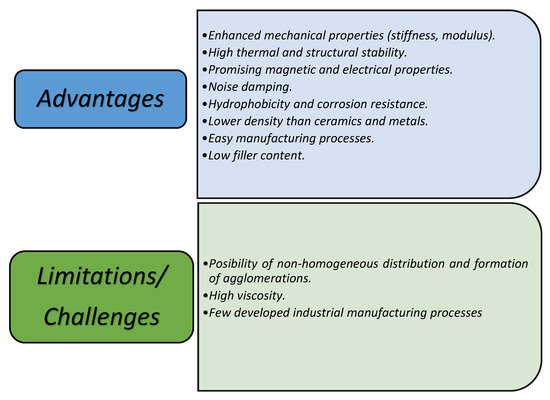

Polymers have had an enormous impact on science and technology, and their interest relating to the development of new macromolecular materials has exponentially increased. Polymer nanocomposites, materials based on a polymeric matrix covalently coupled to reinforcement, display properties of both components. In the aerospace industry, polymer nanocomposites are attractive due to their promising characteristics, among which lightness, mechanical and thermal resistance, radiation and corrosion resistance, and conductive and magnetic properties stand out. The use of them, instead of metal-based materials, has allowed the optimization of design processes and applications in order to provide safer, faster, and eventually cheaper transportation in the future.

- polymer nanocomposite

- filler

- magnetic nanoparticles

- aerospace devices

- nanotechnology

1. Introduction

2. Magnetic Polymer Nanocomposites (MPNs)

-

Magnetic conductive materials: These are useful in manufacturing sensors and devices. They are made up of magnetic nanoparticles in a conductive polymeric matrix. A charge transfer can be established between the surface of the particles and the polymer, so the material acts as an electronic system. Some proposed compositions are magnetite-polyaniline, maghemite-polypyrrole, cobalt ferrite-polypyrrole, and various metal-polymer combinations [45][46]

-

Transparent magnetic materials: As magnetic oxides are considerably more transparent to visible light than nanoparticles, magnetic nanocomposites can be made with reasonable transparency and greater magnetization, by more than an order of magnitude, than stronger ones such as transparent magnets.

3. Synthesis of Magnetic Polymer Nanocomposites

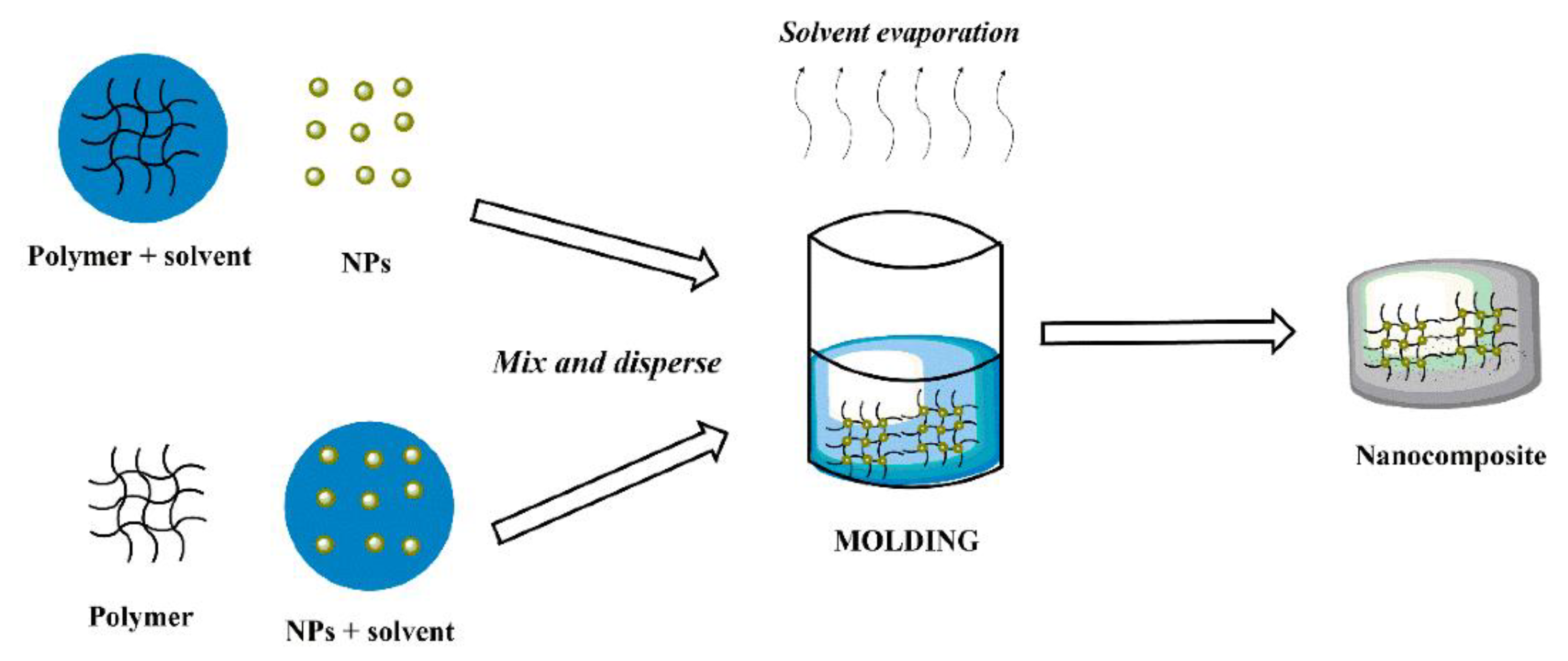

3.1. Molding

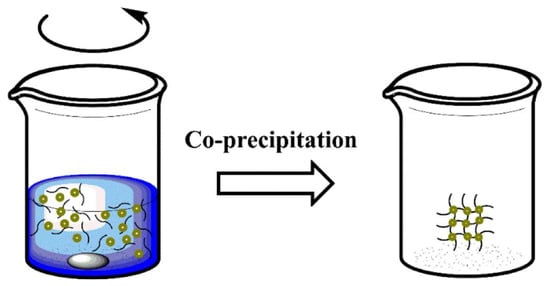

3.2. Coprecipitation

3.3. In Situ Precipitation

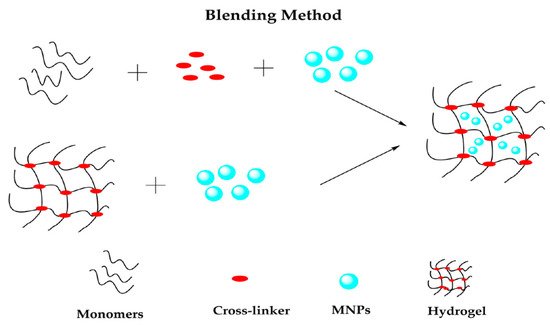

3.4. Blending

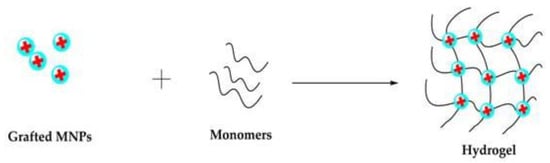

3.5. Grafting Methods

| Synthetic Method | Brief Description |

Advantages | Disadvantages | References |

|---|---|---|---|---|

| Molding | A polymeric stamp is placed in contact with a precursor of a solid material |

|

|

[47] |

| Co-precipitation | Reducing a mixture of metallic ions using a basic solution at low temperature and in an inert atmosphere |

|

|

[53] |

| In situ precipitation | Nanoparticles dispersed in a monomer or monomer solution and polymerization under standard techniques |

|

|

|

| Blending | Polymer melted with a desired amount of filler in presence of an inert gas and heat |

|

|

[60] |

| Grafting | Dispersion of nanoparticles along the surface polymer matrix initiated by radical polymerization |

|

|

[84] |

This entry is adapted from the peer-reviewed paper 10.3390/polym14194084

References

- Muhammad, A.; Rahman, M.R.; Baini, R.; Bin Bakri, M.K. Applications of sustainable polymer composites in automobile and aerospace industry. In Advances in Sustainable Polymer Composites; Rahman, M.R., Ed.; Elsevier: Duxford, UK, 2021; pp. 185–207.

- Ramli, N.; Norkhairunnisa, M.; Ando, Y.; Abdan, K.; Leman, Z. Advanced Polymer Composite for Aerospace Engineering Applications. In Advanced Composites in Aerospace Engineering Applications; Mazlan, N., Sapuan, S.M., Ilyas, R.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–21. ISBN 978-3-030-88191-7.

- Mittal, V. Polymer Nanocomposite Coatings; Mittal, V., Ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9780429098154.

- Laurvick, C.A. Singaraju Nanotechnology in Aerospace Systems. IEEE Aerosp. Electron. Syst. Mag. 2003, 18, 18–22.

- Forloni, G. Responsible nanotechnology development. J. Nanoparticle Res. 2012, 14, 1007.

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931.

- Darwish, M.S.A.; Mostafa, M.H.; Al-Harbi, L.M. Polymeric Nanocomposites for Environmental and Industrial Applications. Int. J. Mol. Sci. 2022, 23, 1023.

- Hanemann, T.; Szabó, D.V. Polymer-Nanoparticle Composites: From Synthesis to Modern Applications. Materials 2010, 3, 3468–3517.

- Pansare, A.V.; Chhatre, S.Y.; Khairkar, S.R.; Bell, J.G.; Barbezat, M.; Chakrabarti, S.; Nagarkar, A.A. “Shape-Coding”: Morphology-Based Information System for Polymers and Composites. ACS Appl. Mater. Interfaces 2020, 12, 27555–27561.

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Developments in polyester composite materials–An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698.

- Qin, Q.H. Introduction to the composite and its toughening mechanisms. In Toughening Mechanisms in Composite Materials; Qin, Q., Ye, J., Eds.; Elsevier: Cambridge, UK, 2015; pp. 1–32.

- Arumugaprabu, V.; Ko, T.J.; Uthayakumar, M.; Joel Johnson, R.D. Failure analysis in hybrid composites prepared using industrial wastes. In Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 229–244.

- Baird, D.G. Polymer Processing. In Encyclopedia of Physical Science and Technology; Elsevier: Amsterdam, The Netherlands, 2003; pp. 611–643.

- Bustamante-Torres, M.; Romero-Fierro, D.; Arcentales-Vera, B.; Pardo, S.; Bucio, E. Interaction between Filler and Polymeric Matrix in Nanocomposites: Magnetic Approach and Applications. Polymers 2021, 13, 2998.

- Ban, C.; Dinca, I.; Stefan, A.; Pelin, G. Nanocomposites as Advanced Materials for Aerospace Industry. INCAS Bull. 2012, 4, 57–72.

- Harito, C.; Bavykin, D.V.; Yuliarto, B.; Dipojono, H.K.; Walsh, F.C. Polymer nanocomposites having a high filler content: Synthesis, structures, properties, and applications. Nanoscale 2019, 11, 4653–4682.

- Park, S.-J.; Seo, M.-K. Types of Composites. In Interface Science and Composites; Elsevier: Amsterdam, The Netherlands, 2011; pp. 501–629.

- Zhu, J.; Wei, S.; Chen, M.; Gu, H.; Rapole, S.B.; Pallavkar, S.; Ho, T.C.; Hopper, J.; Guo, Z. Magnetic nanocomposites for environmental remediation. Adv. Powder Technol. 2013, 24, 459–467.

- Lee, K.-P.; Gopalan, A.; Komathi, S.; Raghupathy, D. Polyaniline-based nanocomposites: Preparation, properties and applications. In Physical Properties and Applications of Polymer Nanocomposites; Tjong, S.C., Mai, Y.-W., Eds.; Elsevier: Cambridge, UK, 2010; pp. 187–243.

- Purkait, M.K.; Sinha, M.K.; Mondal, P.; Singh, R. (Eds.) Magnetic-Responsive Membranes. In Stimuli Responsive Polymeric Membranes; Elsevier: Cambridge, UK, 2018; pp. 193–219.

- Behrens, S.; Appel, I. Magnetic nanocomposites. Curr. Opin. Biotechnol. 2016, 39, 89–96.

- Rathod, V.T.; Kumar, J.S.; Jain, A. Polymer and ceramic nanocomposites for aerospace applications. Appl. Nanosci. 2017, 7, 519–548.

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer composite for antistatic application in aerospace. Def. Technol. 2020, 16, 107–118.

- Wu, S.; Hu, W.; Ze, Q.; Sitti, M.; Zhao, R. Multifunctional magnetic soft composites: A review. Multifunct. Mater. 2020, 3, 042003.

- Anbusagar, N.R.R.; Palanikumar, K.; Ponshanmugakumar, A. Preparation and properties of nanopolymer advanced composites: A review. In Polymer-based Nanocomposites for Energy and Environmental Applications; Jawaid, M., Khan, M., Eds.; Elsevier: Duxford, UK, 2018; pp. 27–73. ISBN 9780081019115.

- Li, Z.; Liu, F.; Yang, G.; Li, H.; Dong, L.; Xiong, C.; Wang, Q. Enhanced energy storage performance of ferroelectric polymer nanocomposites at relatively low electric fields induced by surface modified BaTiO3 nanofibers. Compos. Sci. Technol. 2018, 164, 214–221.

- Li, H.; Wang, L.; Zhu, Y.; Jiang, P.; Huang, X. Tailoring the polarity of polymer shell on BaTiO3 nanoparticle surface for improved energy storage performance of dielectric polymer nanocomposites. Chin. Chem. Lett. 2021, 32, 2229–2232.

- Wilson, J.L.; Poddar, P.; Frey, N.A.; Srikanth, H.; Mohomed, K.; Harmon, J.P.; Kotha, S.; Wachsmuth, J. Synthesis and magnetic properties of polymer nanocomposites with embedded iron nanoparticles. J. Appl. Phys. 2004, 95, 1439–1443.

- Nagaraj, A.; Rajan, M. Future needs and trends: Influence of polymers on the environment. In Polymer Science and Innovative Applications; Al Ali Almaadeed, M., Ponnamma, D., Carignano, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 593–634.

- Sharma, S.; Verma, A.; Kumar, A.; Kamyab, H. Magnetic Nano-Composites and their Industrial Applications. Nano Hybrids Compos. 2018, 20, 149–172.

- Thévenot, J.; Oliveira, H.; Sandre, O.; Lecommandoux, S. Magnetic responsive polymer composite materials. Chem. Soc. Rev. 2013, 42, 7099–7116.

- Rawat, N.K.; Ahmad, S. Unveiling nanoconducting polymers and composites for corrosion protection. In Nanomaterials-Based Coatings; Elsevier: Amsterdam, The Netherlands, 2019; pp. 373–395.

- Pandey, J.K.; Raghunatha Reddy, K.; Pratheep Kumar, A.; Singh, R.P. An overview on the degradability of polymer nanocomposites. Polym. Degrad. Stab. 2005, 88, 234–250.

- Kashiwagi, T.; Du, F.; Douglas, J.F.; Winey, K.I.; Harris, R.H.; Shields, J.R. Nanoparticle networks reduce the flammability of polymer nanocomposites. Nat. Mater. 2005, 4, 928–933.

- Leszczyńska, A.; Njuguna, J.; Pielichowski, K.; Banerjee, J.R. Polymer/montmorillonite nanocomposites with improved thermal properties. Thermochim. Acta 2007, 453, 75–96.

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204.

- Hwu, J.M.; Jiang, G.J.; Gao, Z.M.; Xie, W.; Pan, W.P. The characterization of organic modified clay and clay-filled PMMA nanocomposite. J. Appl. Polym. Sci. 2002, 83, 1702–1710.

- Njuguna, J.; Pielichowski, K.; Fan, J. Polymer nanocomposites for aerospace applications. In Advances in Polymer Nanocomposites; Fengge, G., Ed.; Elsevier: Cambridge, UK, 2012; pp. 472–539. ISBN 9781845699406.

- Camargo, P.H.C.; Satyanarayana, K.G.; Wypych, F. Nanocomposites: Synthesis, structure, properties and new application opportunities. Mater. Res. 2009, 12, 1–39.

- Azeez, A.A.; Rhee, K.Y.; Park, S.J.; Hui, D. Epoxy clay nanocomposites–processing, properties and applications: A review. Compos. Part B Eng. 2013, 45, 308–320.

- Becker, O.; Varley, R.J.; Simon, G.P. Thermal stability and water uptake of high performance epoxy layered silicate nanocomposites. Eur. Polym. J. 2004, 40, 187–195.

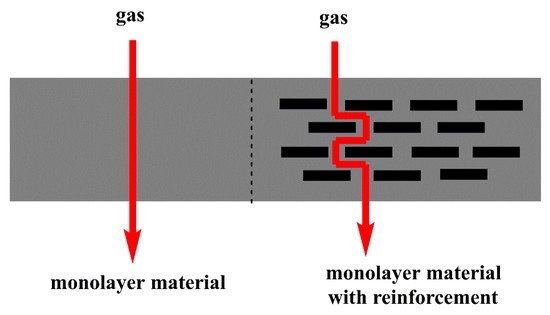

- Choudalakis, G.; Gotsis, A.D. Permeability of polymer/clay nanocomposites: A review. Eur. Polym. J. 2009, 45, 967–984.

- Jalali Dil, E.; Ben Dhieb, F.; Ajji, A. Modeling the effect of nanoplatelets orientation on gas permeability of polymer nanocomposites. Polymer 2019, 168, 126–130.

- Fulco, A.P.P.; Melo, J.D.D.; Paskocimas, C.A.; de Medeiros, S.N.; de Machado, F.L.A.; Rodrigues, A.R. Magnetic properties of polymer matrix composites with embedded ferrite particles. NDT E Int. 2016, 77, 42–48.

- Garzón, A.O.; Landínez, D.A.; Roa-Rojas, J.; Fajardo-Tolosa, F.E.; Peña-Rodríguez, G.; Parra-Vargas, C.A. Production and structural, electrical and magnetic characterization of a composite material based on powdered magnetite and high density polyethylene. Rev. Acad. Colomb. Cienc. Exactas Físicas Y Nat. 2017, 41, 154.

- Zasońska, B.A.; Acharya, U.; Pfleger, J.; Humpolíček, P.; Vajďák, J.; Svoboda, J.; Petrovsky, E.; Hromádková, J.; Walterová, Z.; Bober, P. Multifunctional @silver composites: Synthesis, physico-chemical characterization and antibacterial properties. Chem. Pap. 2018, 72, 1789–1797.

- Lipomi, D.J.; Martinez, R.V.; Cademartiri, L.; Whitesides, G.M. Soft Lithographic Approaches to Nanofabrication. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Oxford, UK, 2012; pp. 211–231.

- Trochu, F.; Gauvin, R.; Gao, D.-M. Numerical analysis of the resin transfer molding process by the finite element method. Adv. Polym. Technol. 1993, 12, 329–342.

- Mallick, P.K. Failure of polymer matrix composites (PMCs) in automotive and transportation applications. In Failure Mechanisms in Polymer Matrix Composites; Elsevier: Cambridge, UK, 2012; pp. 368–392.

- Marques, A.T. Fibrous materials reinforced composites production techniques. In Fibrous and Composite Materials for Civil Engineering Applications; Fangueiro, R., Ed.; Elsevier: Cambridge, UK, 2011; pp. 191–215.

- Nair, A.B.; Joseph, R. Eco-friendly bio-composites using natural rubber (NR) matrices and natural fiber reinforcements. In Chemistry, Manufacture and Applications of Natural Rubber; Elsevier: Amsterdam, The Netherlands, 2014; pp. 249–283.

- Romero-Fierro, D.; Bustamante-Torres, M.; Bravo-Plascencia, F.; Magaña, H.; Bucio, E. Polymer-Magnetic Semiconductor Nanocomposites for Industrial Electronic Applications. Polymers 2022, 14, 2467.

- Gautam, R.K.; Chattopadhyaya, M.C. Functionalized Magnetic Nanoparticles: Adsorbents and Applications. In Nanomaterials for Wastewater Remediation; Elsevier: Oxford, UK, 2016; pp. 139–159.

- Cruz, I.F.; Freire, C.; Araújo, J.P.; Pereira, C.; Pereira, A.M. Multifunctional Ferrite Nanoparticles: From Current Trends Toward the Future. In Magnetic Nanostructured Materials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 59–116.

- Krishna, J.; Perumal, A.S.; Khan, I.; Chelliah, R.; Wei, S.; Swamidoss, C.M.A.; Oh, D.-H.; Bharathiraja, B. Synthesis of nanomaterials for biofuel and bioenergy applications. In Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2021; pp. 97–165.

- Fatimah, I.; Fadillah, G.; Yudha, S.P. Synthesis of iron-based magnetic nanocomposites: A review. Arab. J. Chem. 2021, 14, 103301.

- Mehra, N.; Jeske, M.; Yang, X.; Gu, J.; Kashfipour, M.A.; Li, Y.; Baughman, J.A.; Zhu, J. Hydrogen-Bond Driven Self-Assembly of Two-Dimensional Supramolecular Melamine-Cyanuric Acid Crystals and Its Self-Alignment in Polymer Composites for Enhanced Thermal Conduction. ACS Appl. Polym. Mater. 2019, 1, 1291–1300.

- Gill, N.; Sharma, A.L.; Gupta, V.; Tomar, M.; Pandey, O.P.; Singh, D.P. Enhanced microwave absorption and suppressed reflection of polypyrrole-cobalt ferrite-graphene nanocomposite in X-band. J. Alloys Compd. 2019, 797, 1190–1197.

- Michałowski, S.; Pielichowski, K. Nanoparticles as flame retardants in polymer materials: Mode of action, synergy effects, and health/environmental risks. In Health and Environmental Safety of Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2021; pp. 375–415.

- Rane, A.V.; Kanny, K.; Abitha, V.K.; Thomas, S. Methods for Synthesis of Nanoparticles and Fabrication of Nanocomposites. In Synthesis of Inorganic Nanomaterials; Bhagyaraj, S., Oluwafemi, O., Kalarikkal, N., Thomas, S., Eds.; Elsevier: Cambridge, UK, 2018; pp. 121–139.

- Rahman, M.R.; Hamdan, S. bin Study on physical, mechanical, morphological and thermal properties of styrene-co-glycidyl methacrylate/fumed silica/clay nanocomposites. In Silica and Clay Dispersed Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 71–85.

- Saba, N.; Jawaid, M.; Sultan, M.T.H. Thermal properties of oil palm biomass based composites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Jawaid, M., Tahir, P.M., Saba, N., Eds.; Elsevier: New Delhi, India, 2017; pp. 95–122.

- Palmero, E.M.; Bollero, A. 3D and 4D Printing of Functional and Smart Composite Materials. In Encyclopedia of Materials: Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 402–419.

- Konwar, A.; Kalita, S.; Kotoky, J.; Chowdhury, D. Chitosan–Iron Oxide Coated Graphene Oxide Nanocomposite Hydrogel: A Robust and Soft Antimicrobial Biofilm. ACS Appl. Mater. Interfaces 2016, 8, 20625–20634.

- Wang, Q.; Qin, Y.; Jia, F.; Li, Y.; Song, S. Magnetic MoS2 nanosheets as recyclable solar-absorbers for high-performance solar steam generation. Renew. Energy 2021, 163, 146–153.

- Su, H.; Han, X.; He, L.; Deng, L.; Yu, K.; Jiang, H.; Wu, C.; Jia, Q.; Shan, S. Synthesis and characterization of magnetic dextran nanogel doped with iron oxide nanoparticles as magnetic resonance imaging probe. Int. J. Biol. Macromol. 2019, 128, 768–774.

- Bustamante-Torres, M.; Romero-Fierro, D.; Estrella-Nuñez, J.; Arcentales-Vera, B.; Chichande-Proaño, E.; Bucio, E. Polymeric Composite of Magnetite Iron Oxide Nanoparticles and Their Application in Biomedicine: A Review. Polymers 2022, 14, 752.

- Gopi, S.; Balakrishnan, P.; Sreekala, M.S.; Pius, A.; Thomas, S. Green materials for aerospace industries. In Biocomposites for High-Performance Applications; Ray, D., Ed.; Elsevier: Cambridge, UK, 2017; pp. 307–318.

- Verma, D.; Goh, K.L. Functionalized Graphene-Based Nanocomposites for Energy Applications. In Functionalized Graphene Nanocomposites and Their Derivatives; Elsevier: Amsterdam, The Netherlands, 2019; pp. 219–243.

- Ercan, N.; Durmus, A.; Kaşgöz, A. Comparing of melt blending and solution mixing methods on the physical properties of thermoplastic polyurethane/organoclay nanocomposite films. J. Thermoplast. Compos. Mater. 2017, 30, 950–970.

- Fink, J.K. Poly(p-xylene)s. In High Performance Polymers; Fink, J.K., Ed.; Elsevier: Oxford, UK, 2014; pp. 43–69.

- Vasudeo Rane, A.; Kanny, K.; Abitha, V.K.; Patil, S.S.; Thomas, S. Clay-Polymer Composites. In Clay-Polymer Nanocomposites; Jlassi, K., Chehimi, M., Thomas, S., Eds.; Elsevier: Oxford, UK, 2017; pp. 113–144.

- Flores-Rojas, G.G.; López-Saucedo, F.; Bucio, E. Gamma-irradiation applied in the synthesis of metallic and organic nanoparticles: A short review. Radiat. Phys. Chem. 2020, 169, 107962.

- Thu, T.V.; Takamura, T.; Tsetserukou, D.; Sandhu, A. Preparation and Characterization of Magnetic Thermoplastic-Based Nanocomposites; American Institute of Physics: University Park, MD, USA, 2014; pp. 141–144.

- Pu, Z.; Zhou, X.; Yang, X.; Jia, K.; Liu, X. One step grafting of iron phthalocyanine containing flexible chains on Fe3O4 nanoparticles towards high performance polymer magnetic composites. J. Magn. Magn. Mater. 2015, 385, 368–376.

- Verheyen, L.; Leysen, P.; Van Den Eede, M.-P.; Ceunen, W.; Hardeman, T.; Koeckelberghs, G. Advances in the controlled polymerization of conjugated polymers. Polymer 2017, 108, 521–546.

- Lutz, P.J.; Peruch, F. Graft Copolymers and Comb-Shaped Homopolymers. In Polymer Science: A Comprehensive Reference; Elsevier: Amsterdam, The Netherlands, 2012; pp. 511–542.

- Yang, G.; Park, M.; Park, S.-J. Recent progresses of fabrication and characterization of fibers-reinforced composites: A review. Compos. Commun. 2019, 14, 34–42.

- Francis, R.; Joy, N.; Aparna, E.P.; Vijayan, R. Polymer Grafted Inorganic Nanoparticles, Preparation, Properties, and Applications: A Review. Polym. Rev. 2014, 54, 268–347.

- Hu, X.; Nian, G.; Liang, X.; Wu, L.; Yin, T.; Lu, H.; Qu, S.; Yang, W. Adhesive Tough Magnetic Hydrogels with High Fe3O4 Content. ACS Appl. Mater. Interfaces 2019, 11, 10292–10300.

- Jia, C.; Zhang, R.; Yuan, C.; Ma, Z.; Du, Y.; Liu, L.; Huang, Y. Surface modification of aramid fibers by amino functionalized silane grafting to improve interfacial property of aramid fibers reinforced composite. Polym. Compos. 2020, 41, 2046–2053.

- Islam, M.S.; Deng, Y.; Tong, L.; Faisal, S.N.; Roy, A.K.; Minett, A.I.; Gomes, V.G. Grafting carbon nanotubes directly onto carbon fibers for superior mechanical stability: Towards next generation aerospace composites and energy storage applications. Carbon N. Y. 2016, 96, 701–710.

- Zhao, W.; Li, M.; Peng, H.-X. Functionalized MWNT-Doped Thermoplastic Polyurethane Nanocomposites for Aerospace Coating Applications. Macromol. Mater. Eng. 2010, 295, 838–845.

- Basheer, B.V.; George, J.J.; Siengchin, S.; Parameswaranpillai, J. Polymer grafted carbon nanotubes—Synthesis, properties, and applications: A review. Nano-Struct. Nano-Objects 2020, 22, 100429.