1. Pineapple Production

Pineapple (i.e.,

Ananas comosus, Bromeliaceae family) is a fruit that is native to South America, specifically Brazil, Paraguay, and Argentina. It was discovered on Christopher Columbus’s second visit to this area, and consumption of pineapple spread during the 16th century due to trade along the Spanish and Portuguese sea lanes. Cultivation of this fruit can take between 14 and 20 months and involves three stages: planting and growth of shoots, flowering and harvesting, and the production of new shoots for future plantations [

9].

Worldwide, pineapple cultivation has been very successful. There is a high demand for this fruit in the international market, mostly due to its flavor. Its high fiber content and potassium, iodine, carbohydrates, fiber, and vitamins A, B, and C, have prompted recommendations to consume pineapple to treat such diseases as fluid retention due to its diuretic effects, hypertension, cholesterol, anemia, poisoning due to its purifying action, immune system disorders due to its ability to strengthen defenses and assist in the formation of both red and white blood cells, cardiovascular problems, and obesity, among others [

10,

11].

Due to its tremendous success in the international market, pineapple cultivation has become a global industry. According to FAO, 2019 exports rose to 3.1 million tons, mainly due to the increase in Philippines exports and importations into China. Costa Rica is currently the largest producer and exporter of pineapple, followed by the Philippines and Brazil [

12].

It should be noted that there is a variety of pineapples, each of which has different characteristics that make them widely traded. One variety is the Smooth Cayenne, which has a high yield, good potential for conservation, and organoleptic qualities; this pineapple is sensitive to problems such as black spots and other parasites, however, which can affect the overall quality. It is why MD 2, or the “Golden Pineapple,” was developed in the 1980s; this variety has excellent preservation properties, flavor, color, and minimal sensitivity to parasites and discoloration, and it is the most popular variety in commerce and exportation. There are several other widely distributed varieties, including but not limited to Queen Victoria, Sugar Loaf, and Champaka [

9].

As was already mentioned, Costa Rica is the largest global producer and exporter of pineapple, followed by Philippines and Brazil. As mentioned before, pineapple exportation began in Costa Rica in the 1980s with the integration of the Pineapple Development Company (i.e., Pindeco), which led to increased production and higher crop yield [

13]; this occurred with the use of imported technology and the creation of dependence on chemical inputs, such as herbicides, fungicides, insecticides, and fertilizers [

14]. Production began to increase significantly: 24,204 tons of pineapple were produced in 1984, and this increased to 651,000 tons by 1998 [

3]; production expanded to plantations in the Huetar Norte, the Atlantic Zone, and throughout the Central and South Pacific area. During this period, pineapple production began to gain additional relevance because of reducing poverty in rural sectors through the generation of direct and indirect jobs; there were 4200 direct jobs in 1995, and these grew to more than 31,000 in 2015 [

1].

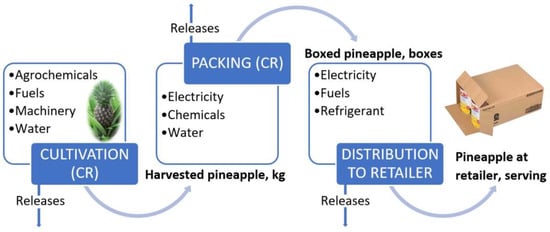

The Costa Rican pineapple production process (

Figure 2) begins with cultivation, which requires the use of agrochemicals, machinery, fuels, and water; this process results in pineapple that can be exported and product that remains for local consumption. In the case of exportation, there is a packaging process before this fruit is exported to different countries and continents, and the United States and the European Union are the main importers of pineapple [

5].

Figure 2. Diagram of fresh pineapple system [

5].

2. Main Raw Materials from Pineapple Biomass

2.1. Lignin

Lignin is one of the most abundant biopolymers and is exclusively found in vascular plants, where it fulfills its function by providing structural integrity and mechanical resistance [

37,

38]. From pineapple peel wastes, lignin is in the range of 15–30% by dry weight [

39]. Lignin is formed by a reaction of photosynthesis in cell walls, and it has a resin role because it fills spaces between cellulose and hemicellulose, thereby providing support for lignocellulosic biomass. Lignin is known for its complex structure, and depending on where it was extracted, it has been found multiple unrepeatable structural units [

40]. Certain characteristics are typical of most lignins; for example, lignins formed as a result of phenylpropanoid contain most of the methoxyl groups of wood, are resistant to acid hydrolysis and produce vanillin, syringaldehyde, and p hydroxybenzaldehyde when reacting with nitrobenzene in an alkaline solution [

37].

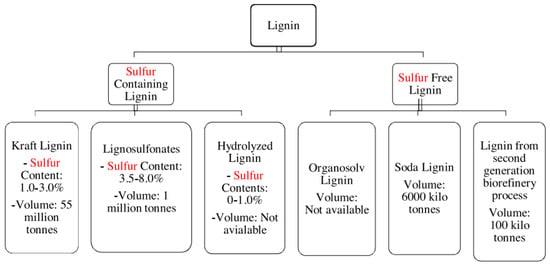

As has already been mentioned, lignin comes in different forms and structures, and these can affect the properties and characteristics of its conversion into value-added products. These are usually classified according to the sulfur content thereof, as shown in

Figure 6; the lignin with the lowest sulfur content is the most ecologically sound and has more applications due to the smell of other types of lignin [

41]. Lignin that contains sulfur is derived from the paper industry and is divided into three categories: Kraft lignin, sulfite lignin, and hydrolyzed lignin. Lignin with no sulfur content is primarily created through biomass conversion technologies and solvent and soda pulping processes; this type of lignin has the highest number of applications in the creation of value-added products [

41].

Figure 6. Different sources of lignin and their current volume on scale global [

41].

Multiple studies have been conducted to improve lignin extraction from lignocellulosic biomass, devise more effective extraction methods, and enhance the purity of extracted lignin, which employed several different methodologies. One of the greatest challenges in the lignin extraction process is the existence of a lignin–carbohydrate complex, which consists of different reactive components that are covalently bonded to hemicellulose; this is why it is necessary to extract lignin and achieve depolymerization in the most efficient manner possible to break these bonds, even though the reactivity of these components creates new C C bonds after depolymerization that form different intermediates with different properties [

39].

There arephysicochemical technology and biological techniques that can be employed during lignin depolymerization: The first is achieved through the use of high temperatures and chemical additives, catalysts, and other compounds, which are commonly used in industrial areas. While the second technique, biological depolymerization, is a slower process, it is more environmentally friendly; this technique uses microorganisms such as bacteria and fungi to degrade lignin due to lignin-modifying enzymes that act by oxidative means, which can be classified according to their specific mechanism-of-action and according to the organism from which they originate [

42].

There are also thermochemical techniques that can be employed. The most-used technique is the hydrogenolysis of lignin by means of solvents and catalyst systems. The most-commonly used solvents for this process are water, various alcohols, and compound solvents, which define the efficiency and distribution of products according to the specific characteristics of each compound, such as solubility, polarity, and the capacity of hydrogen supply [

43]. There are also a variety of catalyst systems, including but not limited to acidic, basic, metallic, and ionic liquid catalyst systems. In the case of liquid acids, there is significant use of formic acid, sulfuric acid, hydrochloric acid, and phosphoric acid; the most commonly used solid acids are zeolite, metal oxides, metal phosphides, and Lewis acid; and basic catalysts include NaOH, KOH, MgO, and Na

2CO

3, and metallic catalysts such as Fe, Ni, Cu, and Co are also used [

43]. Different systems have been devised that use solvent and catalyst variations, as well as different reaction times and temperatures; some examples of these are shown in

Table 2.

Table 2. Conversion of lignin in different solvents [

43].

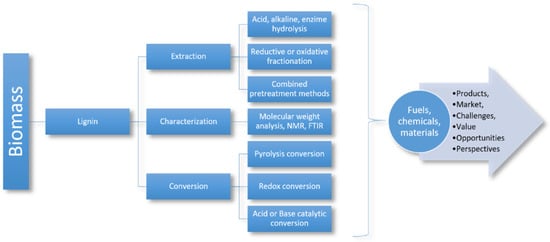

The lignin extraction process consists of three steps, which are illustrated in

Figure 7. The first step is the extraction of lignin from biomass, which can be achieved by several methods, including hydrolysis, oxidation or reduction fractionation, and a combination of pretreatment methods; followed by this. In the second step, the characterization process is continued by molecular weight determination, nuclear magnetic resonance analysis, and Fourier transform (FTIR). In the third and final step, the conversion process is conducted by different methods to obtain different products [

39].

Figure 7. Overview of valorization of lignin to valuable products [

39].

Regarding the environmental impact of this process, the use of products made from lignin have been shown to greatly assist efforts to combat climate change and the greenhouse effect, since one of the main by-products reduces the use of fossil fuels. Furthermore, the use of renewable, environmentally friendly biofuels derived from lignin to produce heat, electricity, and automobile fuel can further reduce the carbon footprint of these products and processes [

41].

2.2. Cellulose

Like lignin, cellulose is a biopolymer widely found in nature, mostly in plant bodies, some types of algae, the extracellular activities of microorganisms, and the structures of some marine animals. It has a semi-crystalline structure that is based on glycosidic bonds, which vary depending on the source from which the cellulose was obtained, resulting in multiple morphologies and structures that generate different physicochemical properties [

56]. Cellulose is a biopolymer composed of groups of two or more repeated glucose units and these can form microfibrils when several cellulose strands are connected to one another. These microfibrils are typically found in the cell walls of trees and plants, and they provide flexibility, strength, and rigidity; the latter is because cellulose is hydrophilic, and absorbing water allows it to create a softer and more flexible wall [

57].

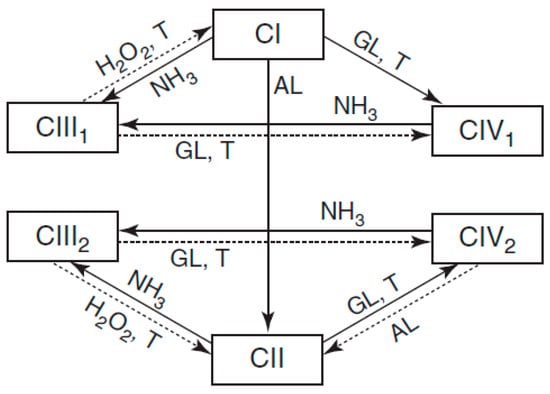

The morphology of cellulose is presented in crystalline form, with a strong system of hydrogen bonds in intra and intermolecular forms, which generate a highly ordered, rigid, and strong crystalline structure. Four polymorphic structures of cellulose are currently known—named as I, II, III, and IV—and the mechanisms of each have been studied to understand the different structures of native cellulose, as shown in

Figure 8 [

58].

Figure 8. Scheme of transitions between various polymorphic crystalline forms of cellulose CI (native cellulose), CII (cellulose), CIII1 and CIII2 (cellulose III1 and III2), and CIV1 and CIV2 (cellulose IV1 and IV2) [

58].

Cellulose is considered a compound with tremendous potential due to certain characteristics it possesses, such as its biodegradable, renewable, hydrophilicity, high absorbent potential, non-toxicity, and mechanical properties and its safety when discarded after use. The wide availability of cellulose in lignocellulosic materials such as wood biomass, coconut, mango, tomato, almonds, and pineapple has made it possible to generate several applications for crude and modified cellulose, with it being most commonly used as an absorbent to eliminate pollutants in wastewater and as a precursor for activated carbon [

59]. Cellulose has also been found to have a property that facilitates the separation of solutions of water and oil; this was investigated, and several materials were created to treat oily wastewater in a simpler, more efficient, and environmentally friendly manner than traditional methods that caused other types of pollution and were typically more expensive [

60].

Regarding the cellulose present in pineapple waste, more than 55% of the fruit is fibrous waste composed of lignin, hemicellulose, and cellulose, with cellulose representing a large proportion of this waste [

61]; as was previously stated, the proportions of each vary according to the source of extraction, as is shown in

Table 3 [

62].

Table 3. Lignocellulosic material composition [

62].

Due to its great abundance in pineapple residues, several treatments, and pretreatments for cellulose, microcellulose, and nanocellulose have been studied to identify applications in the field of biomaterials. Examples for this are biofuels such as bioethanol that are obtained by extracting cellulose from pineapple bagasse, which can be carried out through initial physical pretreatments of the waste such as drying and washing, followed by acid hydrolysis. After two phases of sulfuric acid for six hours, the fermentation of the obtained cellulose obtained is continued with the use of yeast such as S. cerevisiae, and the bioethanol is finally obtained with a final distillation [

63].

The properties of nanocellulose include a high resistance to bending, which is helpful for the reinforcement of polymeric matrices and a great stabilizing potential for suspensions; this is why nanocellulose is used as an excipient in medications for enzymatic immobilization and to provide scaffolding for tissue engineering and biosensors. It is necessary to carry out two different acid hydrolysis processes on cellulose: HCl is added in the first step to obtain microcrystalline cellulose, which is then hydrolyzed with sulfuric acid, thereby reducing the lignin content, and allowing nanocellulose fragments to be obtained [

64]. There are several methods to evaluate the treatments, properties, and composition of nanocellulose extracted from pineapple, which make it possible to obtain information of the chemistry, morphology, crystallinity, and thermal properties thereof that are useful to know when considering possible applications in value-added products. Some of the techniques used are high-resolution liquid chromatography, FTIR, scanning electron microscopy (SEM), X-ray diffraction analysis, and thermogravimetric analysis [

65].

A study on nanocellulose demonstrated the great thermal stability thereof that makes it an affordable means to create bionanocomposites; it was also shown that cellulose pretreatments could be optimized based on tensile properties, reagent concentrations optimized in hydrolysis increases the amount of cellulose that can be obtained, and an efficient pineapple crushing process can improve mechanical properties of nanocellulose, such as its tensile strength [

65]. In another study on the production of nanocellulose from pineapple leaves, acid hydrolysis was used as a pretreatment in conjunction with bleaching to eliminate other hemicellulose and lignin, after which a homogenization process that involved high shear and ultrasounds was carried out to obtain nanocellulose. After the final product was obtained, several studies were conducted, which determined that the degradation temperature of nanocellulose fibers is significantly higher than that of the initial fiber, which indicates that it has great thermal stability and commercial potential [

66].

Nanocellulose is currently being investigated for a variety of valuable applications because of its potential for large-scale production, its mechanical properties, and its characteristics such as low thermal expansion, thermal stability, and biodegradability, among others. Some examples of applications include use in adhesives, paper-based materials, cement, food coatings, drilling liquids, transparent and flexible electronics, catalysis support structures, and biomedical materials [

67].

2.3. Hemicellulose

Hemicellulose is a mixture of several heteropolysaccharides in branched form, which varies depending on the location origin or extraction. The presence of pentoses, hexoses, and uronic acids stands out because of the amorphous nature of its branched shape, which is why hemicellulose is easier to solubilize and hydrolyze than cellulose and is, therefore, easier to obtain. There are two types of hemicelluloses: xylose, which is mainly found in hardwoods, and glucomannan, mainly found in softwoods. Hemicelluloses are found with lignin and cellulose in the cell walls of plants, where it acts as an interface between these compounds through hydrogen bridges, which allows them to fulfill several functions, such as the storage of substances and regulatory functions, providing structure, and controlling cell expansion [

68].

One of the most common applications for all the components of lignocellulosic biomass is the creation of biofuels, such as bioethanol. A study on the role of hemicellulose in this process proved that it can be carried out by enzymatic hydrolysis with a two-phase multiscale process, and it was shown that after an optimal initial mixing that maximizes sugar yields and minimizes costs, said sugars are fermented until bioethanol is obtained with the use of yeasts or bacteria. This process has pretreatment, enzymatic hydrolysis, and fermentation [

69]. Associated with this study, a different study indicated that pretreatment could improve the time and efficiency of enzymatic hydrolysis; microwave radiation was employed in conjunction with a hydrothermal-and-alkaline pretreatment, which resulted in a significant improvement in enzyme digestion, and a yield of 89.4% was obtained, compared to untreated residues wherein only 71.6% and 28.4% were obtained [

70].

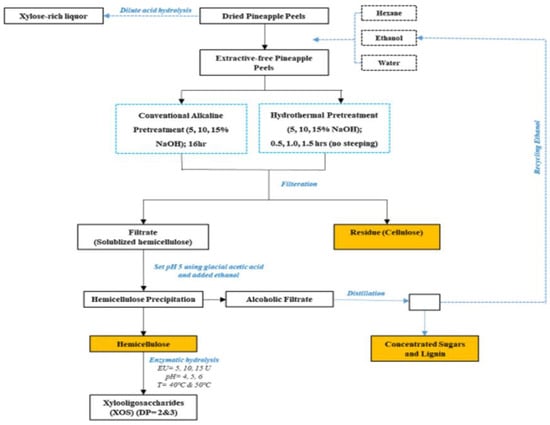

A study on hemicellulose in pineapple peels used an alkali-based method with 5%, 10%, and 15% concentrations and temperatures ranging from 36–65 °C, and a yield of more than 95% of the hemicellulose was obtained under the following conditions: a 15% concentration for 16 h at 45 °C. This study also discussed applying acid hydrolysis directly to the pineapple skin using diluted nitric acid such as xylitol. Finally, the study described the entire process of extracting hemicellulose and converting it into xylooligosaccharides and xylose, which are high-value end products that can be used to create biofuels and other products; this process is presented in

Figure 9 [

71].

Figure 9. Schematic for extraction of hemicellulose from pineapple peel waste and its valorization into xylooligosaccharides [

71].

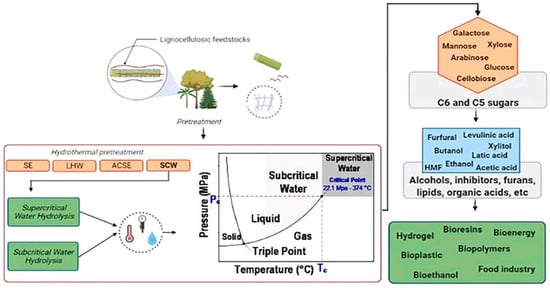

Associated with this study, a different study affirmed that mass fractionation techniques are necessary to achieve the highest, most efficient recovery of hemicellulose, of which a hydrothermal pretreatment was shown to be the most prominent and valuable due to the use of high temperatures and pressures; this study also discussed several pretreatments of this type, such as supercritical water hydrolysis and subcritical water hydrolysis, as shown in

Figure 10; these make it possible to recover a large number of products and result in several applications related to bioresins, bioenergy, hydrogels, bioethanol, food industry, among others [

72].

Figure 10. Hydrothermal pretreatments applied to lignocellulosic biomass and the possibility of multi-product recovery [

72].

This entry is adapted from the peer-reviewed paper 10.3390/polym14224864