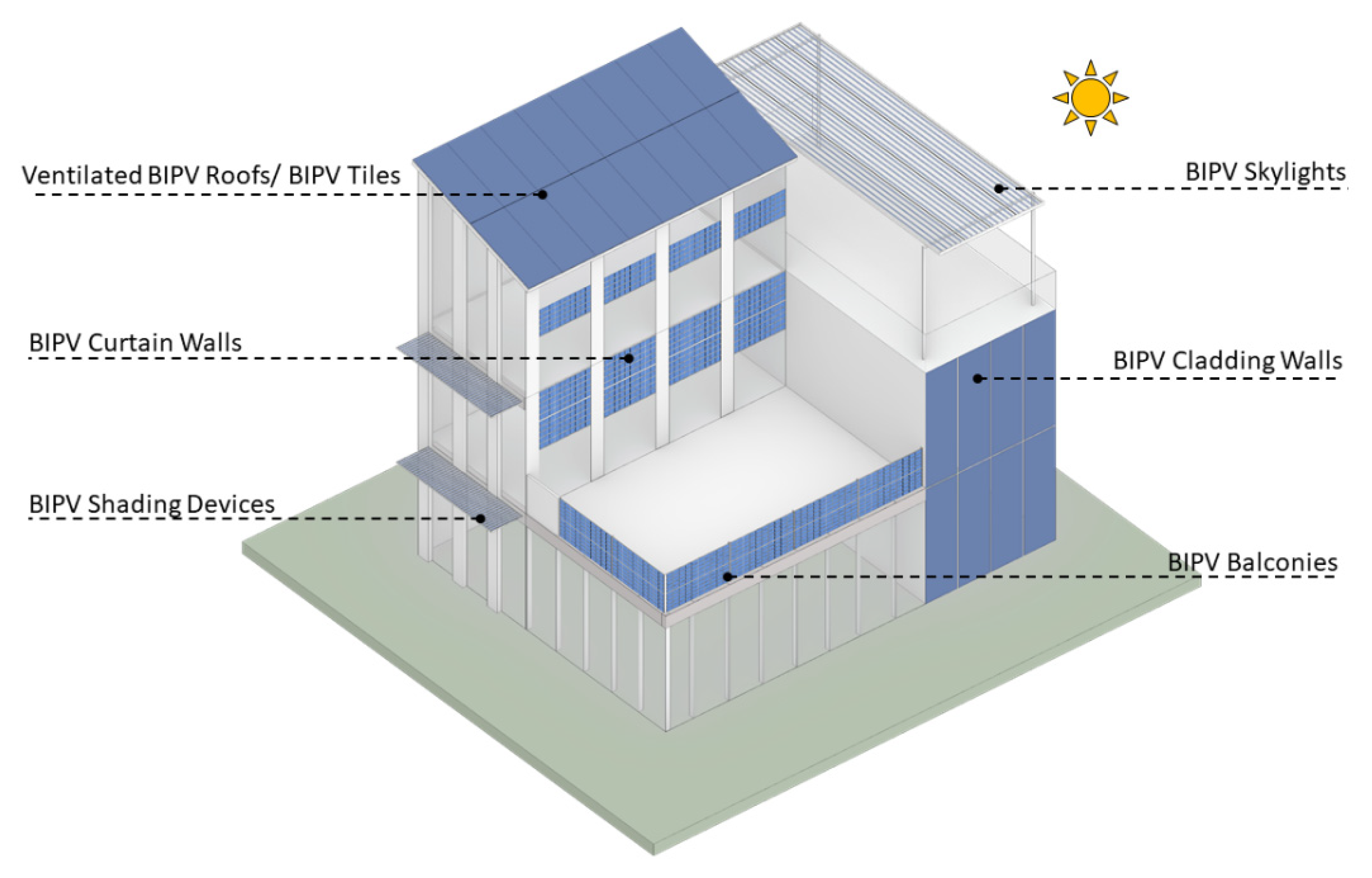

Building-integrated photovoltaics (BIPVs) represent an effective technology to attain zero energy buildings (ZEBs) via solar energy use. A BIPV system can seamlessly integrate PV modules into external building surfaces, such as walls, roofs, shading devices, and decorative components. Moreover, it can generate clean energy. From an environmental and economic perspective, PV energy generation provides more advantages than fossil fuel-based energy generation. First, in contrast to the limited storage of fossil fuels, the solar radiation reaching the Earth’s surface every day contains 10,000 times the energy requirements of humans on a daily basis. Second, the manufacturing process of PV modules produces only a small amount of carbon dioxide (20–30 g carbon dioxide equivalent (CO2e/kWh)).

- building integrated photovoltaics (BIPV)

- photovoltaics

- solar energy

- Singapore

- green building

1. Green Building Concepts in Singapore

1.1. Singapore Building Energy Consumption Landscape

- (1)

-

The average wind speed in Singapore reaches approximately 2 m/s, which is lower than the 4.5 m/s criterion of commercial wind turbines.

- (2)

-

There is no potential to implement tidal power generation due to the narrow tidal range and calm seas.

- (3)

-

Hydroelectric power cannot be employed because there are no year-round river systems with fast-flowing water.

- (4)

-

There are no geothermal energy sources available.

- (5)

-

Biomass-based energy generation is not appropriate in Singapore due to the high population density and land scarcity constraints.

- (6)

-

Nuclear power cannot be safely implemented in cities with high population densities.

1.2. Definition and Indicators of Green Buildings in Singapore and Singapore Green Building Masterplan (SGBMP)

- (1)

-

Sustainable design and management, which includes Base Building Selection, integrative design and management commitment & employee engagement;

- (2)

-

Energy and resource management, which includes air conditioning, lighting, and plug loads, water and waste;

- (3)

-

Office environment which includes occupant evaluation, spatial quality (lighting, acoustics, office design) and indoor air quality;

- (4)

-

Workplace health and wellbeing, which includes healthier eating & physical activity, smoking cessation and mental well-being;

- (5)

-

Advanced green and health features which includes smart office, renewable energy and health promotion.

1.3. Technologies to Achieve Super Low Energy Buildings (SLEBs) in the Tropics

1.4. BIPV Applications in Green Buildings in Singapore

2. Recent Development of BIPV Systems

2.1. Historical Evolution of BIPV Systems

2.2. Building-Integrated Photovoltaics (BIPVs) and Their Development

2.2.1. BIPV Systems

2.2.2. BIPV Roof Systems

2.2.3. BIPV Façades

2.2.4. Accessories

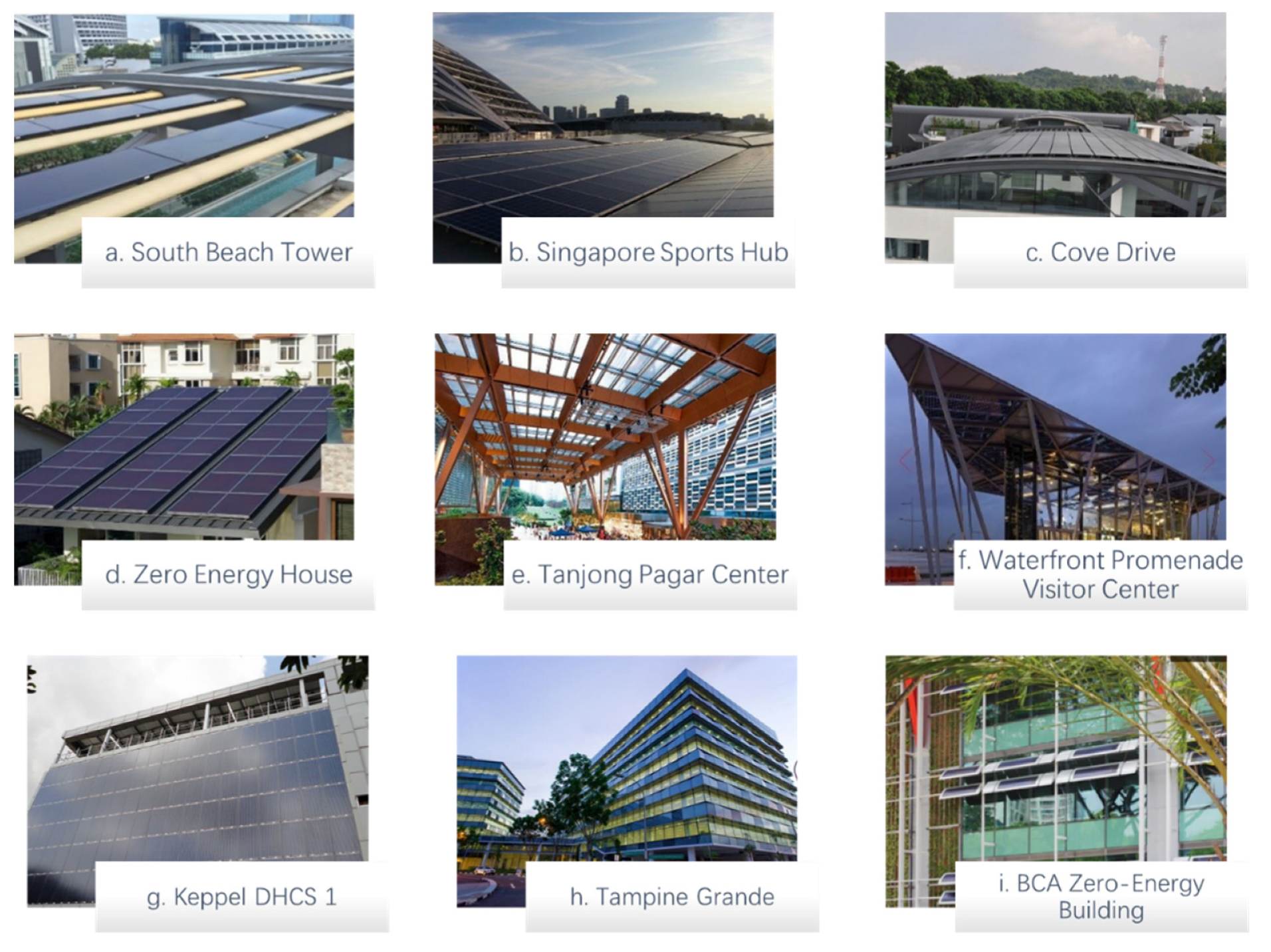

2.3. Singapore BIPV Projects

3. Barriers to BIPV Implementation in Singapore

| Policy barriers | Difficulties in obtaining governmental approvals |

| Uncertainties in BIPV policies in the long-term | |

| Low electricity tariff from conventional sources | |

| Lack of standards, codes or guidelines | |

| Economic barriers | The high upfront capital cost of BIPV |

| The long payback period of BIPV systems | |

| Product barriers | Lack of BIPV modular products |

| The low-energy conversion efficiency of BIPV systems | |

| Reliability problem | |

| Heat transfer issues | |

| Difficulties regarding cabling and connection | |

| Unstable power generation quality | |

| The complexity of the BIPV system | |

| Human resources and social barriers | Lack of professionals |

| Lack of public education and awareness of BIPV | |

| Information barriers | Lack of information on BIPV products, suppliers and policies |

| Lack of life cycle cost analysis knowledge | |

| Lack of BIPV demonstration projects | |

| Lack of design tools |

This entry is adapted from the peer-reviewed paper 10.3390/su141610160

References

- Schönsteiner, K.; Massier, T.; Hamacher, T. Sustainable transport by use of alternative marine and aviation fuels—A well-to-tank analysis to assess interactions with Singapore’s energy system. In Renewable and Sustainable Energy Reviews; Elsevier: Amsterdam, The Netherlands, 2016; Volume 65, pp. 853–871.

- Kosorić, V.; Huang, H.; Tablada, A.; Lau, S.-K.; Tan, H.T.W. Survey on the social acceptance of the productive façade concept integrating photovoltaic and farming systems in high-rise public housing blocks in Singapore. Renew. Sustain. Energy Rev. 2019, 111, 197–214.

- Jacobs, D.; Sovacool, B.K. Feed-in tariffs and other support mechanisms for solar PV promotion. In Comprehensive Renewable Energy; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; Volume 1.

- BCA. Super Low Energy Building; BCA: Singapore, 2018; pp. 1–53.

- The Straitstimes. Budget 2021: Govt will Review Carbon Tax Rate, which will Remain at $5 per Tonne until 2023|The Straits Times; The Straitstimes: Singapore, 2021; Available online: https://www.straitstimes.com/singapore/budget-2021-government-will-review-carbon-tax-rate-which-will-remain-at-5-per-tonne-until (accessed on 15 May 2022).

- Sick, F.; Erge, T. Photovoltaics in Buildings–A Design Handbook for Architects and Engineers; Routledge: London, UK, 1996; p. 280. Available online: https://www.routledge.com/Photovoltaics-in-Buildings-A-Design-Handbook-for-Architects-and-Engineers/Sick-Erge/p/book/9781849711920 (accessed on 15 May 2022).

- Corti, P.; Bonomo, P.; Frontini, F.; Mace, P.; Bosch, E. Building Integrated Photovoltaics: A Practical Handbook for Solar Buildings’ Stakeholders Status Report. Available online: https://www.researchgate.net/publication/351441632_BIPV_Status_Report_2020_Building_Integrated_Photovoltaics_A_practical_handbook_for_solar_buildings%27_stakeholders (accessed on 15 May 2022).

- Heinstein, P.; Ballif, C.; Perret-Aebi, L.-E. Building Integrated Photovoltaics (BIPV): Review, Potentials, Barriers and Myths. Green 2013, 3, 125–156.

- Humm, O.; Toggweiler, P. Photovoltaik und Architektur. In Die Integration von Solarzellen in Gebäudehüllen; Birkhäuser Verlag: Basel, Switzerland, 1993.

- Thomas, H.P. Building Integrated PV and PV/Hybrid Products–The PV:BONUS Experience. Available online: https://www.nrel.gov/docs/fy02osti/31138.pdf (accessed on 15 May 2022).

- Frantzis, L.; Hill, S.; Teagan, P.; Friedman, D. Building-integrated PV-analysis and us market potential. Conf. Rec. IEEE Photovolt. Spec. Conf. 1994, 1, 1204–1207.

- Task 7 Of The IEA PV Power Systems Program-Achievements And Outlook. Available online: https://www.academia.edu/20489501/Task_7_Of_The_IEA_PV_Power_Systems_Program-Achievements_And_Outlook (accessed on 15 May 2022).

- Akata, A.M.E.A.; Njomo, D.; Agrawal, B. Assessment of Building Integrated Photovoltaic (BIPV) for sustainable energy performance in tropical regions of Cameroon. Renew. Sustain. Energy Rev. 2017, 80, 1138–1152.

- IEA. IEA Releases First Clean Energy Progress Report-News-IEA. 2011. Available online: https://www.iea.org/news/iea-releases-first-clean-energy-progress-report (accessed on 15 May 2022).

- Farrell, C.; Osman, A.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.; Kumaravel, V.; Al-Muhtaseb, A.; et al. Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules. Renew. Sustain. Energy Rev. 2020, 128, 109911.

- Tripathy, M.; Sadhu, P.K.; Panda, S.K. A critical review on building integrated photovoltaic products and their applications. Renew. Sustain. Energy Rev. 2016, 61, 451–465.

- Li, D.H.W.; Cheung, G.H.W. Study of models for predicting the diffuse irradiance on inclined surfaces. Appl. Energy 2005, 81, 170–186.

- Emiliano, B. A 19.5% Efficient Solar Tile with Five-Busbar Technolog–pv Magazine International. 2021. Available online: https://www.pv-magazine.com/2021/01/15/a-19-5-efficient-solar-tile-with-five-busbar-technology/ (accessed on 15 May 2022).

- Zhang, T.; Wang, M.; Yang, H. A Review of the Energy Performance and Life-Cycle Assessment of Building-Integrated Photovoltaic (BIPV) Systems. Energies 2018, 11, 3157.

- Agathokleous, R.A.; Kalogirou, S.A. Status, barriers and perspectives of building integrated photovoltaic systems. Energy 2019, 191, 116471.

- Li, M.; Ma, T.; Liu, J.; Li, H.; Xu, Y.; Gu, W.; Shen, L. Numerical and experimental investigation of precast concrete facade integrated with solar photovoltaic panels. Appl. Energy 2019, 253, 113509.

- Freitas, S.; Brito, M.C. Solar façades for future cities. Renew. Energy Focus 2019, 31, 73–79.

- Ghosh, A. Potential of building integrated and attached/applied photovoltaic (BIPV/BAPV) for adaptive less energy-hungry building’s skin: A comprehensive review. J. Clean. Prod. 2020, 276, 123343.

- Huang, M.J. The effect of using two PCMs on the thermal regulation performance of BIPV systems. Sol. Energy Mater. Sol. Cells 2011, 95, 957–963.

- Boafo, F.E.; Kim, J.-H.; Kim, J.-T. Numerical study of slim curtain wall spandrel with integrated vacuum insulation panel: Concept, performance evaluation and challenges. Energy Build. 2019, 183, 139–150.

- Shukla, A.K.; Sudhakar, K.; Baredar, P.; Mamat, R. Solar PV and BIPV system: Barrier, challenges and policy recommendation in India. Renew. Sustain. Energy Rev. 2018, 82, 3314–3322.

- Al-Turki, A.; Zaki, G. Cooling load response for building walls comprising heat storing and thermal insulating layers. Energy Convers. Manag. 1991, 32, 235–247.

- EMA; BCA. Handbook for Solar Photovoltaic Systems; Energy Market Authority, Singapore Publication: Singapore, 2011; pp. 4–9.

- Ren, H.; Xu, C.; Ma, Z.; Sun, Y. A novel 3D-geographic information system and deep learning integrated approach for high-accuracy building rooftop solar energy potential characterization of high-density cities. Appl. Energy 2022, 306, 117985.

- Jayathissa, P.; Luzzatto, M.; Schmidli, J.; Hofer, J.; Nagy, Z.; Schlueter, A. Optimising building net energy demand with dynamic BIPV shading. Appl. Energy 2017, 202, 726–735.

- Kyritsis, A.; Roman, E.; Kalogirou, S.A.; Nikoletatos, J.; Agathokleous, R.; Mathas, E.; Tselepis, S. Households with Fibre Reinforced Composite BIPV modules in Southern Europe under Net Metering Scheme. Renew. Energy 2019, 137, 167–176.

- Kosoric, V.; Wittkopf, S.; Huang, Y. Testing a design methodology for building integration of photovoltaics (PV) using a PV demonstration site in Singapore. Arch. Sci. Rev. 2011, 54, 192–205.

- Lu, Y.; Chang, R.; Shabunko, V.; Tan, A.; Yee, L. The implementation of building-integrated photovoltaics in Singapore: Drivers versus barriers. Energy 2019, 168, 400–408.

- Lau, S.-K.; Kosorić, V.; Bieri, M.; Nobre, A.M. Identification of Factors Influencing Development of Photovoltaic (PV) Implementation in Singapore. Sustainability 2021, 13, 2630.

- Chang, R.; Cao, Y.; Lu, Y.; Shabunko, V. Should BIPV technologies be empowered by innovation policy mix to facilitate energy transitions?-Revealing stakeholders’ different perspectives using Q methodology. Energy Policy 2019, 129, 307–318.