The world is experiencing an accelerated level of advancement in which people aim at enhancing their living standards, while competing for food, water, and energy. This threatens the availability of enough resources for future generations, hence hindering the achievement of sustainability goals. As a result of inequalities and mindless consumption, wastes are generated in abundance impacting the environment and transgressing the Earth into undesired shifts from its equilibrium (i.e., its balance).

Waste management, hence, plays a pivotal role in alleviating the suffering of the environment, and contributes to the prosperity of societies. Examples of typical waste management techniques include landfilling and incineration, both are associated with technical and environmental difficulties. There are other techniques including the application of methods that implement the concept of circular economy, where wastes are reused as input for the production of various commodities thus creating a market for waste. In this review article, the conversion of biosolids (a problematic type of waste) using the pyrolysis process (thermo-chemical process) to produce a charcoal-like materials known as biochar.

- pyrolysis

- biosolids

- biochar

- waste management

- sustainability

- circular economy

- energy

1. Biosolids/Biosludge:

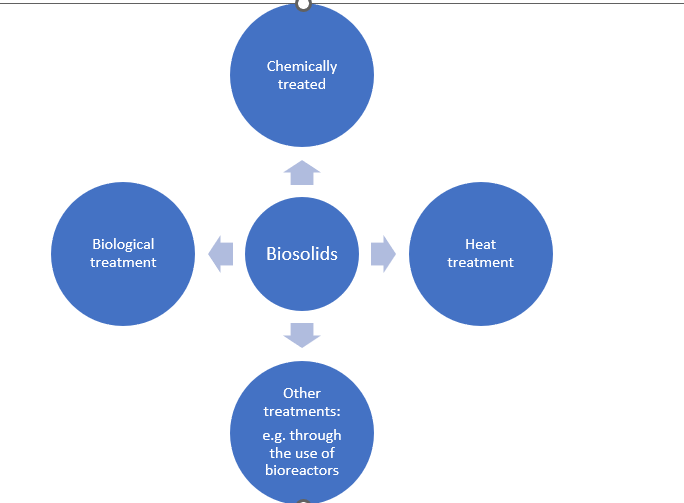

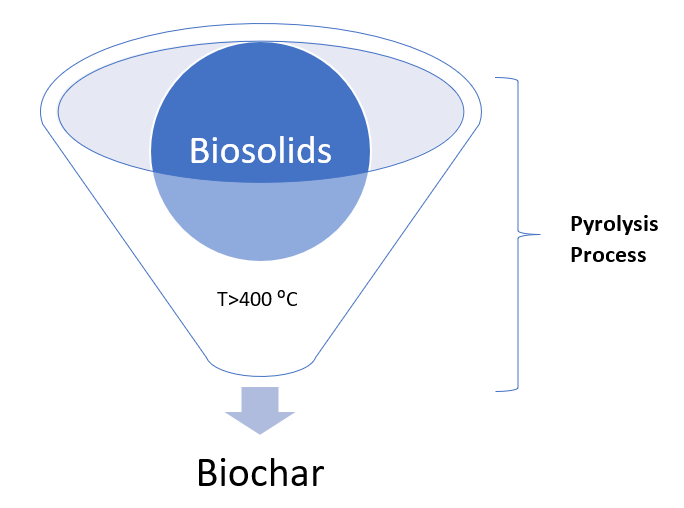

Biosolids or biosludges, which in this review will refer to any form of sludge that has undergone some form of treatment (e.g., chemical, biological, heat treatment, etc.) in order to transform it into a less hazardous and organic form. Additional forms of SS resulting from industrial activities involving the above are also considered (e.g., due to the use of a bioreactor or from the pharmaceuticals industry). The pyrolysis process holds great potential as a thermal treatment method [35,36], that is capable of transforming biomass into value-added products. Typically, a biomass feedstock will undergo thermal treatment to an elevated temperature that goes beyond 400 °C in the pyrolysis process in an inert environment, that involves partial or total removal of oxygen. In addition to containing the gas produced resulting from the thermal degradation of the organic components [37,38], the pyrolysis process results in the production of three major products, namely, biochar, bio-oil, and biogas.

Figure 2: Different classifications of what constitutes biosolids

2. Management of biosolids and the use of the pyrolysis process

Solids resulting from wastewater are either applied to land as soil amendment and nutrient source, incinerated, or landfilled [31]. These solids are full of micropollutants that include organic chemicals originating from consumer-based products, which end up in the sewer drains during disposal (e.g., pharmaceuticals, antimicrobial compounds, personal care products, medicines and hormones, etc.) [32,33]. Therefore, the sewage sludges and wastewater treatment sludges and their by-products from these locations require new and innovative handling methods that alleviate environmental burdens, while producing value-added products, e.g., capacitors [34]. The thermal process of pyrolysis to biochars has been reported to combat some of these issues, for instance, the destruction of organic molecules, the destruction of microorganisms and the fixation of heavy metals, preventing them from leaching out into the soil.

3. The pyrolysis process

Pyrolysis is a relatively uncomplicated technology requiring no complex process plant compared with incineration and gasification and it is quite environmentally friendly [52]. Additional benefits include its ability to handle many waste types [53], while directly producing several product materials (for example, biochars, bio-oils and syngas) [54,55]. In terms of the limitations of the sustainability of the pyrolysis process for a treatment alternative, the issue for wet biosolids feedstock is a problem but it has been stated recently that the introduction of low-cost pre-drying solutions can improve the outcomes, prior to pyrolysis [40]. For example, solar drying methods are promising techniques as a low-cost drying pretreatment in arid environmental conditions, having plentiful sunlight and a low humidity environment. Alternatively, flue gases, available from the combustion of the bio-oils/biogas, in the temperature range 140–180 °C could achieve the same objective and even indirect heat exchange with the hot outlet pyrolysis gases. The pyrolysis process is classified into different types with the slow and fast pyrolysis being among the most commonly applied types.

Figure 1: Depiction of the pyrolysis of biosolids

4. Benefits of Biosolids-Derived Biochars

It is crucial to distinguish between biochars produced from biosolids and those obtained from other types of biomass materials. There are commonalities in the uses of all types of biochar and as such the same benefits are expected from biosolids-derived biochars. From the results of previous work on biochars produced from other types of biomasses, the different biochar products were found successful for use in amending soils in commercial potting soil mixes, green roofs, and commercial agriculture [31]. However, the same benefits from biochars derived from biosolids require further research to determine its applicability, opening room for more research opportunities in the applied side of this type of research.

Furthermore, the addition of different biochars to soils promotes plant growth. This addition is associated with interesting biological and chemical changes such that a shift in rhizosphere microbial and fungal communities to more favorable compositions for plant growth is attained. The same changes can be achieved through the contribution of some chemicals to the soil-system that lead to similar increases in nutrient concentrations [31,115,116].

This entry is adapted from 10.3390/su14159626

This entry is adapted from the peer-reviewed paper 10.3390/su14159626