Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Civil

The environmental concerns of global warming and energy consumption are among the most severe issues and challenges facing human beings worldwide. Due to the relatively higher predicted temperatures (150–180 °C), the latest research on pavement energy consumption and carbon dioxide (CO2) emission assessment mentioned contributing to higher environmental burdens such as air pollution and global warming. However, warm-mix asphalt (WMA) was introduced by pavement researchers and the road construction industry instead of hot-mix asphalt (HMA) to reduce these environmental problems.

- hot-mix asphalt

- warm-mix asphalt

- life cycle assessment

- gas emission

- energy consumption

1. Introduction

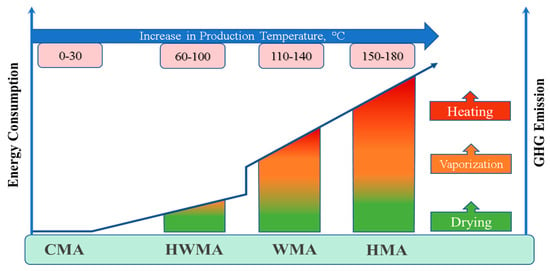

The environmental concerns of global warming are among the most severe issues facing human beings. A contributing factor in the flexible pavement, primarily using HMA, is significant fuel and energy consumption, resulting in pollutant emissions [1]. In contrast, WMA technology was developed to meet sustainability’s economic and environmental needs. However, humans have long been constructing flexible pavements to ensure smooth and durable road pavements [2]. Hence, the pace of road construction has been increasing globally, and 12 million km of roads were constructed in 2000; it is projected that 25 million km of roads will be built by 2050 globally [3]. For example, in Malaysia, the Public Work Department (JKR) reported that there was 237,022 km of roads in 2017 [4]. The construction of about 90% of the world’s paved roads uses asphalt mixture, and the remaining 10% are other types of pavement [5]. The increasing traffic volume necessitates using asphalt binders and mixes with enhanced properties to ensure the durability of asphalt pavements [1]. Generally, asphalt mixtures comprise three main materials, namely aggregate, asphalt binder, and filler. The aggregates and filler make up approximately 94–96% of the total mixture weight, and the remaining 4–6% is asphalt binder. These materials are heated to high temperatures of 150 and 180 °C to ensure proper aggregate coating by the asphalt binder and adequate workability of the mixture. This process consumes a large amount of energy and emits gases. One of the biggest problems faced by the world is global warming [6]. The high pace of transportation contributes to the emissions of large amounts of greenhouse gases that cause global warming [2,7,8,9]. According to the Inventory of U.S. Greenhouse Gas Emissions and Sinks, transportation contributes about 27% of total U.S. GHG emissions in 2020 [10]. The Kyoto Protocol adopted in 1977 aims to develop technologies that reduce the emissions of gases that cause global warming. Therefore, the road construction industry has adopted various techniques to control and reduce the emission of greenhouse gases, and one of them is the warm-mix asphalt (WMA). Generally, there are four types of asphalt mixtures, depending on their production temperature. (i) The cold mix asphalt (CMA) produced at 0–30 °C; (ii) the half-warm mix asphalt (HWMA) produced at 60–100 °C; (iii) the warm mix asphalt (WMA) produced at 110–140 °C; and (iv) the hot mix asphalt (HMA) produced at 150–180 °C. Figure 1 shows the classification of the asphalt mixes based on the production temperature [11]. It is noted that the energy required to achieve the desired workability is exponentially increased from the CMA to HMA, resulting in higher GHG emissions of HMA compared to other mixtures.

Figure 1. Classification of asphalt mixes based on production temperature [11].

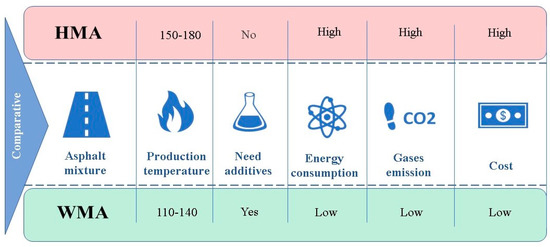

The primary reason and motivation for adopting WMA techniques are to produce an asphalt mixture at a temperature 10–40 °C lower than the conventional hot mix asphalt (HMA), as shown in Figure 2. The low production temperature of WMA has three benefits. It can significantly reduce environmental burdens, including global warming [2] and the emissions of gasses and fumes [12,13,14,15,16,17,18,19,20,21,22]. The economic benefit of the lower production temperature is directly proportional to the low energy consumption [18,23,24,25,26,27,28,29,30,31,32,33,34], which reduces the financial costs [35,36,37]. WMA production and paving are beneficial because they modulate the mixture viscosity, enhance mixture workability, facilitate compaction [38,39,40], allow the use of reclaimed asphalt pavement (RAP) [41,42,43,44], and provide better working conditions and a healthy work environment [45,46,47]. In more detail, and from the environmental perspective, WMA technology reduces CO2 emission based on temperatures during the paving process, which reflect the benefits of paving using WMA techniques that directly affect the workability and compaction of the mixture. WMA techniques serve as compaction aids and minimise the amount of pressure required [38,39,40]. Using the correct laying and compaction temperatures is essential to avoid difficulties. Even though a general temperature drop is permitted within WMA, a little higher temperature between 100 and 150 °C is recommended to be used. The paver screed angle of attack, material movement between the equipment, and thermal segregation could be negatively impacted in certain instances, such as temperature differentials occurring in the surface mix resulted [29]. It is easier to achieve the required densities with WMA in most cases than HMA, even at substantially lower temperatures [27]. This is due to the technologies that have been developed to produce WMA and also to the additives that are used to reduce the viscosity, which makes the mixture easier to manipulate and compact at a lower temperature. However, the operation and maintenance of facilities or plants used for WMA production need additional care to avoid some operational problems [27]. High percentages of RAP can be used in WMA without compromising the asphalt mixture’s workability [48]. Another motivation for using WMA is the possibility of cold weather paving since the mix temperature is closer to the ambient temperature. As a result, the reduction in mixed heat is less dramatic. This closeness of temperatures results in a more extended paving season because there is more time for paving and compaction, and increased hauling distance [35,36,49]. WMA plants can be located close to urban areas because of their low levels of emissions, fumes, and noise. The plants could also be at suitable distances from the construction sites, making it possible to pave in non-attainment areas [24,27,38]. Furthermore, traffic lanes can be opened sooner [50,51,52] due to the small temperature difference reduces the cooling time after construction [38,48]. This is especially desirable in instances such as the rehabilitation of airports and high-traffic roads [20,52,53].

Figure 2. Comparison of HMA and WMA.

2. Sustainable Materials

Sustainable development requires using fewer raw natural materials due to the high cost and energy consumption for extraction and transportation. Sustainable development also reduces the emissions of greenhouse gases and uses recyclable materials without compromising the standard requirements. Figure 3 shows that sustainable development comprises three interrelated areas, economic development, social development, and preservation of the environment. In detail, the economic aspect contributes to profits and cost-effectiveness, while the social aspect represents the contribution of the standard of living and equal opportunity to sustainability. Besides, the environmental aspect reflects the natural resources, pollution prevention, and biodiversity. Figure 3 also clearly implied that WMA technology supposes to be consistent with sustainable development that considers the environmental, economic, and social aspects toward equitability and viability [28].

Figure 3. Sustainable development [28].

Among the goals of constructing sustainable roads are to ensure safe, comfortable, cost-effective travel, reduce waste generation, and reduce the use of raw materials. It prevents the plundering the natural resources by using waste materials as a substitute [54]. Using waste materials in road construction can reduce the overall environmental impacts [55] and requires developing energy-efficient and eco-friendly paving technology [56,57]. Warm mix asphalt technologies enable the utilisation of higher percentages of recycled materials [28], which facilitate the design of perpetual and sustainable pavement based on the 4R policies (reclaim, recycle, reuse, and reduce). Using waste materials in pavement construction and rehabilitation can reduce energy consumption. Various types of recycled aggregates are used in WMA pavements, including reclaimed asphalt pavement (RAP), Recycled Asphalt Shingles (RAS), construction and demolition, and industry by-products (for example, copper or steel slags) [58]. The primary advantage of WMA is the potential to use a higher quantity of RAP [13,21,37,41,42,43,44,59,60,61]. Using RAP to replace the raw material eliminates the need to extract base raw materials and dump asphalt; this reduces the material and end-of-life consequences [31].

Table 1 shows the effect of using different recycled materials in WMA pavements. It can be reported that many recycled materials that were used as a partial or total aggregate replacement led to an improvement in the mechanical performance of WMA mixtures. The addition of RAP materials to the WMA mixture results in a reduction of permanent deformation due to the enhancement of the stiffness modulus of the RAP/WMA-modified mixtures [62]. Furthermore, the composite of RAP and WMA technologies led to improved fatigue resistance mixtures as a result of the balance between the stiff RAP materials and WMA additives that reduce the viscosity and stiffness of the asphalt [63]. Steel slag and furnace slag as waste materials showed an improvement in the fatigue resistance of asphalt mixtures due to the enhanced stiffness modulus [64,65]. It can also be noticed that the combination of RAP materials with steel slag, crumb rubber or glass fibre results in better moisture, fatigue and rutting resistances [63,66,67]. In contrast, using high RAP materials content in asphalt mixture led to lower moisture susceptibility and fatigue resistances [62,68]. As a fibre additive to WMA, jute fibre significantly improves fatigue and fracture resistance due to the enhancing of the adhesion properties of aggregate and binders toward adequate tensile strength [69]. It was also claimed that the addition of hydrated lime and nano-hydrated lime to WMA as fillers enhances the moisture damage resistance as a result of improved cohesion and adhesion properties [70,71].

Table 1. The recycled materials used in WMA.

| Usage | Type of Waste and WMA Additive | Effect | Reference |

|---|---|---|---|

| Aggregate | Glass (10% *) + ZycothermTM (0.05, 0.10, 0.15 and 0.20% **) |

Reduce resilient modulus, creep, and moisture susceptibility | [72] |

| Furnace slag (30% *) + Sasobit® (4% **) or RedisetTM (2% **) | Improve fatigue resistance and stiffness modulus | [64] | |

| Steel slag (40% *) + Surfactant-based chemical additive (0.5% **) | Improve the fatigue resistance and mechanical properties of asphalt mixtures | [65] | |

| RAP (0, 20 and 40% *)+ Steel slag (0 and 40% *) + Sasobit® (1.5% **) | RAP improves moisture sensitivity and resilient modulus Steel slag improves the resilient modulus The mixes containing RAP and/or slag have a lower rutting potential The WMA containing RAP and/or steel slag has enhanced fatigue resistance |

[63] | |

| RAP (30 and 60% *) + crumb rubber (CR) (0, 10 and 20% *) + Sasobit® (4 and 5.5% **) | RAP and crumb rubber have a positive effect on moisture susceptibility The result of the fatigue test showed that using RAP and CR improves the fatigue resistance of the asphalt mixtures |

[66] | |

| RAP (0, 20, 40 and 50% *) + Glass fibre (0.3% ***) + Sasobit® (1.5% **) | Improved rutting and moisture susceptibility resistance | [67] | |

| RAP (20, 30, 40, 50 and 60% *) + Mobile engine oil (10, 12.5, 15, 17.5 and 20% **) + EvothermTM (0.5% **) | Higher RAP proportion results in lower OBC of the RAP-WMA mixes The tensile strength ratio (TSR) decreased with higher amounts of RAP material. Higher rejuvenator dosage reduced the TSR |

[73] | |

| RAP | The use of WMA increases permanent deformation but adding RAP in the mixture resulted in less rutting | [62] | |

| RAP | The 50% RAP WMA has a good fatigue performance | [68] | |

| Fibre | Jute fibre (0, 0.3, 0.5 and 0.7% ***) + Sasobit® (3% **) | Enhanced fracture resistance | [69] |

| Additive or filler | Hydrated Lime (1% ***) + Advera (0.25%**), Sasobit (3.0%**), and Cecabase RT (0.35% **) | Enhanced moisture susceptibility | [70] |

| Nano hydrated lime (1% ***) + Aspha-Min (0.3% ***), Evotherm (0.5% **), and Sasobit (1.5% **) | Increase the indirect tensile strength (ITS) and TSR | [71] |

* By aggregate weight, ** By asphalt binder weight, *** by mixture weight.

3. Components and Production of Asphalt Mixture

WMA and HMA have the same components. WMA is easy to use, and its production does not require major modifications to the existing HMA plant. However, the manufacturing of HMA contributes to a higher percentage of CO2 emissions both in the initial construction stage [65] and the rehabilitation process [66]. The only difference between WMA and HMA is the production temperature [74]. The preparation of HMA requires a high-temperature range of 150 to 180 °C, while the WMA is prepared at a temperature range of 110 to 140 °C [48,75,76,77,78,79,80]. Table 2 presents the advantages and disadvantages of HMA and WMA [21,31,48,77,81,82].

Table 2. The advantages and disadvantages of asphalt mixes.

| Mix Type | Production Temperature | Advantages | Disadvantages |

|---|---|---|---|

| Hot-mix asphalt | 150–180 °C |

|

|

| Warm-mix asphalt | 110–140 °C |

|

|

The mixing and compaction temperatures of WMA can be reduced using organic additives, chemical additives, and water-foaming techniques [9,83,84]. In 2022, Rahmad et al. investigated the use of PG76 in integration with a chemical WMA additive to reduce the temperature during compaction based on environmental sustainability aspects, Rediset, and groundwater and soil contamination. However, it was found that there had been no chemical reaction between PG76 and Rediset. It was also found that after 64 days submerged under water, Rediset-PG76 had no effect on the adjacent water source and soil [8] summarises the different additives and technologies for WMA [21,31,58,84,85]. Even though the technologies differ, they all seek to reduce bitumen viscosity, enhance workability, reduce emissions, and maintain the desired performance. Several studies have shown in Table 3 that these technologies can reduce air pollutants (emissions) and energy consumption [12,21,22,27,49,58,81,83,86,87,88,89,90,91]. Even though the low temperature for producing the mixes the production and paving has several advantages, it could result in poor performance, such as incomplete aggregate drying, poor bitumen coating, and moisture susceptibility due to the presence of water. However, researchers have conducted extensive investigations on these issues and proposed solutions [21]. Furthermore, detailed studies on the cohesion and adhesion failure mechanisms based on advanced laboratory techniques and computational simulation could help in further understanding the reasons behind such common issues toward proposing solutions. In addition, a composite of polymers and nanomaterials into WMA technology could mitigate such moisture susceptibility problems.

Table 3. Warm mix technologies and additives.

| Mix Type | Production Temperature | Advantages | Disadvantages |

|---|---|---|---|

| Hot-mix asphalt | 150–180 °C |

|

|

| Warm-mix asphalt | 110–140 °C |

|

|

Generally, organic additives such as wax or fatty amides reduce asphalt binder viscosity at temperatures over their melting point. These additives should have a melting point higher than the maximum service temperature of the asphalt mixture to increase the rut resistance of the asphalt at high temperatures and limit embrittlement at low temperatures [28]. Chemical additives are liquid surfactants that act at the microscopic interface and do not change the asphalt binder’s viscosity; they are surface agents that increase wetting qualities by lowering the tension between asphalt binders and aggregates and thus reduce internal friction [92,93]. Foaming technologies lower the asphalt binder viscosity by introducing small amounts of water into the hot asphalt binder. As the water evaporates, it expands the binder and reduces binder viscosity; this results in a better aggregate coating. The degree of expansion is dependent on several factors, such as binder temperature and water content [52].

An asphalt mixture is a composite of aggregates, asphalt binders, and fillers. Additives or modifiers are occasionally added to the asphalt binder to improve its performance [94,95,96,97,98]. Aggregates are the main element of asphalt pavements and constitute almost 95% of the mixture. The high percentage of aggregates in asphalt pavements has increased the demand for aggregates in road construction applications. The aggregate materials are often used for the lower pavement layers, such as the base or subbase layer. In 2015, 2660 million tons of aggregates were produced in Europe from quarries, with the UK contributing 110 million tons per year. In addition, France produces approximately 250 million tons per year [99,100]. Malaysia produced 118 million tons of aggregates in 2011 and 160 million tons in 2015 [99,100]. In the United States, aggregate production increased from 1.34 billion tons in 2015 to 1.53 billion tons in 2019. About 72% of the aggregates were used as construction aggregate, primarily for road construction [101].

There are two main phases in asphalt pavement construction and the production and construction of asphalt mixture. The first phase consists of aggregate stacking, heating the aggregates and asphalt binder, and mixing. The second phase is transporting, paving, and compacting the asphalt mixture. The energy consumption during asphalt mixture production is considerably higher than in the transportation and construction phase [102]. The production stage involves heating the aggregates and asphalt and mixing the asphalt mixture. The aggregate heating process for HMA contributes to 67% or more of the total carbon emission, while the asphalt heating and mixing processes contribute only 14% and 12%, respectively [89,103]. According to Stotko [104], about 60% of the energy consumption at the asphalt plant is for drying the aggregates. Peng, Tong, Cao, Li and Xu stated that 76.41% of the total carbon emission is during aggregate heating, while asphalt heating emits 15.67% of the carbon [103]. The moisture content of the aggregate is one of the factors determining the amount of energy consumed during the aggregates drying process [5,76,105,106].

Moreover, the specific heat capacity of the aggregate materials is a critical determiner of the fuel needs and CO2 emissions of WMA and HMA. The same type of aggregate extracted from different sources may have different specific heat capacities even if their specific gravities are similar [107]. Jamshidi et al. [108] investigated the effects of the thermal properties (specific heat capacity) of asphalt binders and aggregate materials on energy consumption and environmental footprints of HMA and WMA. The results showed that using low-specific heat capacity aggregates is more energy-efficient and environmentally friendly. The difference in energy requirements varies with the moisture content [104]; a 1% increase in moisture content results in a 3.5% higher energy consumption to dry the aggregates [106]. Another study has shown that energy consumption increased by 1% for every 0.7 L moisture content [109] and that one of the ways to reduce energy consumption is by reducing the mixing temperature [110]. The energy demand is about 2.62 kWh for a 10 °C increase in the mixture temperature and 8.21 kWh for every 1% increase in moisture content [105]. The fuel for heating or drying the aggregates is one of the sources of emissions, where the energy consumption and CO2 differ with the type of fuel, as shown in Table 4. It can be seen that using natural gas to heat the aggregate results in the lowest CO2 emission compared to different fuel types reported in Table 4, however, natural gas showed to be the highest heating energy required. On the other hand, using fuel oil (N°1/2) as a heating energy source showed to be the lowest among all fuel resources, with a reduction of 9.45% compared to required natural gas energy. However, using fuel oil (N°1/2) results in about 480% CO2 emission higher than the emission due to using natural gas. Furthermore, it was reported that the use of natural gas instead of heavy oil to heat the aggregates reduces carbon emissions by 27.72% and the cost by 18.63% [89]. According to Stotko [104], using WMA could reduce fuel oil consumption by about 8400 GJ and prevent CO2 emission by 620 tons annually based on an asphalt plant in South Africa.

Table 4. Energy and CO2 emission by different fuel types.

| Fuel | Heating Energy for Aggregate [110] | CO2 Emission | ||

|---|---|---|---|---|

| Value | Unit | Value | Unit | |

| Diesel | 42,791,000 | J/kg | 2.6390 | kg/L |

| Heating oil | 42,612,000 | J/kg | - | - |

| Fuel oil (N°1/2) | 42,686,000 | J/kg | 3.2160 | kg/t |

| Natural gas | 47,141,000 | J/kg | 0.1836 | kg/kWh |

| Propane gas | 46,296,000 | J/kg | - | - |

| Electricity | 3,600,000 | J/kWh | 0.5410 | kg/kWh |

This entry is adapted from the peer-reviewed paper 10.3390/ijerph192214863

This entry is offline, you can click here to edit this entry!