, W.; Gao, M.; Li, C.; Zhang, H.; Wang, A.; Huang, Y. Chitosan as a functional additive for high-performance lithium–sulfur batteries. J. Mater. Chem. A 2015, 3, 15235–15240.

- Poosapati, A.; Vadnala, S.; Negrete, K.; Lan, Y.; Hutchison, J.; Zupan, M.; Madan, D. Rechargeable Zinc-Electrolytic Manganese Dioxide (EMD) Battery with a Flexible Chitosan-Alkaline Electrolyte. ACS Appl. Energy Mater. 2021, 4, 4248–4258.

- Liew, S.Y.; Walsh, D.A.; Thielemans, W. High total-electrode and mass-specific capacitance cellulose nanocrystal-polypyrrole nanocomposites for supercapacitors. RSC Adv. 2013, 3, 9158–9162.

- Gonçalves, R.F.; Lizundia, E.; Silva, M.M.; Costa, C.M.; Lanceros-Méndez, S. Mesoporous Cellulose Nanocrystal Membranes as Battery Separators for Environmentally Safer Lithium-Ion Batteries. ACS Appl. Energy Mater. 2019, 2, 3749–3761.

- Kim, J.-M.; Kim, C.; Yoo, S.; Kim, J.-H.; Kim, J.-H.; Lim, J.-M.; Park, S.; Lee, S.-Y. Agarose-biofunctionalized, dual-electrospun heteronanofiber mats: Toward metal-ion chelating battery separator membranes. J. Mater. Chem. A 2015, 3, 10687–10692.

This entry is offline, you can click here to edit this entry!