Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Nanocellulose is used in a variety of fields, including medicine, packaging, cosmetics, electronics, food, automotive, optical materials, aerospace, and other fields. Among its distinctive features are its hygroscopicity and chemical inactivity. Nanocellulose could also be used in a variety of industries due to its lack of high sorption and toxicity.

- biomass

- cellulose

- CNF

- nanocellulose

- nanocomposite

1. Nanocellulose Based Nanocomposites for Sustainable Applications

Nanocellulose is used in a variety of fields, including medicine, packaging, cosmetics, electronics, food, automotive, optical materials, aerospace, and other fields [1][2][3][4][5][6][7][8]. Among its distinctive features are its hygroscopicity and chemical inactivity. Nanocellulose could also be used in a variety of industries due to its lack of high sorption and toxicity [9][10]. In addition to its inexpensive production costs, nanocellulose possesses remarkable characteristics that make it attractive for extensive adoption, including excellent mechanical properties, fatigue resistance, adequate strength, and light weight [3][11][12][13][14][15][16]. Additionally, cellulose has an excellent water-holding capacity, making it ideal for usage in biocompatible coatings and medication discharge, formulations, scaffolds and wound dressing. In terms of the thermal conductivity characteristics of CNF, Adachi et al. [17] reported the experimental study of individual CNFs using the well-established thermal bridge method. The results obtained show thermal conductivity of individual CNFs is found to be approximately 2.2 (±1.2) W/m K at 300 K, and the temperature-dependent data from 40 to 320 K indicate that the phonon transport of CNFs is dominated by boundary scattering. Theoretical simulation results on thermal conductivity of individual CNFs and cellulose bulk crystal support the experimental results and suggest that intermolecular interaction also impedes the thermal transport.

Another application of nanocellulose to highlight is a study on utilization of CNF cellulose nanofiber films for smart heat dissipation by convection [18]. In this research, the kirigami (the traditional art of paper cutting) with a thermally conductive CNF film to propose a flexible cooling system through convective heat dissipation has been used. By stretching the Amikazari (net decoration) pattern produced by kirigami and allowing air convection through its aperture at 3.0 m/s, the thermal resistance was reduced to approximately one-fifth of that without kirigami and convection. The kirigami spaces defined the outlet air velocity, resulting in a significant increase in the heat-transfer coefficient. The kirigami heat dissipation concept enables the design of electronics using a variety of film materials as shape-variant cooling structures, which will move a wide range of thermal engineering and electronics applications. Reshmy et al. [19] stated that the anticipated markets for nanocellulose can be categorized into three levels: (1) high-end applications (like batteries, printed electronics, and paper-based value-added materials); (2) mid-range applications (including structural materials, food); and (3) low-end, widespread pulp and paper commodity applications (like lighter and stronger conventional paper products). Table 1 listed the key applications and potential benefits of nanocellulose [19].

Table 1. Key applications and potential advantages of nanocellulose.

| Application Area | Properties | Key Application |

|---|---|---|

| Food packaging | Flexible, rigid, improved barrier | Packaging films |

| Biomedical | Nontoxic, excellent biocompatibility and biodegradability | Scaffolds, water absorbent pads, antimicrobial films and tampons, sanitary napkins or wound dressing |

| Cosmetics | Durability, compatibility, good elasticity | Composite coating agent for nails, hair, or eyelashes |

| Electronics | High dielectric, excellent mechanical and biocompatible | Sensor, electronic displays and windows |

| Optical materials | Crystalline, flexibility, biocompatible | Electronic transistor, sensors |

| Automobile | Good electrical, thermal, magnetic, physico-chemical properties | Lightweight and high strength components such as bumpers, side panels and dashboards |

| Constructions | Increase fracture toughness, cheaper, low density, high strength | Blocks, sensors to monitor stress levels in bridge |

| Aerospace | High strength, light weight | Windows, sensors |

| Textiles | Easy care, low impurity, good mechanical strength, biocompatible | Antimicrobial medical field, paste printing |

| Paper industry | Easy availability, eco-friendly, renewability | Grease-proof paper |

| Water purification | Biosorable, low cost, nontoxic | Filtration |

2. Food Packaging

The majority of modern food packaging materials are synthetic and non-biodegradable, prompting environmental concerns about the accumulation of plastics in landfills and waterways. The food sector is increasingly in need of environmentally friendly and sustainable materials that meet food-packaging specifications. However, most of the polymer materials pose poor water resistance and mechanical strength that should be improved for food packaging application. The protection provided by the package is a crucial component of the preservation process for the majority of food products. The specifications of a packaging system for fresh, frozen, dehydrated, thermally processed, or aseptic products are determined by: (i) the intrinsic qualities of the food product, such as water activity and oxidation potential, which determine their perishability; (ii) extrinsic factors, such as storage temperature, relative humidity, and exposure to light; and (iii) the required shelf-life. When defining the necessary barrier ability to water vapor, oxygen, and other gases, including odors and light, all these elements must be taken into consideration [20].

Alternatives are being sought in light of the expanding economic and environmental problems around these materials. The advantages of packing materials made of cellulose, in particular nanocellulose, have recently been thought of [3][7][21]. Evidently, long-term usage of such by-products could assist in resolving the difficulties in industry with costs, sustainability, and disposal. Nanocellulose is a type of renewable resource that has the potential to address sustainability problems. In the expanding commercialization of nanotechnologies, nanocellulose is extremely important. As a result, researchers and industrialists are examining and investigating novel nanocellulose manufacturing techniques and applications. From the perspective of packaging, there are several reasons to use nanocellulose, including edibility, flexibility, biodegradability, transparency, antimicrobial, barrier and mechanical characteristics.

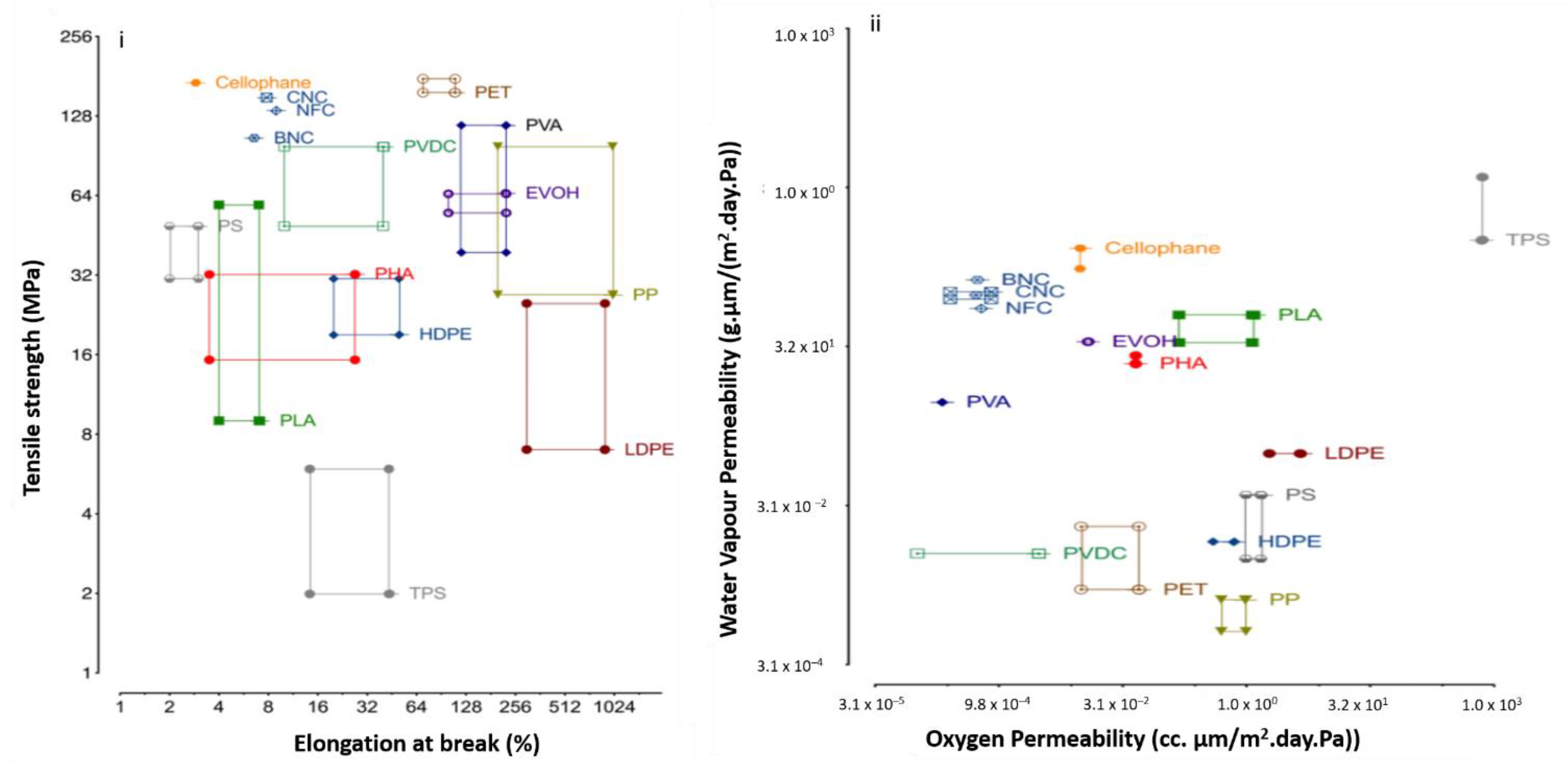

Biopolymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and thermoplastic starch (TPS) have been explored as alternative options for non-biodegradable plastic materials subject to worldwide concern. Silva et al. [22] compares the mechanical properties, i.e., tensile strength, elongation at break and barrier qualities, i.e., water vapor and oxygen permeability of conventional plastics and some biopolymers including PET, PVA, TPS, LDPE, HDPE, PLA, EVOH, as shown in Figure 1. From the analysis, they found out that biopolymers have lower elongation at break and greater water vapor permeability than standard plastics. However, the existing bio-polymer materials lack the performance to meet the most stringent specified criteria for food packaging such as inherent food product properties, extrinsic factors, and shelf life. To increase the performance of the biopolymers for food packaging applications, nanocomposite technology has been considered as a possibility. Plant nanocellulose is considered as a renewable and sustainable source with competitive features that can be used in food packaging manufacture based on its mechanical and barrier properties. Antimicrobial and antioxidant characteristics are two additional functions of employing plant nanocellulose as a material for packaging. Furthermore, nanocellulose is a preferred material for use as a support in active and intelligent packaging. Nanocellulose has grown in popularity as a food packaging component due to its high rigidity, low oxygen content and permeability, as shown in Figure 1 as CNC, BNC and NFC. As nanocellulose may act as a carrier for some active ingredients, such as antioxidants and antimicrobials, it is also able to increase food quality while also extending the shelf life of foods.

Figure 1. (i) Mechanical and (ii) barrier properties of conventional plastics packaging versus nanocellulose. Reproduced from ref. [22].

Srivastava and co-workers [23] used a solution casting approach to synthesize PVA–banana pseudostem fiber (BPF) nanocomposite films that were reinforced with increasing amounts of nanocellulose filler to improve mechanical and barrier properties. The mechanical characteristics of films reinforced with 3 wt.% nanocellulose improved by 14.3% in tensile strength, but the elongation at break decreased by 9.1%. The amount of nanocellulose added decreased the water vapor permeability by 29.7%. The water swelling test revealed positive results, with the film regaining just 16.8% of its weight after 24 h of immersion in water, compared to 67.4% for PVA composite films containing no nanocellulose, making them a viable alternative to plastic packaging films.

Asad et al. [24] developed polyvinyl alcohol (PVA)-based nanocomposite films incorporating TEMPO-oxidize nanocellulose (TONC) suspension with a content ranging from 0.5 to 6% (w/w). It was found that the 4% (w/w) TONC content reinforced nanocomposite had the maximum tensile strength and modulus, with increments of 122 and 29%, respectively, while the elongation at break was reduced by 42.7%. The addition of TONC increased the thermal stability of PVA-based nanocomposite films and boosts its crystallinity due to strong linkage between the hydroxyl groups of the materials, while significant losses are found beyond 2 wt.% loading. The melting temperature peaks and enthalpy of nanocomposite films are significantly reduced when TONC is added beyond 2%. In another study conducted by Zhang et al. that reinforced CNF extracted from Enteromorpha prolifera into PVA matrix, they found that the light transmittance of PVA/CNF composite film could reach more than 94%, and the swelling degree was 250%, which is 29% lower than that of the pure PVA film, and the water resistance was improved when the CNF content was 0.1 wt.%. Furthermore, the tensile strength, elastic modulus and toughness were 99.1%, 1547% and 117.9% respectively, which are higher than those of neat PVA.

Patel and Joshi [25] fabricated composite films by the incorporation of CNF from banana waste into a PVOH matrix. They reported that at 2% CNF in PVOH, the solubility of composite film was 92.54%; beyond this composition, the solubility film falls, which may limit its application as a soluble packaging material. At 2% CNF addition in 10% PVOH film, the tensile strength was examined to be 2.36 kgf with a Young’s modulus of 59.16 N mm−2. Further addition of CNF to PVOH resulted in a significant reduction in the tensile strength. Hence, it has been demonstrated that PVOH/CNF film can be used as a soluble packaging material. Additionally, researchers have developed a strong interest in active and intelligent packaging, and many studies in this area are published annually. An active packaging system, such as one with antibacterial and antioxidant capabilities, absorbs or releases compounds to prolong the food’s shelf life. Intelligent packaging provides information, such as on the freshness of the food, by monitoring the state of packaged food or the surroundings. In terms of these activities, nanocellulose is inert, but it makes a great support for compounds that might have an active or intelligent function in the food packaging system [20].

By impregnating BNC composite films with spherical flavonoid silymarin (SMN)-zein nanoparticles, effective antioxidant activities were demonstrated. These qualities were maintained for at least 72 h owing to the delayed release of the active ingredient. For Staphylococcus aureus, Escherichia coli, and Pseudomonas aeruginosa, the antibacterial activity of the films demonstrated an inhibition ratio of 60, 20, and 30%, respectively. The system was then tested using salmon fish, which demonstrated quality indicators of thiobarbituric acid reactive substance assay values that were 40% and 30% lower than those of the control, respectively [26]. Ferulic acid and feruloylated arabinoxylo-oligosaccharides were used to functionalize arabinoxylans-based nanocomposite films that contained 50% CNF during solvent casting. The films demonstrated antioxidant activity of up to 90% in the 2,2-diphenyl-1-picrylhydrazyl hydrate assay. In addition, the film demonstrated bactericidal activities with a 3-log CFU mL−1 decline against Staphylococcus aureus, bacteriostatic activity against Escherichia coli, and antifungal efficacy towards the polymorphic fungus Candida albicans with a 1.1-log CFU mL−1 reduction [27].

It has also been documented that nanocellulose has been functionalized for intelligent food packaging, particularly for the development of freshness indicators with the intention of detecting food spoilage. Freshness indicators typically assess changes in pH or gas composition inside the packaging, and these changes are translated into a color response, which is simple to quantify and may be linked to the food’s freshness [28]. Indicators for freshness were developed by Kuswandi et al. [29] and Lu et al. [30] using BNC-methyl red and TEMPO-mediated NFC hydrogels with a bromothymol blue/methyl red mixture, respectively. The composites responded to the amount of volatile biogenic amines, and it was discovered that the CO2 levels increased as the chicken spoiled, changing color as a result of the pH adjustment.

The fabricated bagasse nanocellulose-based hydrogels for intelligent packaging with a freshness indicator for monitoring spoilage of chicken breast [30]. In this work, by using TEMPO-mediated oxidation to create nanocellulose from sugarcane bagasse cellulose filaments, a stable self-standing nano-hydrogel matrix was created with an aid of Zn[2]+ cross-linking. The pH-responsive dyes were carried by the nano-hydrogel that act as a freshness indicator for chicken breast in packaging. As the freshness of the chicken meat was indicated by observing variations in CO2 levels inside the chicken meat packing, the hydrogel indicator was found to be responsively sensitive to CO2, where the color changes in response to the increases of bacteria growth [31] were as shown in Figure 2.

Figure 2. (a) Indicator hydrogel for applications in intelligent food packaging; (b) Relationship between color of indicator hydrogel and freshness of chicken breast. Reproduced from ref. [30].

3. Biomedical

Nanocellulose has attracted a lot of attention for its application as a biomedical material, specifically in tissue engineering, drug delivery, cartilage replacements, tissue engineering, cardiovascular applications, wound dressings and medical implants in recent years due to its exceptional physical qualities, particularly surface chemistry, and outstanding biological properties, such as low toxicity, biocompatibility, and biodegradability [32]. It opposes the nature of proteins and prevents hostile tissue reactions; its structure lessens hemolytic and immunogenic reactions. Additionally, it promotes both tissue contact and development. Yet, nanocellulose degrades relatively slowly in both in vivo and in vitro conditions, making it appropriate for long-term applications. It can support heavy loads and has a high wear resistance, making it suitable for use as a scaffold in long-term applications [33].

Siqueira et al. [34] synthesized different nanocellulose-alginate hydrogels containing cellulose nanocrystals, TEMPO-oxidized cellulose nanocrystal (CNCT), cellulose nanofibers or TEMPO-oxidized cellulose nanofiber (CNFT). The morphological and mechanical properties as well as non-cytotoxic behaviour of the CNFT-alginate gels enhanced the bioadhesion, growth, and proliferation of the cells onto the gels. Alginate nanocellulose gels could therefore be used in the field of tissue engineering for purposes including tissue repair or wound healing. In order to ensure perpendicular growth of bacterial nanocellulose produced by Komagataeibacter xylinus E25 in stationary culture, Ludwicka et al. [35] developed composites that were produced in specially designed bioreactors outfitted with a set of perforated mesh stripes threaded vertically to the culture medium. The in vitro inflammatory reactions of the produced biocomposites were examined, and they included mast cell degranulation with N-acetyl-d-hexosaminidase release and mast cell adhesion. The obtained results show that, following the culture and purification processes, the components of the composites are well integrated. When bacterial cellulose is added, the composites become less immunogenic than polypropylene alone.

Even though nanocellulose has the potential to accomplish better-than-conventional polymeric materials in biomedical applications, designing nanocellulose-based biomaterials for wound healing still demands controllability over biophysical and biochemical signals to assist a variety of cellular activities in healing processes. Liu et al. [36] developed bioactive CNF scaffolds with regulated release of basic fibroblast growth factors (bFGFs) for conceivable uses in the treatment of wounds. According to the Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D) analysis, the polyion complex interaction between the positively charged bFGFs and the negatively charged CNF resembles the interaction between bFGFs and heparin sulfate in the extracellular matrix in the body. This connection allows for the possible protection of bFGFs against denaturation in addition to storing it in a form that is easily accessible and from which it is progressively released. By adjusting the CNF surface chemistry and deconstructing the scaffolds in situ, the release profile of bFGFs from the CNF scaffolds was customized. The in-situ enzymatic deconstruction of the scaffolds offers a chance to regulate the bioavailability of bFGFs for cell growth and proliferation, but more critically, to balance the destruction of the scaffolds and the synthesis of new tissue in wound healing. As demonstrated by the MTT assay for cell proliferation and fluorescence imaging of cells cultured in 3D scaffolds, CNF scaffolds loaded with bFGF can significantly promote cell proliferation, even when only a minimal amount of bFGF is loaded. The bioavailability of bFGF is further increased by enzymatic deconstruction of the CNF network, which further encourages cell division. Their research could be a significant step towards the development of nanocellulose-based biomaterials with specific biophysical and biochemical cues for wound healing and other biological applications.

4. Automotive and Aerospace

In addition to exceptional mechanical strength, multi-functional nanocellulose-based nanocomposites also exhibit remarkable combinations of thermal, electrical, optical, and magnetic properties. The mechanical and physical properties of nanocomposites are thought to be significantly influenced by molecular-level interactions between nanocellulose and polymer matrix as well as the presence of a very extensive nanocellulose–polymer interfacial region. It has developed into a group of polymeric materials with improved mechanical properties, increased modulus and dimensional stability, flammable retardation, better scratch and marine resistance, excellent thermal and process characteristics, reduced part warping, and increased impact resistance, making it nearly possible for metal replacement in automotive applications.

The first nylon-6/clay biocomposites were introduced to the market in 1991 by Toyota Motor Co. (Toyota City, Japan) to produce timing belt covers for the Toyota Camry engine in collaboration with the Ube industry. This marked the beginning of the commercial exploitation of polymeric composites. Approximately at the same time as the Mitsubishi GDI 3 (Tokyo, Japan) engines were being produced through injection molding, Unitika Co. of Japan introduced nylon-6 nanocomposite for engine covers. This product appears to offer a 20% weight reduction and a durable surface finish. In 2002, working with Basell (now Lyondell Basell Industries, Rotterdam, The Netherlands), General Motors (Detroit, MI, USA) introduced a polyolefin component for the GM Safari and Chevrolet Astro vans (Detroit, MI, USA) that was gradually covered with 3-percent nanoclay. These nanocomposites were then used for the doors of the Chevrolet Impala [19]. Using nano-enhanced sheet molding materials created by Molded Fibre Glass Companies, Ohio, General Motor (GM) manufactured a single piece rear-floor molded compression assembly for its Pontiac Solace in 2009. This is also applied to GM’s Corvette ZO and Corvette Coupe models. Polymer nanocomposites may be advantageous for the automotive industry in a variety of applications, including engines and power trains, suspension and braking systems, exhaust systems and catalytic converters, frames and body parts, tires, coatings, lubricants, and paints, as well as electrical and electronic equipment. Since then, extensive research on nanocomposites has been conducted on a global scale.

Sanoj and Balasubramaniam [37] developed high performance structural nanocellulose composites for motor vehicle spring suspension systems. In the hybrid composite system, nanofibers are evenly distributed across the system region. Through a shear deformation process, the 3D hierarchical configurations of jute fibril reinforcements in the epoxy matrix system efficiently contribute to the polymer matrix toughening and crack propagation resistance. The hybrid composite system delamination resistance and fracture toughness are greatly improved by these nanofibrils, which serve as a connecting bridge between the glass fiber laminate. This important feature enhances the hybrid composite leaf spring strength, rigidity, and dynamic response when compared to a glass fiber-reinforced composite suspension system.

Other than the automotive industry, Duzik et al. [38] reported that currently CNFs are being developed for use as reinforcement materials in aerospace structural composites to increase adhesion, thermal stability, and mechanical stability. The application of CNF can significantly lower aircraft weight, resulting in reduced fuel consumption. Another CNF structural application is in the NASA HELIOS heliogryo solar sail blade material, which demands for a thin coating of less than 3 µm. Moreover, the small fiber diameter of nanocellulose, like other advanced fiber architectures, allows for the implantation of sensors such as Fibre Bragg grating (FBG). With this technique, anyone may identify object damage by retrieving data at a near distance from the sensor. As a result, the aerospace industry may be able to use nanocellulose aerogels as a novel option to composite structures [39].

5. Sensor

An ideal sensor must be simple to make, affordable, and able to detect analytes quickly with good sensitivity and selectivity. Nanocelluloses are widely accessible, biocompatible, and incredibly adaptable. Due to their enormous surface area and many functional groups, nanocellulose can also interact with a variety of molecules. These elements work together to make nanocellulose appealing for use in sensing applications. Nanocellulose is typically employed as one of the components, together with other stimuli-responsive chemicals, for making sensors [40]. Numerous nanocellulose-based sensing devices showed receptiveness to a variety of stimuli. The most common way that nanocellulose is modified to acquire different properties and functionalities throughout its surface is by combining it with other superficial groups, metal oxide, polymer chains, or even other nanoparticles. This results in low-cost smart materials that are sensitive to biotechnology. This recently developed nanocellulosic material was an excellent choice for numerous sensing system applications.

A green, flexible photonic device for sensing purposes was created by Jaiswal and colleagues using nanocellulose [41]. To develop thermoresponsive hybrid films, CNF and cellulose nanocrystals were combined with a black thermochromic pigment as matrix materials. An all-optical modulation device was demonstrated by making use of the produced film’s thermoresponsive nature. A 660 nm visible diode laser was used to modulate continuous infrared light (1300 nm). They found that films underwent a localized thermochromic change as a result of the laser intensity. A homogeneous cyclic modulation depth of 0.3 dB was attained when the laser was pulsed at 0.3 Hz. From this research, functional nanocellulose hybrid films can be used as a light switch (modulator) in a number of thermally stimulated sensing applications, including temperature monitoring, energy conservation, and counterfeit prevention.

Other than in film forms, when sensors are in the form of highly porous aerogels, the benefits of the high nanocellulose surface area in sensors can be increased. Among all, CNFs are an excellent candidate for producing sensors because of their high porosity and excellent aerogel-forming ability [40]. A lightweight conductive supramolecular aerogel with hierarchically porous 3D structures (porosity of 96.9%) was invented by Wang et al. [42]. This aerogel has excellent capacitance retention, a high conductivity of 0.372 S/cm, and a larger area-normalized capacitance (Cs) of 59.26 mF/cm2 than other 3D chemically cross-linked nanocellulose aerogels by 20 times. By incorporating the electrode material in lightweight supercapacitors and wearable flexible devices, the supramolecular conductive aerogel might also be employed as an all-purpose sensitive sensor for poisonous gas, field sobriety tests, and health monitoring devices. Recent developments in nanocellulose-based composites for sensing applications are listed in Table 2.

Table 2. Recent developments in nanocellulose-based composites for sensing applications.

| Sensor Type | Target | Composite Description |

Detection Limit | Ref. |

|---|---|---|---|---|

| Gas sensor | Ammonia | QCM/CA/PEI/ GO | 1 ppm | [43] |

| Cellulose/TiO2/PANI | 2 ppm | [44] | ||

| Nitrogen dioxide (NO2) | CNC/Fe2O3 | 2 ppm | [45] | |

| Chemical sensor | Formaldehyde | PEI/BC/QCM | 1 ppm | [46] |

| Catechol | CB/CNC/NR | - | [47] | |

| Toluene | rGO/CNC/NR | - | [48] | |

| Enzyme sensor | HNE | Peptide/CNC | 50 mU mL−1 | [49] |

| Cellulase | XG/CNC | - | [50] | |

| Xylanase | CX/CNC | - | [50] | |

| Trypsin | Peptide/PVA/CNC | 20 µg mL−1 | [51] | |

| Ion sensor | Fe3+ | Py/CNC | 10−3 × 10−3 M | [52] |

| Pb2+ | CNINH/CNC | 7 × 10−11 × 10−3 M | [53] | |

| Cu2+ | CPC/CNF | 0.2 × 10−6 M | [54] | |

| Glucose sensor | Glucose | GO/CNF | 250 mg L−1 | [55] |

| Ag/CNC | 0.116 × 10−6 M | [56] |

Abbreviations: QCM: quartz crystal microbalance; CA: cellulose acetate nanofibers; PEI: polyethyleneimine; GO: graphene oxide; polyaniline (PANI); iron oxide (Fe2O3); CB: carbon black; NR: natural rubber; XG: xyloglucan; CX: cationic xylan; Py: pyrene; CNINH: iron sensitive fluorescent ionophore N′-(4-cyanobenzylidene) isonicotinohydrazide; CPC: cyanobacterial C-phycocyanin.

6. Water Purification Treatment

Aquatic ecosystems decline as a result of human-caused water contamination. This limits access to pure water, which is the main cause of death worldwide. Due to its inexpensive cost, high aspect ratio, innate environmental inertness, and huge natural abundance, nanocellulose can be used for water purification. Nanocellulose materials offer great potential for becoming an efficient absorber of contaminants from wastewater. Additionally, the nanocellulose effective functional surface permits the addition of chemical amounts that could improve the ability of pollutants to bind to the nanocellulose. The most studied way to improve the sorptive effectiveness of nanocellulose is probably through carboxylation. According to Yu et al. [57], adding succinic acid moieties to CNC significantly increased the binding effectiveness of aqueous solutions to Cd2+ and Pb2+. Their capacity to remove these harmful heavy metal ions was further enhanced by the conversion of carboxylic acid groups into sodium carboxylates.

Goswami et al. [58] combined chitosan and nanocellulose from sugarcane bagasse to develop the nanocomposite membrane. The nanocomposite membrane was evaluated for its ability to remove chromium ions from aqueous solution (100 ppm) using a vacuum filtering device. During the investigation, a total of 10 cycles were run to assess the chitosan/nanocellulose composite membrane’s ability to remove chromium ions. The first four cycles dramatically reduced the concentration of chromium ions, which ranged from 87 to 29 PPM. The swelling study (5 min) and chemical stability (24 h) were also evaluated where the obtained results revealed that a maximum swelling ratio of 1.8 was achieved within 5 min, whereas the membrane is completely dissolved in acidic medium and swells in basic medium.

In another study, cellulose nanowhiskers (CNW)-filled hydrogel composites based on chitosan-g-poly(acrylic acid) matrices were constructed, and their capacity to adsorb Pb(II) and Cu(II) ions from water was examined [59]. The optimized parameters showed that utilizing 20 mg of the hydrogel composite containing 10 w/w% of CNW, the highest adsorption of Pb(II) (818.4 mg/g) and Cu(II) (325.5 mg/g) was obtained in 30 min at pH 4.0. Functional groups included in the hydrogel matrix and CNWs serve as coordination sites for the adsorption, as determined. According to desorption experiments, the post-utilized hydrogel composite can be renewed and employed once again in different adsorption processes without significantly losing effectiveness. In order to obtain adsorbent materials for real-world applications, these insights may be useful.

A bio-based and water-resistant composite aerogel made of two kinds of cross-linked renewable nanofibers was created by Sorriaux et al. [60]. Through the process of periodate oxidation, CNFs coated with poly(dopamine) and amyloid protein nanofibers are cross-linked to form a double network. The resulting aerogel has a high capacity for adsorbing pollutants and good mechanical strength. The composite aerogel was effectively used to demonstrate the removal of dyes (rhodamine blue, acriflavine, crystal violet, malachite green, acid fuchsin, and methyl orange), organic traces (atrazine, bisphenol A, and ibuprofen), and heavy metal ions (Pb(II) and Cu(II) from water. Moreover, the bio-based aerogel particularly showed good adsorption efficiencies for crystal violet (93.1% in 30 min), bisphenol A (91.7% in 5 min), and Pb(II) ions (94.7% in 5 min), respectively. Additionally, the aerogel ability to adsorb and desorb Pb(II) ions shows that it has a large capacity for reuse because it consistently maintains effective removal rates. The findings imply that this type of strong, bio-based composite aerogel is a viable adsorbent for effectively and sustainably purifying water of a variety of pollutants.

7. Electronic and Optical

Energy-intensive technologies used as technological advancement are gaining attraction. In the case of disposal methods, this could have an impact on the environment. Resource depletion is driven by the use of non-biodegradable plastics, materials produced from petroleum in the production of energy gadgets, and the excessive use of rare elements like gallium and indium [61]. Currently, research is being conducted to introduce nanocellulose applications in electro-active materials such as dielectric materials, electrically conductive materials, microelectronic components, etc. The utility of nanocellulose in electrical applications can be attributed primarily to its flexibility, piezoelectric and dielectric properties, and durability qualities that are similar to those of other bio-derived materials. As nanocellulose is naturally nonconductive, it can be modified with nanocarbon, conductive polymers such as polyaniline (PANI), polythiophene (PTh), polypyrrole (PPy), polyacetylene, and poly(phenylenevinylene), or metallic particles. They can be applied in energy storage devices like Lithium-ion batteries or super capacitors as well as green electronic components like transistors, antennas, and touch screens [62].

CNF film is a viable option for a transparent insulating or semiconducting substrate since it is an inexpensive and environmentally friendly substrate in the semiconductor industry. The invention of transistors made of paper has made low-cost, flexible, and disposable microelectronics a possibility [63]. In conjunction with printed electronics, cellulose modification and the proper production technology will open up a new path for electronics made of cellulose paper, or “papertronics” [64][65]. Han et al. [66] reported a novel type of electroconductive hybrid elastomers based on a natural rubber (NR) matrix and nanostructured CNF-polyaniline (PANI) complexes that combine the conductivity of PANI with the function of CNF as a biotemplate. The CNF-PANI complexes with ideal dispersity and high aspect ratio are developed by in-situ oxidative polymerizing aniline monomers on the surface of CNF templates. These complexes are then uniformly dispersed into NR latex to generate CNF-PANI/NR elastomers with a hierarchical 3D network structure through a latex coagulation process. The nanocomposite showed good stretch ability, low density, optimum conductivity, increased mechanical characteristics, and inherent flexibility. This technique encourages the advance uses of bio-based materials, including CNFs and NR, in potential soft electronics, such as strain sensors and flexible electrodes, by synthesizing multifunctional elastomers in a simple, scalable, and environmentally friendly approach.

Inui et al. [67] produced a high-dielectric-constant (k) of high density cellulose nanopaper composite by mixing a small amount of silver nanowires with CNF in order to produce a high density cellulose nanopaper by increasing the pass number of the fibers (collision number from several 10 μm to about 15–40 nm after 10 passes). A small amount of silver nano wires was dispersed inside the cellulose nanopaper, and keeping them non-percolative dramatically increased the k value of the nanopaper and retained its flexibility. The k value increased with increasing nanopaper density. The cellulose nanopaper contained a densely packed nanostructure, with a density of up to 1.3 g cm−3 and k value of up to 5.3. This research also compared the k values of the fabricated nanopaper with other substrates and the result shows that the traditional paper substrates made from untreated cellulose pulp fiber with micrometer-scale widths exhibited lower k values (k = 2.9 at 1.1 GHz) than typical plastic films such as polyethylene terephthalate (PET) (k = 3.1), polyethylene naphthalate (PEN) (k = 3.4), and polyimide (PI) (k = 3.4). The experiment also found that the low k value of traditional paper may be because of its porous microstructure of micrometer-sized cellulose fibers.

He et al. [68] created cellulose nanofiber/polyaniline (CNF/PANI) composite films using in-situ polymerization of aniline in a nanocellulose solution that was extracted from bamboo fiber. They concluded that the CNF/PANI composites’ mechanical and electrical conductivity results suggested that they may find usage as biological sensors, electromagnetic radiation shielding materials, and anti-static materials. Nanocellulose/graphene oxide electrolytes were also developed as flexible rechargeable zinc–air batteries by Zhang et al. [69]. The nanocellulose improved the electrolytes by providing excellent structural stability, high water content, low anisotropic swelling degree, and superior ionic conductivity.

According to Mishra et al. [70], films with well-arranged CNC may display piezoelectric effects resulting from the combined yield of the individual CNC. The piezoelectric effect increased with the increasing degree of alignment observed, and the orientation of the CNC consequently affected the film’s piezoelectricity. Ultra-thin films with various levels of CNC alignment can produce varying rates of electro-mechanical actuation, which may be employed in applications like ultra-sensitive micro balances. The high degree of crystallinity makes it possible for CNC to alter polarization densities. Additionally, due to its dielectric qualities, it can be employed in a variety of applications as a useful insulating material.

The development of electronic skins for uses including biomedical sensors, robotic prosthetics, and human–machine interfaces has sparked interest in composite materials with flexible and sensing qualities. Iron (III) chloride (FeCl3) oxidant was utilized by Han et al. [71] to develop polypyrrole-coated CNC and CNF, which were then employed to strengthen polyvinyl alcohol (PVA). Self-healing nanocomposite films with superior mechanical strength (409% increase compared to pure PVA and high toughness up to 407.1%) and excellent adhesion (9670 times greater than its own weight) to various substrates in air and water were achieved by the combination of weak H-bonds and iron coordination bonds and the synergistic effect of these components. Liu et al. [72] synthesized a TOCN/Ti3C2TX composite film using vacuum-assisted filtering and dispersion of 2,2,6,6-tetramethylpiperidinyl-1-oxyl (TEMPO)-oxidized CNF (TOCN). Good mechanical qualities are evident in the generated composite film that mimics the nacre-like lamellar structure of real shells. Additionally, the composite material has shown outstanding biocompatibility, antimicrobial, and electromagnetic shielding performance (36 dB). The piezoresistive sensor made from the composite film additionally displayed great sensitivity (11.6 kPa−1), quick response and recovery time (≤10 ms), an extremely low monitoring limit (0.2 Pa), and long-term stability (>10,000 cycles). It was also capable of picking up on human daily movements like chewing and finger bending.

For material-inherent uses, nanocellulose is interesting for photonic applications. The first is that CNCs have a liquid crystalline behaviour that produces opalescent films with a specific optical character; the second is that both CNF and CNC may generate optically clear, independent films. The adaptability of such materials lies in the structure and surface chemistry of cellulose. Nanocellulose can be easily made compatible with both hydrophobic and hydrophilic materials, employed as a host for optically active nanoparticles, and changed to accommodate covalently bound molecules [19]. For instance, CNF films are significant as substrates for optoelectronics as well as for applications like coatings and packaging due to their superior mechanical qualities and optical clarity.

Due to the enticing characteristics of chiral nematic photonic structures, CNCs have garnered significant attention for their applicability in optical applications. Simple evaporation of aqueous suspensions allows CNC to produce colored, nematic, iridescent, and chiral films. Hanif et al. [73] developed a water-stable flexible nanocellulose chiral nematic films through acid vapor cross-linked glutaraldehyde for chiral nematic templating. They reported that chiral nematic organization of the GA cross-linked CNC films was very well organized. Utilizing GA cross-linked CNC films as freestanding template substrates for conducting polymers (polypyrrole) and metal oxides (iron oxide) to construct flexible chiral nematic photonic hybrids increased the water stability of the films. In another study, chiral nematic and layered pseudonematic structural transitions result in reversible optical tunability in chiral photonic CNC) and elastic PU composite films. The composite films have remarkable mechanical flexibility and water resistance. During mechanical stretching and water absorption, the optical quality of the composite CNC/PU film can be modified reversibly. When a film stretches, the CNC structure changes from chiral nematic to layered pseudonematic. When the fixation is complete, shape recovery occurs when the fixation is exposed to water, and the CNC structure returns to its original chiral nematic order. The research and development of smart optical and mechanical sensors is furthered by these reversibly switchable form and optical qualities. Additionally, the aligned PLA/CNF nanocomposite film created by Geng et al. [74] is very transparent and exhibits anisotropic light scattering, which highlights its enormous potential for optical applications.

Nowadays, there is a growing focus on the use of nanomaterials in lithium-ion batteries. Nanomaterials have been widely used in lithium-ion batteries in several electronic gadgets such as smart mobile phones, notebook computers, and digital cameras. For an example, Hou et al. [75] synthesized the silicon/carbon composite nanosheets from waste vermiculite as high-performance anode materials for lithium-ion batteries. Interestingly, the developed anode shows the excellent specific capacity of ~948 mAh g−1 after 350 cycles at 1.0 A g−1 with a capacity retention of 85%. Previously, the use of current rechargeable lithium-ion batteries had several disadvantages such as insufficient power capabilities and suffer from serious safety risks due to their use of flammable liquid electrolytes [3]. Therefore, improvement has been made by developing the lithium–sulphur batteries as a promising energy storage device with high energy density and low cost. Traditionally, graphite has been used in these batteries as an anode electrode mainly because of its high electrical conductivity (~103 S/m) and theoretical capacity (372 mAh g−1) [76]. A big disadvantage of graphite-based electrodes is that they do not have sufficient energy density required to meet today’s energy demands and have a higher cost. The use of nanocellulose in lithium-sulphur batteries also has been widely discovered. Figure 3 shows a conceptual illustration of nanocellulose application in lithium–sulphur batteries. Several research papers in this area have shown good promise to begin a new era of long-lasting and high-energy batteries for a variety of applications such as in the military, transportation, solar panels, windmills as well as in space applications.

Figure 3. A conceptual illustration depicting of nanocellulose application in lithium–sulphur battery. Reproduce from ref. [3].

According to Nair et al. [77], the use of nanocellulose in gel polymer electrolyte resulted in excellent thermal stability (4200 °C), excellent conductivity (41.2 mS cm−1), and has a stable interface toward lithium metal. It also exhibited a specific capacity of ≈100 mAh g−1. Researchers also found that the internal components of the cell were folded without any mechanical break. Therefore, it shows the potential usefulness of nanocellulose as an alternative electrode binder and the feasibility of lithium–sulphur batteries as a new power source. Interestingly, the developed nanocellulose-based gel polymer electrolyte had a stable capacity retention of up to 70 cycles. These stable cycling profiles show that the nanocellulose is an encouraging way toward the realization of green and reliable next-generation high energy lithium–sulphur batteries.

Besides that, Gou et al. [78] also developed nanocellulose as a cation in gel polymer electrolyte for lithium-ion batteries. The nanocellulose membrane with a porous network is prepared and is cross-linked with glutaraldehyde to further its application as a gel polymer electrolyte, and the skeleton membrane that is cross-linked by 6 wt.% glutaraldehyde exhibits satisfactory mechanical properties and thermal stability. Moreover, the gel polymer electrolyte has moderate electrochemical performance and reverse capability.

References

- Thiruganasambanthan, T.; Ilyas, R.A.; Norrrahim, M.N.F.; Kumar, T.S.M.; Siengchin, S.; Misenan, M.S.M.; Farid, M.A.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Zakaria, S.Z.S.; et al. Emerging Developments on Nanocellulose as Liquid Crystals: A Biomimetic Approach. Polymers 2022, 14, 1546.

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Ong, K.K.; Noor, S.A.M.; Jamal, S.H.; Shah, N.A.A.; Halim, N.A.; Ilyas, R.A.; Yunus, W.M.Z.W. Cationic Nanocellulose as Promising Candidate for Filtration Material of COVID-19: A Perspective. Appl. Sci. Eng. Prog. 2021, 14, 580–587.

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Ujang, F.A.; Janudin, N.; Razak, M.A.I.A.; Shah, N.A.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K.; et al. Nanocellulose: The Next Super Versatile Material for the Military. Mater. Adv. 2021, 2, 1485–1506.

- Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Jenol, M.A.; Nurazzi, N.M.; Sapuan, S.M.; Ilyas, R.A. Performance evaluation of cellulose nanofiber reinforced polypropylene biocomposites for Automotive applications. In Biocomposite and Synthetic Composites for Automotive Applications; Woodhead Publishing Series: Amsterdam, The Netherlands, 2020; pp. 119–215.

- Fareez, I.M.; Jasni, A.H.; Norrrahim, M.N.F. Nanofibrillated cellulose based bio-phenolic composites. In Phenolic Polymers Based Composite Materials; Springer: Singapore, 2020; pp. 139–151.

- Norrrahim, M.N.F. Superheated Steam Pretreatment of Oil Palm Biomass for Improving Nanofibrillation of Cellulose and Performance of Polypropylene/Cellulose Nanofiber Composites; Universiti Putra Malaysia: Seri Kembangan, Malaysia, 2018.

- Norrrahim, M.N.F.; Tengku Yasim-Anuar, T.A.; Sapuan, S.M.; Ilyas, R.A.; Hakimi, M.I.; Syed Najmuddin, S.U.F.; Jenol, M.A. Nanocellulose reinforced polypropylene and polyethylene composite for packaging application. In Bio-Based Packaging: Material, Environmental and Economic Aspects; Wiley Online Library: Hoboken, NJ, USA, 2021.

- Lee, C.H.; Lee, S.H.; Padzil, F.N.M.; Ainun, Z.M.A.; Norrrahim, M.N.F.; Chin, K.L. Biocomposites and Nanocomposites. In Composite Materials; CRC Press: Boca Raton, FL, USA, 2021; pp. 29–60.

- Razali, N.A.M.; Mohd Sohaimi, R.; Othman, R.N.I.R.; Abdullah, N.; Demon, S.Z.N.; Jasmani, L.; Yunus, W.M.Z.W.; Ya’acob, W.M.H.W.; Salleh, E.M.; Norizan, M.N.; et al. Comparative Study on Extraction of Cellulose Fiber from Rice Straw Waste from Chemo-Mechanical and Pulping Method. Polymers 2022, 14, 387.

- Djafari Petroudy, S.R. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–83.

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Misenan, M.S.M.; Janudin, N.; Shah, N.A.A.; Halim, N.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K. 7—Nanocellulose as an adsorbent for heavy metals. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 197–211.

- Nurazzi, N.M.; Jenol, M.A.; Kamarudin, S.H.; Aisyah, H.A.; Hao, L.C.; Yusuff, S.M.; Amira, M.N.; Harussani, M.M.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. 19—Nanocellulose composites in the automotive industry. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 439–467.

- Charreau, H.; Cavallo, E.; Foresti, M.L. Patents involving nanocellulose: Analysis of their evolution since 2010. Carbohydr. Polym. 2020, 237, 116039.

- De France, K.; Zeng, Z.; Wu, T.; Nyström, G. Functional materials from nanocellulose: Utilizing structure–property relationships in bottom-up fabrication. Adv. Mater. 2021, 33, 2000657.

- Jenol, M.A.; Norrrahim, M.N.F.; Nurazzi, N.M. 17—Nanocellulose nanocomposites in textiles. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 397–408.

- Ilyas, R.A.; Asyraf, M.R.M.; Aisyah, H.A.; Sapuan, S.M.; Norrrahim, M.N.F.; Ibrahim, R.; Atikah, M.S.N.; Atiqah, A.; Zainudin, E.S.; Ishak, M.R.; et al. 1-Introduction to nanocellulose production from biological waste. In Industrial Applications of Nanocellulose and Its Nanocomposites; Sapuan, S.M., Norrrahim, M.N.F., Ilyas, R.A., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 1–37.

- Adachi, K.; Daicho, K.; Furuta, M.; Shiga, T.; Saito, T.; Kodama, T. Thermal conduction through individual cellulose nanofibers. Appl. Phys. Lett. 2021, 118, 053701.

- Uetani, K.; Kasuya, K.; Wang, J.; Huang, Y.; Watanabe, R.; Tsuneyasu, S.; Satoh, T.; Koga, H.; Nogi, M. Kirigami-processed cellulose nanofiber films for smart heat dissipation by convection. NPG Asia Mater. 2021, 13, 62.

- Reshmy, R.; Philip, E.; Paul, S.A.; Madhavan, A.; Sindhu, R.; Binod, P.; Pandey, A.; Sirohi, R. Nanocellulose-based products for sustainable applicationsrecent trends and possibilities. Rev. Environ. Sci. Biotechnol. 2020, 19, 779–806.

- Shahsavari, S. 2021. Application of Nanocellulose in Food Packaging: A review. Int. J. Bio-Inorg. Hybr. Nanomater. 2021, 10, 5–10.

- Ariffin, H.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Nishida, H.; Hassan, M.A.; Ibrahim, N.A.; Yunus, W.M.Z.W. Oil palm biomass cellulose-fabricated Polylactic Acid composites for packaging applications. In Bionanocomposites for Packaging Applications; Springer: Berlin/Heidelberg, Germany, 2018; pp. 95–105.

- Silva, F.A.G.S.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose bio-based composites for food packaging. Nanomaterials 2020, 10, 2041.

- Srivastava, K.R.; Dixit, S.; Pal, D.B.; Mishra, P.K.; Srivastava, P.; Srivastava, N.; Hashem, A.; Alqarawi, A.A.; Abd_Allah, E.F. Effect of nanocellulose on mechanical and barrier properties of PVA–banana pseudostem fiber composite films. Environ. Technol. Innov. 2021, 21, 101312.

- Asad, M.; Saba, N.; Asiri, A.M.; Jawaid, M.; Indarti, E.; Wanrosli, W.D. 2-Preparation and characterization of nanocomposite films from oil palm pulp nanocellulose/poly (Vinyl alcohol) by casting method. Carbohydr. Polym. 2018, 191, 103–111.

- Patel, B.H.; Joshi, P.V. Banana Nanocellulose Fiber/PVOH Composite Film as Soluble Packaging Material: Preparation and Characterization. J. Packag. Technol. Res. 2020, 4, 95–101.

- Tsai, Y.-H.; Yang, Y.-N.; Ho, Y.-C.; Tsai, M.-L.; Mi, F.-L. Drug release and antioxidant/antibacterial activities of silymarin-zein nanoparticle/bacterial cellulose nanofiber composite films. Carbohydr. Polym. 2018, 15, 286–296.

- Moreirinha, C.; Vilela, C.; Silva, N.H.; Pinto, R.J.; Almeida, A.; Rocha, M.A.M.; Coelho, E.; Coimbra, M.A.; Silvestre, A.J.; Freire, C.S. Antioxidant and antimicrobial films based on brewers spent grain arabinoxylans, nanocellulose and feruloylated compounds for active packaging. Food Hydrocoll. 2020, 108, 105836.

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 1–8.

- Kuswandi, B.; Jayus, O.R.; Abdullah, A.; Heng, L.Y. Novel On-Package Sticker Sensor Based on Methyl Red forReal-Time Monitoring of Broiler Chicken Cut Freshness. Packag. Technol. Sci. 2014, 27, 69–81.

- Lu, P.; Yang, Y.; Liu, R.; Liu, X.; Ma, J.; Wu, M.; Wang, S. Preparation of sugarcane bagasse nanocellulose hydrogel as a colourimetric freshness indicator for intelligent food packaging. Carbohydr. Polym. 2020, 249, 116831.

- Al Obaidi, A.; Karaca, I.M.; Ayhan, Z.; Haskaraca, G.; Gultekin, E. Fabrication and validation of CO2-sensitive indicator to monitor the freshness of poultry meat. Food Packag. Shelf Life 2022, 34, 100930.

- Guise, C.; Fangueiro, R. Biomedical applications of nanocellulose. In Natural Fibres: Advances in Science and Technology towards Industrial Applications; Fangueiro, R., Rana, S., Eds.; Springer: Dordrecht, The Netherlands, 2016; pp. 155–169.

- Nehra, P.; Chauhan, R.P. Eco-friendly Nanocellulose and its Biomedical Applications: Current Status and Future Prospect. J. Biomater. Sci. Polym. Ed. 2020, 32, 112–149.

- Siqueira, P.; Siqueira, É.; De Lima, A.E.; Siqueira, G.; Pinzón-Garcia, A.D.; Lopes, A.P.; Segura, M.E.C.; Isaac, A.; Pereira, F.V.; Botaro, V.R. Three-Dimensional Stable Alginate-NanocelluloseGels for Biomedical Applications: Towards TunableMechanical Properties and Cell Growing. Nanomaterials 2019, 9, 78.

- Ludwicka, K.; Kolodziejczyk, M.; Gendaszewska-Darmach, E.; Chrzanowski, M.; Jedrzejczak-Krzepkowska, M.; Rytczak, P.; Bielecki, S. Stable composite of bacterial nanocellulose and perforated polypropylene mesh for biomedical applications. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 107, 978–987.

- Liu, J.; Shi, Y.; Cheng, L.; Sun, J.; Yu, S.; Lu, X.; Biranje, S.; Xu, W.; Zhang, X.; Song, J.; et al. Growth factor functionalized biodegradable nanocellulose scaffolds for potential wound healing application. Cellulose 2021, 28, 5643–5656.

- Sanoj, P.; Balasubramanian, K. High performance structural nano cellulose composites for motor vehicle spring suspension system. J. Plast. Technol. 2014, 18, 383–389.

- Duzik, A.; Ko, H.U.; Kim, H.J.; Kim, J.; Kim, J.H.; Choi, S.H.; Bryant, R.G. Fabrication Method, Characteristics and Applications of Cellulose Nano Fiber (CNF) Film; NASA/TM-2019-220268; NASA Langley Research Center: Hampton, VA, USA, 2019.

- Bheekhun, N.; Talib, A.R.A.; Hassan, M.R. Aerogels in Aerospace: An Overview. Adv. Mater. Sci. Eng. 2013, 2013, 406065.

- Nguyen, L.H.; Naficy, S.; Chandrawati, R.; Dehghani, F. Nanocellulose for Sensing Applications. Adv. Mater. Interfaces 2019, 6, 1900424.

- Jaiswal, A.K.; Hokkanen, A.; Kumar, V.; Makela, T.; Harlin, A.; Orelma, H. Thermoresponsive Nanocellulose Films as an Optical Modulation Device: Proof-of-Concept. ACS Appl. Mater. Interfaces 2021, 13, 25346–25356.

- Wang, D.C.; Yu, H.Y.; Qi, D.; Ramasamy, M.; Yao, J.; Tang, F.; Tam, K.M.C.; Ni, Q. Supramolecular Self-Assembly of 3D Conductive Cellulose Nanofiber Aerogels for Flexible Supercapacitors and Ultrasensitive Sensors. ACS Appl. Mater. Interfaces 2019, 11, 24435–24446.

- Jia, Y.; Yu, H.; Zhang, Y.; Dong, F.; Li, Z. Colloids and Surfaces B: Biointerfaces Cellulose acetate nanofibers coated layer-by-layer with polyethylenimine and graphene oxide on a quartz crystal microbalance for use as a highly sensitive ammonia sensor. Colloids Surf. B Biointerfaces 2016, 148, 263–269.

- Pang, Z.; Yang, Z.; Chen, Y.; Zhang, J.; Wang, Q.; Huang, F.; Wei, Q. A room temperature ammonia gas sensor based on cellulose/TiO2/PANI composite nanofibers. Colloids Surf. A Physicochem. Eng. Asp. 2016, 494, 248–255.

- Sadasivuni, K.K.; Ponnamma, D.; Ko, H.U.; Kim, H.C.; Zhai, L.; Kim, J. Flexible NO2 sensors from renewable cellulose nanocrystals/iron oxide composites. Sens. Actuators B Chem. 2016, 233, 633–638.

- Hu, W.; Chen, S.; Liu, L.; Ding, B.; Wang, H. Formaldehyde sensors based on nanofibrous polyethyleneimine/bacterial cellulose membranes coated quartz crystal microbalance. Sens. Actuators B Chem. 2011, 157, 554–559.

- Wu, X.; Lu, C.; Han, Y.; Zhou, Z.; Yuan, G.; Zhang, X. Cellulose nanowhisker modulated 3D hierarchical conductive structure of carbon black/natural rubber nanocomposites for liquid and strain sensing application. Compos. Sci. Technol. 2016, 124, 44–51.

- Cao, J.; Zhang, X.; Wu, X.; Wang, S.; Lu, C. Cellulose nanocrystals mediated assembly of graphene in rubber composites for chemical sensing applications. Carbohydr. Polym. 2016, 140, 88–95.

- Edwards, J.V.; Prevost, N.; Sethumadhavan, K.; Ullah, A.; Condon, B. Peptide conjugated cellulose nanocrystals with sensitive human neutrophil elastase sensor activity. Cellulose 2013, 20, 1223–1235.

- Guyomard-Lack, A.; Cerclier, C.; Beury, N.; Jean, B.; Cousin, F.; Moreau, C.; Cathala, B. Nano-structured cellulose nanocrystals-xyloglucan multilayered films for the detection of cellulase activity. Eur. Phys. J. Spec. Top 2012, 213, 291–294.

- Schyrr, B.; Pasche, S.; Voirin, G.; Weder, C.; Simon, Y.C.; Foster, E.J. Biosensors based on porous cellulose nanocrystal–poly (vinyl alcohol) scaffolds. ACS Appl. Mater. Interfaces 2014, 6, 12674–12683.

- Zhang, L.; Li, Q.; Zhou, J.; Zhang, L. Synthesis and Photophysical Behavior of Pyrene-Bearing Cellulose Nanocrystals for Fe3+ Sensing. Macromol. Chem. Phys. 2012, 213, 1612–1617.

- Kacmaz, S.; Ertekin, K.; Gocmenturk, M.; Suslu, A.; Ergun, Y.; Celik, E. Selective sensing of Fe3+ at pico-molar level with ethyl cellulose based electrospun nanofibers. React. Funct. Polym. 2013, 73, 674–682.

- Weishaupt, R.; Siqueira, G.; Schubert, M.; Kämpf, M.M.; Zimmermann, T.; Maniura-Weber, K.; Faccio, G. A Protein-Nanocellulose Paper for Sensing Copper Ions at the Nano- to Micromolar Level. Adv. Funct. Mater. 2017, 27, 1604291.

- Dong, L.; Zhang, X.; Ren, S.; Lei, T.; Sun, X.; Qi, Y.; Wu, Q. Poly(diallyldimethylammonium chloride)–cellulose nanocrystals supported Au nanoparticles for nonenzymatic glucose sensing. RSC Adv. 2016, 6, 6436–6442.

- Wang, S.; Sun, J.; Jia, Y.; Yang, L.; Wang, N.; Xianyu, Y.; Chen, W.; Li, X.; Cha, R.; Jiang, X. Nanocrystalline Cellulose-Assisted Generation of Silver Nanoparticles for Nonenzymatic Glucose Detection and Antibacterial Agent. Biomacromolecules 2016, 17, 2472–2478.

- Yu, X.; Tong, S.; Ge, M.; Wu, L.; Zuo, J.; Cao, C.; Song, W. Adsorption of heavy metal ions from aqueous solution by carboxylated cellulose nanocrystals. J. Environ. Sci. 2013, 25, 933–943.

- Goswami, R.; Mishra, A.; Bhatt, N.; Mishra, A.; Naithani, P. Potential of chitosan/nanocellulose based composite membrane for the removal of heavy metal (chromium ion). Mater. Today Proc. 2021, 46, 10954–10959.

- Rodrigues, F.H.A.; Magalhães, C.E.d.C.; Medina, A.L.; Fajardo, A.R. Hydrogel composites containing nanocellulose as adsorbents for aqueous removal of heavy metals: Design, optimization, and application. Cellulose 2019, 26, 9119–9133.

- Sorriaux, M.; Sorieul, M.; Chen, Y. Bio-Based and Robust Polydopamine Coated Nanocellulose/Amyloid Composite Aerogel for Fast and Wide-Spectrum Water Purification. Polymers 2021, 13, 3442.

- Du, X.; Zhang, Z.; Liu, W.; Deng, Y. Nanocellulose-based conductive materials and their emerging applications in energy devices—A review. Nano Energy 2017, 35, 299–320.

- QuanLing, Y.; JunWei, Y.; ZhuQun, S.; ShuJie, X.; ChuanXi, X. Recent progress of nanocellulose-based electroconductive materials and their applications as electronic devices. J. For. Eng. 2018, 3, 1–11.

- Kim, J.-H.; Yun, S.; Ko, H.-U.; Kim, J. A flexible paper transistor made with aligned single-walled carbon nanotube bonded cellulose composite. Curr. Appl. Phys. 2013, 13, 897–901.

- Kim, J. Disposable and Flexible Chemical Sensors and Biosensors Made with Renewable Materials; World Scientific: Singapore, 2017.

- Gao, Y.; Choi, S. Stepping Toward Self-Powered Papertronics: Integrating Biobatteries into a Single Sheet of Paper. Adv. Mater. Technol. 2016, 2, 1600194.

- Han, J.; Lu, K.; Yue, Y.; Mei, C.; Huang, C.; Wu, Q.; Xu, X. Nanocellulose-templated assembly of polyaniline in natural rubber-based hybrid elastomers toward flexible electronic conductors. Ind. Crops Prod. 2019, 128, 94–107.

- Inui, T.; Koga, H.; Nogi, M.; Komoda, N.; Suganuma, K. A Miniaturized Flexible Antenna Printed on a High Dielectric Constant Nanopaper Composite. Adv. Mater. 2015, 27, 1112–1116.

- He, W.; Tian, J.; Li, J.; Jin, H.; Li, Y. Characterization and properties of cellulose nanofiber/polyaniline film composites synthesized through in situ polymerization. Bioresources 2016, 11, 8535–8547.

- Zhang, J.; Fu, J.; Song, X.; Jiang, G.; Zarrin, H.; Xu, P.; Li, K.; Yu, A.; Chen, Z. Laminated Cross-Linked Nanocellulose/Graphene Oxide Electrolyte for Flexible Rechargeable Zinc–Air Batteries. Adv. Energy Mater. 2016, 6, 1600476.

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in piezoelectric polymer composites for energy harvesting applications: A systematic review. Macromol. Mater. Eng. 2019, 34, 1800463.

- Han, L.; Cui, S.; Yu, H.Y.; Song, M.; Zhang, H.; Grishkewich, N.; Huang, C.; Kim, D.; Tam, K.M.C. Self-Healable Conductive Nanocellulose Nanocomposites for Biocompatible Electronic Skin Sensor Systems. ACS Appl. Mater. Interfaces 2019, 11, 44642–44651.

- Liu, D.; Gao, Y.; Song, Y.; Zhu, H.; Zhang, L.; Xie, Y.; Shi, H.; Shi, Z.; Yang, Q.; Xiong, C. Highly Sensitive Multifunctional Electronic Skin Based on Nanocellulose/MXene Composite Films with Good Electromagnetic Shielding Biocompatible Antibacterial Properties. Biomacromolecules 2022, 23, 182–195.

- Hanif, Z.; Choi, D.; Tariq, M.Z.; La, M.; Park, S.J. Water-Stable Flexible Nanocellulose Chiral Nematic Films through Acid Vapor Cross-Linked Glutaraldehyde for Chiral Nematic Templating. ACS Macro Lett. 2020, 9, 146–151.

- Qu, D.; Chu, G.; Martin, P.; Vasilyev, G.; Vilensky, R.; Zussman, E. Modulating the Structural Orientation of Nanocellulose Composites through Mechano-Stimuli. ACS Appl. Mater. Interfaces 2019, 11, 40443–40450.

- Hou, L.; Xing, B.; Zeng, H.; Kang, W.; Guo, H.; Cheng, S.; Huang, G.; Cao, Y.; Chen, Z.; Zhang, C. Aluminothermic reduction synthesis of Si/C composite nanosheets from waste vermiculite as high-performance anode materials for lithium-ion batteries. J. Alloys Compd. 2022, 922, 166134.

- Lasrado, D.; Ahankari, S. Nanocellulose-based polymer composites for energy applications—A review. J. Appl. Polym. Sci. 2020, 137, 1–14.

- Nair, J.R.; Bella, F.; Angulakshmi, N.; Manuel, A.; Gerbaldi, C. Nanocellulose-laden composite polymer electrolytes for high performing lithium—Sulphur batteries. Energy Storage Mater. 2016, 3, 69–76.

- Gou, J.; Liu, W.; Tang, A. A renewable and biodegradable nanocellulose-based gel polymer electrolyte for lithium-ion battery. J. Mater. Sci. 2020, 55, 10699–10711.

This entry is offline, you can click here to edit this entry!