It is urgent that we increase global food production to support population growth. Food production requires significant resources, amongst them water and energy. Therefore, any losses of food or other agricultural products also means a waste of water and energy resources. A significant amount of these losses occurs during the postharvest stage, primarily during processing and storage. This is considered avoidable food waste. The water-energy-waste nexus (WEW), and its relationship to food production, needs to be investigated from a circular bioeconomy lens. Furthermore, alternative uses of the wastes should be investigated.

- agroecology

- bioenergy

- biorefinery

- compost

- food security

1. Introduction

2. Management of Agro-Wastes

| Plant | Family | Agro-Waste | Bioactive Compounds | Refs. |

|---|---|---|---|---|

| Almond: Prunus dulcis (Mill.) D. A. Webb | Rosaceae | Seed coat | Catechin, kaempferol, isorhamnetin, naringenin, quercetin | [48] |

| Apple: Malus domestica (Suckow) Borkh. | Rosaceae | Pomace, seed, peel | Anthocyanins, catechin, caffeic acid, phloretin glycosides, quercetin glycosides | [49] |

| Banana: Musa sp. | Musaceae | Peel, stalk, pulp | Anthocyanins, auroxanthin, cyaniding, catecholamine, delphinidin, flavonoids, hydroxycinnamic, lutein, neoxanthin, α-and β-carotene, β-cryptoxanthin | [50] |

| Date palm: Phoenix dactylifera L. | Arecaceae | Pulp, seed | Phenolic acids, fatty acids, flavonols, sphingolipids, steroids | [51] |

| Durian: Durio zibethinus L. | Malvaceae | Peel, pulp, rind, seed | Glutathione, γ-glutamyl cysteine, pyridoxamine, cysteine, leucine | [52] |

| Grapefruit: Citrus × paradisi Macfad. | Rutaceae | Peel, pulp, seed | Neohesperidosides, naringenin | [53] |

| Lemon: Citrus limon (L.) Osbeck | Rutaceae | Seed, peel, pulp | Apigenin-6, caffeic acid, coumarate, ferulate | [54] |

| Mango: Mangifera indica L. | Anacardiaceae | Exocarp, pulp, seed | Flavonoids, gallates, hydrolysable tannins, methyl gallate, phenolics | [55] |

| Pineapple: Ananas comosus L. Merr. | Bromeliaceae | Stem, pulp, peel | Catechin, epicatechin, ferulate, gallic acid, phenolics | [56] |

| Pomegranate: Punica granatum L. | Lythraceae | Pulp, seed, peel | Anthocyanins, flavonoids, gallic acid, punicalagin | [57] |

| Strawberry: Fragaria × ananassa | Rosaceae | Sepals and peduncles | Phenolic compounds and antioxidant capacity | [58] |

| Carrot: Daucus carota L. |

Apiaceae | Peel | Anthocyanidin, α-carotene, carotenoids, β-carotene | [59] |

| Potato: Solanum tuberosum L. | Solanaceae | Peel, tuber, leaf | Anthocyanin, caffeic acid, carotenoid, lutein, caffeoylquinic acid | [60] |

| Rice: Oryza sativa L. | Poaceae | Husk, straw, bran | Anthocyanins, caffeic acid, phytosterols, pantothenic, niacin, pyridoxine, tricin | [61] |

| Soybean: Glycine max L. Merr. | Fabaceae | Husk | Chlorogenic acid, ferulate, gallic acid | [62] |

| Tomato: Solanum lycopersicum L. | Solanaceae | Peel, pulp, seed | Caffeic acid, chlorogenic acid, lycopene β-carotene, | [63] |

| Wheat: Triticum aestivum L. | Poaceae | Bran | Caffeic acid, ferulate, gallic acid, p-coumaric acid | [64] |

2.1. Agro-Wastes for Recycling and Composting

2.2. Nano-Management of Agro-Wastes

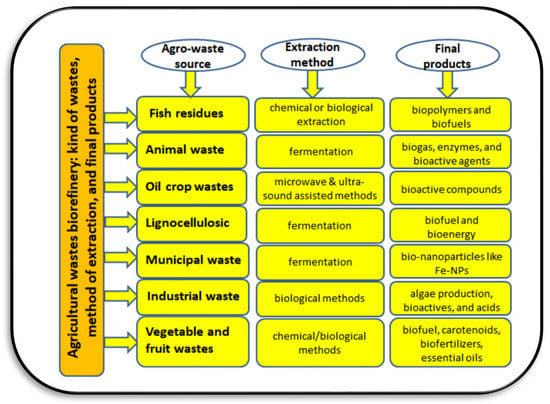

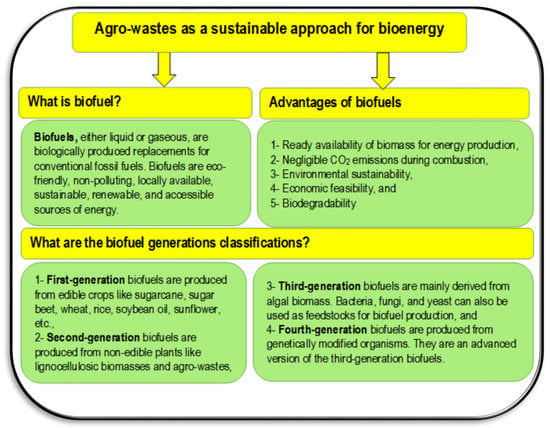

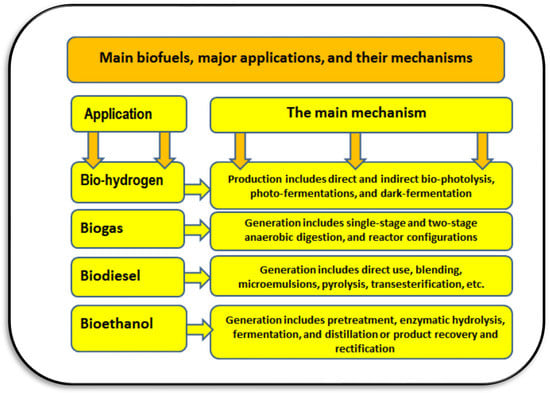

2.3. Agro-Wastes to Produce Bioenergy and Biorefinery

2.4. Agro-Wastes for Plant Tissue Culture Media

This entry is adapted from the peer-reviewed paper 10.3390/su142315717

References

- Ioannou, Z.; Kavvadias, V.; Karasavvidis, C. Recycling of agricultural wastes: Treatment and uses. In Agricultural Wastes: Characteristics, Types, and Management; Foster, C.N., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2015; pp. 1–21.

- Ramírez-García, R.; Gohil, N.; Singh, V. Recent Advances, Challenges, and Opportunities in Bioremediation of Hazardous Materials. In Phytomanagement of Polluted Sites Market Opportunities in Sustainable Phytoremediation; Pandey, V.M., Bauddh, K., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 517–568.

- Chen, C.; Chaudhary, A.; Mathys, A. Nutritional and environmental losses embedded in global food waste. Resour. Conserv. Recycl. 2020, 160, 104912.

- Benyam, A.; Soma, T.; Fraser, E. Digital agricultural technologies for food loss and waste prevention and reduction: Global trends, adoption opportunities and barriers. J. Clean. Prod. 2021, 323, 129099.

- Ogunmoroti, A.; Liu, M.; Li, M.; Liu, W. Unraveling the environmental impact of current and future food waste and its management in Chinese provinces. Resour. Environ. Sustain. 2022, 9, 100064.

- Kamel, R.; El-Wakil, N.A.; Dufresne, A.; Nermeen, A.; Elkasabgy, N.A. Nanocellulose: From an agricultural waste to a valuable pharmaceutical ingredient. Int. J. Biol. Macromol. 2020, 163, 1579–1590.

- El-Bassi, L.; Azzaz, A.A.; Jellali, S.; Akrout, H.; Marks, E.A.N.; Ghimbeu, C.M.; Jeguirim, M. Application of olive mill waste-based biochars in agriculture: Impact on soil properties, enzymatic activities and tomato growth. Sci. Total Environ. 2021, 755, 142531.

- Kwoczynski, Z.; Cmelík, J. Characterization of biomass wastes and its possibility of agriculture utilization due to biochar production by torrefaction process. J. Clean. Prod. 2021, 280, 124302.

- Peerzada, J.G.; Chidambaram, R. A Statistical Approach for Biogenic Synthesis of Nano-Silica from Different Agro-Wastes. Silicon 2020, 13, 2089–2101.

- Singh, S.P.; Endley, N. Fabrication of nano-silica from agricultural residue and their application. In Nanomaterials for Agriculture and Forestry Applications; Husen, A., Jawaid, M., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 117–134.

- Suffo, M.; de la Mata, M.; Molina, S.I. A sugar beet waste based thermoplastic agro-composite as substitute for raw materials. J. Clean. Prod. 2020, 257, 120382.

- Fareed, A.; Zaidi, S.B.A.; Ahmad, N.; Hafeez, I.; Ali, A.; Ahmad, M.F. Use of agricultural waste ashes in asphalt binder and mixture: A sustainable solution to waste management. Constr. Build. Mater. 2020, 259, 120575.

- Mo, K.H.; Thomas, B.S.; Yap, S.P.; Abutaha, F.; Tan, C.G. Viability of agricultural wastes as substitute of natural aggregate in concrete: A review on the durability-related properties. J. Clean. Prod. 2020, 275, 123062.

- Landin-Sandoval, V.J.; Mendoza-Castillo, D.I.; BonillaPetriciolet, A.; Aguayo-Villarreal, I.A.; Reynel-Avila, H.E.; Gonzalez-Ponce, H.A. Valorization of agri-food industry wastes to prepare adsorbents for heavy metal removal from water. J. Environ. Chem. Eng. 2020, 8, 104067.

- Siles-Castellano, A.B.; López, M.J.; Jurado, M.M.; SuárezEstrella, F.; López-González, J.A.; Estrella-González, M.J.; Moreno, J. Industrial composting of low carbon/nitrogen ratio mixtures of agri-food waste and impact on compost quality. Bioresour. Technol. 2020, 316, 123946.

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agrowaste. Sci. Total Environ. 2020, 716, 137065.

- Koutra, E.; Mastropetros, S.G.; Ali, S.S.; Tsigkou, K.; Kornaros, M. Assessing the potential of Chlorella vulgaris for valorization of liquid digestates from agro-industrial and municipal organic wastes in a biorefinery approach. J. Clean. Prod. 2021, 280, 124352.

- Uddin, M.N.; Siddiki, S.Y.A.; Mofijur, M.; Djavanroodi, F.; Hazrat, M.A.; Show, P.L.; Ahmed, S.F.; Chu, Y.-M. Prospects of Bioenergy Production from Organic Waste Using Anaerobic Digestion Technology: A Mini Review. Front. Energy Res. 2021, 9, 627093.

- Arun, K.B.; Madhavan, A.; Sindhu, R.; Binod, P.; Pandey, A.; Reshmy, R.; Sirohi, R. Remodeling agroindustrial and food wastes into value-added bioactives and biopolymers. Ind. Crops Prod. 2020, 154, 112621.

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510.

- Gullón, P.; Gullón, B.; Romaní, A.; Rocchetti, G.; Lorenzo, J.M. Smart advanced solvents for bioactive compounds recovery from agri-food by-products: A review. Trends Food Sci. Technol. 2020, 101, 182–197.

- Lemes, A.C.; Egea, M.B.; Oliveira Filho, J.G.d.; Gautério, G.V.; Ribeiro, B.D.; Coelho, M.A.Z. Biological Approaches for Extraction of Bioactive Compounds from Agroindustrial By-products: A Review. Front. Bioeng. Biotechnol. 2022, 9, 802543.

- Braun, R.; Hertweck, D.; Eicker, U. An approach to cluster the research field of the food-energy-water nexus to determine modeling capabilities at different levels using text mining and cluster analysis. Energy Nexus 2022, 7, 100101.

- Couto, L.C.; Campos, L.C.; da Fonseca-Zang, W.; Zang, J.; Bleischwitz, R. Water, waste, energy and food nexus in Brazil: Identifying a resource interlinkage research agenda through a systematic review. Renew. Sustain. Energy Rev. 2021, 138, 110554.

- Lin, H.; Borrion, A.; da Fonseca-Zang, W.A.; Zang, J.W.; Leandro, W.M.; Campos, L.C. Life cycle assessment of a biogas system for cassava processing in Brazil to close the loop in the water-waste-energy-food nexus. J. Clean. Prod. 2021, 299, 126861.

- Afkhami, P.; Zarrinpoor, N. The energy-water-food-waste-land nexus in a GIS-based biofuel supply chain design: A case study in Fars province, Iran. J. Clean. Prod. 2022, 340, 130690.

- El-Ramady, H.; Brevik, E.C.; Elsakhawy, T.; Omara, A.E.D.; Amer, M.; Abowaly, M.; El-Henawy, A.; Prokisch, J. Soil and Humans: A Comparative and A Pictorial Mini-Review. Egypt. J. Soil Sci. 2022, 62, 101–122.

- Brevik, E.C.; Omara, A.E.D.; Elsakhawy, T.; Amer, M.; Fawzy, Z.F.; El-Ramady, H.; Prokisch, J. The Soil-Water-Plant-Human Nexus: A Call for Photographic Review Articles. Environ. Biodivers. Soil Secur. 2022, 6, 117–131.

- El-Ramady, H.; Faizy, S.E.D.; Amer, M.M.; Elsakhawy, T.; Omara, A.E.D.; Eid, Y.; Brevik, E.C. Management of Salt-Affected Soils: A Photographic Mini-Review. Environ. Biodivers. Soil Secur. 2022, 6, 61–79.

- Koriem, M.A.; Gaheen, S.A.; El-Ramady, H.; Prokisch, J.; Brevik, E.C. Global Soil Science Education to Address the Soil–Water–Climate Change Nexus. Environ. Biodivers. Soil Secur. 2022, 6, 27–39.

- El-Ramady, H.; Törős, G.; Badgar, K.; Llanaj, X.; Hajdú, P.; El-Mahrouk, M.E.; Abdalla, N.; Prokisch, J. A Comparative Photographic Review on Higher Plants and Macro-Fungi: A Soil Restoration for Sustainable Production of Food and Energy. Sustainability 2022, 14, 7104.

- El-Ramady, H.; Hajdú, P.; Töros, G.; Badgar, K.; Llanaj, X.; Kiss, A.; Abdalla, N.; Omara, A.E.-D.; Elsakhawy, T.; Elbasiouny, H.; et al. Plant Nutrition for Human Health: A Pictorial Review on Plant Bioactive Compounds for Sustainable Agriculture. Sustainability 2022, 14, 8329.

- Bayoumi, Y.; Shalaby, T.A.; Fawzy, Z.A.; Shedeed, S.I.; Taha, N.; El-Ramady, H.; Prokisch, J. Grafting of Vegetable Crops in the Era of Nanotechnology: A photographic Mini Review. Environ. Biodivers. Soil Secur. 2022, 6, 133–148.

- Fawzy, Z.F.; El-Ramady, H.; Abd El-Fattah, D.A.; Prokisch, J. Sustainable Applications of Mushrooms in Soil Science: A Call for Pictorial Articles. Egypt. J. Soil Sci. 2022, 62, 101–115.

- Fawzy, Z.F.; El-Ramady, H.; Omara, A.E.D.; Elsakhawy, T.; Bayoumi, Y.; Shalaby, T.A.; Prokisch, J. From Farm-to-Fork: A pictorial Mini Review on Nano-Farming of Vegetables. Environ. Biodivers. Soil Secur. 2022, 6, 149–163.

- Fawzy, Z.F.; El-Ramady, H. Applications and Challenges of Smart Farming for Developing Sustainable Agriculture. Environ. Biodivers. Soil Secur. 2022, 6, 81–90.

- Fawzy, Z.F.; El-Sawy, S.M.; El-Bassiony, A.M.; Zhaojun, S.; Okasha, A.M.; Bayoumi, Y.; El-Ramady, H.; Prokisch, J. Is the Smart Irrigation the Right Strategy under the Global Water Crisis? A Call for Photographical and Drawn Articles. Environ. Biodivers. Soil Secur. 2022, 6, 207–221.

- Fawzy, Z.F.; El-Sawy, S.M.; El-Bassiony, A.M.; Jun, H.; Shedeed, S.I.; Okasha, A.M.; Bayoumi, Y.; El-Ramady, H.; Prokisch, J. Smart Fertilizers vs. Nano-fertilizers: A Pictorial Overview. Environ. Biodivers. Soil Secur. 2022, 6, 191–204.

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel Approaches in the Valorization of Agricultural Wastes and Their Applications. J. Agric. Food Chem. 2022, 70, 6787–6804.

- Gupta, J.; Kumari, M.; Mishra, A.; Akram, M.; Thakur, I.S. Agro-forestry waste management-A review. Chemosphere 2022, 287, 132321.

- Yaashikaa, P.R.; Kumar, P.S.; Varjani, S. Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review. Bioresour. Technol. 2022, 343, 126126.

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127.

- Formela, K.; Kuranska, M.; Barczewski, M. Recent Advances in Development of Waste-Based Polymer Materials: A Review. Polymers 2022, 14, 1050.

- Shrivastava, R.; Singh, N.K. Agro-wastes sustainable materials for wastewater treatment: Review of current scenario and approaches for India. Mater. Today Proc. 2022, 60, 552–558.

- Leite, P.; Belo, I.; Salgado, J.M. Co-management of agro-industrial wastes by solid-state fermentation for the production of bioactive compounds. Ind. Crops Prod. 2021, 172, 113990.

- Mendez-Carmona, J.Y.; Ramírez-Guzman, K.N.; Ascacio-Valdes, J.A.; Sepulveda, L.; Aguilar, C.N. Solid-state fermentation for recovery of carotenoids from tomato waste. Innov. Food Sci. Emerg. Technol. 2022, 80, 103108.

- Reguengo, L.M.; Salgaço, M.K.; Sivieri, K.; Júnior, M.R.M. Agro-industrial by-products: Valuable sources of bioactive compounds. Food Res. Int. 2022, 152, 110871.

- Chen, C.Y.O.; Milbury, P.E.; Blumberg, J.B. Polyphenols in almond skins after blanching modulate plasma biomarkers of oxidative stress in healthy humans. Antioxidants 2019, 8, 95.

- Nile, S.H.; Nile, A.; Liu, J.; Kim, D.H.; Kai, G. Exploitation of apple pomace towards extraction of triterpenic acids, antioxidant potential, cytotoxic effects, and inhibition of clinically important enzymes. Food Chem. Toxicol. 2019, 131, 110563.

- Kraithong, S.; Issara, U. A strategic review on plant by-product from banana harvesting: A potentially bio-based ingredient for approaching novel food and agro-industry sustainability. J. Saudi Soc. Agric. Sci. 2021, 20, 530–543.

- Otify, A.M.; El-Sayed, A.M.; Michel, C.G.; Farag, M.A. Metabolites profiling of date palm (Phoenix dactylifera L.) commercial by-products (pits and pollen) in relation to its antioxidant effect: A multiplex approach of MS and NMR metabolomics. Metabolomics 2019, 15, 119.

- Sangpong, L.; Khaksar, G.; Pinsorn, P.; Oikawa, A.; Sasaki, R.; Erban, A.; Watanabe, M.; Wangpaiboon, K.; Tohge, T.; Kopka, J.; et al. Assessing dynamic changes of taste-related primary metabolism during ripening of durian pulp using metabolomic and transcriptomic analyses. Front. Plant Sci. 2021, 12, 687799.

- Dorado, C.; Cameron, R.G.; Manthey, J.A.; Bai, J.; Ferguson, K.L. Analysis and potential value of compounds extracted from star ruby, rio red, and ruby red grapefruit, and grapefruit juice processing residues via steam explosion. Front. Nutr. 2021, 8, 691663.

- Long, J.M.; Mohan, A. Food flavoring prepared with lemon byproduct. J. Food Process. Preserv. 2021, 45, e15462.

- Wall-Medrano, A.; Olivas-Aguirre, F.J.; Ayala-Zavala, J.F.; Domínguez-Avila, J.A.; Gonzalez Aguilar, G.A.; Herrera-Cazares, L.A.; Gaytan-Martinez, M. Health benefits of mango by-products. In Food Wastes and By-Products: Nutraceutical and Health Potential; Campos-Vega, R., Oomah, B.D., Vergara-Castaneda, H.A., Eds.; Blackwell Publishing: Hoboken, NJ, USA, 2020; pp. 159–191.

- Campos, D.A.; Ribeiro, T.B.; Teixeira, J.A.; Pastrana, L.; Pintado, M.M. Integral valorization of pineapple (Ananas comosus L.) by-products through a green chemistry approach towards added value ingredients. Foods 2020, 9, 60.

- Meselhy, K.M.; Shams, M.M.; Sherif, N.H.; El-Sonbaty, S.M. Phytochemical study, potential cytotoxic and antioxidant activities of selected food byproducts (pomegranate peel, Rice bran, Rice straw & mulberry bark). Nat. Prod. Res. 2020, 34, 530–533.

- Villamil-Galindo, E.; Van de Velde, F.; Piagentini, A.M. Strawberry agro-industrial by-products as a source of bioactive compounds: Effect of cultivar on the phenolic profile and the antioxidant capacity. Bioresour. Bioprocess. 2021, 8, 61.

- Gulsunoglu, Z.; Karbancioglu-Guler, F.; Raes, K.; Kilic-Akyilmaz, M. Soluble and insoluble-bound phenolics and antioxidant activity of various industrial plant wastes. Int. J. Food Prop. 2019, 22, 1501–1510.

- Scharf, R.; Wang, R.; Maycock, J.; Ho, P.; Chen, S.; Orfila, C. Valorisation of potato (Solanum tuberosum) peel waste: Extraction of fibre, monosaccharides, and uronic acids. Waste Biomass Valorization 2020, 11, 2123–2128.

- Bodie, A.R.; Micciche, A.C.; Atungulu, G.G.; Rothrock, M.J., Jr.; Ricke, S.C. Current trends of rice milling byproducts for agricultural applications and alternative food production systems. Front. Sustain. Food Syst. 2019, 3, 47.

- Carneiro, A.M.; Moreira, E.A.; Bragagnolo, F.S.; Borges, M.S.; Pilon, A.C.; Rinaldo, D.; Funari, C.S. Soya agricultural waste as a rich source of isoflavones. Food Res. Int. 2020, 130, 108949.

- Coelho, M.; Pereira, R.; Rodrigues, A.S.; Teixeira, J.A.; Pintado, M.E. Extraction of tomato by-products’ bioactive compounds using ohmic technology. Food Bioprod. Process. 2019, 117, 329–339.

- Seifdavati, J.; Seifzadeh, S.; Ramezani, M.; Mashak, R.B.; Seyedsharifi, R.; Elghandour, M.M.M.Y.; Barbabosa-Pliego, A.; Salem, A.Z.M. Wastes valorization of wheat straw and wheat bran treated with urea, probiotic or organic acids to enhance ruminal gas production and digestibility of pumpkin by-product. Waste Biomass Valorization 2021, 12, 5979–5989.

- Maji, S.; Dwivedi, D.H.; Singh, N.; Kishor, S.; Gond, M. Agricultural Waste: Its Impact on Environment and Management Approaches. In Emerging Eco-Friendly Green Technologies for Wastewater Treatment; Bharagava, R.N., Ed.; Microorganisms for Sustainability; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 329–351.

- Shaaban, S.; Nasr, M. Toward Three R’s Agricultural Waste in MENA: Reduce, Reuse, and Recycle. In Waste Management in MENA Regions; Negm, A., Shareef, N., Eds.; Springer Nature: Cham, Switzerland, 2020; pp. 337–353.

- El-Ramady, H.; El-Henawy, A.; Amer, M.; Omara, A.E.D.; Elsakhawy, T.; Elbasiouny, H.; Elbehiry, F.; Abou Elyazid, D.; El-Mahrouk, M. Agricultural Waste and its Nano-Management: Mini Review. Egypt. J. Soil. Sci. 2020, 60, 349–364.

- Li, S.; Chen, G. Agricultural waste-derived superabsorbent hydrogels: Preparation, performance and socioeconomic impacts. J. Clean. Prod. 2020, 251, 119669.

- Imran, A.; Sardar, F.; Khaliq, Z.; Nawaz, M.S.; Shehzad, A.; Ahmad, M.; Yasmin, S.; Hakim, S.; Mirza, B.S.; Mubeen, F.; et al. Tailored Bioactive Compost from AgriWaste Improves the Growth and Yield of Chili Pepper and Tomato. Front. Bioeng. Biotechnol. 2022, 9, 787764.

- Bhattacharjya, S.; Sahu, A.; Phalke, D.H.; Manna, M.C.; Thakur, J.K.; Mandal, A.; Tripathi, A.K.; Sheoran, P.; Choudhary, M.; Bhowmick, A.; et al. In Situ decomposition of Crop Residues Using Lignocellulolytic Microbial Consortia: A Viable Alternative to Residue Burning. Environ. Sci. Pollut. Res. Int. 2021, 28, 32416–32433.

- Sharma, S.; Singh, P.; Choudhary, O.P.; Neemisha, F.N.M. Nitrogen and rice Straw Incorporation Impact Nitrogen Use Efficiency, Soil Nitrogen Pools and Enzyme Activity in rice-wheat System in north-western India. Field Crops Res. 2021, 266, 108131.

- Imran, A.; Hakim, S.; Tariq, M.; Nawaz, M.S.; Laraib, I.; Gulzar, U.; Hanif, M.K.; Siddique, M.J.; Hayat, M.; Fraz, A.; et al. Diazotrophs for Lowering Nitrogen Pollution Crises: Looking Deep into the Roots. Front. Microbiol. 2021, 12, 637815.

- Khaksar, G.; Sirijan, M.; Suntichaikamolkul, N.; Sirikantaramas, S. Metabolomics for Agricultural Waste Valorization: Shifting Toward a Sustainable Bioeconomy. Front. Plant Sci. 2022, 13, 938480.

- Jones, S.L.; Gibson, K.E.; Ricke, S.C. Critical Factors and Emerging Opportunities in Food Waste Utilization and Treatment Technologies. Front. Sustain. Food Syst. 2021, 5, 781537.

- Patra, A.; Abdullah, S.; Pradhan, R.C. Review on the extraction of bioactive compounds and characterization of fruit industry by-products. Bioresour. Bioprocess. 2022, 9, 14.

- Parras-Alcántara, L.; Lozano-García, B.; Keesstra, S.; Cerdà, A.; Brevik, E.C. Long-term effects of soil management on ecosystem services and soil loss estimation in olive grove topsoils. Sci. Total Environ. 2016, 571, 498–506.

- De Souza, A.G.; Barbosa, R.F.S.; Rosa, D.S. Nanocellulose from Industrial and Agricultural Waste for Further Use in PLA Composites. J. Polym. Environ. 2020, 28, 1851–1868.

- Abdelbasir, S.M.; McCourt, K.M.; Lee, C.M.; Vanegas, D.C. Waste-Derived Nanoparticles: Synthesis Approaches, Environmental Applications, and Sustainability Considerations. Front. Chem. 2020, 8, 782.

- Brevik, E.C.; Hartemink, A.E. Early soil knowledge and the birth and development of soil science. Catena 2010, 83, 23–33.

- Pavalaydon, K.; Ramasawmy, H.; Surroop, D. Comparative evaluation of cellulose nanocrystals from bagasse and coir agro-wastes for reinforcing PVA-based composites. Environ. Dev. Sustain. 2022, 24, 9963–9984.

- Gómez, J.A.; Berni, P.; Matallana, L.G.; Sánchez, Ó.J.; Teixeira, J.A.; Nobre, C. Towards a biorefinery processing waste from plantain agro–Industry: Process development for the production of an isomalto–oligosaccharide syrup from rejected unripe plantain fruits. Food Bioprod. Process. 2022, 133, 100–118.

- Reddy, R.; Sridevi, V.; Kumar, T.H.; Rao, C.S.; Palla, V.C.S.; Suriapparao, D.V.; Undi, G.S. Synthesis of renewable carbon biorefinery products from susceptor enhanced microwave-assisted pyrolysis of agro-residual waste: A review. Process Saf. Environ. Prot. 2022, 164, 354–372.

- Sachdeva, S.; Garg, V.K.; Labhsetwar, N.K.; Singh, A.; Yogalakshmi, K.N. Zero Waste Biorefinery: A Comprehensive Outlook. In Zero Waste Biorefinery; Nandabalan, Y.K., Garg, V.K., Labhsetwar, N.K., Singh, A., Eds.; Energy, Environment, and Sustainability; Springer Nature Singapore Pte Ltd.: Singapore, 2022; pp. 1–22.

- Mukhtar, H. Waste to Energy: Biomass-Based Energy Systems. Front. Bioeng. Biotechnol. 2022, 10, 932981.

- Nair, L.G.; Agrawal, K.; Verma, P. An overview of sustainable approaches for bioenergy production from agro-industrial wastes. Energy Nexus 2022, 6, 100086.

- Subbaiya, R.; Aakash, B.; Shanmugaraja, A.; Devika, R.; Chozhavendhan, S.; Vinoth, S.; Karthiga Devi, G.; Masilamani Selvam, M. Vegetable Waste as an Alternate Plant Tissue Culture Media for Laboratory and Industry. Res. J. Pharm. Technol. 2019, 12, 1521–1528.

- Moscariello, C.; Matassa, S.; Esposito, G.; Papirio, S. From residue to resource: The multifaceted environmental and bioeconomy potential of industrial hemp (Cannabis sativa L.). Resour. Conserv. Recycl. 2021, 175, 105864.

- UN (United Nations). Transforming Our World: The 2030 Agenda for Sustainable Development; Resolution, Adopted by the General Assembly on 25 September 2015. United Nations, New York. Available online: https://www.unfpa.org/sites/default/files/resource-pdf/Resolution_A_RES_70_1_EN.pdf (accessed on 20 October 2022).