Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The energy crisis, the risk of interruptions or irregular supplies of conventional energy carriers, and the need to protect the environment stimulate the search for new solutions to improve the heat balance of buildings with the use of solar energy. Based on the criterion of the storage, distribution, and discharge time of stored heat, passive solar gain solutions can be divided into direct and indirect solar gain systems.

- Trombe wall development

- solar gains

- window modernization

1. Introduction

In the current geopolitical situation and in the face of the growing threat of a deepening energy crisis, the priority is to look for new solutions to reduce the demand for conventional energy, especially in the construction sector, which is responsible for approximately 40% of global energy consumption and over 36% of carbon dioxide emissions [1][2][3]. The activities aimed at meeting this goal, which are limited to legislation that enforces more stringent requirements concerning the thermal resistance of buildings’ envelope elements or systems of heat recovery, are far from satisfactory. Design and execution standards should include the necessity of the use of energy from renewable sources, the implementation of innovative solutions that combine favorable economic effects with provisions for healthcare and the comfort of inhabitants while reducing the unfavorable impact of buildings on the natural environment. Considerable reserves in this respect lie in the elements of the buildings’ envelopes. We are witnessing their evolution from traditional and monofunctional to multifunctional or even interactive based on novel materials with improved properties and the utilization of cutting-edge technologies that enable a response to changing environmental conditions. Elements of buildings’ envelopes have a special feature: the ability to improve thermal balance owing to the photothermal conversion of solar radiation energy.

2. Direct Solar Gain Systems

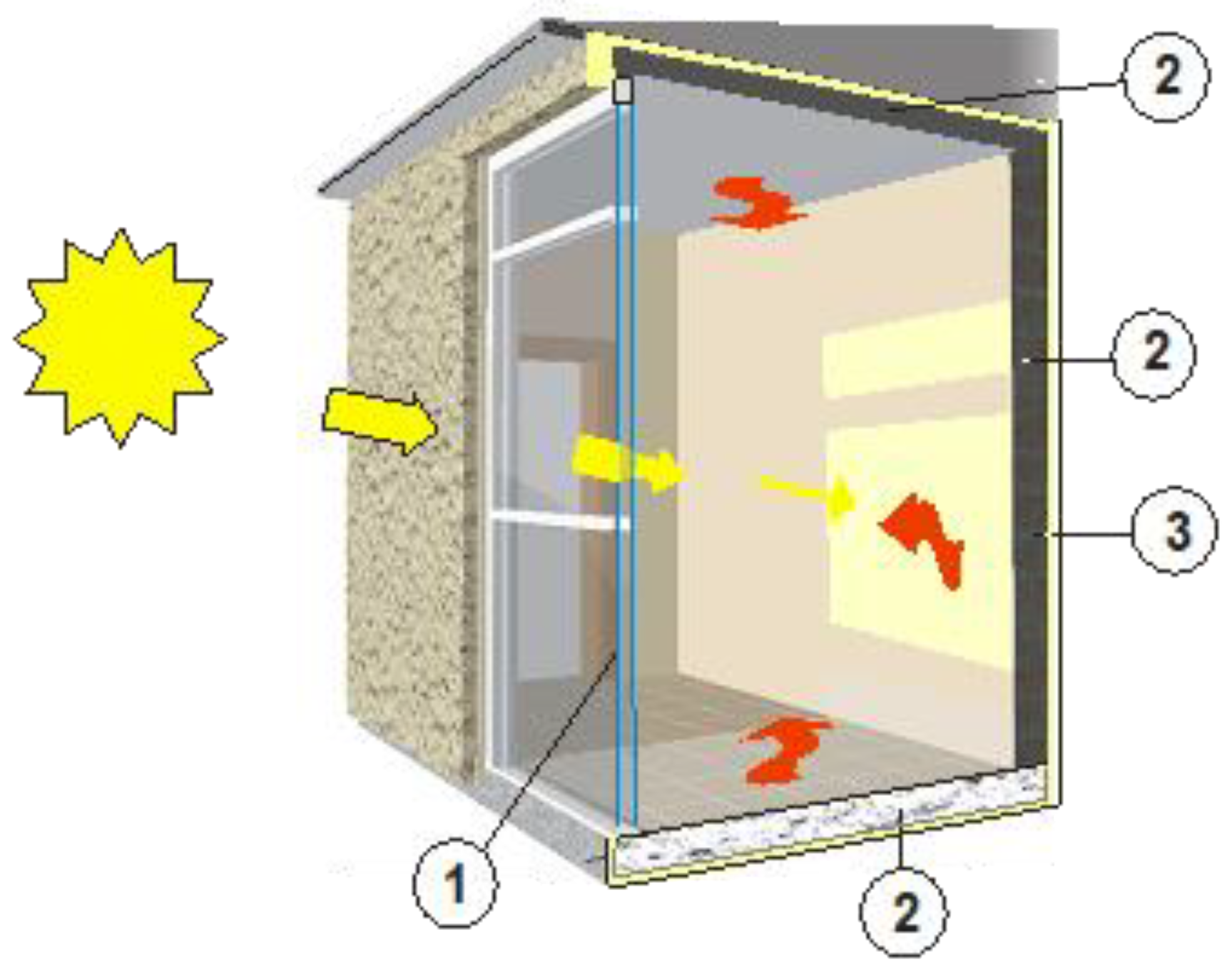

Direct solar gain is the most basic form of solar gain of heat. The solar radiation penetrating through the glazing is absorbed by the thermal mass built into the floor and walls, where it undergoes photothermal conversion (Figure 1). Its quantity is determined by the structural features of the building, the orientation of the glazing relative to the cardinal directions or topography, and vegetation and building elements that may periodically shade the glazing.

Figure 1. Scheme of operation of a direct solar gain system. 1—glazing; 2—thermal mass; 3—thermal insulation.

During the design of direct solar gain systems, it is sufficient to choose the aforementioned elements, the thermal mass of the building, and the heat-gain diversification so as to guarantee maximum heat collection during solar radiation while minimizing the risk of exceeding the target temperature level of interior air.

Among the basic structural features of the building that affect direct solar gain, Jäger [4] includes a south-facing at least double-glazed window of considerable surface and a window night insulation system as protection against excessive heat loss. However, glazings of the considerable area may result in an uncontrolled increase of temperature in rooms. The selection of adequate thermophysical parameters for the glazing according to the function of the room and its orientation relative to the cardinal directions becomes a key factor. The reason why it is difficult to select a universal glazing that yields the most favorable energy balance is that the solar energy transmittance and thermal resistance parameters are significantly divergent. Insulation can be improved by, inter alia, the use of advanced glazed units containing E-low or electrochromic coatings [5][6][7], vacuum glazing [8][9][10], as well as noble gases in the spaces between the glazed units. These methods may considerably reduce the heat transfer coefficient of glazing, Ug (with argon by −22.2%, with krypton by −33.3%, and with xenon −41.1%, respectively), compared with the Ug of glazed units filled only with air [11]. In their experiments on revolving glass panes, Saleh et al. [12] found that the azimuthal rotation of glazing, while maintaining the same original direction of the wall, is an effective means of ameliorating the solar heat gain to the space (alleviating or augmenting the heat gain for cooling or heating purposes, respectively).

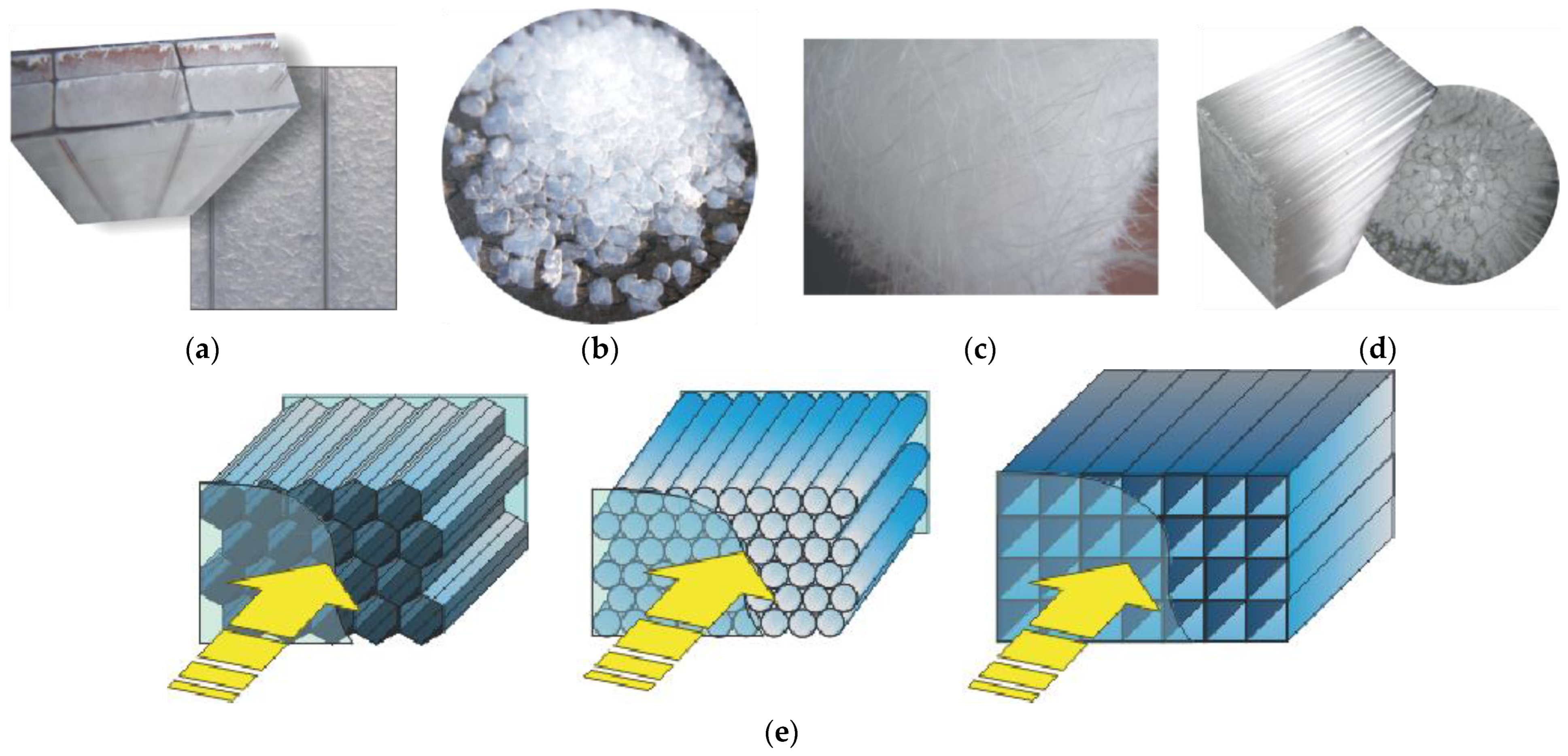

When full transparency of glazing is not required, the spaces between the glazed units can be filled with a transparent insulating material (TIM) [13] which has solar transmittance capacity: e.g., capillary polycarbonate or glazed units filled with granulated aerogel [14][15][16][17] or a cellular filling reducing the proportion of convection in heat exchange (Figure 2).

Figure 2. Examples of transparent insulating materials: (a) chambered polycarbonate filled with aerogel granules, (b) nanogel—aerogel granules, (c) glass fibers, (d) capillary polycarbonate, (e) cellular structures.

In cases of insufficient solar radiation or at night, thermal insulation can be improved by using various types of movable insulation: blinds, blinds with a reflective coating, shutters, and roller blinds [18]. For years, the idea of dynamic insulation has been developed. For example, in the concept described in [19], at night or in the event of insufficient solar radiation, the spaces between the boards are filled under pressure with expanded polystyrene granulate. In addition to increasing the thermal resistance of the wall, analogous solutions can perfectly prevent the building from overheating in the summer and wasting energy on cooling [20][21]. Casini [22] assessed the effect of shading using dynamic windows. Sbar et al. [23] performed a simulation for electrochromic windows in three American cities—Washington, Minnesota, and Phoenix and found energy savings at the level of 10%, 20%, and 4%, respectively. Tests on the prototype of switchable insulated shading (SIS) indicated differences in annual energy consumption by HVAC ranging from 8.2 in cold climates to over 11% in warm and hot climates [24]. Bellia et al. [25] demonstrated savings in cooling energy at a level of 20% in the Palermo climate, 15% in Rome, and 8% in Milan as a result of the application of shading elements in office buildings. Yao [26] presented a study on the impact of dynamic sun blinds on energy and comfort and showed that the energy demand in a building can be reduced by 30.87% using external movable roller blinds for the city of Ningbo in China.

In summer, when required, the glazed part of the elevation can also be shaded by the building’s overhanging elements [27], for example, eaves, jutties, balconies, or loggias.

Direct solar gains are proportional to the windows’ area. However, if they are too large, they can cause periodic temperature fluctuations that cause room overheating and compromise the comfort of using them [28][29][30][31]. In residential buildings, the demand for heating energy is generally the highest in the evening and at night, while the solar gains practically reach their peak during the sunlight hours. One of the ways of improving the effectiveness of direct solar gain systems may be to increase the thermal capacity of the elements of the envelope of rooms not covered with lining that impedes solar energy absorption (e.g., floor carpeting) or link them with the central heat distribution system. It is recommended that the area of a thermal mass element be at least six times larger than that of the glazing [32]. To increase the thermal capacity of partitions, phase change materials PCM are used. The modern PCMs are produced in the form of, inter alia, coated microgranules [33]. Owing to the polymer coating, they can be applied without the danger of uncontrolled leakage or aggressive reactions with materials with which they are combined. PCMs can be an additive to conventional construction materials used mainly for building envelope elements [34][35][36][37][38][39]. On the basis of research conducted in Finland and the USA, Peippo et al. [38] stated that energy savings resulting from the use of PCMs in passive solar applications can range from 10 to 20%, depending on the type of PCM used and the climate in which the solution is functioning. The field tests performed by Kuznik et al. [37] in the climate characteristic of the surroundings of Lyon, France indicated that the use of wall panels modified with the admixture of PCM inside a room can reduce the temperature fluctuations on the wall surface by 3.5 °C. In the studies on a direct solar gain system with PCM of the heat of phase transition of 60 kJ/kg, Chen et al. [34] demonstrated an increase of the savings in the energy for heating the tested room at a level of 10% compared with a room in whose envelope the PCM admixture was not used. Computer simulations of a direct solar gain system performed by Athienitis et al. [40] showed an efficiency of more than 40% of heating energy recovery in a room with a floor containing PCM. The important properties of PCM also include the postponement of the release of the heat stored during solar radiation. Research by Cabeza et al. [41] showed that the maximum temperature in a wall with PCM content is observed about two hours later than in a nonmodified wall.

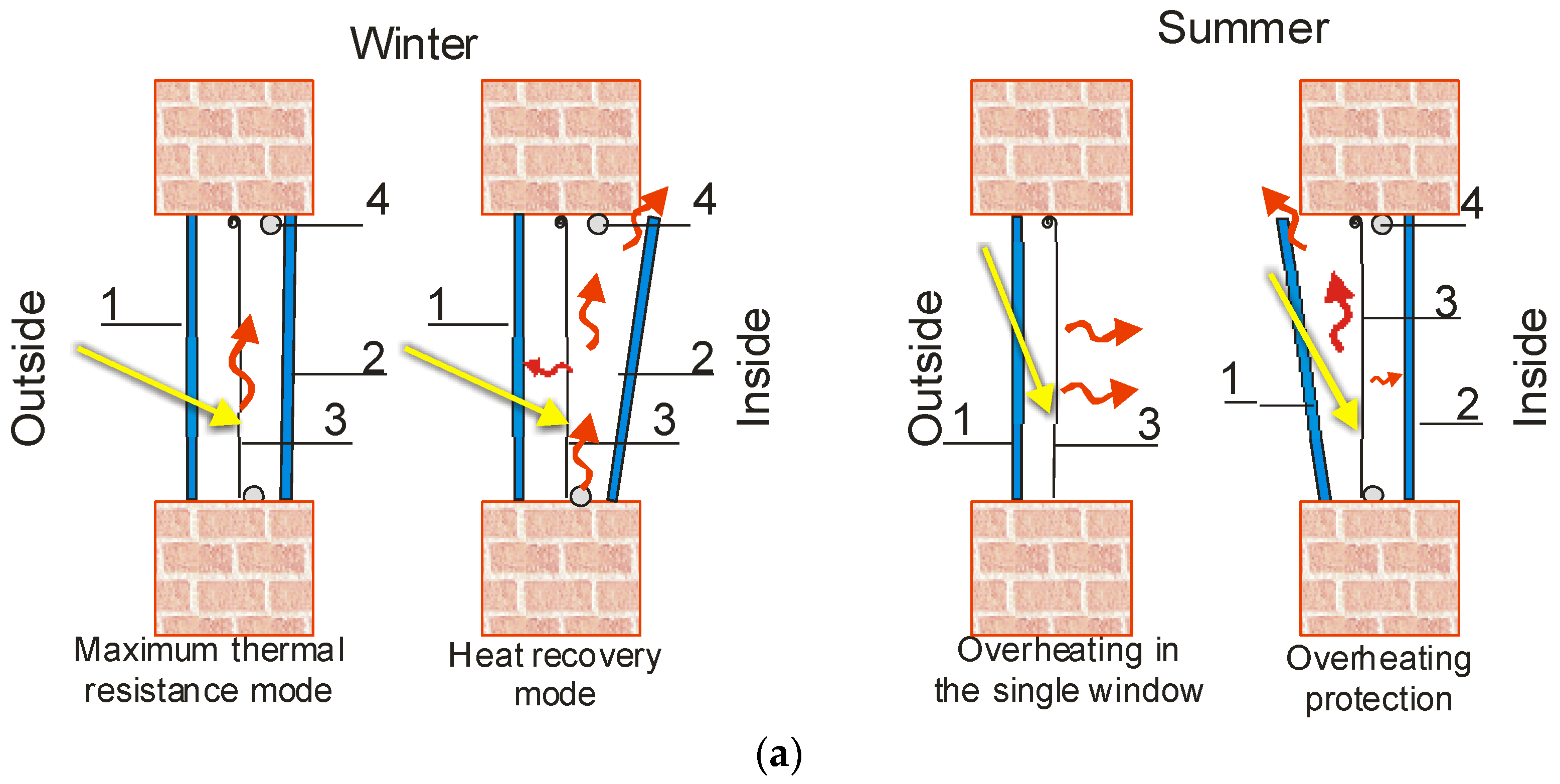

Considerable potential in the area of rational use of solar radiation in direct solar gain systems is seen in the modern double-glazed box windows [42] or a relevant modification of existing windows. Szyszka et al. [43] proposed a method to improve the insulating properties of windows or even an alternative to their replacement when a building is thermo-modernized using the concept of a quasi-box window. The idea is to install a new window from the inside of the building next to the old one (Figure 3).

Figure 3. The conception of the quasi-box window: (a) Winter and summer functions: 1—glazing, 2—added internal window, 3—movable shading element, 4—container with PCM, (b) Made 3 h after sunset thermogram of the quasi-box window and single window in the same temperature inside of the room, (c) Profile line of the temperature of both kinds of window.

The resulting quasi-box window has a higher thermal resistance than a single window. On sunny days, heat accumulates in the space thus created, which depending on the thermal capacity of the unit can reheat the adjacent room, also for a few hours after sunset (Figure 3b,c). This is why in [44][45] the installation of a container with PCM inside the window unit gap was proposed. Additional advantages of the box include efficient protection against overheating when interior shading elements are used. Owing to the tilted external window with the internal one closed the heat absorbed by the rolled-down blind is emitted outside, while protection against heated outdoor air is preserved (Figure 3b,c).

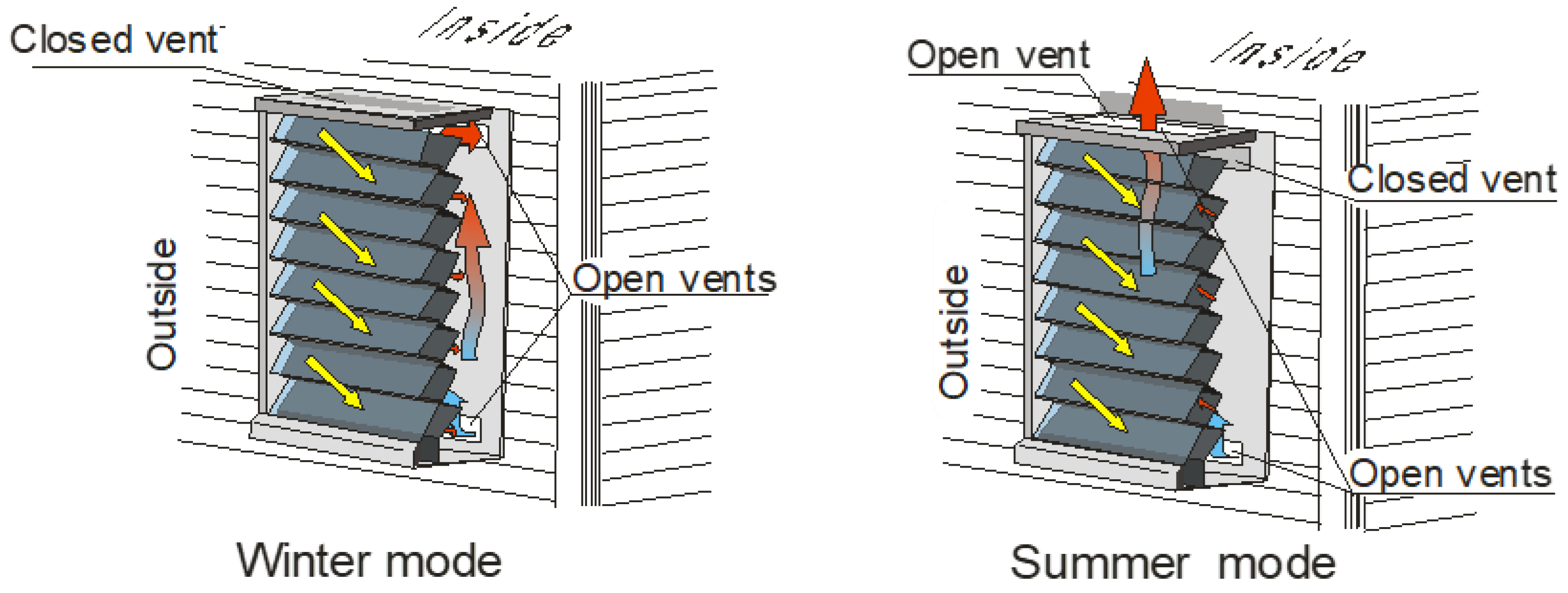

In their tests on an innovative double-skin ventilated window integrated with air purifying blind, Wang et al. [46] demonstrated that, compared to a shading blind, optimizing the inclination angle of the louvers and the position of the shutters used in winter and summer may improve the thermal and visual comfort and generate energy savings at the level of 23.9 kWh/m2 in the winter and 78.8 kWh/m2 in the summer.

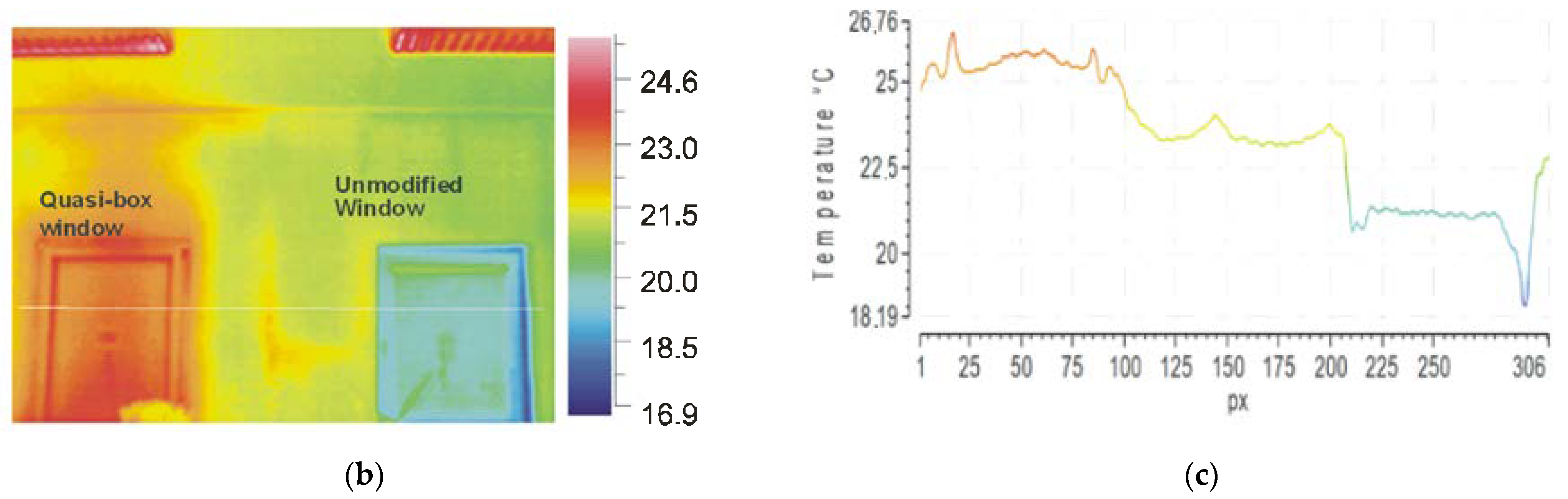

3. Indirect Solar Gain Systems—Trombe Walls

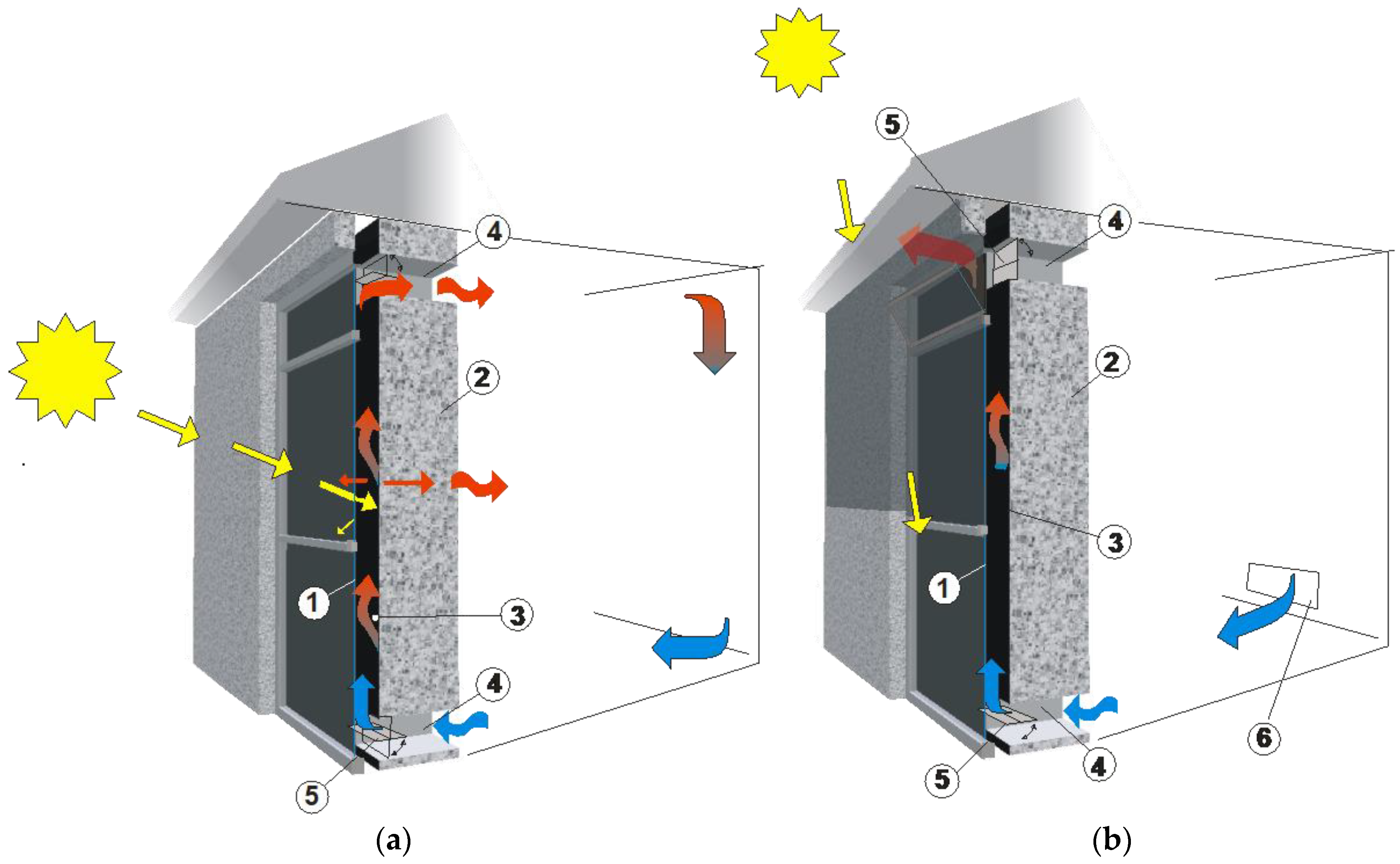

A way to solve problems related to the management of heat gains accumulated in a short time in direct systems is by using the concept of an indirect gains system (IGS). The most common example is the Trombe wall). In this solution, the solar gains are transferred to the building using the so-called thermal mass, usually the wall behind the glazing. By absorbing solar radiation, the wall stores it and then transfers it with a certain delay to the usable space by conduction (Figure 4a). Such location of the thermal mass is also beneficial in the summer, as it minimizes the risk of overheating the rooms. Furthermore, due to the chimney effect, it allows more intensive ventilation of the building with cool air drawn in from the north (Figure 4b).

Figure 4. Scheme of operation of vented Trombe wall: (a) in winter, (b) in summer; 1—glazing, 2—wall, 3—absorbing layer or absorber, 4,—vents, 5—dampers, 6—air supply vent.

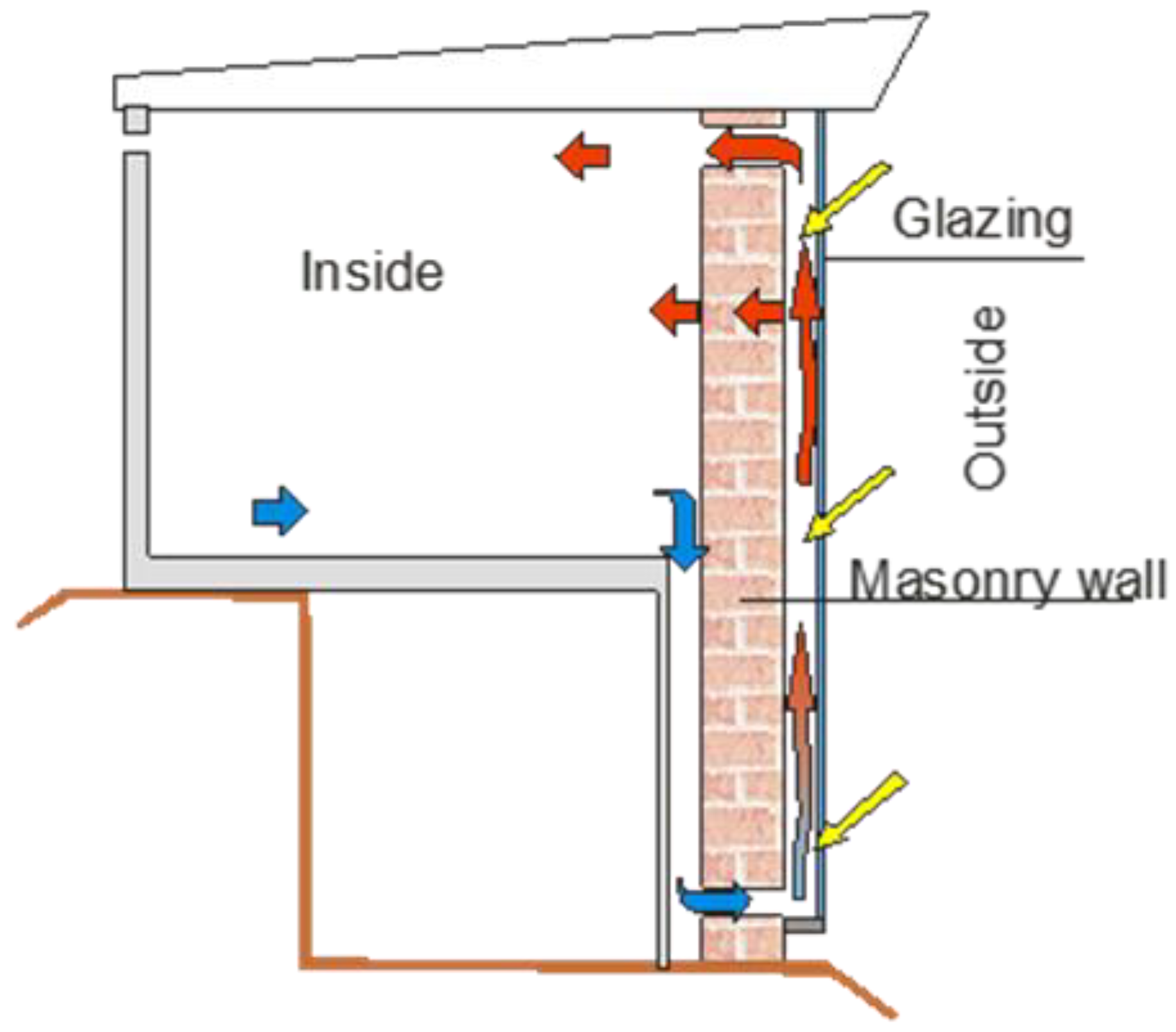

The name Trombe Wall (TW) derives from the name of Felix Trombe, the co-creator of the solution, who, together with Jaques Michel, used it for the first time in 1967 in a building in Odeillo, France [47] and patented it in 1973 [48][49]. In many publications, the originality of the concept is attributed to Edward S. Morse, who in 1881, in the patent application ‘Warming and ventilating apartments by the Sun’s rays” (Figure 5), reserved the type of collector in which solar heat absorbed on a flat or corrugated plate is transferred to a building through vents with circulating air. On the other hand, Trombe Wall, in addition to its ability to heat air in the space behind the glazing, also has the ability to store heat, which is released with a delay depending on the thermal mass of the wall material (Figure 6).

Figure 5. Edward Morse’s wall-mounted collector.

Figure 6. Collector -storage wall designed by Trombe and Michel.

The period of development of the idea of TW was tied in with the energy-efficient construction trend connected with the oil crises of 1973 and 1979. The co-author of the patent, Jaques Michel, explained the main assumptions of the design of TW in a French journal devoted to modern architecture called Architecture d’Aujourd’hui in 1973 [50]. Since then, the wall, as potentially one of the cheapest passive heating systems, has been discussed in numerous research projects across the world and is subject to modifications to improve its thermal efficiency in terms of climatic conditions and functionality [51][52][53][54][55]. TW can be designed as a wall in new buildings [56][57] or as a supplementation to thermal upgrading systems in existing buildings [58][59][60][61][62].

The thermal efficiency of the classical variants of TW is determined by the properties of its components (glazing, wall, absorption layer or absorber, and other additional interacting devices and elements, e.g., movable insulation, shading, etc.). The TW structure should be optimized by taking into account specific climatic conditions, orientation relative to the cardinal directions [63][64], the profile of daily energy demand, the season of the year, and the function of the building. Glazing has a great influence on shaping the heat balance. The criteria for selecting its parameters are analogous to those used in indirect systems. The selection of optimal glazing is really about finding a compromise in given climatic conditions between its properties of transmitting solar radiation and thermal insulation. For instance, Koyunbaba and Yilmaz [57], in the climate conditions of Izmir, Turkey, performed experiments to compare Trombe walls in which various types of glazing were used: single, double, and integrated with a photovoltaic panel. The results of tests indicated that the application of a double-glazed unit reduces heat loss but effects lower solar gains compared with single gazed units. Consequently, the researchers recommended the application of a single-glazed unit combined with movable night insulation. Kisilewicz [65], on the other hand, on the basis of simulation calculations performed for the climate in Poland, recommends the use of glazing with high thermal insulation glazing. He concludes that the thermal resistance of the glazing has a favorable and significant impact on the heating demand. Two-chambered and triple-pane glazing would reduce the demand for heating the adjacent space between 53 and 58% compared to an opaque and well-insulated wall. For the building analyzed, the reduction in heat demand reduction was 14%. The author indicates that a further reduction of heating demand, and also cooling demand, requires an exchange of the indoor air between the thermal zones of the building.

Although the thermal mass restricts temperature fluctuations caused by solar operation, Trombe walls, similar to direct solar gain systems, require protection against overheating in summer. In their study of a classical Trombe wall under moderate climate conditions in Italy, Stazi et al. [66] evaluated three assembly variants: a single glass pane, a glass pane with a Low-E coating, and a double-glazed glass pane. The results indicated that energy consumption can be reduced by up to 55% if the classical TW configuration (a 40 cm thick with single glazing) was replaced by an optimized configuration composed of double glass panes and a wall of small aerated concrete blocks 20 cm thick). A similar effect of double glazing on improving wall heat balance was indicated by the study by Dong et al. [67] and Zhang et al. [68].

In order to increase the thermal insulating capacity of the wall in winter and to prevent its overheating in summer, the use of movable insulation, as in direct solar gain systems, is recommended. The field tests carried out by Miąsik et al. [69] showed a reduction of the mean heat flux by ca. 77% in summer, while in winter energy consumption was observed at the level of a wall of the heat transfer coefficient of U = 0.3 W/m2K.

It should be noted that modification of roller blinds and shutters by the introduction of reflective coatings can improve their favorable operation. The coatings effectively reflect a considerable volume of heat that escapes through the wall. Opening reflective blinds or shutters at an adequate angle can intensify the absorption of solar radiation reflected from their surfaces to the TW absorber [70][71][72].

In unvented walls, the glazing is spaced close to the absorber to minimize the heat loss resulting from the convective exchange between the absorber and the glazing. This distance should be adopted following Torcellini et al. in the range of 2–5 cm [73], while according to Hordeski in the range of 3–6 cm [74]. In Zrikemet et al. [75], to minimize heat loss through a transparent partition, the elimination of the gap and placement of a honeycomb-like structure between the glass pane and the wall were proposed.

In an unventilated wall, heat is distributed by means of conduction within the wall. After the thermal wave has reached the inner surface, heat is released to the adjacent space as a result of radiation and natural convection. This phenomenon can take several dozen hours. It depends on the amount of radiation absorbed, the thickness of the wall, and its physical parameters [76][77].

Materials for the construction of this type of wall are selected based on the fundamental criterion of their high thermal capacity [28]. Most frequently it is concrete, stone, and brick [78], and the wall thickness is adopted in the range of 10 to 41 cm [73]. The thicker the wall, the higher its heat storage capacity; owing to solar radiation absorption, temperature fluctuations on the inner surface decrease. Since the outer surface of the wall is responsible for absorbing solar radiation, improvements are made to its absorbability are undertaken. One of the simplest is to apply a coating based on black or dark matt paint, which results in an absorbability of 0.95 [79]. The studies performed by Özbalta et al. [80] demonstrated the effect of the absorber color on the Trombe wall’s effective operation. The annual energy gains reached by the use of a wall painted with the darkest paints were found to be nearly three times higher than those obtained by the use of light colors.

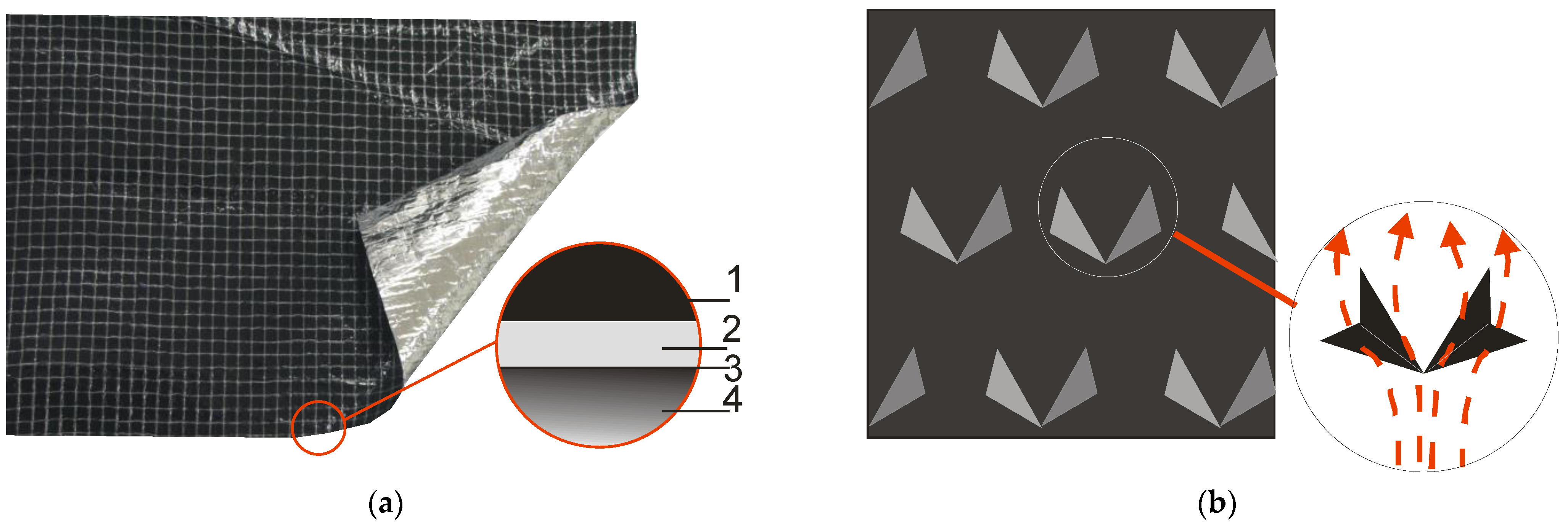

The emissivity of the paint coats is proportional to their absorbability. A method to restrict the heat loss connected with it, resulting from radiation exchange to the environment, is the application of a selective coat [81]. It has a lower emissivity while a high absorbability is maintained. It is made, among other things, on a steel, aluminum, or copper sheet fixed to the outer surface of the wall. For example, a selective coat of black zinc made on galvanized steel has an absorbability of α = 0.96, with an emissivity of ε = 0.12 [76]. In papers by Čekon et al. [82][83][84], an innovative selective absorber whose properties enable solar gain control is presented (Figure 7a). The results of studies by Zhou et al. [85] indicated a favorable effect on the absorber’s ability to absorb heat owing to the use of longitudinal vortex generators(Figure 7b) to improve the performance of PCM—Trombe wall systems.

Figure 7. Absorbers: (a) Selective absorber: 1—polyethylene absorbent layer with 5% pigment, thickness (th.). 20 µm; 2—adhesive polyethylene bridge, th. 2 µm; 3—vapor-coated aluminum, th. 0.04 µm; 4—structural layer of MPET, th. 23 µm, (b) delta winglet vortex generators in the wall surface.

In the classical Trombe wall, an important part of heat distribution to a building is connected with the circulating flux of air heated by the solar radiation absorbed on the wall surface. Effective circulation, especially when natural convection occurs, is affected by the width of the air gap between the glazing and the absorber. This dimension should be selected to reduce air drag. According to Sparrow et al. [86], the width of the space between the glazing and the absorber must be greater than 4.7 cm.

According to Bin et al. [87], the application of circulation vents in a cool climate can improve the efficiency and functionality of the solution. Owing to the ability to absorb heat reception from the heated absorber, the possibility of an excessive increase in its temperature can be restricted, and consequently, heat loss through glazing. According to the calculations quoted in [87], in massive walls with a thickness exceeding 35 cm, the contribution of ventilation in the heat transfer to an adjacent space is assessed at the level of 70% compared to heat conduction. However, vents must be protected against reverse circulation [88]. A 10% to 20% capacity increase [89] can be obtained by the application of closeable flaps, dampers, special foils] and similar solutions. According to [90][91][92][93][94][95][96] heat transfer efficiency via circulation is strictly connected with the construction of the wall and optimization of the time of opening and closing the flaps of circulation vents.

Results of the research on the effect of the application of a ventilated Trombe wall in a building envelope on the level of energy savings differ. In their analyzes performed with ENERGY Plus program for the climate in France (Lyon), Bojić et al. [97] show these savings at the level of 20%. The same level of energy savings is also confirmed, presented in [87], by the results of measurements taken on an actual object in Zion National Park (Utah, USA). On the other hand, in the article by Nowzari et al. [98] the presented results of the analyses performed in TRNSYS (Transient System Simulation) of a 120 m2 building with a 15 m2 Trombe wall in the climatic conditions of Cyprus indicate a reduction in the heat demand at the level of approximately 45%. Moreover, analysis of life-cycle cost (LCC) demonstrated that the construction of this type of wall is more economical than the purchase of a 3 kW gas-fired boiler. Similar results of simulations performed under the corresponding climatic conditions were obtained by Kalogirou et al. [99]. A 25 cm thick south-facing wall reduced the energy demand for heating a model building by about 47%. The study conducted by Dimassini [100] in the climate indicated the efficiency of a ventilated wall in the range of 31.7–45%. Fang showed a similar 30.2% efficiency of a collector-accumulation wall in the conditions typical of the period November–March in Beijing, China, [101][102]. In the period of January to April, as a result of optimization with TRNSYS of a ventilated Trombe wall referring to the surface of the southern wall, with the aim of achieving maximum energy consumption reduction, Jaber et al. [103] evaluated the maximal energy savings at 37.55%. This value corresponded to a 37% contribution of TW in the area of the southern wall.

This entry is adapted from the peer-reviewed paper 10.3390/en15238956

References

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094.

- Available online: https://ec.europa.eu/info/news/focus-energy-efficiency-buildings-2020-lut-17_en (accessed on 15 August 2022).

- Alotaibi, B.S.; Khan, S.A.; Abuhussain, M.A.; Al-Tamimi, N.; Elnaklah, R.; Kamal, M.A. Life Cycle Assessment of Embodied Carbon and Strategies for Decarbonization of a High-Rise Residential Building. Buildings 2022, 12, 1203.

- Jäger, F. Solar Energy Applications in Houses Performance and Economics in Europe; Commission of the European Communities: Brussels, Belgium; Luxembourg, 1981.

- Mouratis, K.; Tudose, I.V.; Romanitan, C.; Pachiu, C.; Popescu, M.; Simistiras, G.; Couris, S.; Suchea, M.P.; Koudoumas, E. WO3 Films Grown by Spray Pyrolysis for Smart Windows Applications. Coatings 2022, 12, 545.

- Teixeira, H.; Gomes, M.G.; Moret Rodrigues, A.; Aelenei, D. Assessment of the visual, thermal and energy performance of static vs. thermochromic double-glazing under different European climates. Build. Environ. 2022, 217, 109115.

- Essa, F.A.; Abdullah, A.; Majdi, H.S.; Basem, A.; Dhahad, H.A.; Omara, Z.M.; Mohammed, S.A.; Alawee, W.H.; Ezzi, A.A.; Yusaf, T. Parameters Affecting the Efficiency of Solar Stills—Recent Review. Sustainability 2022, 14, 10668.

- Pracucci, A.; Magnani, S.; Casadei, O. The Integration of Vacuum Insulated Glass in Unitized Façade for the Development of Innovative Lightweight and Highly Insulating Energy Efficient Building Envelope—The Results of Eensulate Façade System Design. Designs 2020, 4, 40.

- Baek, S.; Kim, S. Optimum Design and Energy Performance of Hybrid Triple Glazing System with Vacuum and Carbon Dioxide Filled Gap. Sustainability 2019, 11, 5543.

- Shi, Y.; Xi, X.; Zhang, Y.; Xu, H.; Zhang, J.; Zhang, R. Prediction and Analysis of the Thermal Performance of Composite Vacuum Glazing. Energies 2021, 14, 5769.

- Aguilar-Santana, J.L.; Jarimi, H.; Velasco-Carrasco, M.; Riffat, S. Review on window-glazing technologies and future prospects. Int. J. Low-Carbon Technol. 2020, 15, 112–120.

- Saleh, M.A.; Kaseb, S.; El-Refaie, M.F. Glass–azimuth modification to reform direct solar heat gain. Build. Environ. 2004, 39, 653–659.

- Paneri, A.; Wong, I.L.; Burek, S. Transparent insulation materials: An overview on past, present and future developments. Sol. Energy 2019, 184, 59–83.

- Abdelrady, A.; Abdelhafez, M.H.H.; Ragab, A. Use of Insulation Based on Nanomaterials to Improve Energy Efficiency of Residential Buildings in a Hot Desert Climate. Sustainability 2021, 13, 5266.

- Buratti, C.; Moretti, E.; Zinzi, M. High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions. Buildings 2017, 7, 8.

- Struhala, K.; Čekon, M.; Slávik, R. Life Cycle Assessment of Solar Façade Concepts Based on Transparent Insulation Materials. Sustainability 2018, 10, 4212.

- Marrone, P.; Asdrubali, F.; Venanzi, D.; Orsini, F.; Evangelisti, L.; Guattari, C.; de Lieto Vollaro, R.; Fontana, L.; Grazieschi, G.; Matteucci, P.; et al. On the Retrofit of Existing Buildings with Aerogel Panels: Energy, Environmental and Economic Issues. Energies 2021, 14, 1276.

- Chen, B.; Chen, X.; Ding, Y.H.; Jia, X. Shading effects on the winter thermal performance of the Trombe wall air gap: An experimental study in Dalian. Renew. Energy 2006, 31, 1961–1971.

- Löhnert, G. Thermal Insulation and Shading System—TWS: An Improvement of "Beadwall" Principle. In Advances in Solar Energy Technology; Bloss, W.H., Pfisterer, F., Eds.; Pergamon: Oxford, UK, 1988; pp. 3508–3513.

- Huang, Y.; Niu, J.L.; Chung, T.M. Energy and carbon emission payback analysis for energy-efficient retrofitting in buildings—Overhang shading option. Energy Build. 2012, 44, 4–103.

- Bhatia, A.; Abhilash, S.; Sangireddy, R.; Garg, V. An approach to calculate the equivalent solar heat gain coefficient of glass windows with fixed and dynamic shading in tropical climates. J. Build. Eng. 2019, 22, 90–100.

- Casini, M. Active dynamic windows for buildings: A review. Renew. Energy 2018, 119, 923–934.

- Sbar, N.L.; Podbelski, L.; Yang, H.M.; Pease, B. Electrochromic dynamic windows for office buildings. Int. J. Sustain. Built Environ. 2012, 1, 125–139.

- Dabbagh, M.; Krarti, M. Experimental valuation of the performance for switchable insulated shading systems. Energy Build. 2022, 256, 111753.

- Bellia, L.; de Falco, F.; Minichiello, F. Effects of solar shading devices on energy equirements of standalone office buildings for Italianm climates. Appl. Therm. Eng. 2013, 54, 190–201.

- Yao, Y. An investigation into the impact of movable solar shades on energy, indoor thermal and visual comfort improvements. Build. Environ. 2014, 71, 24–32.

- Hami, K.; Draoui, B.; Hami, O. The thermal performances of a solar wall. Energy 2012, 39, 11–16.

- Chwieduk, D. Some aspects of modeling the energy balance of a room in regard to the impact of solar energy. Sol. Energy 2008, 82, 870–884.

- Chwieduk, D. Energetyka Słoneczna Budynku; Arkady: Warsaw, Poland, 2011.

- Chwieduk, D. Solar energy of the building. In Works of the Institute of Fundamental Technological Research; Institute of Fundamental Technological Research: Warsaw, Poland, 2006. (In Polish)

- Kisilewicz, T. Influence of Dynamic Properties of Building Partitions on Energy Consumption and Thermal Comfort; Monograph, No. 364; Cracow University of Technology Publishing House: Kraków, Poland, 2004; ISSN 0860-097X. (In Polish)

- Fosdick, J. Passive Solar Heating. Available online: https://www.wbdg.org/resources/passive-solar-heating (accessed on 25 August 2022).

- Available online: https://basf.com/group/corporate/en/general-info:/Brand+Micronal+PCM (accessed on 20 February 2018).

- Chen, C.; Guo, H.F.; Liu, Y.N.; Yue, H.L.; Wang, C.D. A new kind of phase change material (PCM) for energy-storing wallboard. Energy Build. 2008, 40, 882–890.

- Castell, A.; Martorell, I.; Medrano, M.; Pérez, G.; Cabeza, L.F. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010, 42, 534–540.

- Kara, Y.A.; Kurnuç, A. Performance of coupled novel triple glass and phase change material wall in the heating season: An experimental study. Sol. Energy 2012, 86, 2432–2442.

- Kuznik, F.; Virgone, J.; Roux, J.J. Energetic efficiency of room wall containing PCM wallboard: A full-scale experimental investigation. Energy Build. 2008, 40, 148–156.

- Peippo, K.; Kauranen, P.; Lund, P.D. A multicomponent PCM wall optimized for passive solar heating. Energy Build. 1991, 17, 259–270.

- Rao, Z.; Wang, S.; Zhang, Z. Energy saving latent heat storage and environmental friendly humidity-controlled materials for indoor climate. Renew. Sustain. Energy Rev. 2012, 16, 3136–3145.

- Athienitis, A.K.; Chen, Y. The effect of solar radiation on dynamic thermal performance of floor heating systems. Sol. Energy 2000, 69, 229–237.

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113–119.

- Wüest, T.; Grobe, L.O.; Luible, A. An Innovative Façade Element with Controlled Solar-Thermal Collector and Storage. Sustainability 2020, 12, 5281.

- Szyszka, J.; Starakiewicz, A. A quasi-box window concept to improve the thermal-insulation property of old windows—Case study. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 49, p. 00115.

- Musiał, M. Untersuchung des Einflusses der Geometrie auf ihre Pakete PCM Wärmespeichereffizienz. Bauphysik 2019, 6, 324–330.

- Musiał, M.M. Experimental and Numerical Analysis of the Energy Efficiency of Transparent Partitions with a Thermal Storage Unit. J. Ecol. Eng. 2020, 21, 201–211.

- Wang, C.; Li, N.; Gu, T.; Ji, J.; Yu, B. Design and performance investigation of a novel double-skin ventilated window integrated with air-purifying blind. Energy 2022, 254 Part C, 124476.

- Medici, P. The Trombe Wall during the 1970s: Technological device or architectural space? Critical inquiry on the Trombe Wall in Europe and the role of architectural magazines. SPOOL 2018, 5, 45–60.

- Mohamad, A.; Taler, J.; Ocłoń, P. Trombe Wall Utilization for Cold and Hot Climate Conditions. Energies 2019, 12, 285.

- Sadeghi, G.; Mehrali, M.; Shahi, M.; Brem, G.; Mahmoudi, A. Progress of experimental studies on compact integrated solar collector-storage retrofits adopting phase change materials. Sol. Energy 2022, 237, 62–95.

- Michel, J. Chauffage par rayonnement solaire . Archit. d’Aujourd’hui 1973, 167, 88–93.

- Quesada, G.; Rousse, D.; Dutil, Y.; Badache, M.; Hallé, S. A comprehensive review of solar facades. Opaque solar facades. Renew. Sustain. Energy Rev. 2012, 16, 2820–2830.

- Saadatian, O.; Sopian, K.; Lim, C.H.; Asim, N.; Sulaiman, M.Y. Trombe walls: A review of opportunities and challenges in research and development. Renew. Sustain. Energy Rev. 2012, 16, 6340–6351.

- Saadatian, O.; Lim, C.H.; Sopian, K.; Salleh, E. A state of the art review of solar walls: Concepts and applications. J. Build. Phys. 2013, 37, 55–79.

- Wang, X.; Xi, Q.; Ma, Q. A review of current work in research of Trombe walls. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 248, p. 03025.

- Agurto, L.; Allacker, K.; Fissore, A.; Agurto, C.; De Troyer, F.; Rebolledo, B. Bioclimatic Prosthesis: Experimental dataset for a low-cost Trombe wall to existing social housing refurbishment for an intermediate valley (Chillán) city in the south of Chile. Data Brief. 2020, 30, 105547.

- Brito-Coimbra, S.; Aelenei, D.; Gloria Gomes, M.; Moret Rodrigues, A. Building Façade Retrofit with Solar Passive Technologies: A Literature Review. Energies 2021, 14, 1774.

- Koyunbaba, B.K.; Yilmaz, Z. The comparison of Trombe wall systems with single glass, double glass and PV panels. Renew. Energy 2012, 45, 111–118.

- Balaras, C.A. The role of thermal mass on the cooling load of buildings. An overview of computational methods. Energy Build. 1996, 24, 1–10.

- Hassanain, A.A.; Hokam, E.M.; Mallick, T.K. Effect of solar storage wall on the passive solar heating constructions. Energy Build. 2010, 43, 737–747.

- Yilmaz, Z.; Basak Kundakci, A.B. An approach for energy conscious renovation of residential buildings in Istanbul by Trombe wall system. Build. Environ. 2008, 43, 508–517.

- Available online: https://enviroinc.com/trombe-wall/ (accessed on 9 September 2022).

- Paradis, R. Balancing Security/Safety and Sustainability Objectives. Available online: https://www.wbdg.org/resources/balancing-securitysafety-and-sustainability-objectives (accessed on 7 April 2022).

- Świrska-Perkowska, J.; Kucharczyk, A.; Wyrwał, J. Energy Efficiency of a Solar Wall with Transparent Insulation in Polish Climatic Conditions. Energies 2020, 13, 859.

- Ramadan, A.M. Simulation Study of Trombe Wall for Passive Solar Technique of buildings in Egypt. IOP Conf. Ser. Mater. Sci. Eng. 2020, 974, 012023.

- Kisilewicz, T. Glazed building wall as a solar thermal collector. Arch. Civ. Mech. Eng. 2009, 9, 83–99.

- Stazi, A.; Mastrucci, P. Munafò Life cycle assessment approach for the optimization of sustainable building envelopes: An application on solar wall systems. Build. Environ. 2012, 58, 278–288.

- Dong, J.; Chen, Z.; Zhang, L.; Cheng, Y.; Sun, S.; Jie, J. Experimental investigation on the heating performance of a novel designed trombe wall. Energy 2019, 168, 728–736.

- Zhang, L.; Dong, J.; Sun, S.; Chen, Z. Numerical simulation and sensitivity analysis on an improved Trombe wall. Sustain. Energy Technol. Assess. 2021, 43, 100941.

- Miąsik, P.; Krasoń, J. Thermal Efficiency of Trombe Wall in the South Facade of a Frame Building. Energies 2021, 14, 580.

- Langdon, W.K. Movable Insulation; Knowledge Publications: Barpeta Road, India, 2009.

- Stazi, F.; Mastrucci, A.; di Perna, C. Trombe wall management in summer conditions: An experimental study. Sol. Energy 2012, 86, 2839–2851.

- Stazi, F. Thermal Inertia in Energy Efficient Building Envelopes; Elsevier Inc.: Amsterdam, The Netherlands, 2017.

- Torcellini, P.; Pless, S. Trombe Walls in Low-Energy Buildings: Practical Experiences; Technical Report; NREL Report No. CP-550-36277; National Renewable Energy Laboratory: Golden, CO, USA, 2004.

- Hordeski, M.F. Dictionary of Energy Efficiency Technologies; Fairmont Press: New York, NY, USA, 2004.

- Zrikem, Z.; Bilgen, E. Theoretical study of a non-convective trombe wall collector with honeycomb structure Original Research. Sol. Wind. Technol. 1986, 3, 33–44.

- Briga-Sá, A.; Paiva, A.; Boaventura-Cunha, J.; Lanzinha, J.C. Contribution of the Trombe wall to sustainable buildings: Experimental work. In Proceedings of the 38th IAHS World Congress on Housing Science, Istanbul, Turkey, 16 April 2012.

- Smolec, W. Photothermal Conversion of Solar Energy; PWN: Warsaw, Poland, 2000. (In Polish)

- Hu, Z.; He, W.; Ji, J.; Zhang, S. A review on the application of Trombe wall system in buildings. Renew. Sustain. Energy Rev. 2017, 70, 976–987.

- Thumann, A.; Mehta, D.P. Handbook of Energy Engineering; Fairmont Press: New York, NY, USA, 2008.

- Özbalta, T.; Kartal, S. Heat gain through Trombe wall using solar energy in a cold region of Turkey. Sci. Res. Essays 2010, 5, 2768–2778.

- Nwachukwu, N.P.; Okonkwo, W.I. Effect of an absorptive coating on solar energy storage in a Trombe wall system. Energy Build. 2007, 40, 371–374.

- Čekon, M.; Čurpek, J. A transparent insulation façade enhanced with a selective absorber: A cooling energy load and validated building energy performance prediction model. Energy Build. 2019, 183, 266–282.

- Čekon, M.; Slávik, R. A Non-Ventilated Solar Façade Concept Based on Selective and Transparent Insulation Material Integration: An Experimental Study. Energy 2017, 10, 815.

- Čekon, M.; Struhala, K.; Kopkáně, D. Preparation and Characterization of a Selective Polymer-Based Solar Absorber for Building Integration. Appl. Sci. 2020, 10, 7861.

- Zhou, G.; Pang, M. Experimental investigations on thermal performance of phase change material—Trombe wall system enhanced by delta winglet vortex generators. Energy 2015, 93, 758–769.

- Sparrow, E.M.; Azevedo, L.F.A. Vertical channel natural convection spanning between the fully developed and the single-plate boundary-layer limit. Int. J. Heat Mass Transf. 1985, 28, 1847–1857.

- Bin, C.; Cuiying, C.; Wenxiu, Y. A calculation model of passive solar house with Trombe wall. Renew. Energy Proc. 2006, 600–803.

- Onbasioglu, H.; Egrican, A.N. Experimental approach to the thermal response of passive systems. Energy Convers. Manag. 2002, 43, 2053–2065.

- Krüger, E.; Suzuki, E.; Matoski, A. Evaluation of a Trombe wall system in a subtropical location. Energy Build. 2013, 66, 364–372.

- Shen, J.; Lassue, S.; Zalewski, L.; Huang, D. Numerical study on thermal behavior of classical or composite Trombe solar walls. Energy Build. 2007, 39, 962–974.

- Liu, Y.W.; Feng, W. Integrating passive cooling and solar techniques in to the existing building in South China. Adv. Mater. Res. 2012, 368, 3717–3720.

- Liu, Y.; Wang, D.; Ma, C.; Liu, J. A numerical and experimental analysis of the air vent management and heat storage characteristics of a trombe wall. Sol. Energy 2013, 91, 1–10.

- Bevilacqua, P.; Benevento, F.; Bruno, R.; Arcuri, N. Are Trombe walls suitable passive systems for the reduction of the yearly building energy requirements? Energy 2019, 185, 554–566.

- Briga-Sá, A.; Paiva, A.; Lanzinha, J.-C.; Boaventura-Cunha, J.; Fernandes, L. Influence of Air Vents Management on Trombe Wall Temperature Fluctuations: An Experimental Analysis under Real Climate Conditions. Energies 2021, 14, 5043.

- Bevilacqua, P.; Bruno, R.; Szyszka, J.; Cirone, D.; Rollo, A. Summer and winter performance of an innovative concept of Trombe wall for residential buildings. Energy 2022, 258, 124798.

- Mota, A.; Briga-Sá, A.; Valente, A. Development of a Wireless System to Control a Trombe Wall for Poultry Brooding. AgriEngineering 2021, 3, 853–867.

- Bojić, M.; Johannes, K.; Kuznik, F. Optimizing energy and environmental performance of passive Trombe wall. Energy Build. 2014, 70, 279–286.

- Nowzari, R.; Atikol, U. Transient Performance Analysis of a Model Building Integrated with a Trombe-Wall. In Proceedings of the 7th IASME WSEAS International Conference on Heat Transfer, Thermal Engineering and Environment, Moscow, Russia, 20–22 August 2009.

- Kalogirou, S.; Florides, G.; Tassou, S. Energy analysis of buildings employing thermal mass in Cyprus. Int. J. Renew. Energy 2002, 27, 353–368.

- Dimassi, N.; Dehmani, L. Thermal Efficiency of a Solar Wall in Tunisia. ISRN Renew. Energy 2012, 2012, 465249.

- Fang, X.; Li, Y. Numerical simulation and sensitivity analysis of lattice passive solar heating walls. Sol. Energy 2000, 69, 55–66.

- Fang, X.; Yang, T. Regression methodology for sensitivity analysis of solar heating walls. Appl. Therm. Eng. 2008, 28, 2289–2294.

- Jaber, S.; Ajib, S. Optimum design of Trombe wall system in Mediterranean region. Sol. Energy 2011, 85, 1891–1898.

This entry is offline, you can click here to edit this entry!