Load monitoring systems make it possible to obtain information on the status of the various loads powered by an electrical system. The term “electrical load” indicates any device or circuit that absorbs energy from the system to which it is connected, and which therefore influences electrical quantities such as power, voltage, and current. These monitoring systems, designed for applications related to energy efficiency, can also be used in other applications. The information derived from Non-Intrusive Load Monitoring (NILM) systems can be used in order to create Energy Management Systems (EMS), Demand Response (DR), anomaly detection, maintenance, and Ambient Assisted Living (AAL). An EMS allows the user to measure and control the use and production of energy within a plant. Due to the benefits offered to both the consumers and distributors of electricity, EMSs are becoming increasingly important for reducing consumption.

1. EMS for Smart Homes and Microgrids

NILM techniques allow for the real-time detection of devices that are active. They can be used within EMSs, providing information on the electrical consumption of individual appliances. To apply these techniques advantageously, it is firstly important to classify the load devices on the basis of the programmability or, otherwise, of their use. The former are devices whose operation cannot be delayed (e.g., lighting, kitchen, or refrigerator). The latter devices can operate in variable time intervals based on the price of energy (e.g., washing machines and dryers). Heating, Ventilation, and Air Conditioning (HVAC) systems are particularly important to this aim.

The EMS allows you to program the switching on of appliances, giving higher priority to appliances that have a higher energy consumption. In addition to power consumption, the switching times, operating range, and frequency of use for each class of equipment are important parameters for load management. These parameters are provided by NILM systems. In

[1][2], the reduction in the cost of electricity is achieved by formulating the problem as a minimization problem, taking into account the scheduling flexibility of household appliances by consumers. The results show that the system can reduce the cost of energy for consumers in a meaningful way. These load scheduling techniques facilitate the time shift of existing loads in off-peak periods, so costs are minimized.

Çimen et al.

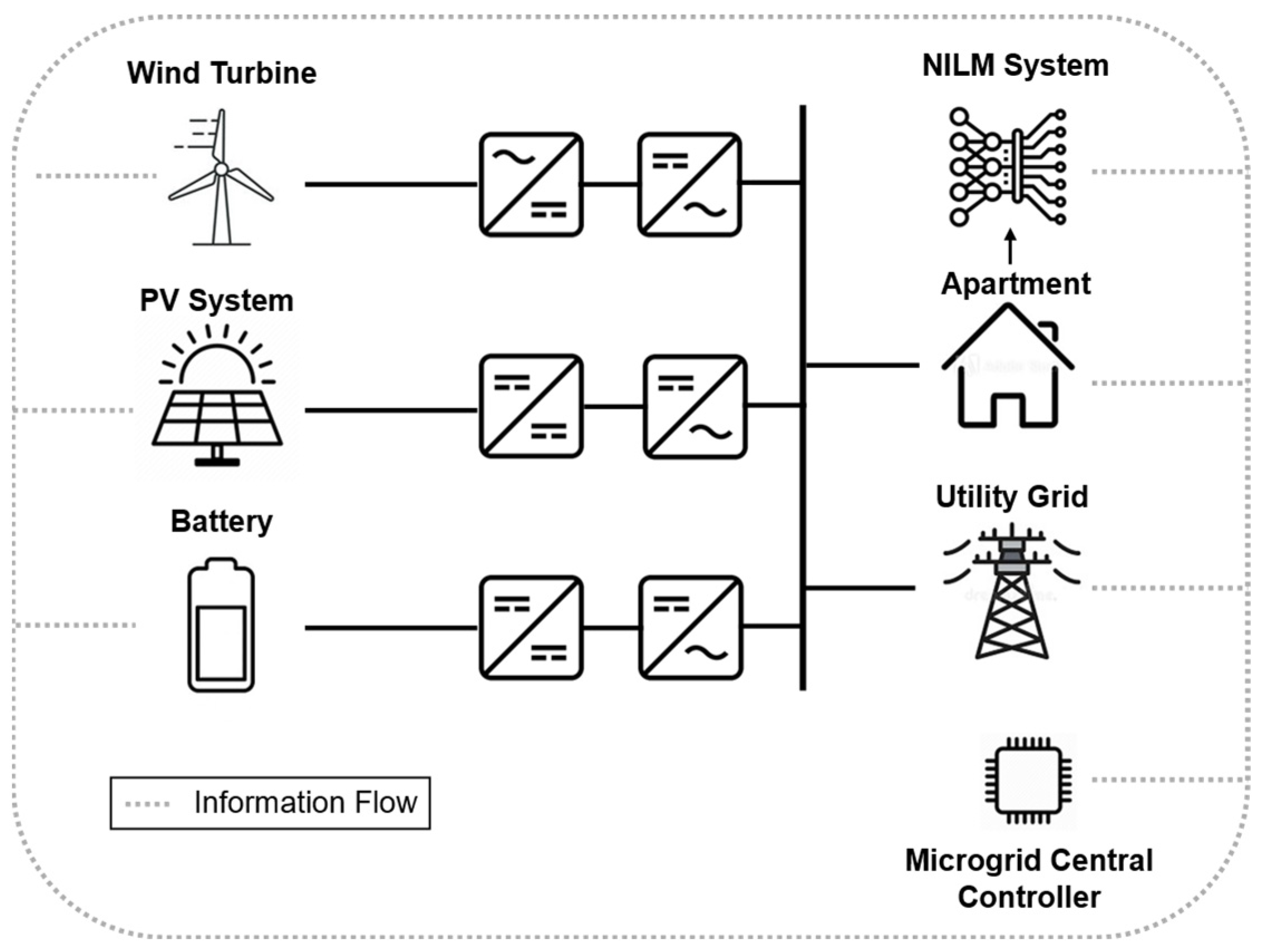

[3] propose an NILM-based EMS to manage the operation of household appliances, in coordination with renewable sources and batteries within a residential microgrid. Residential grids include energy storage systems, some distributed generation units and one or more homes. These electrical systems can be used both in connected mode and in stand-alone mode, thanks to their flexible structure.

Figure 1 shows the structure of the proposed microgrid.

Figure 1. The microgrid structure with generation and storage sections.

On the power supply side, the energy sources include the public grid, a photovoltaic system, a wind turbine, and an energy storage system unit. Each system is managed by a microcontroller, through the information obtained from a NILM system, such as appliance activations, turn-on and turn-off times, power absorbed in the various operating conditions, and periods preferred by the user. The system optimizes the energy supplied by renewable source plants by minimizing the absorption of electricity from the grid.

In

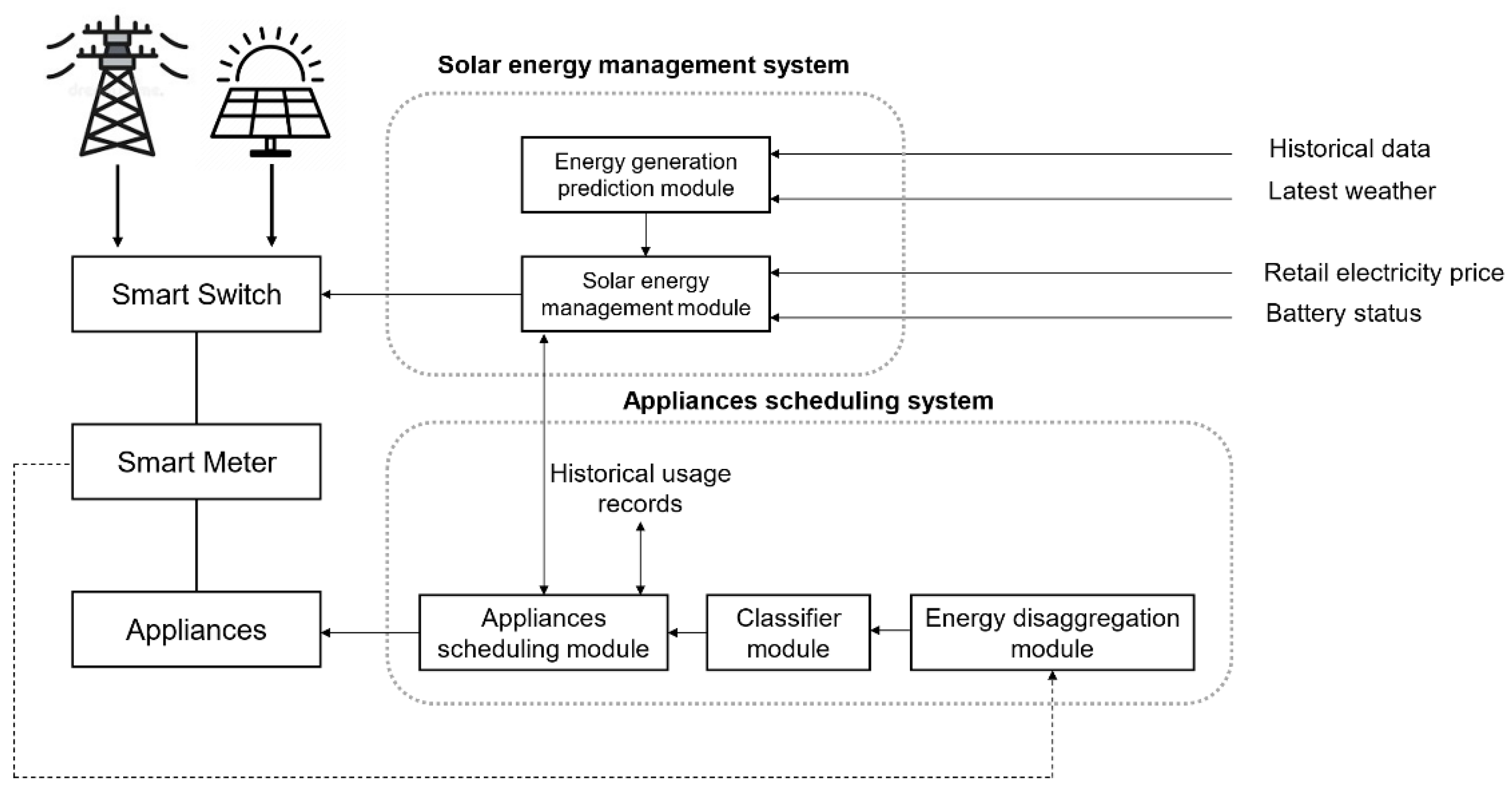

[4], Xia et al. propose an EMS that allows minimization of the cost of domestic electricity while satisfying the needs of comfort and safety. The system consists of a first module called the Solar Energy Management System which maximizes solar energy utilization, and a second module called the Appliances Scheduling System which minimizes the electricity load during peak hours. Using this EMS, the running time of the appliance is automatically programmed based on considerations concerning the preferences of the family, the day-ahead electricity price, and the historical data of electricity use. At the same time, the system uses the photovoltaic system and the storage systems in order to consume the minimum amount of energy from the grid. In the two subsystems that make up the EMS, a smart meter is used to collect the reading of the household’s overall energy consumption and transmit it to the energy disaggregation module.

The framework modules, shown in Figure 2, are described below.

-

Energy generation prediction module: this module generates a forecast based on historical meteorological data for the considered position.

-

Solar energy management module: this module controls the switch starting from the output of the previous block, the state of the battery, and the price of electricity. The various loads can be powered by both the solar system and the electricity grid; therefore, the system will include a controlled switch capable of connecting both power sources by absorbing energy from one or the other source. Therefore, this module optimizes the use of the collected solar energy. When the photovoltaic energy production exceeds the load demand, the photovoltaic energy is used as a priority, and the surplus energy is stored in the storage system. Only in the event that the photovoltaic energy (generated during the day or stored during the night) is not sufficient to support all the appliances in operation, does the system absorb energy from the grid.

-

Energy disaggregation module: in order to implement efficient programming, the EMS should be aware of the details of the runtime of each device to deduce the activities of users on an average day. The preferences and habits of users are deduced on the basis of this detailed information at the appliance-level by imposing a certain level of priority, so as not to upset their routine too much. Therefore, to obtain appropriate planning strategies for a certain household, the consumption patterns of each appliance are key information.

-

Classifier module: this module is designed to discriminate between the programmable and non-programmable devices. The classification process is based on various parameters such as the flexibility and user preferences for each device. Initially, the classification module generates a profile of user preferences, preset according to the varied devices and historical data.

-

Appliances scheduling module: this module classifies appliances as programmable or non-programmable and is responsible for programming the start time of programmable one.

Figure 2. The EMS framework which illustrates the smart switch management system and the necessary modules.

2. NILM Systems in EMS

The optimal scheduling of appliances is traced back to an optimization problem, formulated as (1), solved through dynamic programming algorithms to search for sequences of states of each appliance that lead to a lower cost of electricity at the end of the day:

where cost is the sum of the costs of the energy absorbed by the grid,

N is the number of schedulable appliances, is a set of discrete time intervals over a whole day (configurable by each user), and is the price of electricity over the interval

t.

The problem appears to be a constrained optimization problem since the time intervals that can be taken into consideration in the search for the minimum must be compatible with the information on the user behavior of the appliances, obtained from energy disaggregation.

Each appliance is characterized by a working mode m which is associated with both a specific power absorption, , and a different impact on the result. For example, a dishwasher that performs a wash in eco mode has a reduced energy consumption as it heats less water, but takes longer to finish the cycle, with a consequent impact on user comfort. Therefore, the optimization algorithm must find a working mode that minimizes the cost of the bill while maintaining certain levels of comfort.

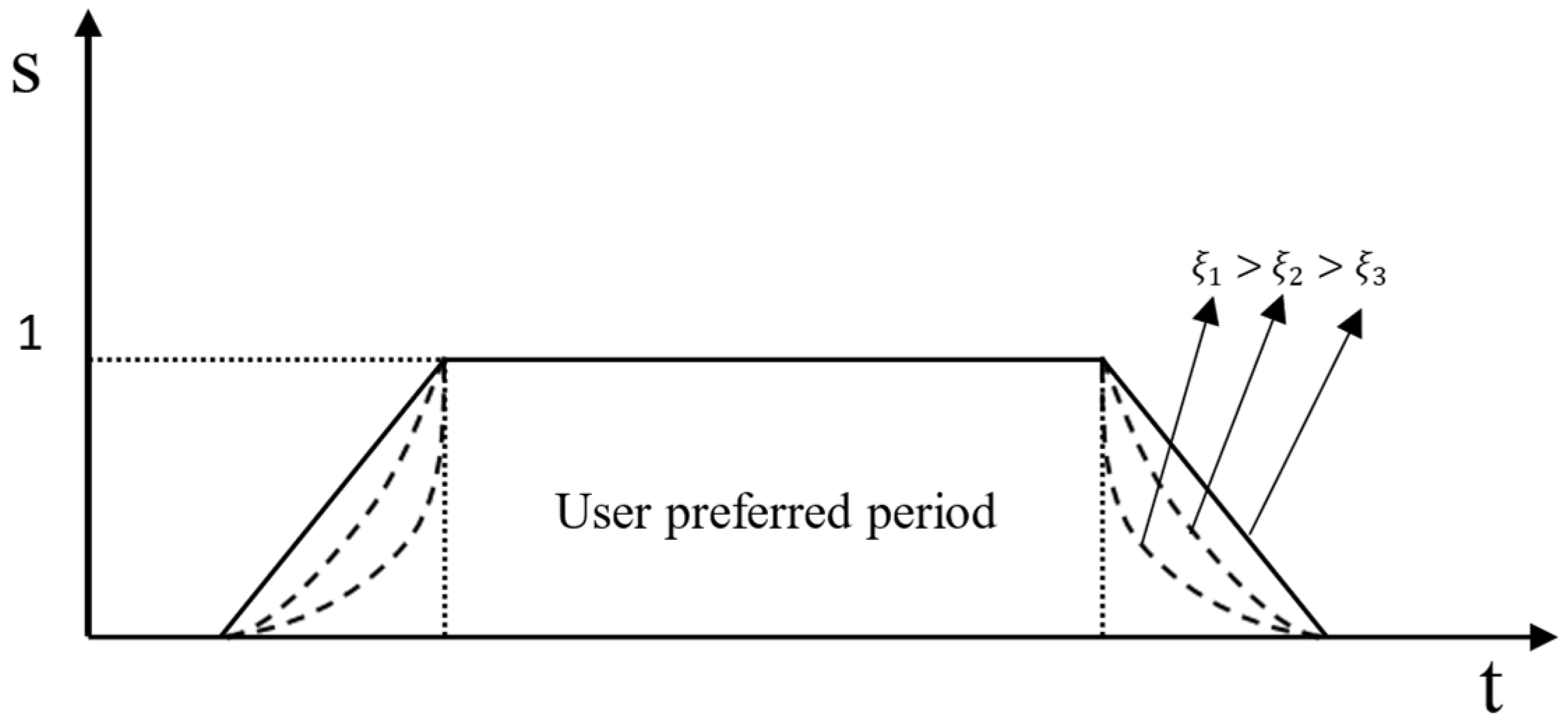

To take into account the user’s satisfaction, the parameter is introduced, which is equal to one when the appliances work in the period preferred by the user and decreases as this period varies. Its distribution model can be changed by a factor ξ, depending on the degree of tolerance. Figure 3 shows the distribution of user satisfaction as a function of a hypothetical appliance operating time.

Figure 3. User satisfaction level and degree of tolerance.

The scheduling algorithm must therefore also try to maximize the user’s comfort level. This problem can be formulated as in (2):

where corresponds to the user satisfaction value, introduced above, at time for appliance .

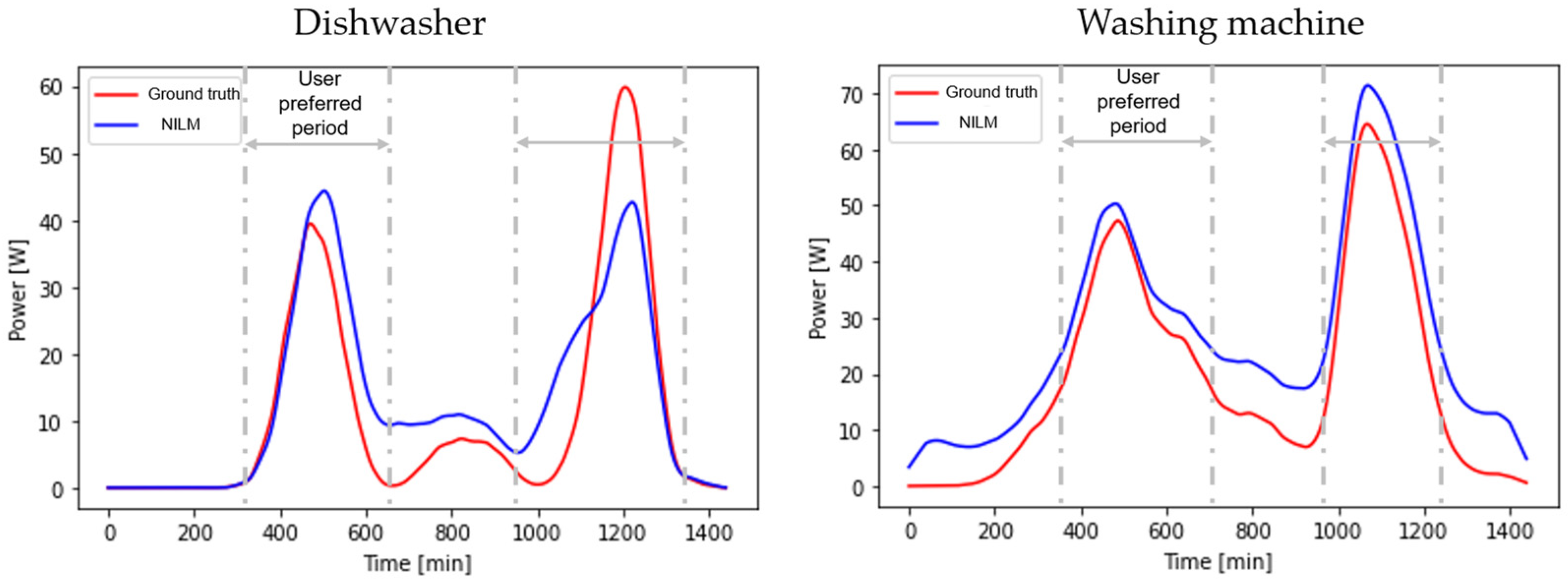

As previously introduced, the parameters necessary for scheduling household appliances can be obtained with the aid of the NILM algorithm. As an example, Figure 4 shows the power distributions of two appliances over 24 h.

We obtained these distributions by processing the power measurements available from the REFIT dataset

[5], which provides aggregate and appliance-level power metering for several homes over a period of approximately two years. The red curve represents the power distribution, calculated with the power measurements at the appliance level. We obtained the blue curve by processing the corresponding aggregate power signal through an artificial Sequence-to-Point neural network, implemented in accordance with

[6]. Since the REFIT dataset contains aggregated power and power supply data at the appliance level for 21 homes, data from homes that had washing machines and dishwashers were used for training the model. A house not seen during the training phase was therefore chosen to obtain the analysis shown in

Figure 4. The peaks indicate the periods when the device is used most frequently. Therefore, if the appliance is scheduled outside the gray dotted lines, customer satisfaction could be reduced according to the curve in

Figure 3.

Figure 4. Power distribution of a dishwasher and a washing machine.

Similarly, in

[7] the authors propose a NILM system based not on DL as in

[3], but on Bayesian theory. The proposed system also provides for the scheduling of appliances in order to optimize the power flows in a Smart Home. In

[8] the IoT criteria for implementing an EMS based on NILM are outlined. In particular, the cited work refers to FHMM algorithms, but what was said can also be extended to other approaches such as DL, Combinatorial Optimization, and event-based.

An NILM system serving an EMS must have a high level of disaggregation accuracy; therefore, it must be able to determine, as closely as possible, the energy consumption profiles at the appliance level. It must also be able to provide information on the status (ON or OFF) in which the devices are positioned in order to guarantee correct feedback in scheduling. Comparing EMSs based on NILM with those based on ILM, it is clear that the main drawback linked to the use of NILM systems lies in their lower accuracy in estimating information, as can also be guessed from Figure 4. In fact, NILM algorithms will always present greater uncertainty in estimating consumption and appliance status compared to intrusive systems. However, the use of NILM systems allows one to obtain the necessary feedback for energy management through a single installation, which represents a significant advantage, especially for those homes that were not born “smart”.

This entry is adapted from the peer-reviewed paper 10.3390/en15239011