The growing need for increasingly miniaturized devices has placed high importance and demands on nanofabrication technologies with high-quality, low temperatures, and low-cost techniques. The development and advances in atomic layer deposition (ALD) processes boosted interest in their use in advanced electronic and nano/microelectromechanical systems (NEMS/MEMS) device manufacturing. In this context, non-thermal plasma (NTP) technology has been highlighted because it allowed the ALD technique to expand its process window and the fabrication of several nanomaterials at reduced temperatures, allowing thermosensitive substrates to be covered with good formability and uniformity.

- plasma-enhanced atomic layer deposition

- plasma-assisted atomic layer deposition

- plasma-assisted atomic layer etching

1. Deposition: Plasma-Assisted Atomic Layer Deposition

1.1. Oxides

-

Wide viewing angle.

-

Low latency.

-

Low power consumption.

-

Ultra-thin lightness and thickness.

-

Mechanically flexible.

- (1)

-

Yeom et al. [84] grew indium oxide (InOx) using Et2InN(SiMe3)2 and O2 plasma as reactants. The deposition temperature varied between 100 and 250 °C with a GPC of 0.145 nm/cycle. The authors showed that thin-film transistors (TFTs) built with nano-crystalline InOx had a higher carrier density as the temperature ramp increased from 150 to 250 °C. This effect is due to oxygen deficiency at higher deposition temperatures. The TFTs showed high linear mobility of 39.2 cm2 V−1 s−1 for nano-crystalline InOx grown at 250 °C. Therefore, this result indicates that InOx TFTs are a strong candidate for next-generation high-performance TFTs.

- (2)

-

Egorov et al. [85] used PA-ALD for TaOx deposition with a controllable concentration of oxygen vacancies (VO). Ta(OC2H5)5 was used as a reactant of Ta, and Ar/H2 plasma as a co-reactant. The VO control made through the fractional mixture of Ar and H2 in the plasma generation was responsible for controlling the leakage current of the resistive switching memory devices in the range of five orders of magnitude compared to the Ta2O5 film grown via thermal ALD. Ultimately they used the Ta2O5/TaOx stack with reliable resistance switching up to approximately 106 switching cycles, in contrast to the single-layer Ta2O5 memory, which demonstrated an order of a few hundred switching cycles.

- (3)

-

Jha et al. [86] grew HfO2 thin films by PA-ALD for non-volatile memory applications. For this, they investigated the electrical and ferroelectric properties of metal-insulator-semiconductor (MIS) and metal-insulator-metal (MIM) capacitors with different thicknesses between 5 and 20 nm deposited on Si and TiN/Si. The best results were achieved for 10 nm films. A memory window of 4 V was found for the MIS structure and the MIM structure, with a maximum remaining polarization of 4 μC/cm2. The non-volatile memories based on HfO2 thin films showed a data retention structure of more than ten years with a fatigue resistance of 1012 read/write cycles.

- (4)

-

Henning et al. [87] used an aluminum oxide monolayer (~0.3 nm) deposited by PA-ALD for gallium nitride encapsulation in the c-plane (GaN), which is enabled by the partial conversion of surface oxide GaN to AlOx using sequential exposure to trimethylaluminum (TMA) and H2 plasma. This thin AlOx monolayer decreases the work function that increases the reactivity with phosphonic acids under standard conditions, leading to self-assembled monolayers with densities close to the theoretical limit. This high reactivity of TMA with surface oxides opens the opportunity to extend this ultra-fine (<1 nm) aluminum oxide deposition approach to other III-V-based dielectrics and semiconductors, with relevance for applications in (photo) electrocatalysis, optoelectronics, and chemical sensing.

- (5)

-

Xiao et al. [88] studied the effect of HfO2 and ZrO2 on n-channel p-channel metal oxide semiconductor field-effect transistors (nFETs and pFETs), CMOS inverters, and CMOS ring oscillators were fabricated to test the quality of HfO2 thin films, and ZrO2 applied as a gate oxide. They used tetrakis(dimethylamino), hafnium (Hf[N(CH3)2]4), and tetrakis (dimethylamino) zirconium (IV) (Zr [N(CH3)2]4) as precursors, respectively, of Hf and Zr. The manufactured nFTTs and pFETs have good electrical properties of n or p-type field-effect transistors, while CMOS inverters based on HfO2 and ZrO2 have good electrical transfer characteristics. Both manufactured ring oscillators demonstrated satisfactory oscillation waveforms, and the ZrO2 gate oxide caused the oscillator to oscillate faster than the HfO2 gate oxide.

1.2. Nitrides

1.3. Sulfides, Phosphates and Others

2. Modification: Surface Modification on Polymers

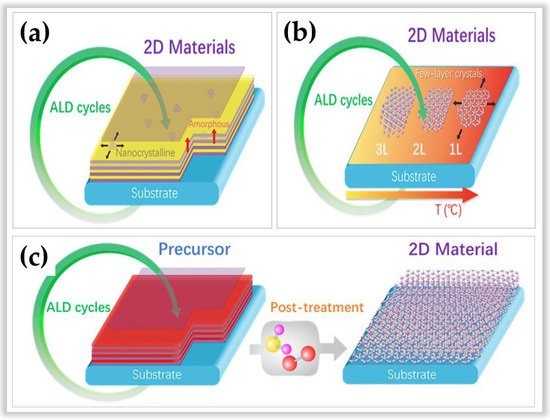

3. Efforts to Produce High-Quality 2D Layered Structures

66. Xiong, Y.-Q.; Li, X.-C.; Chen, Q.; Lei, W.-W.; Zhao, Q.; Sang, L.-J.; Liu, Z.-W.; Wang, Z.-D.; and Yang, L.-Z. Characteristics and properties of metal aluminum thin films prepared by electron cyclotron resonance plasma-assisted atomic layer deposition technology. Chinese Phys. B 2012, 21, 078105.

67. Starostin, S.A.; Keuning, W.; Schalken, J.-P.; Creatore, M.; Kessels, W.M.M.; Bouwstra, J.B.; van de Sanden, C.M.; de Vries, H.W. Synergy between plasma-assisted ALD and roll-to-roll atmospheric pressure PE-CVD processing of moisture barrier films on polymers. Plasma Process. Polym. 2015, 13(3), 311-315.

68. Ziegler, J.; Mews, M.; Kaufmann, K.; Schneider, T.; Sprafke, A.N.; Korte, L.; and Wehrspohn, R.B. Plasma-enhanced atomic-layer-deposited MoOx emitters for silicon heterojunction solar cells. Appl. Phys. A 2015, 120, 811-816.

69. Garud, S.; Gampa, N.; Allen, T.G.; Kotipalli, R.; Flandre, D.; Batuk, M.; Hadermann, J.; Meuris, M.; Poortmans, J.; Smets, A. et al. Surface passivation of CIGS solar cells using gallium oxide. Status Solidi A 2018, 215(7), 1700826.

70. Ghods, A.; Saravade, V.G.; Zhou, C.; and Ferguson, I.T. Field-effect passivation of metal/n-GaAs Schottky junction solar cells using atomic layer deposited Al2O3/ZnO ultrathin films. Vac. Sci. Technol. A 2020, 38, 012406.

71. Koushik, D.; Jost, M.; Ducinskas, A.; Burgess, C.; Zardetto, V.; Weijtens, C.; Verheijen, M.A.; Kessels, W.M.M.; Albrecht, S.; and Creatore, M. Plasma-assisted atomic layer deposition of nickel oxide as hole transport layer for hybrid perovskite solar cells. Mater. Chem. C 2019, 7, 12532-12543.

72. Imai, T.; Mori, Y.; Kanomata, K.; Miura, M.; Ahmmad, B.; Kubota, S.; and Hirose, F. Room-temperature plasma enhanced atomic layer deposition of aluminum silicate and its application in dye-sensitized solar cells. Vac. Sci. Technol. A 2018, 36, 01A106.

73. Potscavage, W.J.; Yoo, S.; Domercq, B.; and Kippelen, B. Encapsulation of pentacene/C60 organic solar cells with Al2O3 deposited by atomic layer deposition. Phys. Lett. 2007, 90, 253511.

74. Wei, H.; Qiu, P.; Peng, M.; Wu, Q.; Liu, S.; Na, Y.; He, Y.; Song, Y.; and Zheng, X. Interface modification for high-efficient quantum dot sensitized solar cells using ultrathin aluminum nitride coating. Surf. Science 2019, 476, 608-614.

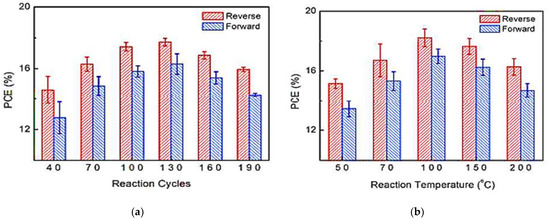

75. Wang, C.; Zhao, D.; Grice, C.R.; Liao, W.; Yu, Y.; Cimaroli, A.; Shrestha N.; Roland, P.J.; Chen, J.; Yu, Z., et al. Low-temperature plasma-enhanced atomic layer deposition of tin oxide electron selective layers for highly efficient planar perovskite solar cells. Mater. Chem. A 2016, 4(31), 12080-12087.

76. Reichel, C.; Reusch, M.; Kotula, S.; Granek, F.; Richter, A.; Hermle, M.; and Glunz, S.W. Insulating and passivating plasma-enhanced atomic layer deposited aluminum oxide thin films for silicon solar cells. Thin Solid Films 2018, 656, 53-60.

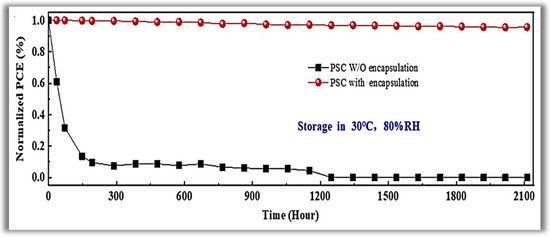

77. Wang, H.; Zhao, Y.; Wang, Z.; Liu, Y.; Zhao, Z.; Xu, G.; Han, T.-H.; Lee, J.-W.; Chen, C.; Bao, D.; et al. Hermetic seal for perovskite solar cells: An improved plasma enhanced atomic layer deposition encapsulation. Nano Energy 2020, 69, 104375.

78. Wang, D.; Wright, M.; Elumalai, N.K.; and Uddin, A. Stability of perovskite solar cells. Sol. Energy Mater. Sol. Cells 2016, 147, 255-275.

79. Han, T.-H.; Lee, Y.; Choi, M.-R.; Woo, S.-H.; Bae, S.-H.; Hong, B.H.; Ahn, J.-H.; and Lee, T.-W. Extremely efficient flexible organic light-emitting diodes with modified graphene anode. Nat. Photonics 2012, 6, 105-110.

80.Aziz, H.; Popovic, Z.; Xie, S.; Hor, A.-M.; Hu, N.-X.; Tripp, C.; and Xu, G. Humidity-induced crystallization of tris(8.hydroxyquinoline) aluminum layers in organic light-emitting devices. Phys. Lett. 1998, 72, 756.

81. Hoffmann, L.; Theirich, D.; Hasselman, T.; Räupke, A.; Schlaman, D.; and Riedl, T. Gas permeation barriers deposited by atmospheric pressure plasma enhanced atomic layer deposition. J. Vac. Sci. Technol. A 2016, 34(1), 01A114-1.

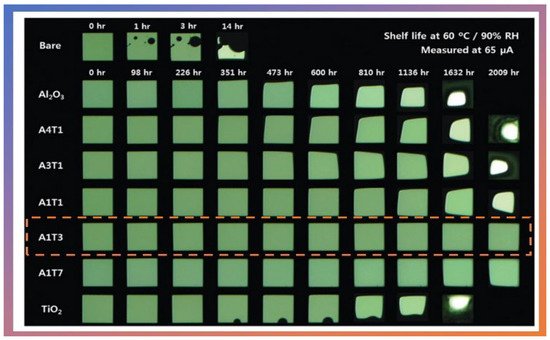

82. Kim, L.H.; Jeong, Y.J.; An, T.K.; Park, S.; Jang, J.H.; Nam, S.; Jang, J.; Kim, S.H.; and Park, C.E. Optimization of Al2O3/TiO2 nanolaminates thin films prepared with different oxide ratios, for use in organic light-emitting diode encapsulation, via plasma-enhanced atomic layer deposition. Chem. Chem. Phys. 2016, 18, 1042.

83. Jing, Y.; Merkx, J.M.; Cai, J.; Cao, K.; Kessels, W.M.M.; Mackus, J.M.; and Chen, R. Nanoscale encapsulation of perovskite nanocrystal luminescent films via plasma-enhanced SiO2 atomic layer deposition. ACS Appl. Mater. Interfaces 2020, 12(47), 53519-53527.

84. Yeom, H.-I.; Ko, J.B.; Mun, G.; and Park, S.-H.K. High mobility polycrystalline indium oxide thin-film transistors by means of plasma-enhanced atomic layer deposition. Mater. Chem. C 2016, 4(28), 6873-6880.

85. Egorov, K.V.; Kuzmichev, D.S.; Chizhov, P.S.; Lebedinskii, Y.Y.; Hwang, C.S.; and Markeev, A.M. In situ control of oxygen vacancies in TaOx thin films via plasma-enhanced atomic layer deposition for resistive switching memory applications. ACS Appl. Mater. Interfaces 2017, 9(15), 13286-13292.

86. Jha, R.K.; Singh, P.; Goswami, M.; and Singh, B.R. Plasma enhanced atomic layer deposition HfO2 ferroelectric films for non-volatile memory applications. Journal of Elec. Materi. 2020, 49, 1445-1453.

87. Henning, A.; Bartl, J.D.; Zeidler, A.; Qian, S.; Bienek, O.; Jiang, C.-M.; Paulus, C.; Rieger, B.; Stutzmann, M.; and Sharp, I.D. Funct. Mater. 2021, 31(33), 2101441.

88. Xiao, Z.; Kisslinger, K.; Chance, S.; and Banks, S. Comparison of hafnium dioxide and zirconium dioxide by plasma-enhanced atomic layer deposition for the application of electronic materials. Crystals 2020, 10, 136.

89. Otto, L.M.; Hammack, A.T.; Aloni, S.; Ogletree, D.F.; Olynick, L.; Dhuey, S.; Stadler, J.H.; and Schwartzberg, A.M. Plasma-enhanced atomic layer deposition for plasmonic TiN. Of SPIE 2016, 9919, 99190N.

90. Krylov, I.; Zoubenko, E.; Weinfeld, K.; Kauffman, Y.; Xu, X.; Ritter, D.; and Eizenberg, M. Obtaining low resitivity (~100 uW cm) TiN films by plasma enhanced atomic layer deposition using a metalorganic precursor. Vac. Sci. Technol. 2018, 36(5), 051505.

91. Kim, H.; Song, H.; Shin, C.; Kim, K.; Jang, W.; Kim, H.; Shin, S.; and Jeon, H. Dielectric barrier characteristics of Si-rich silicon nitride films deposited by plasma atomic layer deposition. Vac. Sci. Technol. 2017, 35(1), 01A101-1.

92. Seppänen, H.; Kim, I.; Etula, J.; Ubyivovk, E.; Bouravleuv, A.; and Lipsanen, H. Aluminum nitride transition layer for power electronics applications grown by plasma-enhanced atomic layer deposition. Materials 2019, 12, 406.

93. Han, J.H.; Kim, H.Y.; Lee, S.C.; Kim, D.H.; Park, B.K.; Park, J.-S.; Jeon, D.J.; Chung, T.-M-; and Kim, C.G. Growth of tantalum nitride film as a Cu diffusion barrier by plasma-enhanced atomic layer deposition from bis((2-(dimethylamino)ethyl)(methyl)amido)methyl(tert-butylimido)tantalum complex. Surf. Sci. 2016, 362, 176-181.

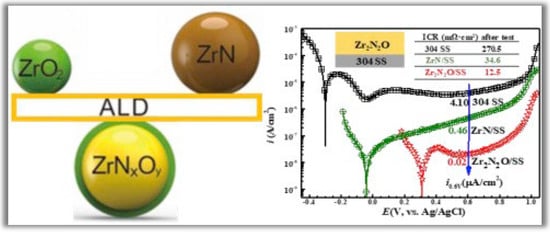

94. Wang, X.-Z.; Muneshwar, T.P.; Fan, H.-Q.; Cadien, K.; and Luo, J.-L. Achieving ultrahigh corrosion resistance and conductive zirconium oxynitride coating on metal bipolar plates by plasma enhanced atomic layer deposition. Power Sources 2018, 397, 32-36.

95. Sowa, M.J.; Yemane, Y.; Zhang, J.; Palmstrom, J.C.; Ju, L.; Strandwitz, N.C.; Prinz, F.B.; and Provine, J. Plasma-enhanced atomic layer deposition of superconducting niobium nitride. Vac. Sci. Technol. A 2017, 35(1), 01B143.

96. Tian, L.; Bottala-Gambetta, I.; Marchetto, V.; Jacquemin, M.; Crisci, A.; Reboud, R.; Mantoux, A.; Berthomé, G.; Mercier, F.; Sulpice, A.; et al. Improved critical temperature of superconducting plasma-enhanced atomic layer deposition of niobium nitride thin films by thermal annealing. Thin Solid Films 2020, 709, 138232.

97. Di Bartolomeo, A. Emerging 2D materials and their Van der Waals heterostructures. Nanomaterials 2020, 10(3), 579.

98. Groven, B.; Heyne, M.; Mehta, A.N.; Bender, H.; Nuytten, T.; Meersschaut, T.; Verdock, P.; Elshocht, S.V.; Vandervorst, W.; et al. Plasma-enhanced atomic layer deposition of two-dimensional WS2 from WF6, H2 plasma, and H2S. Mater. 2017, 29, 2927-2938.

99. Balasubramanyam, S.; Shirazi, M.; Bloodgood, M.A.; Wu, L.; Verheijen, M.A.; Vandalon, V.; Kessels, W.M.M.; Hofmann, J.P.; Bol, A.A. Edge-site nanoengineering of WS2 by low-temperature plasma-enhanced atomic layer deposition for electrocatalytic hydrogen evolution. Mater. 2019, 31(14), 5104-5115.

100. Sharma, A. Verheijen, A.; Wu, L.; Karwal, S.; Vandalon, V.; Knoops, H.C.M.; Sundaram, R.S.; Hofmann, J.P.; Kessels, W.M.M.; et al. Low-temperature plasma-enhanced atomic layer deposition of 2D MoS2: large area, thickness control and tunable morphology. Nanoscale 2018, 10(18), 8615-8627.

101. Vandalon, V.; Verheijen, M.A.; Kessels, W.M.M.; and Bol, A.A. Atomic layer deposition of Al doped MoS: synthesizing a p-type 2D semiconductor with tunable carrier density. ACS Appl. Nano Mater. 2020, 3(10), 10200-10208.

102. Bugot, C.; Bouttemy, M.; Schneider, N.; Etcheberry, A.; Lincot, D.; and Donsanti, F. New insights on the chemistry of plasma-enhanced atomic layer deposition of indium oxysulfide thin films and their use as buffer layers in Cu(In,Ga)Se2 thin film solar cell. Vac. Sci. Technol. 2018, 36(6), 061510.

103. Wang, H.; Song, S.; Song, Z.; Zhou, Z.; Yao, D.; and Lv, S. Fast and scalable phase change materials Ti-Sb-Te deposited by plasma-enhanced atomic layer deposition. J. Mater. Sci.: Mater. Electron. 2020, 31, 5833-5837.

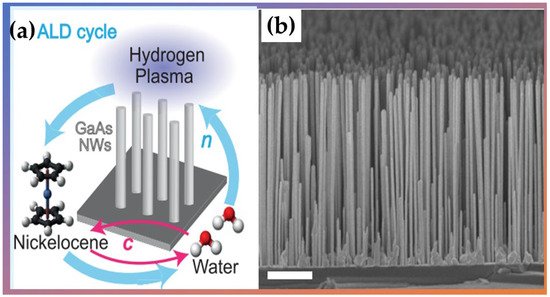

104. Giordano, M.C.; Baumgaertl, K.; Steinvall, S.E.; Vuichard, M.; Fontcuberta i Morral, A.; Grundler, D. Plasma-enhanced atomic layer deposition of nickel nanotubes with low resistivity and coherent magnetization dynamics for 3D spintronics. ACS Appl. Mater. Interfaces 2020, 12, 40443-40452.

105. Chiper, A.S. Tailoring the working gas flow to improve the surface modification of plasma-treated polymer. Letters 2021, 305, 130832.

106. Levchenko, I.; Xu, S.; Baranov, O.; Bazaka, O.; Ivanova, E.P.; and Bazaka, K. Plasma and Polymers: recent progress and trends. Molecules 2021, 26(13), 4091.

107. Parsons, G.N.; Atasanov, S.E.; Dandley, E.C.; Devine, C.K.; Gong, B.; Jur, J.S.; Lee, K.; Oldham, C.J.; Peng, Q.; Spagnola, J.C.; et al. Mechanism and reactions during atomic layer deposition on polymers. Chem. Rev. 2013, 257, 3323-3331.

108. Kim, G.H.; Lee, J.G.; and Kim, S.S. Surface modification of polymeric substrates to enhance the barrier properties of an Al2O3 layer formed by PEALD. Electron. 2017, 239-246.

109. Kääriäinen, T.O.; Lehti, S.; Kääriäinen, M.-L.; and Cameron, D.C. Surface modification of polymers by plasma-assisted atomic layer deposition. Coat. Technol. 2011, 205, S475-S479.

110. Cho, S.-W.; Jeong, J.-A.; Bae, J.-H.; Moon, J.-M.; Choi, K.-H.; Jeong, S.W.; Park, N.-J.; Kim, J.-J.; Lee, S.H.; Kang, J.-W.; et al. Highly flexible, transparent, and low resistance indium zinc oxide-Ag-indium zinc oxide multilayer anode on polyethylene terephthalate substrate for flexible organic light light-emitting diodes. Thin Solid Films 2008, 516(21), 7881-7885.

111. Rahy, A.; Bajaj, P.; Musselman, I.H.; Hong, S.H.; Sun, Y.-P.; and Yang, D.J. Coating of carbon nanotubes on flexible substrate and its adhesion study. Appl. Surf. Sci. 2009, 255(15), 7084-7089.

112. Choi, M.-C.; Kim, Y.; and Ha, C.-S. polymers for flexible displays: from material selection to device applications. Polym. Sci. 2008, 33(6), 581-630.

113. Fang, M.; Zhang, H.; Sang, L.; Cao, H.; Yang, L.; Ostrikov, K.; Levchenko, I.; and Chen, Q. Plasma-assisted ALD to functionalize PET: towards new generation flexible gadgets. Print. Electron. 2017, 2, 022001.

114. Lee, Y.; Seo, S.; Oh, I.-K.; Lee, S.; and Kim, H. Effects of O2 plasma treatment on moisture barrier properties of SiO2 grown by plasma-enhanced atomic layer deposition. Ceram. Int. 2019, 45, 17662-17668.

115. Kovács, R.L.; Gyöngyösi, S.; Langer, G.; Baradács, E.; Daróczi, L.; Barkóczy, P.; and Erdélyi. Effect of nanoscopic defects on barrier performance of thin films deposited by plasma-enhanced atomic layer deposition on flexible polymers. Thin Solid Films 2021, 738, 138960.

116. Sun, C.; Zhang, J.; Zhang, Y.; Zhao, F.; Xie, J.; Liu, Z.; Zhuang, J.; Zhang, N.; ren, W.; and Ye, Z.-G. Design and fabrication of flexible strain sensor based on ZnO-decorated PVDF via atomic layer deposition. Surf. Sci. 2021, 562, 150126.

117. Cai, J.; Han, X.; Wang, X.; and Meng, X. Atomic Layer Deposition of Two-Dimensional Layered Materials: Processes, Growth Mechanisms, and Characteristics. Matter 2020, 2(3), 587-630.

118. Haider, A.; Ozgit-Akgun, C.; Goldenberg, E.; Okyay, A.K.; Biyikli, N. Low-Temperature Deposition of Hexagonal Boron Nitride via Sequential Injection of Triethylboron and N2/H2 Plasma. Am. Ceram. 2014, 97(12), 4052-4059.

119. Park, H.; Kim, T.K.; Cho, S.W.; Jang, H.S.; Lee, S.I.; and Choi, S.-Y. Large-scale synthesis of uniform hexagonal boron nitride films by plasma-enhanced atomic layer deposition. Rep. 2017, 7, 40091.

120. Kim, Y.; Song, J.-G.; Park, Y.J.; Ryu, G.H.; Lee, S.J.; Kim, J.S.; Jeon, P.J.; Lee, C.W.; Woo, W.J.; Choi, T.; Jung, H.; Lee, H.-B.-R. Self-Limiting Layer Synthesis of Transition Metal Dichalcogenides. Rep. 2016, 4, 18754.

121. Park, K.; Kim, Y.; Song, J.-G.; Kim, S.J.; Lee, C. W.; Ryu, G.H.; Lee, Z.; Park, J.; and Kim, H. Uniform, large-area self-limiting layer synthesis of tungsten diselenide. 2D Materials 2016, 3, 014004.

122. Martella, C.; Melloni, P.; Cinquanta, E.; Cianci, E.; Alia, M.; Longo, M.; Lamperti, A.; Vangelista, S.; Fanciulli, M.; and Molle, A. Engineering the Growth of MoS2 via Atomic Layer Deposition of Molybdenum Oxide Film Precursor. Electron. Mater. 2016, 2(10), 1600330.

123. Keller, B.D.; Bertuch, A.; Provine, J.; Sundaram, G.; Ferralis, N.; and Grossman, J.C. Process Control of Atomic Layer Deposition Molybdenum Oxide Nucleation and Sulfidation to Large-Area MoS2 Monolayers. Mater. 2017, 29, 5, 2024–2032.

124. Dai, T.-J.; Fan, X.-D.; Ren, Y.-X.; Hou, S.; Zhang, Y.-Y.; Qian, L.-X.; Li, Y.-R.; Liu, X.-Z. Layer-controlled synthesis of wafer-scale MoSe2 nanosheets for photodetector arrays. Mater. Sci. 2018, 53, 8436–8444.

125. Song, J.-G.; Park, J.; Lee, W.; Choi, T.; Jung, H.; Lee, C.W.; Hwang, S.-W.; Myoung, J.M.; Jung, J.-H.; Kim, S.-H. et al. Layer-Controlled, Wafer-Scale, and Conformal Synthesis of Tungsten Disulfide Nanosheets Using Atomic Layer Deposition. ACS Nano 2013, 7, 12, 11333–11340.

126.Zeng, W.; Feng, L.-P.; Su, J.; Pan, H.-x.; and Liu, Z.-T. Layer-controlled and atomically thin WS2 films prepared by sulfurization of atomic-layer-deposited WO3 films. J. Alloys Compd. 2018, 745, 834-839.

127. Liu, H.F.; Antwi, K.K.A.; Wang, Y.D.;Ong, L.T.;Chua, S.J.; Chi D.Z. Atomic layer deposition of crystalline Bi2O3 thin films and their conversion into Bi2S3 by thermal vapor desulfurization. RSC Advances 2014, 4(102), 58724-58731.

128. Jang, B.; Yeo, S.; Kim, H.; Shin, B.; and Kim, S.-H. Fabrication of single-phase SnS film by H2 annealing of amorphous SnSx prepared by atomic layer deposition. Vac. Sci. Technol. A 2017, 35, 031506.

129. Hao, W.; Marichy, C.; Journet, C.; and Brioude, A. A novel two-step ammonia-free atomic layer deposition approach for boron nitride. ChemNanoMat, 2017, 3, 656–663.

This entry is adapted from the peer-reviewed paper 10.3390/nano12193497