Coating materials have gained researchers’ interest, finding applications in different areas such as antimicrobial coatings for biomedical applications, coatings for increasing the shelf-life of commercial products, or coatings for the conservation of cultural heritage artifacts.

- functional coatings

- natural materials

- antimicrobial

1. Introduction

In recent decades, coating materials have gained researchers’ interest, and the registered progress has led to the evaluation of their potential use in different applications, including some of great importance, such as the development of antimicrobial coatings for biomedical applications, coatings applied for increasing the shelf-life of commercial products, or coatings used for the conservation of cultural heritage artifacts. In its widest sense, a coating represents a thin layer of material that, when deposited or applied on the surface of a support material, improves the surface properties of the substrates and creates a protective barrier against detrimental external factors [1]. Considering their envisaged properties and final applications, different types of coatings were developed, from monolayer to nanostructured and/or nanometric-scale multilayer coatings [2].

The permanent search for new types of coating materials, accompanied by the shift in consumer’s habits towards “bio-products” led to an increasing interest regarding the application of functional coatings based on natural products, especially in industries such as food or cosmetic. In the food industry, as an example regarding the potential of natural alternatives, the use of wax coatings on citrus (as a method to protect them against microbial spoilage) was known and applied in ancient China [3]; nowadays, the development of new materials and production technologies has new valences—to obtain enhanced biodegradability and eco-friendly properties [4].

For other applications, such as development of antifouling coatings, the interest is to replace classical used materials (such as tributyltin or zinc pyrithione), which can have negative effects on non-target organisms, with some natural-based alternatives [5].

Widely applied, natural and synthetic polymers are commonly used as coating layers, and their enrichment with nanoparticles, inorganic and organic materials increases the variety of available coatings, with the developed hybrid materials overcoming deficiencies by combining the advantages of each component [6,7].

2. Coating Materials for Different Industries

2.1. Food Industry

3.2. Cosmetic Industry

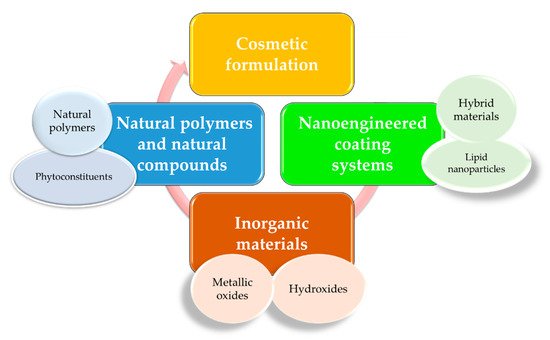

For coating systems used in cosmetic formulations and pharmaceutic industry, the approach is different than in the above discussed sections dedicated to medical devices or food industry. The subject is very vast, and itself can be a topic for a review paper, but some interesting examples of coating materials and active substances will be discussed. The development of new coating delivery systems in cosmetic formulations and pharmaceutic industry, nowadays follow concerns regarding the use of green technologies and non-toxic environmental materials. Developing cosmetic formulations is a significant challenge as there can appear diverse bottlenecks, the final target efficacy (sun screen protection, antiaging, antiwrinkle, etc.) being dependent on the vehicle formulation, choice of emulsifiers, solvents and emollients.

Different types of nanoengineered coating systems (e.g., liposomes, niosomes, transferosomes, lipid nanoparticles, core-shell materials), polymeric microparticles, nanoparticles, inorganic materials, etc., have been successfully used in cosmetic formulations, improving the penetration of active substances into the skin (Figure 3).

For cosmetic formulations, the requirements are different than for a topical pharmaceutical preparation, many factors influencing the properties of the final products. The coating material of the active substance must be compatible with the oil-water emulsion, water-oil emulsion or double emulsion in the case of cosmetic formulations [116].

3.3. Coatings for Miscellaneous Applications

Different types of pollutants are produced nowadays in large amounts due to a rapid increase in the world population and widespread industrialization, so the development of new materials for environmental remediation represents a goal of outmost importance [147]. Advanced oxidation processes (AOP) are by far the most applied methods for removing hazardous compounds from water. Catalytic ozonation represents an AOP process with high efficiency in the application on effluents with a low and average flow rate and pollutants concentration [148]. The optimization of this process, in order to achieve better performances is very difficult and requires multiparametric monitoring of oxidation reaction, the catalyst playing a main role. In the last decade, numerous materials and technologies were proposed for a better and complete oxidation processes. In porous structures, nanoparticles are formed inside pores as a result of a multistep, costly and difficult process without having a very good control over their chemical composition, dimensions, and shape [149].

An interesting alternative is represented by the immobilization of catalyst in the form of thin-films coatings using different substrates (glass, quartz, polymers, textile materials, etc.), according to their uses, having the advantage of being cost effective and easily recycled after washing [150,151]. Thin film morphology containing phytosynthesized metallic or metal oxides nanoparticles gained more attention in the last decades, being suitable for catalytic processes, since this approach includes advantages of using nanoparticles and avoid the diffusivity problems (in fixed bed systems) or daunting separation step (in slurry approach). Another innovative and eco-friendly aspect of this type of materials consists in the preparation of novel thin-film catalysts using plant extracts, without harmful substances [152,153]. Additionally, phyto-mediated metallic or metal oxide nanoparticles can act as catalysts themselves (being coated by the phytoconstituents), or be included in nanocomposite materials for the catalytic reduction of organic dyes [151,154,155], or can be coated by natural minerals, such as perlite [156].

For other environmental applications, coating materials based on natural product can be successfully applied. This is the case of sensors developed using silver nanoparticles coated with natural polymers, such as xylan, which are able to detect Hg2+ at a 4nM detection limit [157] or natural minerals such as Cs2SnI6 perovskite used for coating ZnO nanorods for solar cells [158]. Coatings based on rhamnolipid biosurfactant, gum karaya and xanthan gum are able to inhibit the agglomeration of nanoparticles, such as zero valent iron nanoparticles, in order to be used for organic and inorganic bioremediation [159,160,161,162]. For soil remediation applications, coating layer has a double role: protect the inorganic core against agglomeration and percolate into the spaces between soil particles in order to travel longer distances before being trapped by the soil matrix [163].

Environmental factors affect not only the human health, being able to damage important cultural heritage objects which are kept in outdoor conditions. The use of protective coatings gained importance in heritage conservation, and coatings based on natural products replace successfully chemical hazardous substances [164]. From the category of inorganic compounds, calcium hydroxide can be used as a coating material, due to its property to be transformed under natural atmospheric conditions into a hard coating of insoluble CaCO3. Moreover, when Ca(OH)2 is applied in its nanoparticle state, the deposition and penetration of prepared suspensions through external porous of the surface are enhanced. Daniele and Taglieri reported the efficiency of consolidation with this type of coating more than 75% for stone samples [165], while Lanzón et al. reported that nanoparticles with dimensions in the range 200 to 600 nm can penetrate through conventional pores of mechanically weak materials (lime mortars), this type of coating being used for the consolidation of deteriorated walls of the Roman Theatre of Cartagena [166]. Despite the disadvantages (160 repetitions) presented by Slízková et al. [167], the use of alcohols as dispersion media can overcome the drawbacks of a large number of applications of the coating material [166].

As a very interesting aspect regarding the potential use of natural resources for the development of next-generation materials for highly specialized scientific, medical or precision equipment, the biomachining process can be mentioned. It represents the metal processing using lithotrophic (usually extremophile) bacteria, as an intermediate step, before applying the final functional coatings. An example on this topic is the work of Díaz-Tena et al., presenting the application of Acidithiobacillus ferrooxidans for biomachining oxygen-free copper, resulting in a finished and/or engraved material surface, without the shortcomings of traditional processing methods [168].

For wooden cultural heritage objects, the appropriate materials for coating layers are natural products, such as proteins, lipids, polysaccharides, or terpenoids, having a waterproofing role and, occasionally, as ingredients of binding media [169], while for iron artefacts, adding natural compounds (tannins) into commercial resins can inhibit their corrosion [170]. For conservation studies, natural polymer coatings are preferred instead of resins, for indoor objects, due to their water-solubility, thus avoiding the use of harmful solvents, necessary for the application and removal of commonly used commercial protective coatings. Giuliani et al. used a coating based on chitosan, which acted as a reservoir for the inhibitors benzotriazole and mercaptobenzothiazole, for bronze artefacts, contributing to the formation of a barrier layer, thus improving the protective properties of the treatment [171].

Conservation methods based on the chemical strategies of using natural coatings can be adapted for paper artefacts, too. Jia et al. obtained an antibacterial and antifungal composite material based on ZnO/cellulose nanocrystals, and the chemical and mechanical properties of coated papers after dry heat and UV accelerated aging were measured, in order to demonstrate the efficiency of the treatment [172], the cellulose layer having a good compatibility and affinity with paper cellulose fibers. The treated papers had higher thermal and UV stability and exhibited an inferior loss of strength. For papers coated with chitosan nanoparticles, the protection is due to the formation of chitosan protective layer when the nanoparticles combined with H2O and H+, the deacidification of the paper being produced (a pH increase from 5 to 7 being recorded), also increasing tensile strength and folding endurance [173].

This entry is adapted from the peer-reviewed paper 10.3390/coatings11040429