A flat-twin is a two-cylinder internal combustion engine with the cylinders on opposite sides of the crankshaft. It is a flat engine with two cylinders. Used in motorcycles for more than a century, flat-twins have also been used in automobiles, light aircraft, stationary powerplants, and household appliances. Early flat-twin motorcycles' engines were mounted with the cylinders in line with the frame. This caused uneven cooling of the cylinders and required the motorcycle to have a long wheelbase. Later flat-twin motorcycles' engines were mounted with their cylinders across the frame for better air cooling and a shorter wheelbase. Disadvantages of this layout include torque reaction in the motorcycle in turns and the potential to damage cylinder heads.

- flat-twin

- flat-twins

- internal combustion

1. Crank Configurations

The traditional crank configuration used with flat-twin engines is the boxer twin whose 180° crankshaft moves the pistons in phase with each other. In this configuration, the primary force generated by one piston counteracts that generated by the other at all times, resulting in excellent primary balance. Since the pistons are not in line with each other, the equal and opposing forces generate a rocking couple on the crankshaft.[1] Unlike the ignition of a V-twin or a 180° parallel twin, a boxer engine has equally spaced firing intervals, adding to its smoothness.

The flat-twin engine in the 1897 Lanchester 8 hp phaeton had two counter-rotating crankshafts.[2] Each piston was attached to one crankshaft by a thick connecting rod and to the other crankshaft by two thinner connecting rods, one on either side of the other piston's thick connecting rod.[2][3] This allowed both cylinders to have the same axis. It also had the torque reaction of one crankshaft cancel the torque reaction of the other, cancelling torque reaction in the engine.[2] The pistons in the Lanchester engine moved so that one piston was on top while the other was at bottom dead center, creating an uneven firing cycle. Lanchester used this engine design until 1904.[3]

There have been flat-twin engines with one crank pin shared by both connecting rods, thereby have only one crank throw. An experimental aircraft engine built before 1910 by Richard Pearse in New Zealand had both pistons and both connecting rods as part of a single rigid assembly that drove the crankpin through a sliding bearing contained within a crosshead.[4]

2. Crankcase Pressure

Uniquely among flat engines a boxer twin suffers from differences in crankcase pressures as the pistons alternately compress and expand the crankcase gases. This issue is usually addressed by means of a crankcase breather,[5] as in the BMW R90S. This crankcase pumping effect is also found on singles and 360° parallel twins.[5] Crankcase pressure differentials have scope for providing a form of supercharging, but while such an innovation has yet to be used on a production engine, it has been used to aid lubrication.

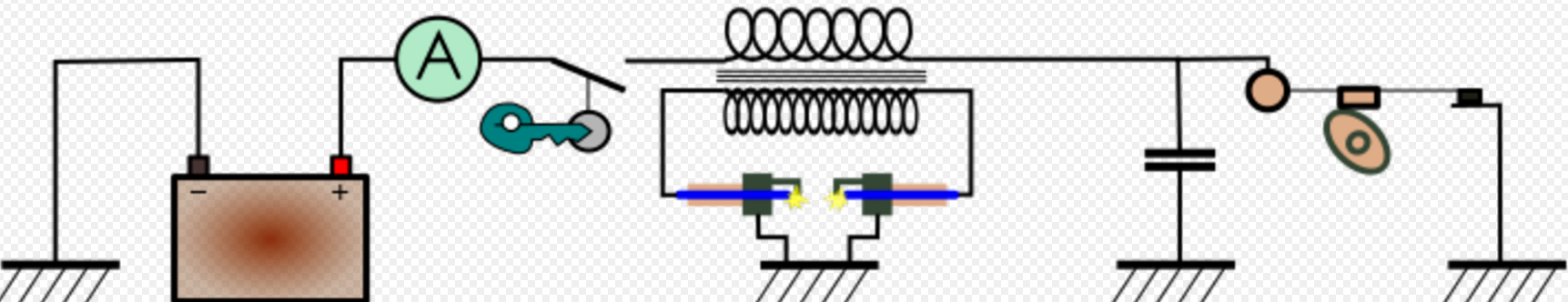

3. Ignition Systems

Boxer-twin engines are well suited to the wasted spark ignition system, a distributor-less ignition system using a double-ended coil firing both spark plugs on each revolution, that is, on both the compression stroke and the exhaust stroke. This system requires only a single contact breaker and single coil to run two cylinders.[6]

4. Applications

4.1. Motorcycles

The first flat-twin motorcycle engine was the Fée,[7] later renamed "Fairy", which was built by the Light Motors Company from 1905 until the company folded in 1907.[8][9] The Douglas Engineering Company, one of Light Motors' suppliers, took over the manufacturing rights and developed motorcycles based on the Fée system under their own name.[9][10]

BMW Motorrad manufactures a number of flat-twin engine motorcycles,[11][12] as do Ural and Dnepr.

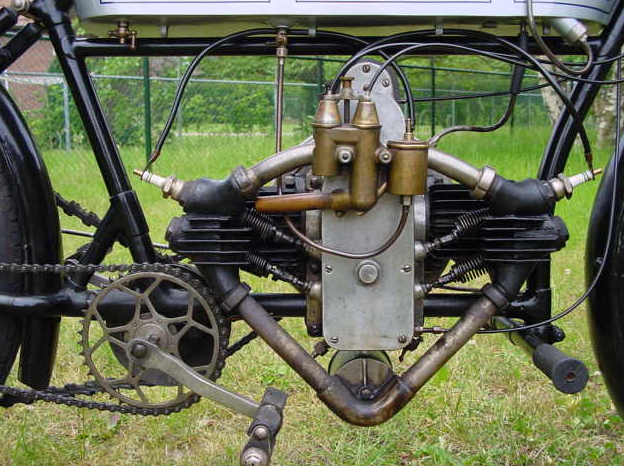

Engine alignment: cylinders along frame

The 1905 Fée bicycle engine system included a flat-twin engine, mounted with the cylinders in line with the frame, with chain drive to a primary shaft with a pulley driving the rear wheel of the bicycle.[10] The 1907 Douglas, developed from the Fée system, had a belt drive to the rear wheel driven directly from the engine.[10] Later developments of the Douglas motorcycle were made with the cylinders in line with the frame until the Second World War.[13]

Other early flat-twin motorcycles used a similar layout, with their cylinders aligned along the frame and therefore with the crankshaft running transverse to the frame. This position allowed the use of a conventional motorcycle drivetrain by belt or chain to the rear wheel.[14][15] Another advantage of this layout is its low centre of gravity.[15] However, in this layout, the front cylinder is more heavily cooled than the rear cylinder,[14][15] and the wheelbase tends to be excessive due to the length of the engine.[15] In 1914 the main supplier of rear-hub gearboxes, Sturmey-Archer, introduced a 3-speed countershaft gearbox with integral kick-starter.[16] The photograph at right shows the gearbox located low down behind the engine where the kick-start is convenient for operation. While this was a relatively easy modification for vertical single-cylinder or V-twin engined motorcycles, the length of the pair of cylinders along the frame made this location difficult without having a long wheelbase. Douglas, and the Fée motorcycle that preceded it, had used a countershaft below the engine;[17] some later models used a gearbox above the engine,[15][18] though where the engine was short enough the preferred option was the conventional layout.[19]

In a review of flat twin engines in 1916, Motor Cycle magazine listed the following (all except the ABC engines were fitted with cylinders in line with the frame):[20]

- ABC 2.5 hp (bore 60 mm, stroke 44 mm), 249 cc - "the smallest flat-twin at present on the road".[20]

- ABC 3.5 hp (bore 70 mm, stroke 64 mm), 494 cc - designed by G.W. Bradshaw.

- Bradbury 3.5 hp (bore 68 mm, stroke 68.7 mm), 499 cc. Introduced c1914.

- Brough 3.5 hp (bore 70 mm, stroke 64.5 mm) 497 cc, all Brough motorcycles used the flat-twin layout from end of 1914

- Brough 6 hp (bore 70 mm, stroke 90 mm) 692 cc, developed by Brough during the war and mainly intended for sidecar work after the war

- Douglas 2.75 hp (bore 60.5 mm, stroke 60 mm) 345 cc, the original Douglas, but with mechanically operated inlet valves from 1912

- Douglas 4 hp (bore 72 mm, stroke 68 mm) 544 cc, an updated design bearing little in common with the smaller engine

- Humber 6 hp (bore 78 mm, stroke 78 mm) 746 cc, water-cooled and with Claudel-Hobson automatic carburettor

- Humber 3.5 hp (bore 68 mm, stroke 68.75 mm) 497 cc, brand new in October 1916 with Longuemare-Hardy carburettor

- Matchless 6 hp (bore 70 mm, stroke 95 mm) 732 cc, expected for 1917 season

- Indian 2.5 hp (bore 50.8 mm, stroke 63.5 mm) 257 cc, "The only flat-twin at present on the American market"[20]

- Montgomery 6 hp (bore 75 mm, stroke 78 mm) 688 cc, produced essentially for sidecar work.

- Williamson 8 hp (bore 85 mm, stroke 85 mm) 964 cc, made by Douglas intended originally water-cooled for cyclecars but made as water-cooled and air-cooled for Williamson motorcycles

Other motorcycles with this layout included the Helios in Germany and the Indian Model O and Harley-Davidson Model W in the United States.[21]

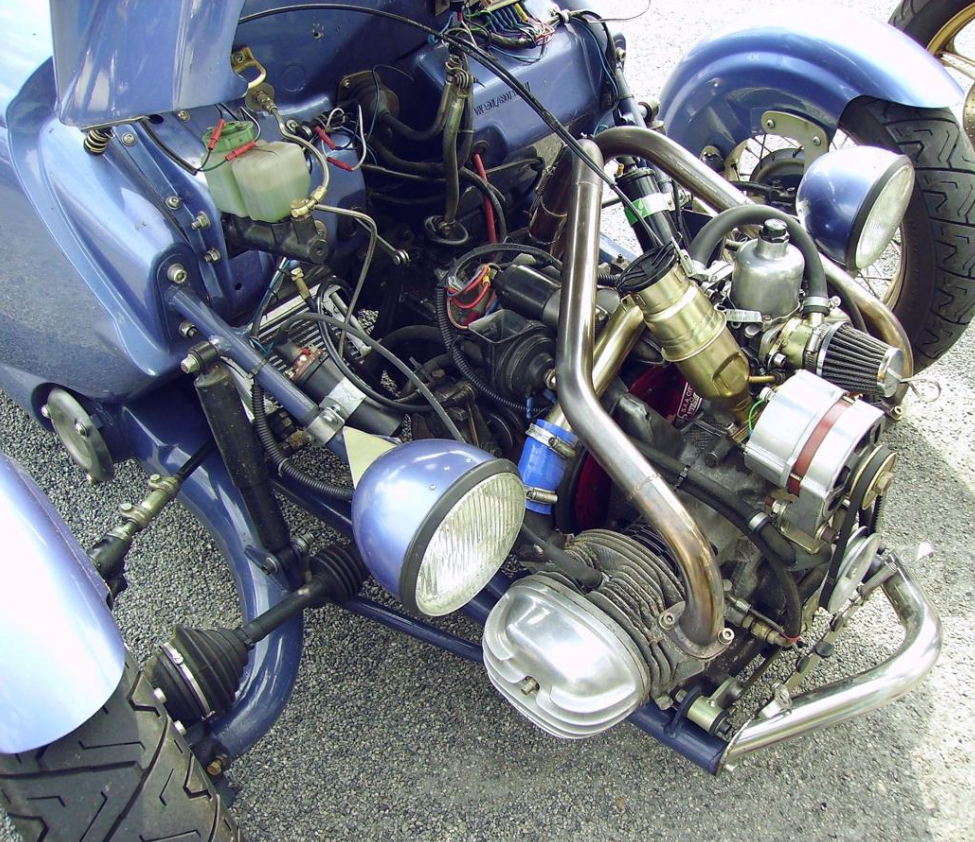

Engine alignment: cylinders across frame

In 1916,[20] ABC introduced a motorcycle with a flat-twin engine with the cylinders across the frame, and therefore with the crankshaft running longitudinally when referenced to the frame. To accommodate chain drive, the ABC used a bevel drive at the gearbox to change the direction of the drive through ninety degrees.[22] The 1923 BMW R32 used a similar engine position with a drive shaft using bevel gears to power the rear axle.[23]

This position allowed both cylinders to protrude into the airflow, providing excellent air cooling for each cylinder.[15][24] The Harley-Davidson XA, which used a flat-twin engine with the cylinders across the frame, maintained an oil temperature 100 °F (56 °C) cooler than a Harley-Davidson WLA with a V-twin with the cylinders in line with the frame.[25]

Many motorcyclists appreciate the way the cylinders in this layout provide protection to the rider in the event of a collision or fall, and keeps their feet warm in cold weather.[15][26]

A disadvantage of this layout is that it exposes the cylinders and valve covers to the danger of collision damage.[15][26] Longitudinal crankshaft mounting is also associated with a torque reaction that tends to twist the motorcycle to one side on sharp acceleration or when opening the throttle in neutral and in the opposite direction on sharp deceleration. Many modern motorcycle manufacturers correct for this effect by rotating flywheels or alternators in the opposite direction to that of the crankshaft.[27][28]

Another disadvantage of this layout is that the engine has to be high enough in the frame to provide the cylinder heads with banking clearance in turns, which raises the flat-twin engine's otherwise low center of gravity.[29]

4.2. Automobiles

The Lanchester Engine Company used their twin-crank flat-twin engines from 1897 until 1904 when they were re-incorporated as the Lanchester Motor Company.[2][3]

Benz & Cie showed their first boxer engine, the two-cylinder "contra engine", in 1897.[30]

Flat-twin engines were used in some of Henry Ford's early cars, including the Ford 1903-04 Model A, Model C, and Model F.[31][32]

Flat-twin engines were later used in several economy cars, including Jowett cars from 1906 to 1937[33] and later in the Jowett Bradford van from 1945 to 1954,[34] postwar Citroën and Panhard front wheel drive cars, rear-engined BMW cars, Steyr-Puch 500, DAF Daffodil, and the Toyota Publica and Toyota Sports 800.

Brazilian manufacturer Gurgel Motores developed the water-cooled Enertron flat-twin engine based on the Volkswagen air-cooled boxer-four. The Enertron engine was used in Gurgel's BR-800, Supermini and Motomachine cars between 1988 and 1995.

4.3. Aviation

Flat-twins have been used to power light aircraft from the first decade of the twentieth century,[35][36] although most piston-engined aircraft have used more cylinders for more power. Notable flat-twin aircraft engines include that used for Alberto Santos-Dumont's 1909 pioneering ultralight aircraft, the Santos-Dumont Demoiselle, which used various flat-twin engines from Darracq, Dutheil et Chalmers and Clément-Bayard; they were also used in Richard Pearse's monoplane,[36] with the Jean A. Roche-designed Aeronca C-2 and C-3 aircraft, using their Aeronca E-107 flathead twin and E-113 overhead valved flat-twin engine designs; two important European flat-twins from the Golden Age of Aviation before World War II were the Czechoslovak Praga B2, and the British Bristol Cherub. In the modern era, HKS produced the 700 series flat twin for lightplanes and ultralights.

In larger aircraft, flat-twin engines have been used in auxiliary power units (APUs). A notable example was made by ABC Motors between the World Wars.[37] During World War II, the Reidel firm in Germany designed and manufactured a two-stroke flat-twin engine to start all three jet engine designs that the Luftwaffe were expecting for production-line status in 1944-45: the Junkers Jumo 004 and BMW 003[38] axial-flow turbojets,[39] as well as the prototype-only, higher-thrust Heinkel HeS 011 design.

4.4. Miscellaneous

Maytag used its Model 72 flat-twin engines to power washing machines, although they were used as proprietary engines for other purposes as well.[40][41] Maytag began manufacturing the Model 72 engine in 1937 and, after a break in production from May 1942 to June 1945 due to World War II, continued manufacturing them until the 1950s.[40][42] Production ended some time between 1952[42] and 1960.[40]

During World War II, motorcycle manufacturer Douglas built generators powered by their flat-twin engines,[43] Norman Engineering Company produced flat twin generators from 1932 to 1968, and Enfield Industrial Engines (part of Enfield Cycle Company) produced 250 cc and 350 cc flat twin 2-stroke petrol stationary engines during the war which were used for generators and other military uses. After the war they built flat-twin air-cooled diesel engines, with applications ranging from farm use to marine use. Coventry-Victor introduced a diesel version of their existing 688 cc petrol flat-twin in 1932, and went on to produce flat-twin diesel and petrol engines for a variety of industrial and marine uses well into the post-war period.[44]

Two-stroke flat-twins were a popular choice for use in outboard motors, as they were smoother than single-cylinder engines. They lost popularity in the late 1940s to straight-twin two-strokes with 180-degree crankshafts that were easier to start and had an acceptable amount of vibration.[45]

The content is sourced from: https://handwiki.org/wiki/Engineering:Flat_twin_engine

References

- Wilson 1995, "Engine blueprint" sidebar on page 27

- Rogliatti 1973, p. 140.

- Smith 2010.

- Drawing of replica engine, from Sherwood 1999 http://www.billzilla.org/ffeng.gif

- Cameron 1992, p. 14.

- "2CV Stuff: A Series Ignition System - Specifications" (pdf). Grantham, Lincolnshire, UK: Oui2. Archived from the original on 2012-03-16. https://web.archive.org/web/20120316122922/http://www.2cvstuff.com/Files/ignition.pdf. Retrieved 2013-05-18.

- "The engine of the future". The Motor Cycle (Iliffe & Sons Ltd.): 283. October 5, 1916.

- Wilson 1995, p. 219.

- Wilson 1995, p. 218.

- Partridge 1976, p. 42.

- "BMW Motorrad USA - Bikes". bmwmotorcycles.com/. Archived from the original on 2008-08-22. https://web.archive.org/web/20080822022309/http://www.bmwmotorcycles.com/bikes/index.jsp?bikeSection=. Retrieved 2008-12-22.

- Wilson 1995, pp. 26–32.

- Wilson 1995, p. 51.

- Norbye 1984, p. 15.

- Willoughby 1977, p. 23.

- "A Sturmey-Archer Countershaft Gear". The Motor Cycle (Iliffe & Sons Ltd.): 274. 27 August 1914.

- Drawing of 1911 Douglas http://www.motorcycles20thcentury.com/motors/drawing/Douglas-1911.jpg

- Drawing of 1932 Douglas K32 http://www.motorcycles20thcentury.com/motors/normal/Douglas-K32-1932.jpg

- Drawing of 1926 Douglas http://www.motorcycles20thcentury.com/motors/normal/Douglas-1926.jpg

- "Flat Twins". The Motor Cycle (Iliffe & Sons Ltd.): 400–403. November 9, 1916.

- Helios: Norbye 1984, p. 15 Wilson 1995, p. 26 Indian: Wood 2001b, p. 71 Harley-Davidson: Mitchel 1997, pp. 44–45 Wood 2001a, p. 127

- Wilson 1995, p. 10.

- Wilson 1995, p. 26.

- Wilson 1995, pp. 26–27.

- Wood 1999, p. 127.

- Wilson 1995, p. 27.

- Friedman et al. 2000.

- Battisson 1997.

- Cocco 2004, p. 118.

- English 2010.

- Kimes 1996, p. 572.

- Brooke 2008, pp. 38–44.

- Specification tables, Culshaw & Horrobin 2013, pp. 188–189 https://books.google.com/books?id=hVZWnZbUJOYC&pg=PA189

- Culshaw & Horrobin 2013, p. 373.

- Sherwood 1999.

- SciMedia 2012.

- Chaplin & Nixon 1939, p. 358.

- Schulte, Rudolph C. (1946). "Design Analysis of BMW 003 Turbojet - "Starting the Engine"". United States Army Air Force - Turbojet and Gus Turbine Developments, HQ, AAF. http://legendsintheirowntime.com/LiTOT/Content/1946/Av_4603_DA_BMW003.html. "Starting procedure is as follows: Starting engine is primed by closing electric primer switch, then ignition of turbojet and ignition and electric starting motor of Riedel engine are turned on (this engine can also be started manually by pulling a cable). After the Riedel unit has reached a speed of about 300 rpm, it automatically engages the compressor shaft of the turbojet. At about 800 rpm of the starting engine, starting fuel pump is turned on, and at 1,200 rpm the main (J-2) fuel is turned on. The starter engine is kept engaged until the turbojet attains 2,000 rpm, at which the starter engine and starting fuel are turned off, the turbojet rapidly accelerating to rated speed of 9,500 rpm on the J-2 fuel"

- Gunston 1997, p. 141.

- Shelton 1999.

- Citations for Maytag 72 engine: Kinney 2007 "Maytag Service Instructions" (pdf) pp. 11–16 http://www.oldengine.org/docs/Maytag_SM.pdf. Hunn 2005, p. 42

- "Maytag Multi-Motor Engines". Maytag Collector's club. http://www.maytagclub.com/page-37.htm. Retrieved 2009-01-08.

- Brown 2007.

- Baldwin 1987, p. 111.

- Holcolmb 1964, pp. 34–35.