Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Management

The disruptions caused by the COVID-19 pandemic have forced many companies in the logistics sector to innovate, or even transform their business and underlying processes. Closing borders, limited supply and manpower, and continuous changes in regulations challenged many logistics firms to innovate.

- COVID-19

- digitalization

- logistics

- resiliency

- sustainability

1. Introduction

The COVID-19 pandemic has brought huge disruptions and challenges to supply chains, affecting many industries worldwide. For instance, in various countries, healthcare systems have been under extreme levels of stress due to the capacity issues such as shortage in personnel, equipment, and space in hospitals and the poor governance of infections [1,2,3]. Many airlines suffered huge losses and bankruptcies because of increased travel restrictions and uncertainties posed by changing regulations [4]. Recreational industries such as restaurants, hotels, and gyms were also hit by huge losses due to implemented lockdowns to curb the spread of infections [5].

The logistics sector is also experiencing risks and challenges brought by COVID-19 pandemic. Crossing border of goods became much more complex due to imposed lockdowns at national and international levels, hampering logistics operations and causing delays in delivery of goods. A decline and shortage of logistics service providers (LSPs) for transporting goods were also observed, especially at the beginning of the pandemic [6]. Many manufacturing companies were forced to close plants due to government regulations, thereby reducing the supply of goods. Other companies shifted their focus on manufacturing in-demand products during COVID-19. In the global logistics transportation alone, the value of losses in revenue due to COVID-19 pandemic is estimated to be 1.1 trillion euros in 2020 [7].

The COVID-19 pandemic has also affected, both positively and negatively, the adoption of innovation in the logistics sector. On the one hand, authors have argued that the COVID-19 pandemic sped up the transformation and innovation in the logistics sector, e.g., [8,9,10,11]. Online businesses blossom since the start of the pandemic and lead to increased need for innovations in logistics to deliver goods to consumers [8]. Companies have also recognized the need to adopt robust and resilient supply chains and logistics by making them smart, digitalized, and sustainable during the COVID-19 pandemic [9,10]. For example, in airline industries, COVID-19 led to innovations such as the utilization of touchless technologies at airports, the use of ultraviolet light (UV) for disinfecting aircrafts, and the use of biometrics to accelerate check-in processes [11]. COVID-19 is also reported as a main driver behind the adoption of digitalized and data-driven solutions in LSPs [6]. On the other hand, some authors reported that many logistics companies still struggle to innovate mainly due to the obstacles brought by COVID-19, e.g., [12,13]. Even though many EU countries have adopted the use of digital freight documents during the pandemic, a few countries have not yet switched to digital freight documents, causing bottlenecks in the operational processes of the LSP sector [6]. For Small and Medium Enterprises (SMEs), their capacity to innovate has been limited due to their size, ownership structure, and vulnerability to external shocks such as the pandemic [13].

2. Logistics Innovations in Response to COVID-19 Pandemic

The COVID-19 pandemic revealed the vulnerability of many businesses that rely on traditional way of operating [11]. This enhanced the demand for business innovations to cope with the challenges brought by the COVID-19 pandemic. Innovations are not only related to the introduction of new products such as goods or services to the market, but also to the improvements and advancements in the business processes, procedures, and routines [21]. However, there are opposing views when it comes to the response of firms to innovation during a crisis. Some studies argue that hardships and crises, such as the COVID-19 pandemic, incentivize companies to innovate to cope with the shocks and effects of the crisis [11,21]. Other studies suggest that crises reduce and discourage firms to invest in innovations as many innovation activities become unsustainable [12,22].

Innovations play an important role in keeping supply chains and the underlying logistics processes viable, especially in times of disruptive events such as COVID-19 pandemic. As defined by Ivanov and Dolgui [23], viability is the ability of the system to cope with demands of surviving in a changing environment. Viability is an important aspect for businesses to survive, avoid market collapses, and secure provision with goods and services [23].

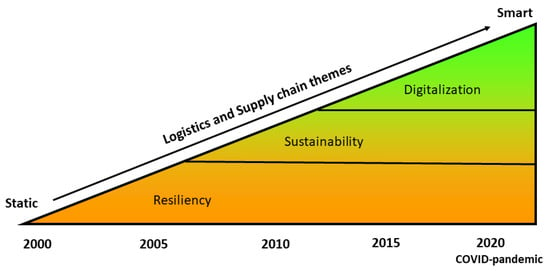

Resiliency, sustainability, and digitalization are key concepts towards viable supply chains and logistics [9]. These key concepts have emerged through time and have been individually studied by scholars. The COVID-19 pandemic period demonstrated that the (potential) added value of these key concepts should be considered in conjunction. Figure 1 shows the evolution of these concepts and the ways in which it leads to the development of smart logistics and supply chains. Ivanov [9] argued that logistics and supply chain viability can only be achieved by approaching the resiliency, sustainability, and digitalization at an holistic perspective and not individually. The concepts of resiliency, sustainability, and digitalization found in Figure 1 are used to analyze the trends and innovations in logistics before and after the onset of COVID-19 pandemic. The remainder of this section elaborates these concepts.

Figure 1. The evolution of the three key concepts based on Ivanov [9].

Resiliency refers to the ability of an entity to adapt to both positive and negative shocks and disruptions caused by both internal and external environments [24]. The first studies on resiliency in the context of supply chains and logistics, which are still of relevance today, date back to the early 2000s [9,25,26]. The resiliency of the chain relates to visibility, managing risks, and reducing the complexity of networks [27].

The resiliency of supply chains and logistics processes can be enhanced via sustainability strategies. Sustainability plays an important role in reducing the environmental impacts of commercialization and industrialization and in reducing inefficiencies and wastes in the operation. The era of sustainability in supply chains and logistics started around 2010 [9]. The early focus on sustainability revolves around three themes, namely reverse logistics, emission assessment and the greening of logistical activities and supply chains [28]. Specific examples under these sustainability themes include reduced CO2 emissions of freight and transport companies, using green packaging, bundling goods, optimizing routes, using spaces more efficiently and reducing wastes in processes [29]. As the definition of sustainability continues to evolve, the social and economic aspect of sustainability also began to be incorporated in the study of sustainability in relation to supply chains and logistics [30]. Social topics include the incorporation of corporate social responsibility such as fair trade and wages, good employment practices, good working conditions, and responsible relationships with suppliers and customers. Economic aspects include the maximization of shareholder wealth or value while taking into consideration the environmental and social values.

Digitalization has also been linked to transforming supply chains and logistics towards a more sustainable and resilient state than before [31]. The availability of digital solutions, data and computing powers makes it possible to model and analyze logistics in an integrated and more detailed manner. Specifically, digitalization has potential impact to reduce CO2 emissions from logistics, empty drives, fuel consumption and number of vehicles to deliver goods to consumers [31,32]. Although digitalization has been an ongoing topic for decades, the era of digitalization that includes Industry 4.0 and Data Analytics only started to dominate the field of supply chain and logistics since the beginning of 2015 [33,34]. Digitalization in logistics includes implementation of new information technologies such as Internet of Things (IoT), blockchain, simulation, sensors and the use of generated data to make logistics smart [35]. The advantages of digitalization in logistics include but are not limited to real-time and full transparency of information across the supply chain, decentralized and interconnected processes, and self-governing management that includes automation [32].

This entry is adapted from the peer-reviewed paper 10.3390/pr10122667

This entry is offline, you can click here to edit this entry!