1. Polymer WG-Based Low-Cost Biosensors

Today, biosensors are widely used in biological diagnostics as well as a variety of other fields, including forensics, environmental monitoring, food control, drug development, and point-of-care monitoring of illness progression

[1][2]. The creation of biosensors may make use of a broad variety of methodologies. As a result of their interaction with high-affinity biomolecules, a variety of analytes may be sensitively and specifically detected

[3][4]. Every biosensor contains a particular set of static and dynamic properties

[5][6]. The efficiency of the biosensor is enhanced by the optimization of these properties

[7].

1.1. Selectivity

Perhaps the most crucial component of a biosensor is selectivity. A bioreceptor’s selectivity refers to its capacity to identify a particular analyte in a sample that contains various admixtures and impurities. The interplay of an antigen and an antibody is the greatest illustration of selectivity. Antibodies often serve as receptors and are immobilized on the transducer’s surface. The antigen is then introduced to a solution (often a buffer including salts), which is subjected to the transducer, where antibodies only bind with the antigens. Selectivity is the key factor to be taken into account while developing a biosensor

[8].

1.2. Limit of Detection

The limit of detection (LOD) of a biosensor is the lowest conc. of analyte that it can detect

[9]. A biosensor is necessary for several medical and environmental monitoring applications to confirm the existence of traces of analytes in a sample at analyte conc. as low as ng/mL or even fg/mL. For instance, prostate cancer is linked to blood levels of the prostate-specific antigen (PSA) of 4 ng/mL, for which doctors recommend biopsy procedures. As a result, LoD is thought to be a key characteristic of a biosensor.

1.3. Stability

The biosensing system’s stability refers to how susceptible it is to environmental perturbations within and outside of it. A biosensor under study may experience a drift in its output signals because of these disruptions

[10]. This may result in a conc. measurement inaccuracy and compromise the biosensor’s quality and precision. In situations where a biosensor needs lengthy incubation periods or ongoing monitoring, stability is the most important component. The reaction of electronics and transducers may be temperature-sensitive, which might affect a biosensor’s stability. To achieve a steady response from the sensor, proper tuning of the electronics is necessary. The degree to which the analyte attaches to the bioreceptor—the affinity of the bioreceptor—can also have an impact on stability. High-affinity receptors promote the analyte’s covalent or strong electrostatic connection, which strengthens a biosensor’s stability. The deterioration of the bioreceptor over time is another element that has an impact on a measurement’s stability.

1.4. Repeatability

The biosensor’s repeatability refers to its capacity to provide the same results under identical testing conditions. The transducer and electronics in a biosensor are precise and accurate, which defines repeatability. When a sample is tested more than once, accuracy refers to the sensor’s capability to offer a mean value that is near to the real value while precision refers to the sensor’s ability to produce identical findings every time. The inference built on a biosensor’s response is very reliable and robust when the signals are reproducible

[10].

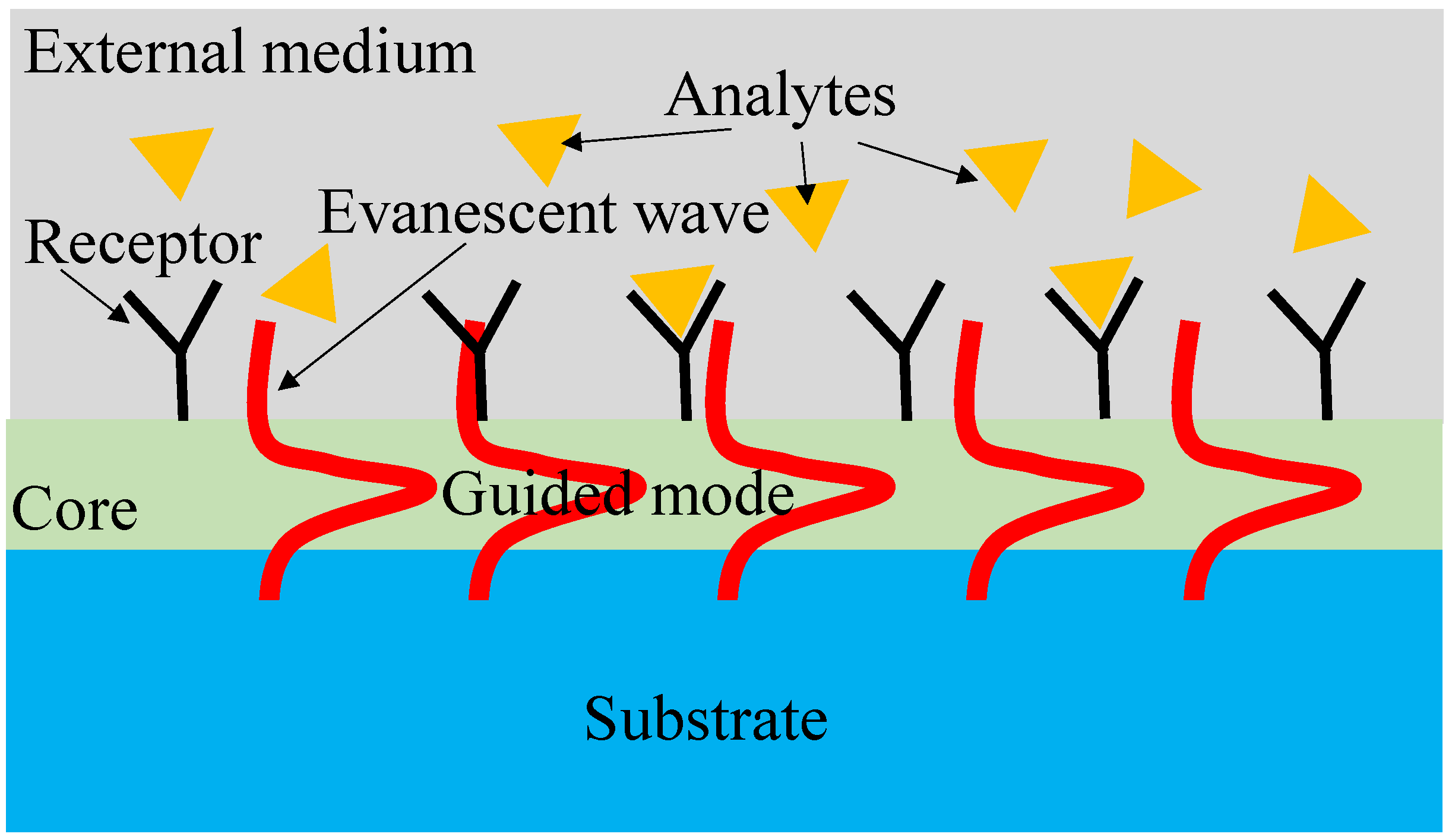

The optical sensors based on evanescent wave monitor changes in the RI. These sensors make use of the confinement of the electromagnetic waves in a dielectric and/or metal structure to generate a propagating or localized electromagnetic mode. The evanescent wave is created when a portion of the confined light disperses into the surrounding medium as shown in

Figure 1. Local changes in the optical properties of the excited electromagnetic mode, most significantly a change in the effective RI, are brought on by RI shifts in the surrounding medium through this evanescent wave

[11]. When a receptor layer is affixed to the guiding structure’s surface, the corresponding analyte is exposed to it, and the resulting (bio)chemical interactions between them change the RI locally. The interaction’s amplitude may be measured by comparing it to the analyte’s conc. and the interaction’s affinity constant. The evanescent wave only reaches the exterior medium up to hundreds of nanometers and perishes exponentially; consequently, the background from the external medium will be little impacted. As a result, only variations near the sensor surface will be noticed.

Figure 1. Evanescent field sensing mechanism.

The interferometric evanescent wave sensing technique is used by planar-integrated optical biosensors to provide highly sensitive label-free detection of biomolecules. Using injection molding and spin-coating, a novel polymer WG device design is proposed that enables the production of disposable sensor chips at a cheap cost

[12]. To couple light into and out of the biosensor, surface grating couplers and lateral tapers were included. By adding a thin layer of inorganic high-index material to these polymer gratings, the coupling strength is improved, allowing for grating size reduction and effective lateral tapering into single-mode WGs

[12].

For detecting effective medication doses of ginkgolide A for the suppression of pulmonary microvascular endothelial cell (PMVEC) apoptosis, a fluorinated cross-linked polymer Bragg WG grating-based optical biosensor is developed

[13]. PMMA was created as the sensing window cladding and fluorinated photosensitive polymer SU-8 (FSU-8) as the sensing core layer. Pharmacological experiments were used to examine and examine the ginkgolide A medication conc. range that was most efficient for inhibiting PMVEC apoptosis (5–10 g/mL). The device’s framework was built to be created and manufactured using direct UV writing technology. With varying refractive indices of various drug conc., the characteristics of the biosensor were simulated. The biosensor’s sensitivity was determined to be 1606.2 nm/RIU. The limit of detection (LoD) and resolution were specified as 3 × 10

−5 RIU and 0.05 nm, respectively

[13].

A multilayer polymeric-inorganic composite WG arrangement was used to produce an evanescent field sensor

[14]. The low RI polymer layers are covered by layers of a Ta

2O

5 thin film that was produced by sputtering, creating the composite WG structure. According to the results, the polymer-based sensor can detect molecules adhering to surfaces down to a limit of around 100 fg/mm

2 for molecular adsorption detection and an LoD of 3 × 10

−7 RIU for RI sensing. The inorganic coating on the polymer layer was discovered to successfully limit water absorption into the WG, which led to stabilized sensor operation in addition to greatly increasing sensitivity. By examining antibody–antigen binding interactions, it was demonstrated that the created sensor can be used in precise molecular detection

[14].

For the detection of biomolecules in the lower nano-molar (nM) range, a surface plasmon resonance (SPR) biosensor based on a planar-optical multi-mode polymer WG structure is presented in

[15]. With a measuring resolution of 4.3 × 10

−3 RIU, the fundamental sensor exhibits a sensitivity of 608 nm/RIU when subjected to variations in RI. C-reactive protein (CRP) was detected in a buffer solution with a response of 0.118 nm/nM by integrating the SPR sensor with an aptamer-functionalized, gold-nanoparticle (AuNP)-enhanced sandwich assay. The biosensor is highly suited for low-cost disposable lab-on-a-chip operations because of the multi-mode polymer WG structure and the straightforward concept. It may also be employed with very straightforward and affordable equipment. The sensor specifically offers the ability for quick and multiplexed identification of various biomarkers on a single integrated technology

[15].

There is much interest in polymer-based materials used in photonic circuits, such as benzocyclobutene (BCB), SU8, and PMMA, for label-free, cost-effective biosensing and communications applications

[16][17]. It is simple to embed optical components and electronics into polymers

[18]. In comparison to low-contrast polymer-based WGs, high-index contrast materials like silicon and silicon nitride give substantial loss inside wall scattering

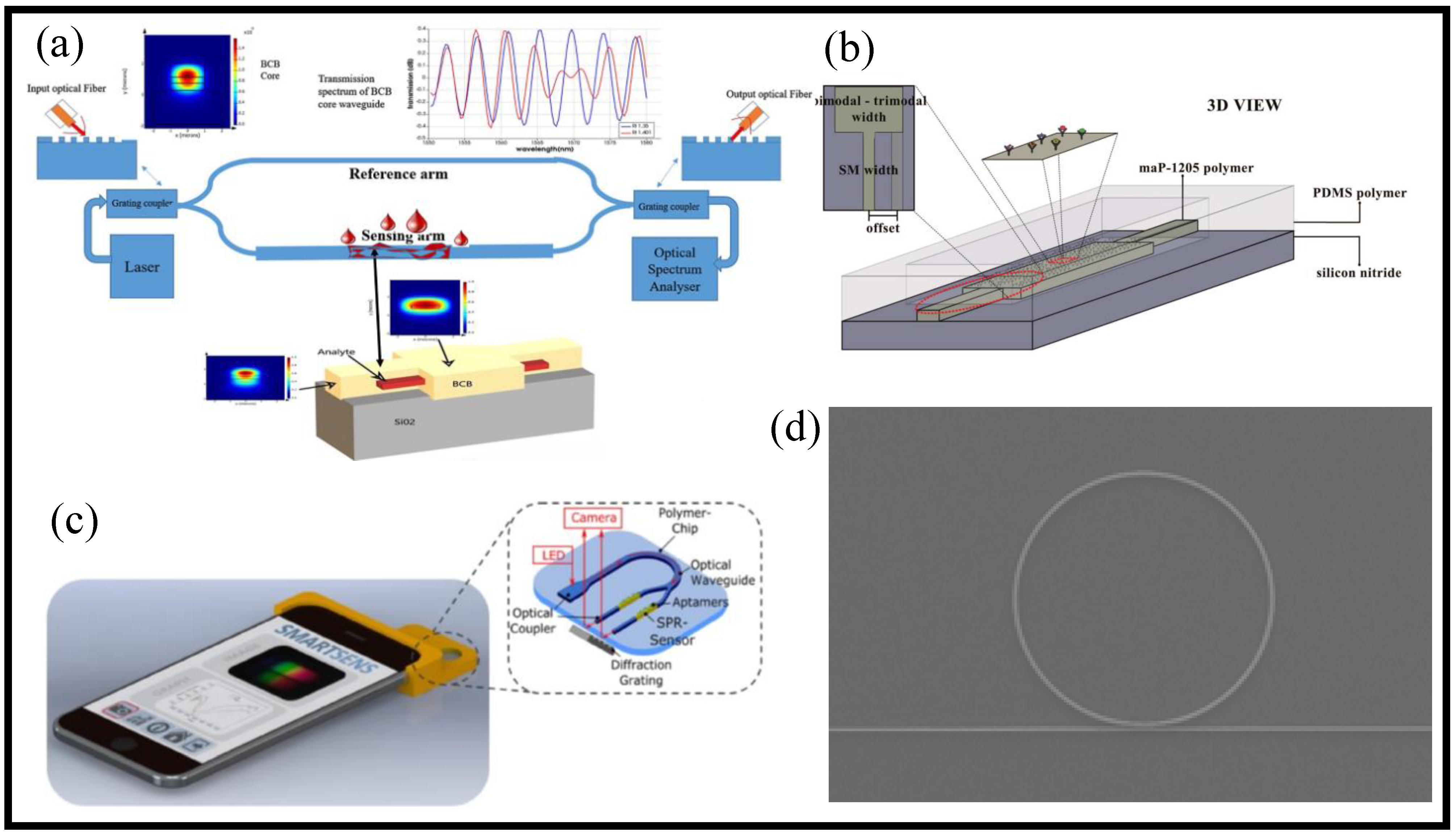

[19][20]. This eliminates any manufacturing limitations and enables the construction of polymer-based WGs with a large footprint in a silicon wafer and minimal side wall scattering loss. These polymer materials may be used in a variety of devices, and by doping impurities, one can adjust the material’s optical, thermal, and electrical properties. High sensitivity is provided by an RI-based biosensor using a unique horizontal slot WG structure composed of cost-effective polymer material in an MZI configuration as shown in

Figure 2a

[21]. The possibility of creating novel hybrid WGs for sensors using silicon wafer-based polymer material has arisen because of the recent need for low-cost point-of-care biosensors. The core of the sensor is made of SU8 material, the outside layer of the sensor is made of PMMA, and the inner layer is made of BCB.

Figure 2. Polymer WG-based biosensors, (

a) BCB and SU-8 photonic WG in MZI architecture for point-of-care device

[21], (

b) Multimode interferometer

[22], (

c,

d) SEM image of the polymer WG resonator

[23].

It is suggested and quantitatively proved that a novel evanescent wave biosensor based on the modal interaction between the fundamental mode and the second-order mode is possible

[22]. It is feasible to create a device where only the fundamental and second-order modes may propagate, without stimulation of the first-order mode, by considering the characteristics of their symmetry as shown in

Figure 2b. Due to the significant contact between the evanescent field and the outer surface as a comparison to prior evanescent wave-based biosensor designs, it is feasible to obtain a high sensitivity response in the biosensor arrangement with this mode selection. The LoD of the device is ~7.34 × 10

−7 RIU. Although polymeric WGs have been suggested as a means of lowering production costs, it has not been feasible to create biosensors with sensitivity levels that are on par with those made available by silicon photonic technology due to the polymeric material’s low RI. Therefore, a multimode interferometer has two special features that combine to improve the sensitivity of a modal biosensor interferometer: first, a novel modal interferometer with greater penetration depth by high order mode evanescent tail; and second, a high modal interaction by coupling mode theory optimization. This feature is essential for making lab-on-chip technologies accessible and widely manufactured in underdeveloped parts of the globe

[22].

It is the first time that an all-optical plasmonic sensor platform based on integrated planar-optical WG structures in a polymer chip has been published as shown in

Figure 2c

[24]. The detection of 25-hydroxyvitamin D (25OHD) in human serum samples using an aptamer-based assay was performed to show the sensor system’s usefulness for biosensing. The devised assay allowed for the achievement of 25OHD conc. between 0 and 100 nM with a sensitivity of 0.752 pixels/nM. It is possible to simultaneously detect several analytes, including biomarkers, because of the WG structure of the sensor’s miniaturization and parallelization capabilities. It is possible to fabricate large-scale, economically priced sensors by integrating the entire optical setup onto a single polymer chip. The proposed concept is particularly appealing for its wider use in lab-on-chip solutions due to the widespread use and accessibility of smartphone electronics

[24].

Numerous studies are being conducted on optical micro-ring resonators as a possible label-free biosensing technology for use in environmental monitoring and medical diagnostics. The surface mass loading or the change in RI brought on by the presence of analytes in the surrounding media is investigated in these micro-rings using the evanescent fields of the resonant light

[25]. It is suggested to use the high-quality SU-8 micro-ring resonators made by NIL for biosensing applications

[23]. The SEM image of the ring resonator is shown in

Figure 2d. Due to its exceptional optical and mechanical qualities, strong corrosion resistance, and high thermal stability, SU-8 polymer has received extensive research in the fields of photonics and microfluidics. Its high level of cross-linking has a special ability to build sidewalls with straight profiles and large aspect ratios. A record-high intrinsic Q-factor of 8.0 × 10

5 is attained by UV imprinting the device with a transparent polymer mold that was copied from a smooth-sidewall silicon master mold.

2. Polymer WG-Based Gas Sensors

For detecting various harmful gases, several optical WG-based techniques have been put forth

[26]. These methods may be roughly divided into two subgroups: RI sensing and optical absorption sensing

[27][28]. The principle behind RI sensing is to track changes in the analyte’s RI, which would affect the output light’s frequency or phase. Since each gas has a distinct absorption wavelength, optical absorption spectroscopy-based WG sensors are more selective than RI sensing. The conc. of the gas can be estimated by analyzing the light attenuation that occurs when the light of a certain wavelength flows through the gas

[29]. According to the Lambert–Beer Law, increasing the optical path—the distance over which light interacts with the analyte—will lower the LoD

[30]. For optical WG sensors, the ambient gas interacts with the WG’s evanescent field and serves as its cladding

[31].

Beginning in the early 1980s, conducting polymers including polypyrrole (PPy), polyaniline (Pani), polythiophene (PTh), and their derivatives were utilized as the active layers of gas sensors

[32]. The sensors built of conducting polymers offer numerous better properties in contrast to most of the widely viable sensors, which are often based on metal oxides and operated at high temperatures. These feathers in particular are guaranteed to be at room temperature and have high sensitivity and rapid reaction times. Conducting polymers are simple to make using chemical or electrochemical methods, and it is simple to change their molecular chain structure via copolymerization or structural derivations. Additionally, conducting polymers have outstanding mechanical qualities that make it simple to fabricate sensors.

The selective and sensitive sensing of harmful greenhouse gases is a significant challenge in the environmental and industrial domains due to the growing emphasis on environmental protection and monitoring

[27][33]. Carbon dioxide (CO

2) is one of the principal greenhouse gases that is created in the environment. According to the operating environments and application areas, several specific kinds of CO

2 sensors have been produced during the last few decades. CO

2 sensors can be broadly categorized as electrochemical gas sensors, optical gas sensors, and acoustic gas sensors based on the detecting processes they use

[27][34][35]. The choice and design of the sensing material used in a sensing device have a substantial impact on how well the sensor performs since a gas sensor relies on active interaction between the sensing layer and the target gas. Metal oxide, polymers, carbon compounds including carbon nanotubes (CNTs) and graphene, metal–organic frameworks (MOFs), and composites of these materials are the most often employed active materials in CO

2 sensing

[36][37]. A flexible CO

2 gas sensor working at room temperature based on CNTs is developed on a low-cost polyimide substrate

[36]. Resistive networks are utilized in gas detection to create very uniform CNT thin films using a trustworthy and repeatable transfer technique. When the ambient CO

2 gas conc. was 800 ppm, the flexible gas sensor had a high sensitivity of 2.23%.

MOF-based optical gas sensors, which focus primarily on light–gas interaction within a thin MOF layer, are preferable due to their properties of minimal drift, high gas selectivity to other gases—pertinent for the optical gas sensing part—and the high porosity, large surface area, and tailor-made pore sizes related for the optical gas sensing part. Metal–organic frameworks are porous crystalline solids that are put together by the coordination of inorganic building units by organic linker molecules. Because MOFs’ pores may be replaced with different substances, they are appealing for use in a variety of applications, including gas storage, gas separation, catalysis, and sensing.

Air and hydrogen mixes may catch fire easily. Therefore, hydrogen sensors are crucial for quick leak identification during handling. Existing solutions, nevertheless, fall short of the high-performance standards established by stakeholders, and deactivation brought on by poisoning—such as that caused by carbon monoxide—remains a significant issue. In a plasmonic metal–polymer hybrid nanomaterial idea, deactivation resistance is supplied by a specially designed tandem polymer membrane, while the polymer coating lowers the apparent activation energy for hydrogen transport into and out of the plasmonic nanoparticles

[38]. This provides subsecond sensor response times in conjunction with the optimum volume-to-surface ratio of the signal transducer given exclusively by nanoparticles. In addition, sensor LoD is improved, hydrogen sorption hysteresis is reduced, and sensor operation in challenging chemical conditions is made possible without long-term deactivation symptoms

[38].

The development of affordable PCB-integrated optical WG sensors is shown using a unique platform

[39]. The sensor design depends on the utilization of multimode polymer WGs that can be created directly on common PCBs and chemical dyes that are readily accessible in the market, allowing the assembly of all crucial sensing elements (electronic, photonic, and chemical) on low-cost substrates. Furthermore, it uses WG arrays functionalized with various chemical dyes to permit the detection of many analytes from a single device. The devices may be made using PCB manufacturing techniques that are standard practice, such as pick-and-place assembly and solder-reflow operations. An FR4 substrate is used to construct an ammonia gas sensor that is PCB integrated as a proof of concept. The sensor’s functionality depends on the way ammonia molecules affect the optical transmission properties of chemically functionalized optical WGs. In addition to the basic modeling and characterization investigations, the manufacturing and assembly of the sensor unit are discussed. At normal temperatures, the device achieves a sensitivity of around 30 ppm and a linear response of up to 600 ppm. Finally, principal-component assessment is used to show how it is possible to identify numerous analytes from a single device

[39].

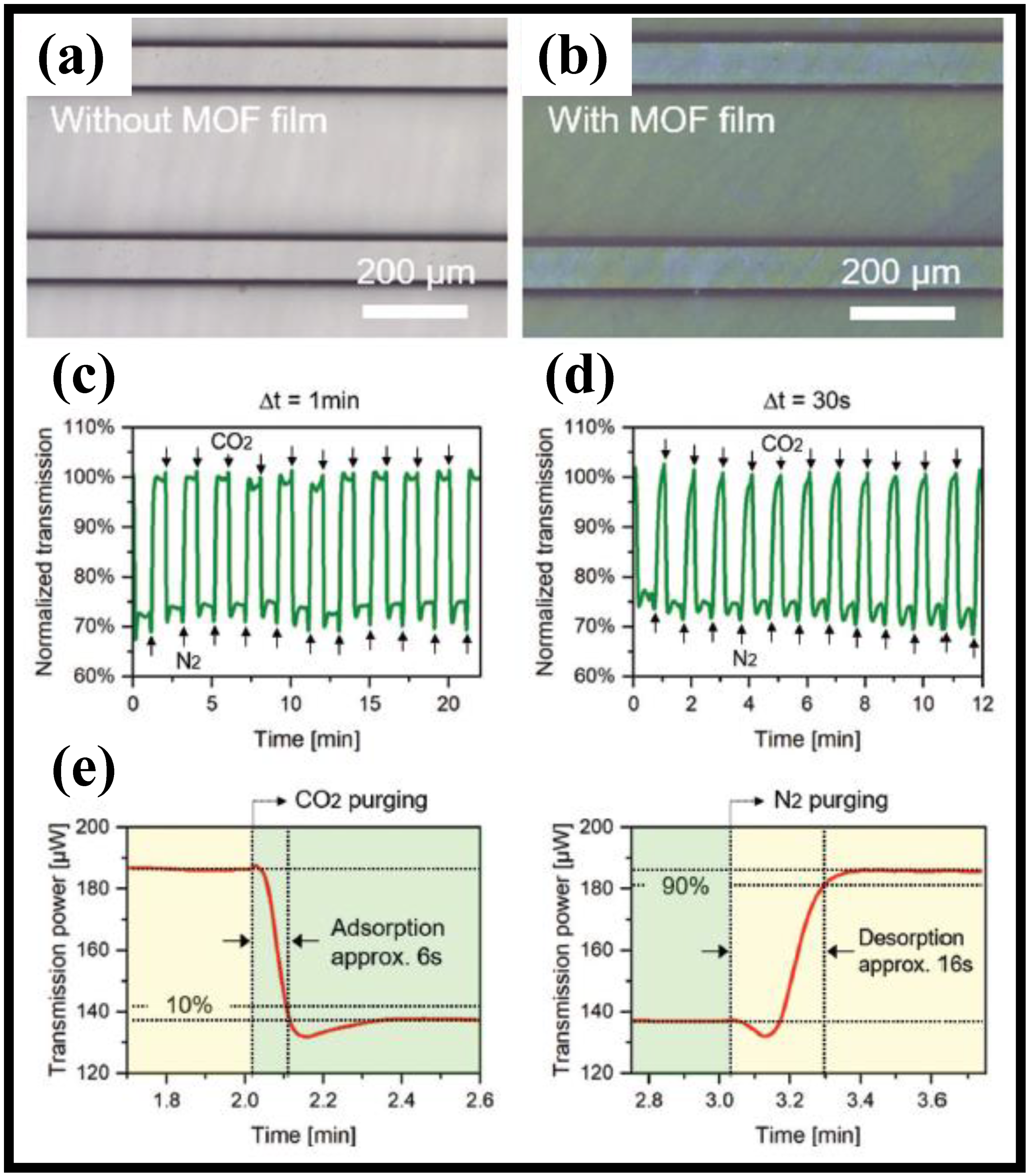

For the detection and sensing of CO

2, a cheap gas sensor based on planar polymer optical WGs with an embedded zeolite imidazole framework-8 (ZIF-8) thin film is presented

[40]. The PMMA planar optical WGs are formed by hot embossing, which makes them flexible and economical. A simple solution approach is used to evenly produce thin ZIF-8 films on the surface of WGs, which is essential for the envisioned mass manufacturing of metal–organic framework-based sensing devices. The microscope image of the WG without MOF film and with MOF film is shown in

Figure 3a,b, respectively.

Figure 3. Microscope images of (

a) uncoated

[40], (

b) ZIF-8 coated WG

[40], (

c) response of the MOF-coated WG to CO

2 with gas switching time intervals of 1 min

[40], (

d) response of the MOF-coated WG to CO

2 with gas switching time intervals of the 30 s

[40], and (

e) adsorption and desorption time of MOF-coated WG sensor

[40].

Figure 3c depicts the recording of optical signal transmission out of the MOF-coated WG with a gas switching time interval of

t = 1 min. Several cycles were repeated. The alternate purging of N

2 and CO

2 caused the transmission signal to shift frequently and reproducibly. When CO

2 was released into the gas cell, the transmission rapidly fell and maintained a largely constant level. The repeated cycle tests provide additional evidence of the proposed MOF-based polymer WGs’ resilience and effectiveness as sensors. A further experiment with

t = 30 s was carried out to test the optical response of the planar WG sensor to CO

2 exposure during shorter gas changeover times.

Figure 3d depicts the outcome. The optical signal leaving the WG here also changes regularly due to the alternate purging of N

2 and CO

2. Additionally, it can be shown that the short gas switching time results in a high-power level when N

2 is purged that lacks a clear steady state. The time from the response’s beginning to 90% of its maximum in a steady state is referred to as the adsorption and desorption times. The MOF-coated PMMA WG used in this study exhibits CO

2 adsorption and desorption times of approximately 6 s and 16 s, respectively, as shown in

Figure 3e. These findings show that the diffusion of gases into the MOF sensing layer from the surrounding medium occurs at a very high rate. According to experimental findings, the developed optical elements have good reversibility of the gas molecules’ adsorption and desorption, a sensitivity of 2.5 μW/5 vol% toward CO

2 [40].

3. Polymer WG-Based Temperature Sensors

In several industries and applications, including healthcare, consumer electronics, transportation, and aerospace, temperature sensors are crucial

[41][42]. To meet the expanding demands for automation in production and monitoring, there is an expanding market for temperature sensors that are high-performing, trustworthy, and affordable

[43]. Such sensors are increasingly being included in materials (such as composites) during the manufacturing process. Conventional electronic-based temperature sensors are unsuitable for several tasks because of their sensitivity to electromagnetic interference

[44].

Optical WGs on a planar substrate are an intriguing solution to fibers for sensing since they may incorporate splitters, optoelectronic components, or even whole Bragg grating interrogation systems

[45][46]. Comparatively to single fiber sensors, the use of planar foils makes it easier to position and align the sensors during integration. Due to the wide range of materials that are readily accessible, each with unique features and optimized for certain manufacturing methods, Bragg grating-based sensors in polymer WGs are becoming more and more popular in several applications

[47][48][49][50][51][52][53]. Because of its high thermo-optic coefficient, superior thermal stability, and relatively low absorption loss from visible to telecom wavelengths, Ormocer, an inorganic-organic hybrid polymer, is an excellent option to be utilized in the implementation of a Bragg grating-based temperature sensor. Additionally, the material is economical, simple to utilize, and risk-free to handle without specific safeguards. However, due to its oxygen inhibition and liquid condition during UV exposure, traditional contact mask lithography makes it challenging to define nanometer-scale WG features. An equivalent has been imprinting-based technology; however, because of the rather thick residual layer, the reported structures made with this approach are inverted-rib WGs

[54]. To create a highly sensitive Ormocer-based WG Bragg grating temperature sensor, a novel capillary filling-based duplication technique is suggested

[55]. A series of polymer WGs imprinted with a wide area grating is patterned on top of an under-cladding layer to create the sensor, which has a sensitivity of −249 pm/°C at ambient temperature and a working wavelength of 1530 nm

[55].

The use of switchable molecular compounds in a polymer WG-based temperature sensor system is described in

[56]. A maskless lithographic optical system is used to manufacture the polymer WG cladding, and hot embossing equipment is used to copy it onto polymer material (for instance polymethyl methacrylate (PMMA)). The substance used to monitor changes in outside temperature is a molecular combination of iron, amino, and triazole. A mixture of core material (NOA68) is used to fill the WG’s core for this purpose, and doctor blading and UV curing are used to solidify the molecular complex. In the low-spin state, two distinct absorption bands are present in the molecular complex’s UV/VIS light spectrum. A spin-crossover transition takes place when the temperature gets close to room temperature, which causes the molecular complex to go from violet pink to white (or spectral characteristics). With a hysteresis width of around 12 °C and a sensitivity of 0.08 mW/°C, the measurement of optical power transmitted through the WG as a function of temperature displays a memory effect. In situations where electromagnetic interference might skew the results, this permits optical rather than electrical temperature detection

[56].

A polymer WG incorporated in an optical fiber micro-cavity-based MZI was presented

[57]. Femtosecond laser micromachining, fiber splicing, and single-mode fibers were used to create the micro-cavity with two symmetric apertures. The 70 μm long polymer WG was then fabricated using the two-photon polymerization manufacturing technique and incorporated into the micro-cavity. A complete interference spectrum and over 25 dB of fringe visibility were displayed by the MZI. The suggested MZI’s temperature sensitivity exceeded 447 pm/°C because of the strong thermo-optical coefficient of the polymer material. Due to its flawless linearity (99.7%) and persistence, it may be utilized as a trustworthy temperature sensor

[57].

It is suggested to use an asymmetric MZI with varying widths in the two interferometer arms as the foundation for an ultra-sensitive polymeric WG temperature sensor

[58]. The device’s sensitivity was improved by using a polymer with a higher thermo-optic coefficient (TOC). The effect of the two arms’ distinct widths and the cladding materials’ various TOCs on the sensor’s sensitivity was investigated and experimentally proven. The devices were created by combining a straightforward all-wet etching method with conventional photolithography. The sensitivity of the WG temperature sensor was found to be 30.8 nm/°C when the cladding material Norland optical adhesive 73 (NOA 73) and the width difference of 6.5 μm were used. Additionally, the lowest temperature resolution was almost 0.97 × 10

−3 °C. The sensor has the specific benefits of high sensitivity, high resolution, simple manufacture, low cost, and biological compatibility, making it potentially useful for temperature detection of organisms, molecular analysis, and biotechnology

[58].

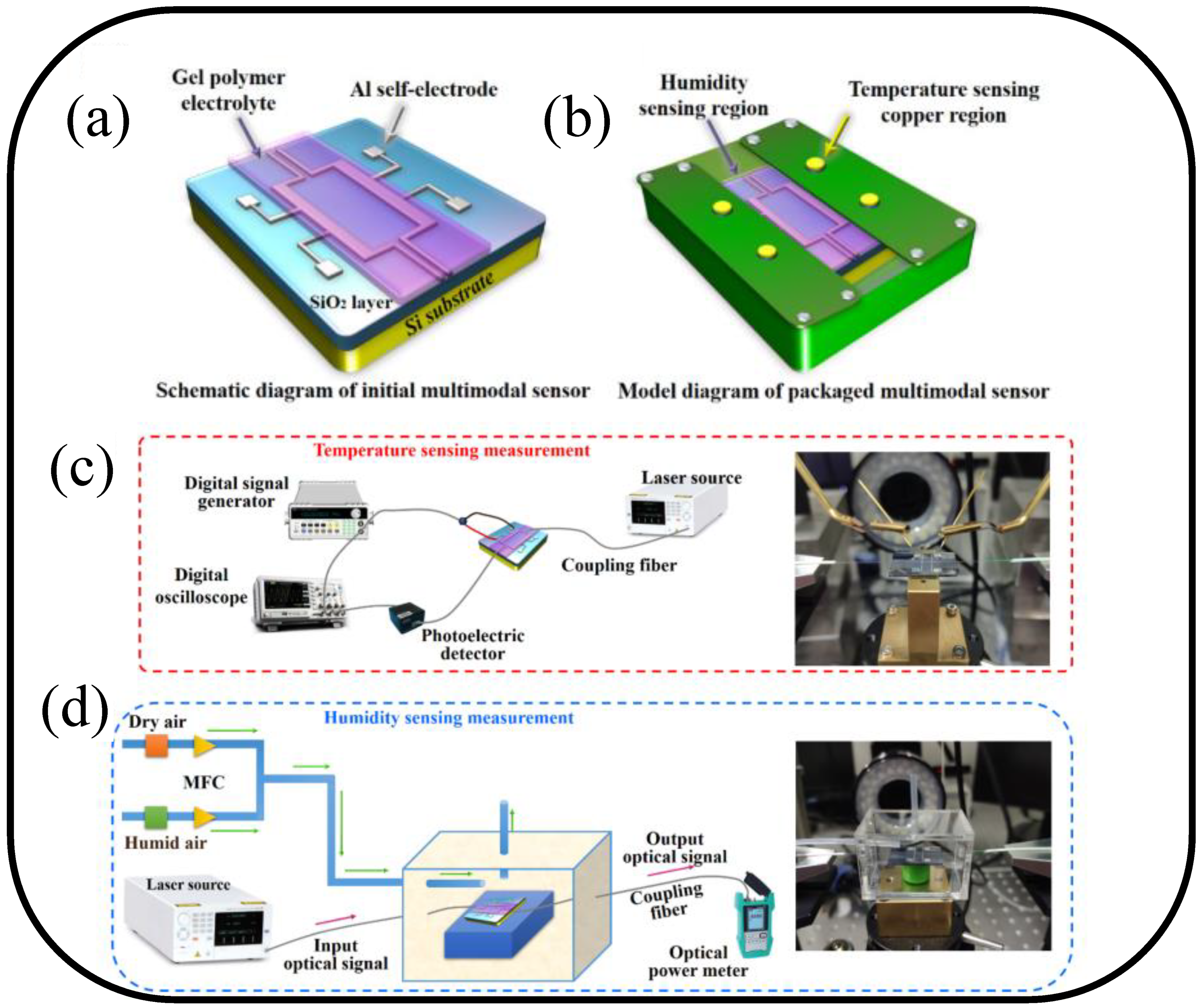

With the use of bottom metal printing technology, multimodal responsive optical WG sensors that make use of a stable cross-linking gel polymer electrolyte have been successfully created

[59].

Figure 4a depicts the prototype optical WG multimodal sensor’s schematic structure diagram. First, Si substrates with SiO

2 buffer layers are used to fabricate metal thermo-inducting electrode designs. Spin-coating and UV curing are used to cure a gel polymer electrolyte that was self-created as a sensing WG material on metal electrodes. By using the bottom metal printing process, the MMI WG sensing structure is directly defined through electrode areas. The lift-off technique is used to detach the polymer films off the thermo-inducting electrodes’ pads on both sides. Next, a printed circuit board (PCB) is attached to the overall sensing WG chip using adhesive. On either side of the chip, two further PCBs are connected. Copper and aluminum metal electrode pads on two different PCBs with holes that are aligned to them might make a thermo-inducting contact.

Figure 4b provides the packed chip’s complete model diagram.

Figure 4c,d show the measurement systems of the multimodal photonic chip for temperature and humidity sensing applications, respectively

[59].

Figure 4. Graphical illustration of (

a) the prototype of optical WG multimodal sensor

[59], (

b) packaged photonic multimodal sensor

[59], (

c) measuring systems of the sensor for temperature

[59], and (

d) measuring systems of the sensor for humidity

[59].

It is simulated to characterize temperature and humidity sensing using a polymer electrolyte. Considering the study of ion relaxation dynamics, the multimodal responsive features of the photonic chip are established: optical attenuation and phase variables for temperature and humidity sensing, respectively. The device’s temperature and humidity sensitivities were measured at 0.5 rad/°C and 1.14 dB/% RH, respectively, in the monitoring temperature (36.0–38.0 °C) and relative humidity (45%–65%) ranges. The multifunctional sensor’s quick reaction times may be calculated to be 4.21 ms and 1.32 s, for temperature and humidity, respectively. This study offers a workable plan for the development and use of temperature and humidity sensors in possible medical procedures

[59].

4. Polymer WG-Based Mechanical Sensors

Polymer WG-based mechanical sensors are devices that use the optical properties of a polymer WG to detect mechanical changes. When the WG is deformed due to mechanical stress or strain, the refractive index of the material changes, which alters the way that light propagates through it. This change in the optical properties of the WG can be measured and used to detect the presence and magnitude of the mechanical stress or strain. Polymer WG mechanical sensors have a number of potential applications, including in structural health monitoring, biomedical sensing, and environmental monitoring. There are different types of polymer WG-based mechanical sensors, including cantilever-based sensors, micro-ring resonator sensors, and Mach–Zehnder interferometer sensors. Each of these sensors has its own advantages and disadvantages, and the choice of sensor depends on the specific application requirements.

Optical sensors with low residual stress, straightforward manufacturing, and low cost have been created employing polymer-based WG systems. In general, the mechanical characteristics of polymers may be described in a manner quite similar to those of metals or other common crystalline materials. This is especially true for elastic moduli and other classes of strength measures like yield and tensile strengths. A wide range of biomedical applications in sensing, diagnostics, and phototherapy have demonstrated considerable potential for biocompatible polymeric optical WGs with soft and flexible mechanical features

[60]. Today, transparent touch-sensitive panels for portable devices like smartphones and tablet computers are commonly used. These panels have become more functional and versatile, enabling multipoint touch interaction in addition to single point touch, which is a growing trend in touch sensing in electronic devices. Besides contact detection, pressure-based touchscreen interaction increases usability. For instance, a touch-sensitive keyboard performs better when pressing the keys. Recently, flexible or even stretchy touch sensors were developed so they can work with flexible screens

[44].

A high sensitivity of 8.2 ppm/Pa has been established for an optomechanical pressure sensor employing polymer multimode interference (MMI) couplers

[61]. It has been established that a polymer WG sensor with a symmetric multilayer design may be used to detect low humidity conc.

[62]. When water molecules diffuse into the polymer WG, the sensor records the resultant optical phase shifts. It is possible to reach a sensitivity of several parts per million for humidity levels. Additionally, the sensor provides the absolute sign of the movement of the generated interference fringes, which makes it simple to identify trends in the index (increase or reduction) in the sensing layer. This work shows a very promising future for the development of a small, disposable optical sensor with a cheap cost for humidity sensing applications

[62].

Stretchable polymeric optical WGs have also been researched for wearable body temperature readings in addition to mechanical sensing

[63]. One of the most important physiological indicators that accurately identifies stages of health is body temperature. The reading of wearable temperature sensors should be resistant to body motions and independent of mechanical deformation for continuous and long-term temperature monitoring. Utilizing PDMS optical fibers that have integrated upconversion nanoparticles, a unique stretchable optical temperature sensor that can maintain its sensing capability despite massive strain deformations (up to 80%) has been produced

[63].

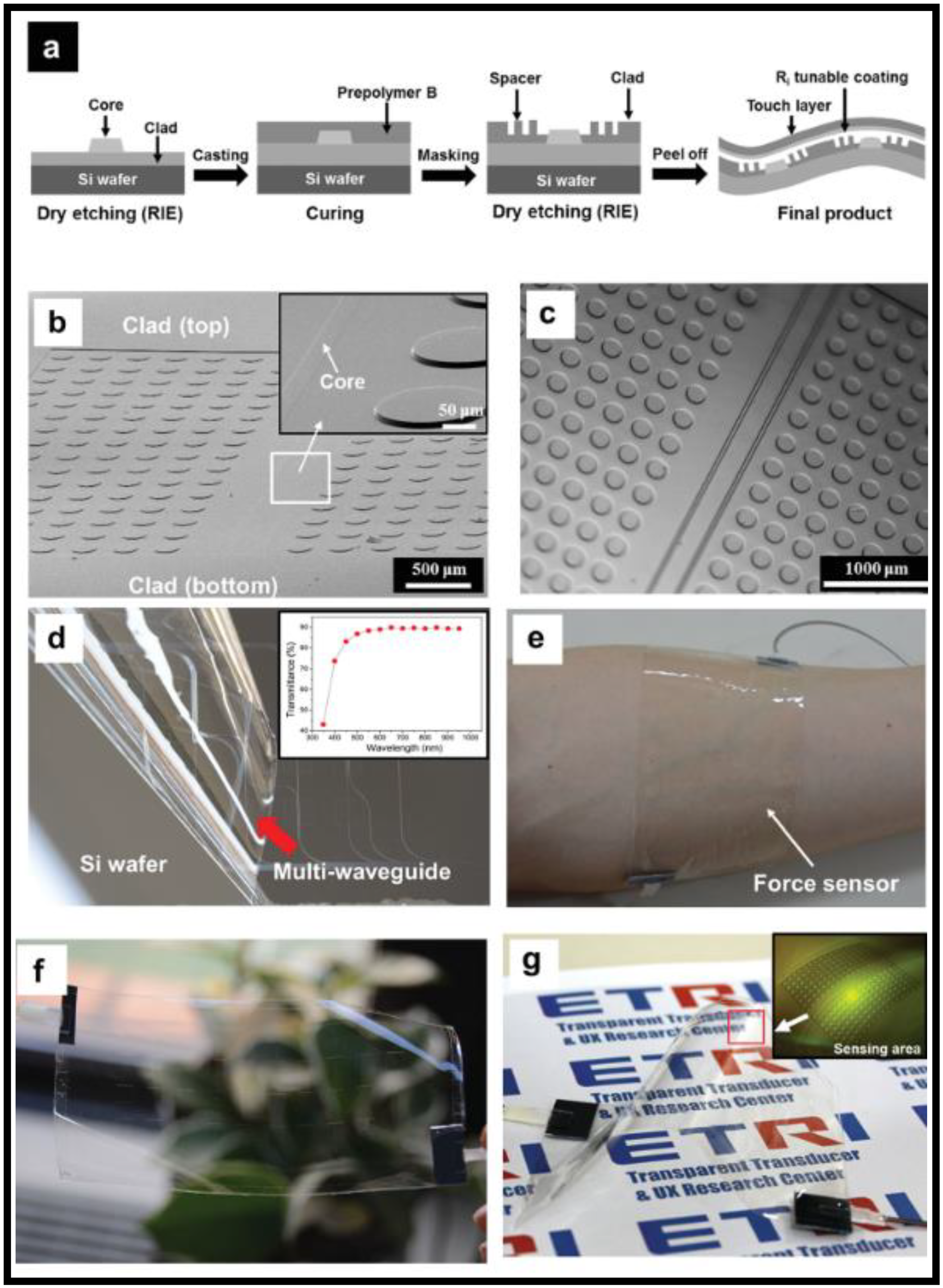

The main criteria, such as thin-film design, localized force sensing, multiple-point identification, and bending resilience, as well as a quick response for a tactile sensor functioning on curved surfaces, are satisfied by a polymer WG-based transparent and flexible force sensor array

[64]. A contact force with a location at 27 different spots is detected by the force sensor array separately. The sensor array is elastic, thin (total thickness: 150 μm), as well as very transparent (transmittance: up to 90%). The force sensor can detect contact forces at one or more points with a quick response (response delay: 10 ms), high replicability (Pearson correlation coefficient: as high as 0.994, hysteresis: as low as 6.7%), high sensitivity (as high as 16% N

−1), and high bendability (10.8% sensitivity degradation at a bending radius of 1.5 mm), all without utilizing any electronic components. Without noticeably degrading its function, the sensor can detect pressure on curved objects as well as soft ones like the human body. For detecting dynamic contact forces on different surfaces, the force sensor could be employed in a variety of applications

[64]. The fabrication process of the sensor is shown in

Figure 5a. The SEM image and an optical microscope image of the sensing area is shown in

Figure 5b,c, respectively. Despite its multilayered configuration, the WG layer exhibits excellent optical transparency of 90% in the range of 550–1000 nm, allowing removal from the stiff substrate without mechanical damage as shown in

Figure 5d. Due to the soft nature of the materials utilized for both the clad and core, the WG-based thin force sensor is mechanically resilient to bending, twisting, or folding and is capable of close contact with a forearm with great transparency and flexibility as shown in

Figure 5e–g

[64].

Figure 9. (

a) Fabrication process of a WG-based sensor, (

b) SEM image, and (

c) optical microscope image of a WG

[64], (

d) an image showing the construction of the waveguide layer being peeled from a Si wafer

[64], (

e) photo demonstrating the close proximity of a thin-film sensor to a forearm

[64], (

f) the transparency of the sensor

[64], and (

g) a photograph and an optical microscope image (inset) of a force sensor deformed by mechanical bending

[64].

A photopolymerizable resin solution that self-writes a strain sensor WG is described as an experimental demonstration

[65]. The sensor is created between two multi-mode optical fibers using ultraviolet (UV) light waves, and it functions as a sensor by examining the power that is passed through the WG in the infrared (IR) wavelength range. Following sensor failure brought on by loading, the WG uses UV resin to re-bridge the gap between the two optical fibers. Measurements reveal similarities in the responses of the original and self-repaired sensors under strain

[65].

Due to the weak mechanical strengths of most synthetic hydrogels, hydrogel optical WGs are frequently brittle and unstable when subjected to strain deformations. Due to the possibility of WG structural damage from body/tissue movement, this property limits their use in wearable or implanted sensors. For the creation of optical fibers, hybrid ionic/covalent hydrogels with high stretchability and toughness were used to produce great deformability and robustness. Hybrid alginate–polyacrylamide hydrogels have been molded and dip-coated to create robust, stretchable hydrogel optical fibers with an overall step-index profile

[66].

This entry is adapted from the peer-reviewed paper 10.3390/coatings13030549