Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Civil

Prefabrication is a well-established method that is widely accepted and executed across many countries around the globe. Much work goes into prefabrication projects that span across several project phases. Some of the most unique and important aspects are acquiring raw materials, manufacturing, transporting, and installing prefabricated elements on a site. Post-occupancy, the study of the on-site performance of end products, validates the achievement of the expected design objectives, furthering the development of the project processes, and also helps identify research voids that must be filled. Technology has a way of expanding as it upgrades itself by virtue of growth in research and development areas. There is an ever-growing demand for the adaptation of new technologies in the prefab industry. Many stakeholders such as the clients, contractors, industry practitioners (e.g., architects/designers), and end-users are involved in this process, and it is important to consider their perspectives.

- prefabrication

- sustainability

- materials

- technology

1. Material Adaptation in Prefab

Traditional construction methods involve materials such as timber, concrete, steel, and clay. During the initial years of prefab, timber had a major role, but later, steel and concrete were incorporated into prefab designs [19]. With an increased focus on sustainability in construction, the prefabrication industry has replaced traditional materials with agro-industrial by-products. The increased carbon footprints, higher energy consumption during manufacturing processes, and transportation challenges accompanying the exploitation of natural resources led to greener/sustainable alternatives to replace traditionally used prefab materials [20]. The utilisation of locally available raw materials has also ensured better performance and a reduction in construction costs [21]. Moreover, cement is an energy-intensive construction material, has significant usage in traditional concrete and other construction products, and is also responsible for about 7–8% of total CO2 emissions [22,23,24]. Hence, a paradigm shift towards using materials such as fly ash, rice husk ash, silica fume, ground granulated blast furnace slag (GGBFS), geopolymers activated with other bio-ashes, and other similar materials has been observed over the past few decades [7,25,26,27,28,29,30]. The replacement of naturally available aggregates with crushed aggregates, industrial by-products, construction and demolition (C&D) waste, and recycled concrete aggregates was found to be efficient in a sustainable approach [7,21,31,32].

Prefabrication, a factory-based process, offers the flexibility of choosing raw materials, whether from locally available natural sources or manufactured sources. The flexibility has resulted in cost-effective and energy-efficient end products. Further research into the development of such designs has yielded the idea of precast concrete sandwich panels [26] and precast large construction panel (PLCP) [20] systems. These were developed with an insulating member sandwiched between two layers of concrete, often called concrete wythes, connected with the help of mechanical connectors.

Portland cement concrete, foamed concrete (FC), ultra-high-performance concrete (UHPC), textile-reinforced concrete (TRC), and fibre-reinforced concrete (FRC) have all been tested as concrete panels [26,27,28,29]. Adding to this list are high-performance fibre-reinforced concrete (HPFRC), ultra-high-performance fibre-reinforced concrete (UHPFRC), and self-compacting concrete (SCC). Other novel enhancements include using high-density geopolymer (HDG) in concrete sections and light gauge steel-framed structure (LGSFS) in steel sections [20,30,31,33,34].

Insulating materials act as the media of thermal resistance, and the materials used for this purpose are expanded polystyrene (EPS), polyurethane (PUR), polyisocyanurate (PIR), extruded polystyrene (XPS), vacuum-insulated panel (VIP), and several others [26,35,36]. Reinforcements such as steel, glass mesh, bamboo, carbon textile, polypropylene fibres (PF), and glass fibre-reinforced polymer (GFRP) bars have been used for making the prefab panels [37,38,39,40].

As fly ash is widely available across the globe, its involvement in mix designs has helped cement usage reduction as well as the enhancement of material properties. Many of the old structures have reached their service life and their demolition is necessary. Increased waste from demolition is a challenge to manage and dispose. Advancements in construction have enabled the utilisation of many alternate raw materials as mentioned in the earlier literature. Lean technologies and the need for energy-efficient construction practices have led to panelised prefabrication systems with the application of insulation materials. Utilising the locally available natural and alternate raw materials proved their significance in cost reduction and environmental safety.

2. The Basic Building Blocks of Prefab

Prefabrication is a reliable and cost-efficient alternative to traditional construction practices. It was first implemented as precast railway sleepers in the late 19th century but rose to prominence during World War II due to its ability to expedite construction. The war served as a catalyst that led inventors to expand the knowledge base of prefab, and the prefab industry grew from the simplistic size-constrained railway sleepers to design-friendly complex construction components. Gradual advancements over the years led to small-scale beams, columns, slabs, mid-scaled walls, roof panels, modular rooms, and eventually to full-scale houses. Prefabrication has proven useful for framed structures, where structures are made of either homogenous or composite elements, and for load-bearing structures such as panelised and modular buildings [56,57].

The concept of maintaining thermal comfort inside buildings has resulted in the insertion of insulating materials into the conventional building components. Such advancement brought in the production of precast concrete sandwich panels, where an insulating sheet is inserted between two precast concrete wythes and connected through connectors [26,30,33,35,43]. The introduction of insulating material in precast walls, roofs, and floor panels was achieved using materials such as magnesium oxide (MgO) boards, orthotropic shell components, and plasterboard, along with concrete [11,41]. Bonding between concrete wythes and insulating layers was achieved by inserting mechanical connectors, applying epoxy, or using an in-pressure casting technique [43,51,52].

The precast approach is used even for the smallest of the components, such as cover blocks, and non-structural elements, such as door and window frames [21]. The precast panels are also being used as building envelopes, such as façade panels, which increase both aesthetic value and energy efficiency of structures [38,50]. Apart from the major elements used in buildings, there are specific components such as the embedded parts, polyethylene plastic strips, and waterproof plastic, which are helpful during assembly, achieved through innovation in precast technology [10]. In summary, whatever level of complexity was expected, the prefabrication industry achieved it in time by adapting and innovating to meet the changing needs. Moreover, most of the prefabrication included wall panels either structurally placed or as sandwich panels.

3. Performance

Various combinations of materials were trialled over the years to manufacture prefab elements. The aim was to achieve better properties compared to traditional construction products and components. Some of the properties are discussed in the following sections.

3.1. Mechanical Performance

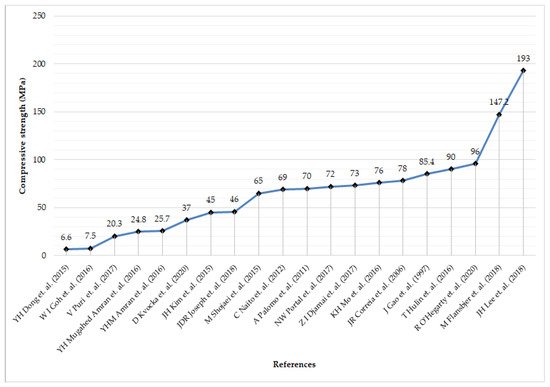

With the increasing demand for longer spans, high-rise buildings, and larger structures, the major governing factor in concrete’s performance lies between compressive strength and density among the other mechanical properties [47]. Similar expectations exist for prefab elements. The majority of the studies in prefab construction have been conducted to determine the compressive strength of various prefab elements. A significant improvement was observed in prefab elements wherein the compressive strength of high- and ultra-high-performance concrete reached up to 193 MPa [26,30,33,49,53]. In comparison, the conventional concrete reaches only up to 20 MPa. Figure 3 shows the variation in compression strength starting from 6.6 MPa to 193 MPa studied in this review.

Figure 3. Compressive strength in the presented literature.

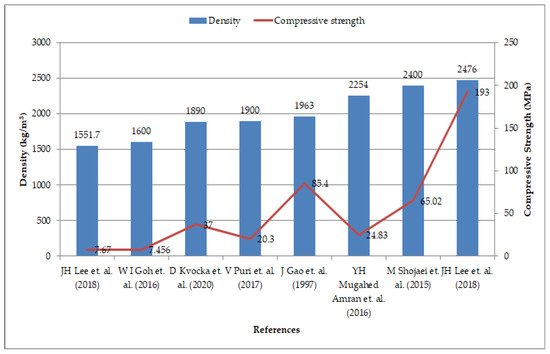

With the focus of reducing dead loads, several attempts have been made to develop lightweight concrete by using various foaming agents and inserting insulating materials as a sandwich layer between two concrete wythes [49,55]. The density of concrete was brought down to a minimum of 801 kg/m3 when compared to a density of 2400 kg/m3 for conventional and high-performance concretes. It was even brought down to 200–300 kg/m3 for use as an insulation material [43]. A graph showing the relationship between density and compressive strength is plotted in Figure 4. Based on the literature review, many researchers have attempted to achieve high strength for low-density products. However, it is evident that high-density concrete produces high strength.

Figure 4. Density and compressive strength in the presented literature.

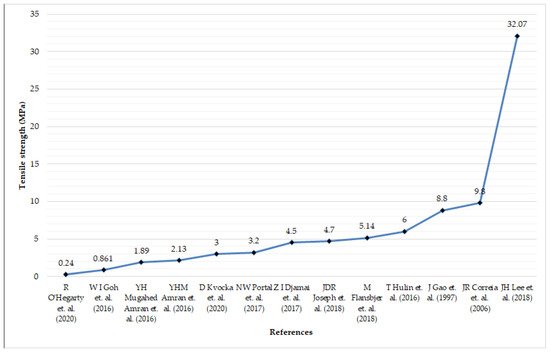

Apart from these, other mechanical properties such as flexural and tensile strength were tested in many studies, yielding better results for their respective panels [33,34,49,53]. There was a gradual increase in tensile strength from 0.24 MPa to 9.8 MPa (see Figure 5). However, in one particular study, an increase in the tensile strength to more than 300% was observed with the addition of UHPFRC. These mechanical properties determine if the panels will be load-bearing or non-load bearing.

Figure 5. Tensile strength in the presented literature.

The mechanical properties of the building elements are hindered by the natural deterioration during their service life. Various aspects such as weathering, aging, and other chemical attacks play a crucial role in this hindrance. Durability is one such criteria that is evaluated for materials and end products to determine the effect of these aspects on the material properties. Water absorption, carbonation resistance, chloride penetration, freeze–thaw tests, and ultraviolet (UV) tests are some of the methods performed to determine durability [58,59]. Along with these, various other Fourier transform infrared spectroscopy analyses were performed in earlier research studies to understand the aging process of the material [59,60,61]. Hence, the investigation of the durability parameters addresses the issues related to long-term sustenance of the structure by maintaining the designed mechanical properties.

3.2. Thermal Performance

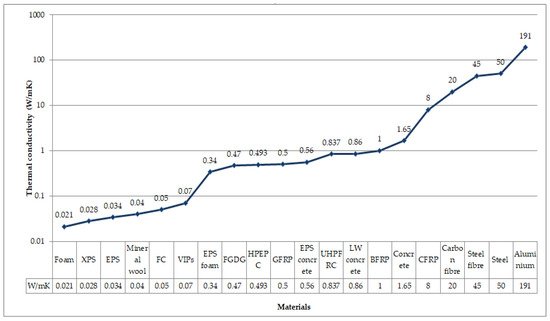

Extreme climate has been forcing people to stay indoors within a controlled environment in a thermal comfort range. The concept of indoor environment quality (IEQ) has come into existence and is achieved through controlled indoor air quality (IAQ), temperature, humidity, lighting, and noise [5]. From the perspective of building physics, the prefab elements minimise thermal conductivity primarily because of the presence of non-conductive composite elements, resulting in occupants’ comfort [14]. The literature review shows that the thermal conductivity of various materials used in the traditional construction industry has been studied, and materials with the least thermal conductivity/transmittance were selected for experimental trials [28,48,62]. Various insulation materials were considered, which have U-values ranging from 0.08 to 3.55 W/m2-K [26]. Low U-values indicate better insulating performance. For prefab construction, insulating materials such as EPS, XPS, and PUR were used between concrete panels, and better results were obtained because of low thermal conductivity [35]. Figure 6 lists various types of materials in the construction industry with their thermal conductivities. Although other insulation materials have better thermal properties and strength, researchers have opted for EPS because of its greater availability, lesser density, and lower cost.

Figure 6. Thermal conductivities in the presented literature.

4.3.3. Life Cycle Assessment (LCA)

Life cycle assessment (LCA) is a sustainability concept that conveys the environmental impacts related to the different phases of a product’s life cycle. This could involve either cradle-to-grave or cradle-to-gate phases of a product, including but not limited to raw material extraction, material processing, transportation, product manufacturing, usage, repair and maintenance, and finally, product re-use, recycling, or final disposal [63,64].

The major LCA phases in prefabrication include securing material, transportation, construction, operation, and recycling. First, the material is secured, which includes extracting, cleaning, sorting, and storing. The material is then precast or prefabricated for later use. The prefabs are then transported for installation, along with other equipment and necessary resources. The structure with prefabs is commissioned and undergoes maintenance due to wear and tear. At the end of the structure’s life, the prefab elements are demolished and recycled or managed through local waste management guidelines [53]. Material weight, energy, emissions, toxicities, water, solid waste, and percentage usage of recycled and recyclable materials are all considered in the analysis. LCA modelling is a crucial task where data are collected from many industry stakeholders, which requires significant time and effort [54].

The product phase in the life cycle is critical because it contributes the most to the environmental footprint. This phase generates heat during material production while consuming both electricity and fuel [31]. Cement production, for example, generates heat while consuming electricity and fuel, which is responsible for around 7% of the world’s carbon emissions [7,29]. Thus, finding alternatives such as recycled materials (which reduces carbon emissions by up to 20%), alkali-activated materials, TRC, and others are more environmentally friendly than the conventional concrete consisting of virgin materials [21,31,45]. The precast and prefab techniques are also effective in reducing carbon emissions by 10% per m3 and reducing wastage by about 84% [67,68].

Conventional construction contributes 24% of greenhouse gas emissions and 40% of energy use [69]. However, prefab constructions were proved to consume less energy, produce less wastage, and emit fewer emissions when compared to conventional methods during the construction and end-of-life stages [42,66]. The carbon emissions are further discerned to decrease with the increase in the prefabrication rate [70]. The concept of net-zero energy building (nZEB) also includes prefab elements whose ultimate aim is to create an energy-efficient building where net energy flowing to/from a building sums to zero [69]. The factors responsible for making construction environmentally friendly are choosing optimal designs, decreasing material and labour transportation, and increasing modular construction [65]. Some studies also proved that the construction involving recycled and geopolymeric materials has less of an impact on the environment [31,45].

4. Technology

Initially, precast yards focused on simple elements such as railway sleepers. As the technology advanced, they have extended their manufacturing to a variety of other precast elements such as columns, beams, slabs, wall panels, façades, and staircases. Moreover, the technological advancements led to significant cost reductions. For instance, cost reductions of 25% are expected while using filler slabs, 20–30% while reusing waste materials, 40% when using wall panels over brick walls, and around 7% by implementing modular over structural insulated panels [11,21,37].

Off-site prefabrication has seen tremendous enhancements in mechanisation, along with adaptation to advances in automation, simulation, robotics, and reproduction [19,71,72]. These have increased the efficiencies of mechanical and automated processes, virtually eliminating the need for direct human interaction. The processes are also found to be 27% economical while implementing them. Technological advancements have improved efficiencies and minimised waste, playing a vital role in their widespread acceptance throughout the prefab industry. Reduced construction time, better quality control, preferable durability standards, and reduced on-site disruption are found beneficial, whereas shortages of specialised manpower, restricted transport, and limited design flexibility have hindered its growth [73].

Over the past decade, Building Information Modelling (BIM) has proven to be an efficient digitising platform for creating, storing, accessing, communicating, and presenting information about construction projects. Furthermore, BIM is identified as a valued process involving multi-disciplinary coordination and integration of activities throughout the life cycle of the building and its components [74,75]. The literature review shows that projects’ pre-construction, construction, and post-construction phases benefit from BIM, where precast elements and structures are digitally virtualised, reducing design costs by up to 30% [76,77]. A rapid increase in Internet of Things (IoT) applications coupled with BIM has also helped improve the operations involving prefabricated elements [61]. This combination of IoT and BIM additionally helps in evaluating the structure during its service life phase through sensors, data acquisition, damage detection, and modelling systems [78].

5. Stakeholder Views

Stakeholders who either affect or are affected by the construction prefabrication; sustainability; materials; technologyindustry or prefab industry are owners, clients, users, contractors, designers, supervisors, manufacturers, engineers, and policy makers [16,79,80]. There is a need for these stakeholders to comprehend the gaps and failures of the process and try to use their knowledge to make it adaptable. Proper codes, policies, regulations, and laws regarding the processes must be developed by certain stakeholders such as politicians, city authorities, and engineers who can manage certain risks [81]. Current industry practitioners are ready to take up the advancements in the construction industry, whether from a material or technology perspective [82]. Moreover, some stakeholders have mentioned a lack of scientific studies that enable justifying the selection of prefab versus conventional construction approaches [10]. With the increasing technological advancements, there is a need for stakeholders to familiarise themselves with the rising concerns regarding global warming and greenhouse gas emissions and work towards developing necessary regulations and policies for their control [68,83]. Their perception, strategic objectives, and implementation policies are observed as some of the major factors in setting up a prefab manufacturing unit [84].

Social housing mainly depends on income level, size of dwelling, and affordability [21]. As prefab technology covers these parameters, several stakeholders have adopted this technology for low-cost housing. Additionally, many value-enhancing parameters such as durability, safety, aesthetics, environmental aspects, and profitability are considered while opting for prefab [16]. The technology is around 40% more time-efficient, has better thermal and energy efficiency, and offers greater quality control [66,85,86,87]. Considering stakeholder demands regarding real-time monitoring of on-site assembly, advancements such as smart construction objects have been achieved using sensors and BIM [76]. Regardless of these gains, stakeholders usually prefer traditional methods over prefab technology mainly because of a conservative mindset towards the need for higher installation precision, costlier technology, and the inability to determine the benefits to the project [88,89,90].

This entry is adapted from the peer-reviewed paper 10.3390/en15207548

This entry is offline, you can click here to edit this entry!