Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Manufacturing

The Product Service System (PSS), the dominant hybrid solution of providing services in addition to or instead of product ownership, promises competitiveness and sustainability through the identification of customer value.

- Intelligent Product Service System

- Industrial PSS

- Product Service System (PSS)

1. Introduction

Companies are attempting to stay ahead of their competitors in the current extremely competitive business environment by implementing the latest manufacturing trends. Thus, we are currently living through the Fourth Industrial Revolution, also known as “Industry 4.0” [1,2]. Industry 4.0 is based on manufacturing trends such as the Internet of Things (IoT), Big Data Analytics (BDA), Cyber Physical Systems (CPS), advanced sensors and networking, intelligent algorithms, and Virtual and Augmented Reality to upgrade the manufacturing process and enable the creation of personalized products [3]. Therefore, two cornerstone principles underlying Industry 4.0 are digitalization and servitization, also known as the Internet of Services (IoS) [4].

The innovative Mass Personalization (MP) paradigm, not fully investigated under Industry 4.0, represents a high-tech manufacturing automation strategy, enabling the better integration and smoother cooperation of hardware devices and machinery (IoT), software systems, and humans in the extended manufacturing value chain. Smart Factories, the core of this new paradigm, are characterized by a high degree of digitalization and data centricity. Jointly cooperative working teams of humans and robots autonomously guided by lights out are collaborative, operating in the so-called Lights-out Factories. Extreme automation until “everything is connected to everything else” creates vulnerabilities that have not been investigated extensively so far. The next industrial revolution, Industry 5.0, is expected to cope with these new challenges by bringing the efficiency of manufacturing systems and supply chains beyond limits. Industry 5.0 aims at democratizing the co-production of knowledge by employing cutting-edge digital technologies, e.g., Big Data and IoT, being supported by three main pillars: (a) human centricity; (b) resilience, and (c) sustainability. One of the main focuses relies on the development of Product Platforms aiming at improving the production efficiency and creating high added value for the customer/end-user [5].

During the last decades, manufacturing systems are undergoing a series of changes in order to transform their business models from craftsmanship towards a more customer-oriented manufacturing approach, in an attempt to tackle the volatility of modern market landscape. By extension, this transformation enables the better alignment to customer demands, as a result of the mass customization and personalization, Business-to-Business (B2B), and Business-to-Customer (B2C) paradigms. Consequently, enterprises require competitive business strategies and powerful engineering tools to enable multi-dimensional knowledge exchange throughout the supply chain [6]. Under the framework of Industry 4.0, companies are increasingly shifting their business models from manufacturing and offering only tangible products to the design and development of complete solutions, which include services. By extension, this move enables the development of more sustainable products [7], making it critical for industrialized countries to shift to the Industrial Product Service System (IPSS) paradigm [8]. The importance of servitization is widely recognized in industry as it moves toward mass customization manufacturing systems [9].

The Product Service System (PSS) [10], the dominant hybrid solution of providing services in addition to or instead of product ownership, promises competitiveness and sustainability through the identification of customer value. The academic community has long recognized the importance of evaluation in the early stages of PSS development, but as indicated by [11], PSS evaluation is still an immature field with few concrete results and approaches. Furthermore, the integration of cutting-edge digital technologies in the design and distribution of PSS can be considered as a cornerstone, based on the findings of Sala et al. in [12]. In this research, the authors focus on the implementation of AR technology as a PSS in the field of Maintenance, Repair, and Training.

Maintenance is a widely offered service because it is regarded as a critical activity throughout the lifecycle of a product. Engineers can now identify faults and malfunctions in products more easily and precisely thanks to recent technological advances in information and communication technologies (ICT) [13,14]. To that end, the three steps listed below can be used towards addressing this problem. To begin, data can be retrieved from Cloud repositories (historical data from previous maintenance procedures). Thereinafter, they will be processed using appropriate algorithms. Finally, they either predict when components will fail (predictive maintenance) [15] or evaluate the health of components (condition-based maintenance).

The Industrial Internet of Things (IIoT) allows businesses to provide more innovative solutions [16]. Among these technologies, AR enables the intuitive visualization of virtual information (of any kind, including data, 3D models, audio, and video) on the user’s field of view, thus in modern manufacturing environments, the visualization of insightful data (machine health monitoring, machine specifications, assembly instructions, etc.) is enabled [17]. The combination of AR and maintenance has facilitated engineers to design and develop services (realized as mobile applications) for the provision of remote maintenance support (also known as tele-maintenance) [18]. Furthermore, visualizing the assembly steps of components that lead to the final product clarifies the maintenance process of complex industrial equipment [19]. Similarly, Cloud Computing and Cloud Manufacturing open up new opportunities for enterprises [20], as they can transform traditional business models in such a way that stakeholders not only maintain their competitive edge but also ensure their continued existence in the global market.

2. PSS under the Framework of the Fourth Industrial Revolution (Industry 4.0)

The investigation of the academic literature has provided evidence of the potential benefits associated with the digitization and digitalization of manufacturing systems, following the Industry 4.0 paradigm, and the shift to what is also known as intelligent manufacturing. This extends to the integration of IoT devices, including smart sensors, which are in turn integrated with processing units, and capable of performing data processing tasks with high computational speeds [22]. Moreover, engineers are more capable of developing a complete solution towards the PSS business models [23]. The authors in references [24,25] have investigated the potential of the pillar Industry 4.0 digital technologies and techniques such Cloud technologies, as well as Predictive Analytics (PA), in order to fully utilize the vast amount of data produced on a daily basis on the shopfloor level (Big Data). Big Data, however, require further processing by suitable algorithms in order to be transformed to information and by extension (based on the use of Artificial Intelligence (AI) approaches) to become useful knowledge. Afterwards, such knowledge will be useful for the development of novel Product Service offerings. Strozzi et al., in their research work [26], concentrate on Additive Manufacturing (AM), emphasizing the advantages of such technologies. More specifically, with AM, small batch products can be produced, up to one-off production, thus promoting the mass customization and personalization paradigms. As a result, individual customer requirements can be met more easily. Consequently, customized and adaptive PSS can become more feasible for manufacturers. However, since the complexity of modern manufacturing systems as well as the complexity of the products has increased, the authors in [9] have proposed a framework for the collaborative design of highly customized PSSs in order to compensate for the complexity mentioned before and facilitate manufacturers to establish better communication channels with their customers. In addition to that, a common issue that needs further attention from engineers is the setup of the suitable technological infrastructure required for the support the servitization transformation [25].

Taking into consideration the above-mentioned points, the ongoing advances in cutting-edge digital technologies under the framework of Industry 4.0, and the research work of the authors in [27], the key technologies and techniques of the design and development of the next generation of technology-driven PSSs are summarized in Table 1. Furthermore, based on the context of each technological field, the resulting PSSs are presented. For example, the integration of sensing systems and the utilization of the IIoT will enable engineers to develop smarter products, and BDA will enable the analysis of data from the usage of the PSS as a system, i.e., the usage of the tangible product, as well as the utilization of the associated service(s), etc.

Table 1. Correlation of key Industry 4.0 and their contributions to servitization.

| Industry 4.0 Technology | PSS Approach | References |

|---|---|---|

| IIoT and smart sensors | Smarter products | [28] |

| BDA and AI | Data-driven services | [29] |

| Blockchain | Smarter service | [30,31] |

| AR | Smarter service design and delivery, Training, Maintenance | [32] |

| Cloud Computing | Flexible computing resources for digital services | [33] |

| AM | Product customization and adaptation | [34] |

| Energy Services | Servitization, environmental impact, resource planning, Energy Demand Management, scheduling | [35,36] |

3. Smart—Intelligent PSS

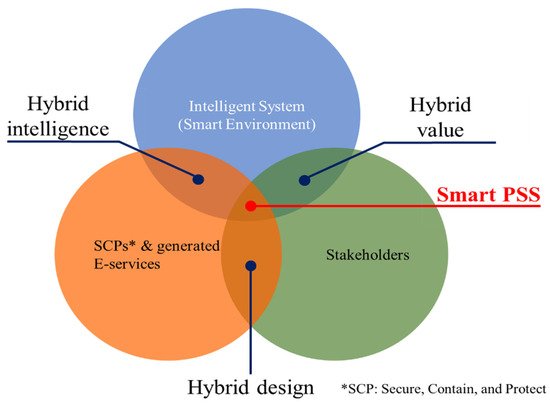

The definition of a Smart PSS is as follows: “an IT-driven value cocreation business strategy involving various stakeholders as players, intelligent systems as infrastructure, smart, connected products as media and tools, and their generated e-services as key values delivered that continuously strives to meet individual customer needs in a sustainable manner.” [37] Stakeholders, Service and Performance Checkout System (SCPs) and e-services, and intelligent systems are key elements, according to the definition, while value co-creation with sustainable concerns is the business value proposition. Stakeholders are participants in the value co-creation process who are divided into three categories: users, service providers, and manufacturers and vendors.

-

Users: The people who demand or consume the value.

-

Service providers: The companies/individuals who are responsible for designing, sharing, and/or performing maintenance of the offered services are designated as service providers.

-

Manufacturers and vendors: All parties involved in the SCP manufacturing process are represented by manufacturers and vendors.

Additionally, the authors in [37] have presented the Smart PSS solution design, which is a complex process, with three general hybrid concerns outlined, as illustrated in Figure 1. More specifically, the design and development of a Smart PSS requires the co-existence of three entities, namely the intelligent system, the stakeholders, and the IT providers. The conjunction of the above-mentioned entities in pairs, starting from the top in a clockwise fashion, leads to the “hybrid value” creation, which corresponds to the added value offered by PSSs and the extension of the product lifecycles, as a result of the integration of intangible services to the tangible/physical products. Moving on, the “hybrid design”, corresponds to the creation of new services, thus new products, and by extension new a PSS as a result of the cooperation of the stakeholders with the PSS engineers/designers. The two parties have to collaborate closely in order to address existing challenges. Finally, “hybrid intelligence” corresponds to the utilization of data and information acquisition, processing, and transmission through a wide variety of smart and intelligent tools, technologies, and techniques.

Figure 1. Smart Product Service System Solution, adopted from [37].

This entry is adapted from the peer-reviewed paper 10.3390/app12115349

This entry is offline, you can click here to edit this entry!