Bharat stage emission standards (BSES) are emission standards instituted by the Government of India to regulate the output of air pollutants from internal combustion engines and Spark-ignition engines equipment, including motor vehicles. The standards and the timeline for implementation are set by the Central Pollution Control Board under the Ministry of Environment & Forests and climate change. The standards, based on European regulations were first introduced in 2000. Progressively stringent norms have been rolled out since then. All new vehicles manufactured after the implementation of the norms have to be compliant with the regulations. Since October 2010, Bharat Stage (BS) III norms have been enforced across the country. In 13 major cities, Bharat Stage IV emission norms have been in place since April 2010 and it has been enforced for entire country since April 2017. In 2016, the Indian government announced that the country would skip the BS-V norms altogether and adopt BS-VI norms by 2020. On November 15, 2017 The Petroleum Ministry of India in consultation with Public Oil Marketing Companies decided to bring forward the date of BS-VI grade auto fuels in NCT of Delhi with effect from April 1, 2018 instead of April 1, 2020. In fact, Petroleum Ministry OMCs were asked to examine the possibility of introduction of BS-VI auto fuels in the whole of NCR area from April 1, 2019. This huge step was taken due the heavy problem of air pollution faced by Delhi which became worse around this year. The decision was met with disarray by the automobile companies as they had planned the development according to roadmap for 2020. The phasing out of 2-stroke engine for two wheelers, the cessation of production of Maruti 800 & introduction of electronic controls have been due to the regulations related to vehicular emissions. While the norms help in bringing down pollution levels, it invariably results in increased vehicle cost due to the improved technology & higher fuel prices. However, this increase in private cost is offset by savings in health costs for the public, as there is lesser amount of disease causing particulate matter and pollution in the air. Exposure to air pollution can lead to respiratory and cardiovascular diseases, which is estimated to be the cause for 6.2 lakh early deaths in 2010, and the health cost of air pollution in India has been assessed at 3% of its GDP.

- health cost

- health costs

- vehicular

1. Motor Vehicles

1.1. History

The first emission norms were introduced in India in 1991 for petrol and 1992 for diesel vehicles. These were followed by making the Catalytic converter mandatory for petrol vehicles and the introduction of unleaded petrol in the market.[1]

On 29 April 1999 the Supreme Court of India ruled that all vehicles in India have to meet Euro I or India 2000 norms by 1 June 1999 and Euro II will be mandatory in the NCR by April 2000. Car makers were not prepared for this transition and in a subsequent judgement the implementation date for Euro II was not enforced.[2][3]

In 2002, the Indian government accepted the report submitted by the Mashelkar committee. The committee proposed a road map for the roll out of Euro based emission norms for India. It also recommended a phased implementation of future norms with the regulations being implemented in major cities first and extended to the rest of the country after a few years.[4]

Based on the recommendations of the committee, the National Auto Fuel policy was announced officially in 2003. The roadmap for implementation of the Bharat Stage norms were laid out till 2010. The policy also created guidelines for auto fuels, reduction of pollution from older vehicles and R&D for air quality data creation and health administration.[5]

1.2. Background Information

| Standard | Reference | YEAR | Region |

|---|---|---|---|

| India 2000 | Euro 1 | 2000 | Nationwide |

| Bharat Stage II | Euro 2 | 2001 | NCR*, Mumbai, Kolkata, Chennai |

| 2003.04 | NCR*, 13 Cities† | ||

| 2005.04 | Nationwide | ||

| Bharat Stage III | Euro 3 | 2005.04 | NCR*, 13 Cities† |

| 2010.04 | Nationwide | ||

| Bharat Stage IV | Euro 4 | 2010.04 | NCR*, 13 Cities† |

| 2017.04 | Nationwide | ||

| Bharat Stage V | Euro 5 | (to be skipped) | |

| Bharat Stage VI | Euro 6 | 2018.04 | Delhi NCR[6] |

| 2020.04 (proposed)[7] | Nationwide | ||

| * National Capital Region (Delhi)

† Mumbai, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmedabad, Pune, Surat, Kanpur, Lucknow, Sholapur, Jamshedpur and Agra |

|||

The above standards apply to all new 4-wheel vehicles sold and registered in the respective regions. In addition, the National Auto Fuel Policy introduces certain emission requirements for interstate buses with routes originating or terminating in Delhi or the other 10 cities.

Progress of emission standards for 2-and 3-wheelers:[8]

| Standard | Reference | Date |

|---|---|---|

| Bharat Stage II | Euro 2 | 1 April 2005 |

| Bharat Stage III | Euro 3 | 1 April 2010 |

| Bharat Stage IV | Euro 4 | 1 April 2017 |

| Bharat Stage VI | Euro 6 | April 2020 with mandate (proposed) |

In order to comply with the BSIV norms, 2- and 3-wheeler manufacturers will have to fit an evaporative emission control unit, which should lower the amount of fuel that is evaporated when the motorcycle is parked.

1.3. Trucks and Buses

Emission standards for new heavy-duty diesel engines—applicable to vehicles of GVW > 3,500 kg—are listed in Table 3.

| Year | Reference | Test | CO | HC | NOx | PM |

|---|---|---|---|---|---|---|

| 1992 | – | ECE R49 | 17.3–32.6 | 2.7–3.7 | – | – |

| 1996 | – | ECE R49 | 11.20 | 2.40 | 14.4 | – |

| 2000 | Euro I | ECE R49 | 4.5 | 1.1 | 8.0 | 0.36* |

| 2005† | Euro II | ECE R49 | 4.0 | 1.1 | 7.0 | 0.15 |

| 2010† | Euro III | ESC | 2.1 | 0.66 | 5.0 | 0.10 |

| ETC | 5.45 | 0.78 | 5.0 | 0.16 | ||

| 2010‡ | Euro IV | ESC | 1.5 | 0.46 | 3.5 | 0.02 |

| ETC | 4.0 | 0.55 | 3.5 | 0.03 | ||

| * 0.612 for engines below 85 kW

† earlier introduction in selected regions, see Table 1 ‡ only in selected regions, see Table 1 |

||||||

More details on Euro I–III regulations can be found in the section on EU heavy-duty engine standards.

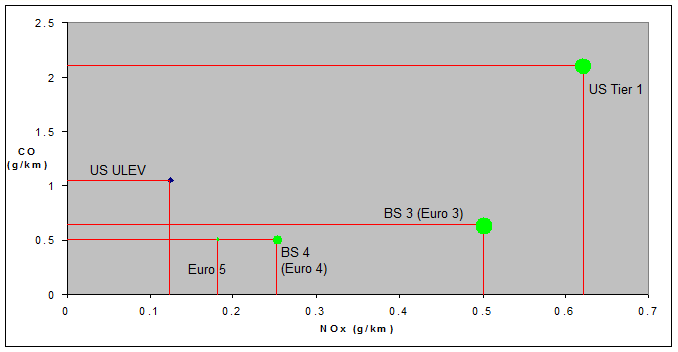

1.4. Light-Duty Diesel Vehicles

Emission standards for light-duty diesel vehicles (GVW ≤ 3,500 kg) are summarised in Table 4. Ranges of emission limits refer to different classes (by reference mass) of light commercial vehicles; compare the EU light-duty vehicle emission standards for details on the Euro 1 and later standards. The lowest limit in each range applies to passenger cars (GVW ≤ 2,500 kg; up to 6 seats).

| Year | Reference | CO | HC | HC+NOx | NOx | PM |

|---|---|---|---|---|---|---|

| 1992 | – | 17.3–32.6 | 2.7–3.7 | – | – | – |

| 1996 | – | 5.0–9.0 | – | 2.0–4.0 | – | – |

| 2000 | Euro 1 | 2.72–6.90 | – | 0.97–1.70 | 0.14–0.25 | – |

| 2005† | Euro 2 | 1.0–1.5 | – | 0.7–1.2 | 0.08–0.17 | – |

| 2010† | Euro 3 | 0.64 0.80 0.95 |

– | 0.56 0.72 0.86 |

0.50 0.65 0.78 |

0.05 0.07 0.10 |

| 2010‡ | Euro 4 | 0.50 0.63 0.74 |

– | 0.30 0.39 0.46 |

0.25 0.33 0.39 |

0.025 0.04 0.06 |

| † earlier introduction in selected regions, see Table 1

‡ only in selected regions, see Table 1 |

||||||

The test cycle has been the ECE + EUDC for low power vehicles (with maximum speed limited to 90 km/h). Before 2000, emissions were measured over an Indian test cycle.

Engines for use in light-duty vehicles can be also emission tested using an engine dynamo-meter. The respective emission standards are listed in Table 5.

| Year | Reference | CO | HC | NOx | PM |

|---|---|---|---|---|---|

| 1992 | – | 14.0 | 3.5 | 18.0 | – |

| 1996 | – | 11.20 | 2.40 | 14.4 | – |

| 2000 | Euro I | 4.5 | 1.1 | 8.0 | 0.36* |

| 2005† | Euro II | 4.0 | 1.1 | 7.0 | 0.15 |

| * 0.612 for engines below 85 kW

† earlier introduction in selected regions, see Table 1 |

|||||

1.5. Light-Duty Petrol Vehicles

4-wheel vehicles

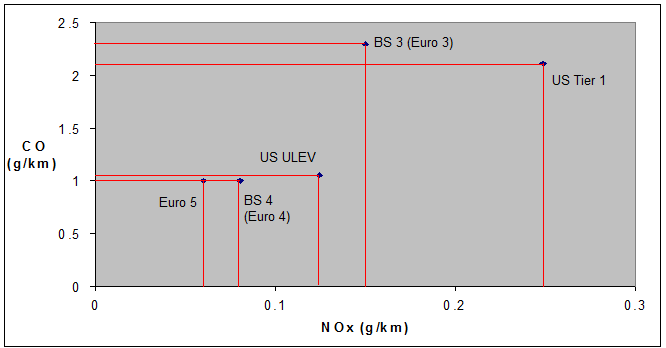

Emissions standards for petrol vehicles (GVW ≤ 3,500 kg) are summarised in Table 6. Ranges of emission limits refer to different classes of light commercial vehicles (compare the EU light-duty vehicle emission standards). The lowest limit in each range applies to passenger cars (GVW ≤ 2,500 kg; up to 6 seats).

| Year | Reference | CO | HC | HC+NOx | NOx |

|---|---|---|---|---|---|

| 1991 | – | 14.3–27.1 | 2.0–2.9 | – | |

| 1996 | – | 8.68–12.4 | – | 3.00–4.36 | |

| 1998* | – | 4.34–6.20 | – | 1.50–2.18 | |

| 2000 | Euro 1 | 2.72–6.90 | – | 0.97–1.70 | |

| 2005† | Euro 2 | 2.2–5.0 | – | 0.5–0.7 | |

| 2010† | Euro 3 | 2.3 4.17 5.22 |

0.20 0.25 0.29 |

– | 0.15 0.18 0.21 |

| 2010‡ | Euro 4 | 1.0 1.81 2.27 |

0.1 0.13 0.16 |

– | 0.08 0.10 0.11 |

| * for catalytic converter fitted vehicles † earlier introduction in selected regions, see Table 1 ‡ only in selected regions, see Table 1 |

|||||

Petrol vehicles must also meet an evaporative (SHED) limit of 2 g/test (effective 2000).

3- and 2-wheel vehicles

Emission standards for 3- and 2-wheel petrol vehicles are listed in the following tables.[9]

| Year | CO | HC | HC+NOx |

|---|---|---|---|

| 1991 | 12–30 | 8–12 | – |

| 1996 | 6.75 | – | 5.40 |

| 2000 | 4.00 | – | 2.00 |

| 2005 (BS II) | 2.25 | – | 2.00 |

| 2010.04 (BS III) | 1.25 | – | 1.25 |

| Year | CO | HC | HC+NOx |

|---|---|---|---|

| 1991 | 12–30 | 8–12 | – |

| 1996 | 5.50 | – | 3.60 |

| 2000 | 2.00 | – | 2.00 |

| 2005 (BS II) | 1.5 | – | 1.5 |

| 2010.04 (BS III) | 1.0 | – | 1.0 |

| Year | CO | HC+NOx | PM |

|---|---|---|---|

| 2005.04 | 1.00 | 0.85 | 0.10 |

| 2010.04 | 0.50 | 0.50 | 0.05 |

1.6. Overview of the Emission Norms in India

- 1991 – Idle CO Limits for Petrol Vehicles and Free Acceleration Smoke for Diesel Vehicles, Mass Emission Norms for Petrol Vehicles.

- 1992 – Mass Emission Norms for Diesel Vehicles.

- 1996 – Revision of Mass Emission Norms for Petrol and Diesel Vehicles, mandatory fitment of Catalytic Converter for Cars in Metros on Unleaded Petrol.

- 1998 – Cold Start Norms Introduced.

- 2000 – India 2000 (Equivalent to Euro I) Norms, Modified IDC (Indian Driving Cycle), Bharat Stage II Norms for Delhi.

- 2001 – Bharat Stage II (Equivalent to Euro II) Norms for All Metros, Emission Norms for CNG & LPG Vehicles.

- 2003 – Bharat Stage II (Equivalent to Euro II) Norms for 13 major cities.

- 2005 – From 1 April Bharat Stage III (Equivalent to Euro III) Norms for 13 major cities.

- 2010 – Bharat Stage III Emission Norms for 2-wheelers, 3-wheelers and 4-wheelers for entire country whereas Bharat Stage – IV (Equivalent to Euro IV) for 13 major cities for only 4-wheelers. Bharat Stage IV also has norms on OBD (similar to Euro III but diluted)

- 2017 – Bharat Stage IV Norms for all vehicles.

- 2018 - BS-VI fuel norms from April 1, 2018 in Delhi instead of 2020[10]

- 2020 – Proposed date for country to adopt Bharat Stage VI norms for cars, skipping Bharat Stage V

1.7. CO2 Emission

India's auto sector accounts for about 18% of the total CO

2 emissions in the country. Relative CO

2 emissions from transport have risen rapidly in recent years, but like the EU, currently there are no standards for CO

2 emission limits for pollution from vehicles.

Obligatory labelling

There is also no provision to make the CO

2 emissions labelling mandatory on cars in the country. A system exists in the EU to ensure that information relating to the fuel economy and CO

2 emissions of new passenger cars offered for sale or lease in the Community is made available to consumers to enable consumers to make an informed choice.

2. Non-Road Diesel Engines

2.1. Construction Machinery

Emission standards for diesel construction machinery were adopted on 21 September 2006. The standards are structured into two tiers:

- Bharat (CEV) Stage II—These standards are based on the EU Stage I requirements, but also cover smaller engines that were not regulated under the EU Stage I.

- Bharat (CEV) Stage III—These standards are based on US Tier 2/3 requirements.

The standards are summarised in the following table:

| Engine Power | Date | CO | HC | HC+NOx | NOx | PM |

|---|---|---|---|---|---|---|

| kW | g/kWh | |||||

| Bharat (CEV) Stage II | ||||||

| P < 8 | 2008.10 | 8.0 | 1.3 | – | 9.2 | 1.00 |

| 8 ≤ P < 19 | 2008.10 | 6.6 | 1.3 | – | 9.2 | 0.85 |

| 19 ≤ P < 37 | 2007.10 | 6.5 | 1.3 | – | 9.2 | 0.85 |

| 37 ≤ P < 75 | 2007.10 | 6.5 | 1.3 | – | 9.2 | 0.85 |

| 75 ≤ P < 130 | 2007.10 | 5.0 | 1.3 | – | 9.2 | 0.70 |

| 130 ≤ P < 560 | 2007.10 | 5.0 | 1.3 | – | 9.2 | 0.54 |

| Bharat (CEV) Stage III | ||||||

| P < 8 | 2011.04 | 8.0 | – | 7.5 | – | 0.80 |

| 8 ≤ P < 19 | 2011.04 | 6.6 | – | 7.5 | – | 0.80 |

| 19 ≤ P < 37 | 2011.04 | 5.5 | – | 7.5 | – | 0.60 |

| 37 ≤ P < 75 | 2011.04 | 5.0 | – | 4.7 | – | 0.40 |

| 75 ≤ P < 130 | 2011.04 | 5.0 | – | 4.0 | – | 0.30 |

| 130 ≤ P < 560 | 2011.04 | 3.5 | – | 4.0 | – | 0.20 |

The limit values apply for both type approval (TA) and conformity of production (COP) testing. Testing is performed on an engine dynamo-meter over the ISO 8178 C1 (8-mode) and D2 (5-mode) test cycles. The Bharat Stage III standards must be met over the useful life periods shown in Table 11. Alternatively, manufacturers may use fixed emission deterioration factors of 1.1 for CO, 1.05 for HC, 1.05 for NOx, and 1.1 for PM.

| Power Rating | Useful Life Period | |

|---|---|---|

| hours | ||

| < 19 kW | 3,000 | |

| 19–37 kW | constant speed | 3,000 |

| variable speed | 5,000 | |

| > 37 kW | 8,000 | |

2.2. Agricultural Tractors

Emission standards for diesel agricultural tractors are summarised in Table 12.

| Engine Power | Date | CO | HC | HC+NOx | NOx | PM |

|---|---|---|---|---|---|---|

| kW | g/kW·h | |||||

| Bharat (Trem) Stage I | ||||||

| All | 1999.10 | 14.0 | 3.5 | - | 18.0 | - |

| Bharat (Trem) Stage II | ||||||

| All | 2003.06 | 9.0 | - | 15.0 | - | 1.00 |

| Bharat (Trem) Stage III | ||||||

| All | 2005.10 | 5.5 | - | 9.5 | - | 0.80 |

| Bharat (Trem) Stage III A | ||||||

| P < 8 | 2010.04 | 5.5 | - | 8.5 | - | 0.80 |

| 8 ≤ P < 19 | 2010.04 | 5.5 | - | 8.5 | - | 0.80 |

| 19 ≤ P < 37 | 2010.04 | 5.5 | - | 7.5 | - | 0.60 |

| 37 ≤ P < 56 | 2011.04 | 5.0 | - | 4.7 | - | 0.40 |

| 56 ≤ P < 75 | 2011.04 | 5.0 | - | 4.7 | - | 0.40 |

| 75 ≤ P < 130 | 2011.04 | 5.0 | - | 4.0 | - | 0.30 |

| 130 ≤ P < 560 | 2011.04 | 3.5 | - | 4.0 | - | 0.20 |

Emissions are tested over the ISO 8178 C1 (8-mode) cycle. For Bharat (Trem) Stage III A, the useful life periods and deterioration factors are the same as for Bharat (CEV) Stage III, Table 11.

3. Electricity Generation

3.1. Generator Sets

Emissions from new diesel engines used in generator sets have been regulated by the Ministry of Environment and Forests, Government of India [GSR 371 (E), 17 May 2002]. The regulations impose type approval certification, production conformity testing and labelling requirements. Certification agencies include the Automotive Research Association of India (ARAI) and the Vehicle Research and Development Establishment (VRDE). The emission standards are listed below.

| Engine Power (P) | Date | CO | HC | NOx | PM | Smoke |

|---|---|---|---|---|---|---|

| g/kWh | 1/m | |||||

| P ≤ 19 kW | 2004.01 | 5.0 | 1.3 | 9.2 | 0.6 | 0.7 |

| 2005.07 | 3.5 | 1.3 | 9.2 | 0.3 | 0.7 | |

| 19 kW < P ≤ 50 kW | 2004.01 | 5.0 | 1.3 | 9.2 | 0.5 | 0.7 |

| 2004.07 | 3.5 | 1.3 | 9.2 | 0.3 | 0.7 | |

| 50 kW < P ≤ 176 kW | 2004.01 | 3.5 | 1.3 | 9.2 | 0.3 | 0.7 |

| 176 kW < P ≤ 800 kW | 2004.11 | 3.5 | 1.3 | 9.2 | 0.3 | 0.7 |

Engines are tested over the 5-mode ISO 8178 D2 test cycle. Smoke opacity is measured at full load.

| Date | CO | NMHC | NOx | PM |

|---|---|---|---|---|

| mg/N·m3 | mg/N·m3 | ppm(v) | mg/N·m3 | |

| Until 2003.06 | 150 | 150 | 1100 | 75 |

| 2003.07 – 2005.06 | 150 | 100 | 970 | 75 |

| 2005.07 | 150 | 100 | 710 | 75 |

Concentrations are corrected to dry exhaust conditions with 15% residual O2.

3.2. Power Plants

The emission standards for thermal power plants in India are being enforced based on Environment (Protection) Act, 1986 of Government of India and it's amendments from time to time.[11] A summary of emission norms for coal- and gas-based thermal power plants is given in Tables 15 and 16.

| Capacity | Pollutant | Emission limit |

|---|---|---|

| Coal based thermal plants | ||

| Below 210 MW | Particulate matter (PM) | 350 mg/N·m3 |

| 210 MW & above | 150 mg/N·m3 | |

| 500 MW & above | 50 mg/N·m3 | |

| Gas based thermal plants | ||

| 400 MW & above | NOX(V/V at 15% excess oxygen) | 50 PPM for natural gas; 100 PPM for naphtha |

| Below 400 MW & up to 100 MW | 75 PPM for natural gas; 100 PPM for naphtha | |

| Below 100 MW | 100 PPM for naphtha/natural gas | |

| For conventional boilers | 100 PPM | |

| Power Generation Capacity | Stack Height (Metre) |

|---|---|

| Less than 200/210 MWe | H = 14 (Q)0.3 where Q is emission rate of SO2 in kg/h, H = Stack height in metres |

| 200/210 MWe or less than 500 MWe 200 | 200 |

| 500 MWe and above | 275 (+ Space provision for FGD systems in future) |

The norm for 500 MW and above coal-based power plant being practised is 40 to 50 mg/N·m and space is provided in the plant layout for super thermal power stations for installation of flue gas desulfurisation (FGD) system. But FGD is not installed, as it is not required for low sulphur Indian coals while considering SOx emission from individual chimney.

In addition to the above emission standards, the selection of a site for a new power plant has to maintain the local ambient air quality as given in Table 17.

| Category | Conc g/m3 | |||

|---|---|---|---|---|

| SPM | SOx | CO | NOx | |

| Industrial and mixed-use | 500 | 120 | 5,000 | 120 |

| Residential and rural | 200 | 80 | 2,000 | 80 |

| Sensitive | 100 | 30 | 1,000 | 30 |

| Existing Air Quality | Recommendation |

|---|---|

| SOx > 100 μg/m3 | No project |

| SOx = 100 μg/m3 | Polluted area, max from a project 100 t/day |

| SOx < 50 μg/m3 | Unpolluted area, max from a project 500 t/day |

However the norms for SOx are even stricter for selection of sites for World Bank funded projects (refer Table 18). For example, if SOx level is higher than 100 μg/m3, no project with further SOx emission can be set up; if SOx level is 100 μg/m3, it is called polluted area and maximum emission from a project should not exceed 100 t/day; and if SOx is less than 50 μg/m3, it is called unpolluted area, but the SOx emission from a project should not exceed 500 t/day. The stipulation for NOx emission is that its emission should not exceed 260 g of NOx/GJ of heat input.

In view of the above, it may be seen that improved environment norms are linked to financing and are being enforced by international financial institutions and not by the policies/laws of land.

4. Fuels

Fuel quality plays a very important role in meeting the stringent emission regulation.

The fuel specifications of petrol and diesel have been aligned with the Corresponding European Fuel Specifications for meeting the Euro II, Euro III and Euro IV emission norms.

The BS IV grade fuel was introduced in 2010 and is available in 39 cities, as reported in 2016. The rest of the country has to make do with BS III fuel.[12]

The use of alternative fuels has been promoted in India both for energy security and emission reduction. Delhi and Mumbai have more than 1 lakh commercial vehicles running on CNG fuel. Delhi has the largest number of CNG commercial vehicles running anywhere in the World. India is planning to introduce Bio-diesel, ethanol petrol blends in a phased manner and has drawn up a road map for the same. The Indian auto industry is working with the authorities to facilitate for introduction of the alternative fuels. India has also set up a task force for preparing the Hydrogen road map. The use of LPG has also been introduced as an auto fuel and the oil industry has drawn up plans for setting up of auto LPG dispensing stations in major cities.

4.1. Indian Petrol Specifications

| Serial No. | Characteristics | Unit | Bharat Stage II | Bharat Stage III | Bharat Stage IV | Bharat Stage V | Bharat Stage VI |

|---|---|---|---|---|---|---|---|

| 1 | Density 15 °C | kg/m3 | 710–770 | 720–775 | 720–775 | ||

| 2 | Distillation | ||||||

| 3 | a) Recovery up to 70 °C (E70) b) Recovery up to 100 °C (E100) c) Recovery up to 180 °C (E180) d) Recovery up to 150 °C (E150) e) Final Boiling Point (FBP), Max f) Residue Max |

% Volume % Volume % Volume % Volume °C % Volume |

10–45 40–70 90 - 210 2 |

10–45 40–70 - 75 min 210 2 |

10–45 40–70 - 75 min 210 2 |

||

| 4 | Research Octane Number (RON), Min | 88 | 91 | 91 | |||

| 5 | Anti Knock Index (AKI)/ MON, Min | 84 (AKI) | 81 (MON) | 81 (MON) | |||

| 6 | Sulphur, Total, Max | % mass | 0.05 | 150 mg/kg | 50 mg/kg | 10 mg/kg | 10 mg/kg |

| 7 | Lead Content (as Pb), Max | g/l | 0.013 | 0.005 | 0.005 | ||

| 8 | Reid Vapour Pressure (RVP), Max | Kpa | 35–60 | 60 | 60 | ||

| 9 | Benzene, Content, Max a) For Metros b) For the rest |

% Volume | - 3 5 |

1 | 1 | ||

| 10 | Olefin content, Max | % Volume | - | 21 | 21 | ||

| 11 | Aromatic Content, Max | % Volume | - | 42 | 35< |

4.2. Indian Diesel Specifications

| S. No | Characteristic | BSII | BSIII | BSIV | BSV | BSVI |

|---|---|---|---|---|---|---|

| 1 | Density kg/m3 15 °C | 820-800 | 820–845 | 820–845 | ||

| 2 | Sulphur Content mg/kg max | 500 | 350 | 50 | 10 | 10 |

| 3(a) 3(b) |

Cetane Number minimum and / or Cetane Index |

48 or 46 |

51 and 46 |

51 and 46 |

||

| 4 | Polycyclic Aromatic Hydrocarbon | - | 11 | 11 | ||

| 5 (a) (b) (c) |

Distillation Reco Min At 350 °C Reco Min At 370 °C 95% Vol Reco at 0 °C |

85 95 - |

- - 360 |

- - 360 |

4.3. Diesel Fuel Quality in India

| Date | Particulars |

|---|---|

| 1995 | Cetane number: 45; Sulfur: 1% |

| 1996 | Sulfur: 0.5% (Delhi + selected cities) |

| 1998 | Sulfur: 0.25% (Delhi) |

| 1999 | Sulfur: 0.05% (Delhi, limited supply) |

| 2000 | Cetane number: 48; Sulfur: 0.25% (Nationwide) |

| 2001 | Sulfur: 0.05% (Delhi + selected cities) |

| 2005 | Sulfur: 350 ppm (Euro 3; selected areas) |

| 2010 | Sulfur: 350 ppm (Euro 3; nationwide) |

| 2016 | Sulfur: 50 ppm (Euro 4; major cities) |

| 2017 | Sulfur: 50 ppm (Euro 4; nationwide) |

| 2020 (proposed) | Sulfur: 10ppm (Euro 6; entire country) |

4.4. Indian Bio-Diesel Specifications

| S No | Characteristics | Requirement | Method of Test, ref to | |

|---|---|---|---|---|

| Other Methods | [P:] of IS 1448 | |||

| (1) | (2) | (3) | (4) | (5) |

| i. | Density at 15 °C, kg/m3 | 860–900 | ISO 3675 | P:16/ |

| ISO 12185 | P:32 | |||

| ASTM | ||||

| ii. | Kinematic Viscosity at 40 °C, cSt | 2.5–6.0 | ISO 3104 | P:25 |

| iii. | Flash point (PMCC) °C, min | 120 | P:21 | |

| iv. | Sulphur, mg/kg max | 50.0 | ASTM D 5453 | P:83 |

| v | Carbon residue (Ramsbottom)*, % by mass, max | 0.05 | ASTM D 4530ISO 10370 | - |

| vi. | Sulfated ash, % by mass, max | 0.02 | ISO 6245 | P:4 |

| vii. | Water content, mg/kg, max | 500 | ASTM D 2709 | P:40 |

| ISO 3733 | ||||

| ISO 6296 | ||||

| viii | Total contamination, mg/kg, max | 24 | EN 12662 | - |

| ix | Cu corrosion, 3 h at 50 °C, max | 1 | ISO 2160 | P:15 |

| x | Cetane No, min | 51 | ISO 5156 | P:9 |

| xi | Acid value, mg KOH/g, max | 0.50 | - | P:1 / Sec 1 |

| xii | Methanol @, % by mass, max | 0.20 | EN 14110 | - |

| xiii | Ethanol, @@ % by mass, max | 0.20 | - | |

| xiv | Ester content, % by mass, min | 96.5 | EN 14103 | - |

| xv | Free Glycerol, % by mass, max | 0.02 | ASTM D 6584 | - |

| xvi | Total Glycerol, % by mass, max | 0.25 | ASTM D 6584 | - |

| xvii | Phosphorus, mg/kg, max | 10.0 | ASTMD 4951 | - |

| xviii | Sodium & Potassium, mg/kg, max | To report | EN 14108 & | - |

| EN 14109 | - | |||

| xix | Calcium and Magnesium, mg/kg, max | To report | ** | - |

| xx | Iodine value | To report | EN 14104 | - |

| xxi | Oxidation stability, at 110 °C h, min | 6 | EN 14112 | - |

| * Carbon residue shall be run on 100% sample

** European method is under development |

||||

5. Criticism and Commentary

5.1. Ineffectiveness of Present Pollution Control System

Presently, all vehicles need to undergo a periodic emission check (3 months/ 6 months) at PUC Centres at Fuel Stations and Private Garages which are authorised to check the vehicles. In addition, transport vehicles need to undergo an annual fitness check carried out by RTOs for emissions, safety and road-worthiness.

The objective of reducing pollution not achieved to a large extent by the present system. Some reasons for this are: – Independent centres do not follow rigorous procedures due to inadequate training – Equipment not subjected to periodic calibration by independent authority – Lack of professionalism has led to malpractice – Tracking system of vehicles failing to meet norms non-existent

5.2. Comparison between Bharat Stage and Euro Norms

The Bharat Stage norms have been styled to suit specific needs and demands of Indian conditions. The differences lie essentially in environmental and geographical needs, even though the emission standards are exactly the same.

For instance, Euro-III is tested at sub-zero temperatures in European countries. In India, where the average annual temperature ranges between 24 and 28 °C, the test is done away with.

Another major distinction is in the maximum speed at which the vehicle is tested. A speed of 90 km/h is stipulated for BS-III, whereas it is 120 km/h for Euro-III, keeping emission limits the same in both cases

In addition to limits, test procedure has certain finer points too. For instance, the mass emission test measurements done in g/km on a chassis dynamometer requires a loading of 100 kg weight in addition to unloaded car weight in Europe. In India, BS-III norms require an extra loading of 150 kg weight to achieve the desired inertia weight mainly due to road conditions here.[13]

5.3. Non-Existence of CO2 Limits

Various groups and agencies have criticised the government and urged the government of India to draft mandatory fuel efficiency standards for cars in the country, or at least to make the CO

2 emissions labelling mandatory on all new cars in the country. The auto companies should inform the customers about a vehicle's emissions.[14]

5.4. Lag behind Euro Standards

There has been criticism of the fact that the Indian norms lag the Euro norms. As of 2014, only a few cities meet Euro IV or Bharat Stage IV standards that are nine years behind Europe. The rest of India gets Bharat Stage III standard fuel and vehicles, which are 14 years behind Europe.[15] Also, there was a suggestion from some bodies to implement Euro IV norms after Euro II norms, skipping the Euro III norms totally. This is because the Euro III norms are only a small improvement over Euro II, whereas Euro IV norms mark a big leap over Euro II. According to a study conducted by the Desert Research Institute and the Indian Institute of Technology Delhi, the only way to stabilise fine particulates (PM2.5) at the 2011 levels despite the five-fold rise in vehicular density is nationwide implementation of Bharat V standards by 2015.[16]

5.5. Cycle Beating

For the emission standards to deliver real emission reductions it is crucial that the test cycles under which the emissions have to comply as much as possible reflect normal driving situations. It was discovered that manufacturers of engine would engage in what was called 'cycle beating' to optimise emission performance to the test cycle, while emissions from typical driving conditions would be much higher than expected, undermining the standards and public health. In one particular instance, research from two German technology institutes found that for diesel cars no 'real' NOx reductions have been achieved after 13 years of stricter standards.[17]

6. Regulatory Framework

In India the Rules and Regulations related to driving licence, registration of motor vehicles, control of traffic, construction & maintenance of motor vehicles etc. are governed by the Motor Vehicles Act 1988 (MVA) and the Central Motor Vehicles rules 1989 (CMVR). The Ministry of Shipping, Road Transport & Highways (MoSRT&H) acts as a nodal agency for formulation and implementation of various provisions of the Motor Vehicle Act and CMVR.[18]

To involve all stake holders in regulation formulation, MoSRT&H has constituted two Committees to deliberate and advise Ministry on issues relating to Safety and Emission Regulations, namely –

- CMVR- Technical Standing Committee (CMVR-TSC)

- Standing Committee on Implementation of Emission Legislation (SCOE)

6.1. CMVR- Technical Standing Committee (CMVR-TSC)

This Committee advises MoSRT&H on various technical aspects related to CMVR. This Committee has representatives from various organisations namely; Ministry of Heavy Industries & Public Enterprises (MoHI&PE)), MoSRT&H, Bureau Indian Standards (BIS), Testing Agencies such as Automotive Research Association of India (ARAI),International Centre for Automotive Technology (ICAT - www.icat.in), Vehicle Research Development & Establishment (VRDE), Central Institute of Road Transport (CIRT), industry representatives from Society of Indian Automobile Manufacturers (SIAM), Automotive Component Manufacturers Association (ACMA) and Tractor Manufacturers Association (TMA) and representatives from State Transport Departments. Major functions the Committee are:

- To provide technical clarification and interpretation of the Central Motor Vehicles Rules having technical bearing, to MoRT&H, as and when so desired.

- To recommend to the Government the International/ foreign standards which can be used in lieu of standard notified under the CMVR permit use of components/parts/assemblies complying with such standards.

- To make recommendations on any other technical issues which have direct relevance in implementation of the Central Motor Vehicles Rules.

- To make recommendations on the new safety standards of various components for notification and implementation under Central Motor Vehicles Rules.

- To make recommendations on lead time for implementation of such safety standards.

- To recommend amendment of Central Motor Vehicles Rules having technical bearing keeping in view of Changes in automobile technologies.

CMVR-TSC is assisted by another Committee called the Automobile Industry Standards Committee (AISC) having members from various stakeholders in drafting the technical standards related to Safety. The major functions of the committee are as follows:

- Preparation of new standards for automotive items related to safety.

- To review and recommend amendments to the existing standards.

- Recommend adoption of such standards to CMVR Technical Standing Committee

- Recommend commissioning of testing facilities at appropriate stages.

- Recommend the necessary funding of such facilities to the CMVR Technical Standing Committee, and

- Advise CMVR Technical Standing Committee on any other issues referred to it

The National Standards for Automotive Industry are prepared by Bureau of Indian Standards (BIS). The standards formulated by AISC are also converted into Indian Standards by BIS. The standards formulated by both BIS and AISC are considered by CMVR-TSC for implementation.

6.2. Standing Committee on Implementation of Emission Legislation (SCOE)

This Committee deliberates the issues related to implementation of emission regulation. Major functions of this Committee are –

- To discuss the future emission norms

- To recommend norms for in-use vehicles to MoSRT&H

- To finalise the test procedures and the implementation strategy for emission norms

- Advise MoSRT&H on any issue relating to implementation of emission regulations.

Based on the recommendations from CMVR-TSC and SCOE, MoSRT&H issues notification for necessary amendments / modifications to the Central Motor Vehicle Rules.

In addition, the other Ministries like Ministry of Environment & Forest (MoEF), Ministry of Petroleum & Natural Gas (MoPNG) and Ministry of Non-conventional Energy Sources are also involved in formulation of regulations relating to Emissions, Noise, Fuels and Alternative Fuel vehicles.

The content is sourced from: https://handwiki.org/wiki/Engineering:Bharat_Stage_emission_standards

References

- "Ministry of Road Transport & Highways". http://morth.nic.in/index2.asp?sublinkid=121&langid=2.

- "SC dilutes Euro norms". The Indian Express. 15 May 1999. Archived from the original on 29 January 2004. https://web.archive.org/web/20040129004215/http://www.expressindia.com/ie/daily/19990515/ibu15020.html.

- "Maruti board on a junket as market share falls". The Indian Express. 31 July 1999. http://www.indianexpress.com/Storyold/112535/.

- "Maruti board on a junket as market share falls". The Indian Express. 9 January 2002. http://www.hindu.com/thehindu/2002/01/09/stories/2002010901501300.htm.

- "National Auto Fuel Policy Announced". http://pib.nic.in/archieve/lreleng/lyr2003/roct2003/06102003/r0610200313.html.

- "Bharat Stage 6 Fuel goes on sale in Delhi NCR: Here’s how it’ll affect your car" (in en-US). The Financial Express. 2018-04-02. http://www.financialexpress.com/auto/car-news/bharat-stage-6-fuel-goes-on-sale-in-delhi-ncr-heres-how-itll-affect-your-car/1118188/.

- Press Trust of India [@PTI_News] (6 January 2016). "Govt decides to skip BS-V; leapfrog to BS-VI emission norms by April 1, 2020: Transport Minister Nitin Gadkari.". https://twitter.com/PTI_News/status/684653623813341184.

- "Emission Standards: India: On-Road Vehicles and Engines". Dieselnet.com. http://www.dieselnet.com/standards/in/. Retrieved 29 June 2009.

- "Vehicular Technology in India | Emission Norms – SIAM India". SIAM India.. Archived from the original on 11 June 2009. https://web.archive.org/web/20090611052002/http://www.siamindia.com/scripts/emission-standards.aspx. Retrieved 29 June 2009.

- http://www.downtoearth.org.in/news/bs-vi-fuel-norms-from-april-1-2018-in-delhi-59126

- Emission standards for power plants http://www.imteag.com/02-2007-10.pdf

- Karunakaran, Naren (26 Apr 2016). "Hasty introduction of Euro VI fuel norms triggers a slugfest between automakers, oil companies". The Economic Times/The Times of India. http://economictimes.indiatimes.com/industry/auto/news/industry/hasty-introduction-of-euro-vi-fuel-norms-triggers-a-slugfest-between-automakers-oil-companies/articleshow/51987185.cms. Retrieved 3 July 2016.

- Abhishek Sengupta (20 February 2005). "TOI article on Bharat Stage norms". The Times of India. http://timesofindia.indiatimes.com/business/india-business/every-thing-about-bharat-stage-norms/articleshow/1026422.cms. Retrieved 2 February 2011.

- Pratyush (9 January 2008). "Greenpeace urges government for CO2} limits". Pratyush.instablogs.com. Archived from the original on 13 July 2011. https://web.archive.org/web/20110713042153/http://pratyush.instablogs.com/entry/greenpeace-urges-india-to-set-mandatory-co2-emission-standards-for-carmakers/. Retrieved 2 February 2011.

- http://justearthnews.com/environment-details/E/88/cse-calls-for-urgent-action-over-who-report-on-india-pollution.html

- http://www.hindustantimes.com/india-news/india-needs-stringent-norms-to-curb-vehicular-pollution-study/article1-1187165.aspx

- "T&E Bulletin, March 2006" (PDF). transportenvironment.org. http://www.transportenvironment.org/docs/Bulletin/2006/2006-02_bulletin146_web.pdf. Retrieved 2 February 2011.

- "Emission regulatory framework in India". Siamindia.com. Archived from the original on 27 January 2011. https://web.archive.org/web/20110127104228/http://www.siamindia.com/scripts/regulatoryframework.aspx. Retrieved 2 February 2011.