1. Construction Methods

The main cable construction approaches of a suspension bridge are the air spinning (AS) and prefabricated parallel wire strand (PPWS) methods. The AS method takes the steel wire as the traction unit, multiple wires are made into a strand in the catwalk, and then multiple strands are bound to form the main cable. Different from the AS method, the PPWS method takes the cable strand as the traction unit, and then strands are bound to the main cable. The AS approach has been broadly utilized in the United States and Europe, and the PPWS method has been extensively employed in Japan [

57,

58]. China has mastered the PPWS erection technology [

4] by referring to Japan.

- (1)

-

AS method

The study of the AS approach has had a long history in Europe and America, but there are few practical engineering cases built in recent years, which leads to little relevant information being available. Most suspension bridges in China are built on the basis of the PPWS approach for the main cable erection, and there are few investigations on the AS method. The Yang Baoshan Bridge completed in 2022 is the first bridge constructed by China independently using the AS method, which is of great significance. The main cable’s construction principle and the technology of the AS method for the Yang Baoshan Bridge were reported by Liu et al. [

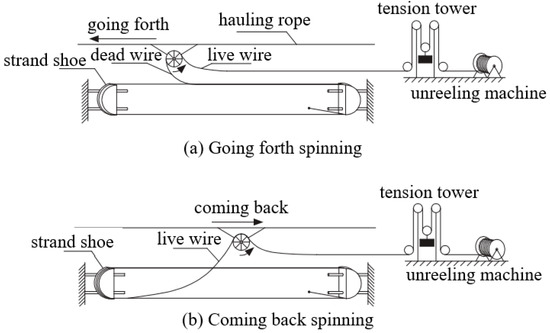

59]. It was pointed out that as the main cable was erected, the wire was released by the unreeling machine, and the constant tension of the wire was adjusted by the tension tower. The steel wire was driven back and forth between the two banks by a spinning wheel, thus carrying out wire erection operations. When the spinning wheel reaches the strand shoe position on both sides, the workers pull the steel wire out of the spinning wheel and hang it on the strand shoe, repeating the above operation until the single strand was erected. The basic principle of erection has been demonstrated in

Figure 8. Since the 21st century, suspension bridges have been also rapidly developed in Republic of Korea. Moon et al. [

60] introduced some improvement measures in the process of erecting the main cable using the AS method at the Yi Sun-Shin Bridge in Republic of Korea, focusing on the improvement of the spinning wheel to effectively avoid wire derailment during the erection process. To efficiently erect the main cable for long-span suspension bridges, the AS and PPWS technologies and associated equipment were currently being developed in Republic of Korea, based on a report by Kim et al. [

5]. Kim et al. [

61] briefly reported the erection methods and technical characteristics of five types of suspension bridges in Republic of Korea.

Figure 8. Construction principle of the AS method.

- (2)

-

PPWS method

PPWS is an approach of transporting prefabricated parallel high-strength steel wire strands to the site for installation. The main procedures of the PPWS method have been presented in

Figure 9. Yoo et al. [

62] reported the latest development and application of high-strength prefabricated parallel steel wire in Republic of Korea. The development and application process of high-strength PPWS strand were mainly introduced, including the test results of the strand performance test. The production system of the PPWS was also introduced, and the key points of its production equipment and production process were expounded. Recently, a 1960 MPa grade steel wire cable strand [

2] was created in China, and it was successfully used on the Nansha Bridge. The excellent mechanical properties of the strand were investigated through tests and numerical analysis.

Figure 9. The main procedures of the PPWS method: (a) arrangement and binding of the steel wire, (b) the strand forming, (c) transportation of the strand, (d) the traction of the strand, (e) adjustment of the strand, (f) main cable forming.

The AS and PPWS approaches have different characteristics. The suitable main cable erection method should be selected based on the needs of the features of the construction conditions, the main cable quality, construction period, and cost requirements. The characteristics of these two main methods based on the analysis given in the literature have been summarized in Table 1.

Table 1. Summary of characteristics of two methods.

2. Sag Control of Cable Strands

An important step in building the main cable is adjusting the strands’ sag. Controlling the sag of the cable strand, regardless of the type of erection technique used, is essential for maintaining control over the main cable shape. Particularly, China is experiencing a period of tremendous development for suspension bridges, where many of the recent works on this subject have been carried out. Through literature surveys [

57,

64,

65,

66], the general principles for the current adjustment of the sag of cable strands are summarized in the following.

- (1)

-

Sag adjustment method

In installing the main cable, the first strand is usually exploited as the reference strand, whose mid-span sag is controlled through absolute elevation. A strand other than the reference strand is called a general strand, whose mid-span sag is controlled by the height difference from the reference strand. The adjustment of each cable strand is carried out in accordance with the principle of the main span first, then the side span, and finally, the anchor span.

The core of sag adjustment calculation is aimed at determining the relationship equation between the adjustment of the unstressed cable length and the deviation of the sag, which is called the cable adjustment formula here. Although the cable adjustment formula [

67,

68] derived from the parabolic theory is easy to calculate, there are differences between the parabola and the actual shape of the cable. Tan et al. [

69] used catenary theory to derive the cable adjustment formula and obtained accurate results. However, the calculation is cumbersome and requires repeated iterations. Unlike the above derivation, Wang [

70] utilized the strand adjustment formula obtained via data fitting to adjust the reference strand of the Ying Wuzhou Yangtze River Bridge in China. An improved approach for reference strand adjustment calculation was also proposed by Deng et al. [

71]. The main cable shape equation was expanded using the Taylor formula at the targetfree cable state. The relationship between the cable length adjustment and the mid-span vector height variation was then obtained by solving the expanded equation. The method is easy to calculate and is highly accurate.

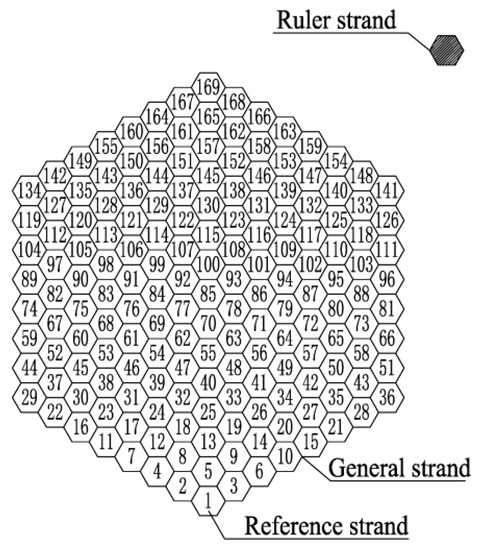

The key to sag adjustment is to ensure the accuracy of the reference strand alignment. In order to prevent the reference strand from being squeezed and become drooping by the general strand in the later stage, some scholars have made special treatment of the reference strand, such as the use of relative reference strands [

72,

73], adding strands that are not part of the main cable as a reference [

74], and canceling the sag adjustment step [

75]. To reduce the error accumulation in the main cable erection of the Run Yang Bridge, Li et al. [

72] reported that when adjusting the general strands, the three rows of strands at the bottom took the No. 1 strand as the reference, and when adjusting the sag of the remaining strands, a strand that had been adjusted at the same row or at the outermost of the next row was chosen as the reference. Then, the same approach was also exploited on Xi Houmen Bridge [

73]. This was conducted to solve the problem where the reference strand was pressed by general strands in the later stage and could not be employed as a reference for general strand erection. A ruler strand [

74] in

Figure 10, separated from the main strand, was proposed as a reference for the alignment control of the main strand. Tang et al. [

75] invented a strands erection methodology based on multi-standard wires, which can locate strands according to their marking points. Since the production accuracy of cable strands was enhanced by setting multiple standard wires, it was only necessary to align the cable strand mark points with the corresponding marks on the saddle during erection, and the strand sag did not need to be adjusted.

Figure 10. Space position of strands.

- (2)

-

Environmental conditions for the sag adjustment

The precision of the main cable erection is greatly influenced by temperature [

76]. According to the construction specifications [

66] in China, the sag adjustment of cable strand alignment should be carried out when the temperature becomes stable at night, and when the wind force is less than level 5. The temperature stability condition is that the temperature differences in the length direction and cross-section should not be greater than 2 °C and 1 °C, respectively.

In the sag measurement process of the cable strand, environmental factors such as temperature, wind, and rain lessen the measurement accuracy and efficiency, which directly affect the erection quality of the cable strand. Although a variety of advanced measurement techniques have been developed to enhance the measurement efficacy and accuracy, most of them were first proposed for the structural health monitoring of the finished bridges [

77,

78]. Although advanced measurement techniques in the construction process are not common, Huang et al. [

74] proposed a general strands alignment measurement approach based on the vision, and developed a vision-based sag measurement system, as demonstrated in

Figure 11. The actual height difference between the general strand and the reference strand was obtained by collecting and analyzing the image data, and the field experiment verified that the measurement error of this methodology is lower than 3 mm. However, the method solved the problem where the elevation of the cable strand cannot be measured, or where the accuracy is too poor in the strong wind environment [

79], it is still affected by the complex temperature field.

Figure 11. Vision-based system for relative sag measurement.

- (3)

-

Allowable deviation of the sag adjustment

The adjustment quality of the cable strand sag directly affects the free cable shape. In China, the construction specifications [

66] require that the strand shape should be controlled by the allowable deviation of mid-span elevation. The specific requirements have been presented in

Table 2.

Table 2. Precision requirements of strands erection.

The adjusting tolerance of the relative sag difference between the reference strand and the general strands during the construction of the Minami Bisan-Seto Bridge in Japan was ±30 mm [

57]. However, Birdsall suggested that this tolerance was too liberal, and perhaps 6 mm of deviation is acceptable [

80]. Although the specification has clear requirements for the erection accuracy of general strands, due to the complex factors affecting the erection accuracy of strands, the accuracy control of many projects has not yet adopted a unified standard in China, and the specific statistics have been presented in

Table 3.

Table 3. Control standards for erection accuracy of various bridges.

As for the erection of general strands, it is generally required to achieve the ideal state of “half approaching, half separation” between adjacent strands. To reduce the mutual interference between the strands in the erection process, and to alter the fuzzy requirements of the above idea, some scholars have quantified the inter-strand distance.

The reference strand will be pressed by general strands, due to internal and external temperature differences. During the erection of the Minami Bisan-Seto Bridge’s reference strand in Japan [

57], the height of the reference strand was raised compared with the theoretical position according to experience, but no specific basis or numerical value was given. When a suspension bridge was being built in Southwest China, the ideal state was not achieved when the strands were erected according to the principle of “half approaching, half separation”. To avoid the accumulation of errors, the second reference strand was exploited in time [

85]. In the erection of the strands of the Miaozui Yangtze River Bridge [

86], all the general strands were raised by 3 cm compared with the reference strand, to prevent the compression of the reference strand. The inter-strand distance was quantified while Jin Dong Bridge’s main cable was erected [

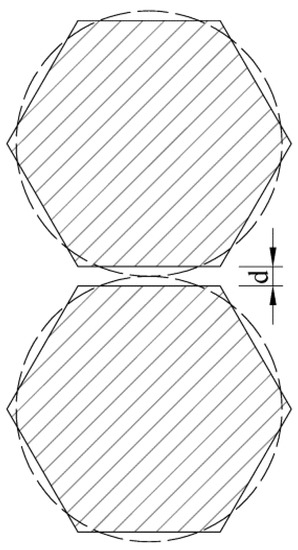

65]. The inter-strand distance, denoted by d in

Figure 12, represents the difference between a circle’s diameter having an area equal to a hexagon, and the vertical separation between the top and bottom borders of the hexagon. During the erection of the strands of the Wu Fengshan Yangtze River Bridge [

84], the temperature difference of 0.5 °C determined how far the strands were spaced in the main span’s center; that is, to ensure that the strands would not collide with each other over a temperature range of 0.5 °C.

Figure 12. Quantified inter-strand distance.

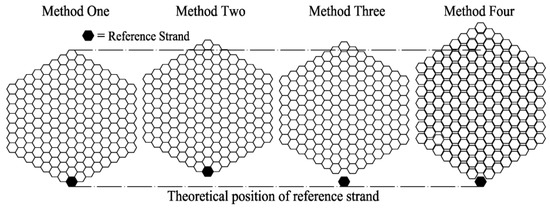

According to the literature analysis, currently, there are four methods for controlling the inter-strand distance in the main cable erection process, as shown in

Figure 13. The first method is that the inter-strand distance is controlled according to the principle of “half approaching, half separation”. Nevertheless, it is difficult to achieve due to the existence of errors, and new reference strands must be added [

85]. The second approach is to raise all the strands to a particular height [

57]. The third method is to lift all the general strands as a whole to a specific height [

86], and the fourth approach is to lift all the general strands to a specific height over the adjacent layer [

65,

84]. From the above, there is no unified control or evaluation standard for cable erection. The main reason is that the cable erection alignment is sensitive to error factors. Complex influencing factors and an irreversible erection process make it difficult to form a unified and accurate control method.

Figure 13. Various control methods of the inter-strand distance.

3. Other Control Technologies

Although strand manufacturing accuracy and overall quality can meet the requirements of cable shape control, there are some studies and attempts to improve the accuracy of cable strand production and to simplify the manufacturing process. For this purpose, Zhao et al. [

87] invented an approach to control the manufacturing accuracy of cable strands by using a ruler wire. This methodology exploited a ruler wire to measure the standard wire in cable strands, which reduced the discreteness of deviation in the traditional production process of standard wire between cable strands. However, this method is very dependent on the standard wire, and once the standard wire deviates, it leads to more serious consequences. Dan [

88] developed a segmental suspension length measurement method to control the length of the cable, that is, when the cable strand was suspended freely, the length of the strand can be indirectly measured by controlling the alignment of the suspended strand. This approach can eliminate the influence of the elastic modulus and the steel wire diameter error on the stress-free cable length, and avoid the problem of artificial tension in traditional methods. However, this method has high requirements for manufacturing sites and is not used in practical engineering.

Additionally, Wang et al. [

89] suggested a novel lateral bracing-based method (LBM), which solved the problem of 3D curved cable configuration transformation for spatial suspension bridges. This is also the embodiment of advanced construction methods in the main cable erection process.

To sum up, both the AS method and the PPWS method are focused on new technology, new equipment, and high-strength materials. Although the characteristics of the AS and PPWS methods are different, the adjustment of sag is the key to controlling the cable shape in these two approaches. The improved cable adjustment formula makes the cable strand erection calculation more efficient and accurate. The use of relative reference strands is the mainstream method to ensure the quality of erection, but there are also interesting methods such as the use of the ruler cable and mark method to erect cable strands, which enriches the means of cable strand erection. The measurement method based on machine vision undoubtedly provides a new idea for construction measurement. Although the relevant specifications stipulate the deviation range of cable erection, the error control standards of specific projects are still not uniform. However, quantifying the cable spacing to achieve cable pre-lifting is a commonly used method in current projects, but the quantitative values and control methods are different. In addition, the cable strand manufacturing and temporary construction equipment were studied to ensure erection accuracy. The above exploration undoubtedly promotes the development of the main cable shape control of suspension bridges.

This entry is adapted from the peer-reviewed paper 10.3390/app13053106