Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Chemistry, Physical

An extremely efficient lubrication system is achieved in synovial joints by means of bio-lubricants and sophisticated nanostructured surfaces that work together.

- aqueous boundary lubrication

- friction

- wear resistance

1. Introduction

The origin of friction is the energy dissipation processes that occur as two surfaces slide against each other [1]. Friction forces between two surfaces are often characterized by the effective friction coefficient, μeff, that is, calculated by taking the ratio of friction force (FFriction) and applied load (FLoad). The friction coefficient in synovial joints in mammals was found to be as low as 0.001 as measured by hip function simulator machines, even though values reported in different studies vary significantly [2]. It can be safely concluded that the friction coefficient is well below 0.01. For example, Gale et al. have reported values in the range of 0.002~0.006 [3]. This extremely efficient aqueous lubrication ability of the synovial joint is achieved by an association of lubricin, hyaluronan, phospholipids, and aggrecan [4,5,6]. Lubricin and aggrecan, bottlebrush-like biomacromolecules that have densely grafted pendant chains are abundant in synovial joints [7,8]. It is believed that these bottlebrush structured biomacromolecules play key roles for a number of critical biological functions, for example, hydration, aqueous boundary lubrication, wear resistance as well as mediating the rheological and mechanical properties under pressure [8,9].

2. Bio-Lubricants

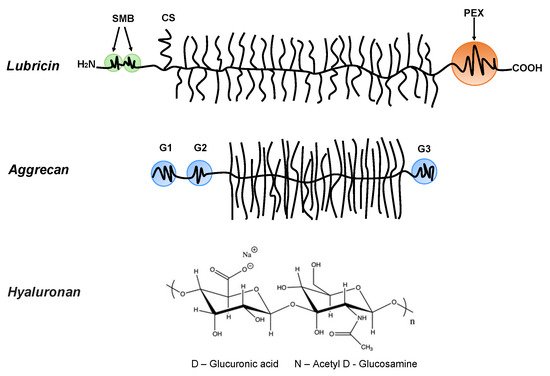

Bio-lubricants including lubricin, hyaluronan, and phospholipids as well as aggrecan, which is important for the mechanical response of cartilage, play important roles in reducing friction forces and providing shock absorbing mechanical responses to articular cartilage surfaces [8]. These molecular structures are very different, but they share a common feature that they contain highly hydrophilic groups that bind water and allow for the hydration lubrication mechanism [55] to be operative. Lubricin is a glycoprotein with a bottlebrush structure. It is composed of the N-terminal by 2-somatomedin B (SMB)-like domains, the C-terminal with a hemopexin (PEX)-like domain, chondroitin sulfate (CS) side chain, and a densely glycosylated and mucin-like domain in the middle (Figure 1) [56,57]. It has been suggested that lubricin is able to counteract damages of the superficial zone of cartilage, and contributes to the preservation of chondrocytes in the joints [58]. The bottlebrush structure in lubricin and mucins also reduces the interpenetration zone, that is, the region where polymer chains on two opposing surfaces carrying such molecules overlap. This suggests that the bottlebrush structured polymers are promising candidates for reducing friction forces as the energy dissipation related to dragging polymer chains through the interpenetration zone is minimized. The interfacial lubrication studies of various types of mucins have shown that friction forces between surfaces can be reduced by mucins, which can be attributed to their extensive hydration, which arises from the large amount of oligomeric carbohydrate side chains [59,60,61,62,63,64]. Aggrecan also has a bottlebrush structure domain in the middle (Figure 1) [65,66]. The friction forces between surfaces with covalently attached cartilage aggrecan was found to be rather low (μeff = 0.03 ± 0.01~0.11 ± 0.01, depending on the ionic strength of the solution) [67], even though this molecule’s most important function in the synovial joint area is found within the cartilage where it is associated with hyaluronan, and together with collagen, builds the intricate nanostructure of cartilage. For instance, the compressive resistance of articular cartilage has important contributions from hierarchical brush-on-brush structures formed by one hyaluronan associated with as many as 100 aggrecan molecules [68].

Figure 1. Lubricin: containing the N-terminal 2-somatomedin B (SMB)-like domains and the C-terminal hemopexin (PEX)-like domain. Lubricin also contains a chondroitin sulfate (CS) side chain, and in the middle region, it has a densely glycosylated and mucin-like domain. Aggrecan: containing three globular domains (G1, G2, and G3), and in the middle, it has a large extended domain heavily modified with glycosaminoglycans. Hyaluronan (HA): the anionic disaccharide building unit of hyaluronan.

Hyaluronan and phospholipids also play important roles to achieve efficient aqueous lubrication systems [5,69,70,71,72,73,74,75]. Hyaluronan is a linear anionic polysaccharide (Figure 1). In fact, hyaluronan alone is not enough to reduce friction forces between surfaces [76,77]. However, hyaluronan is responsible for the viscous and elastic properties of the synovial fluid, which is very important for reducing the friction forces between articular cartilage [78,79]. It has also been reported that hyaluronan/aggrecan aggregates can achieve better lubrication than hyaluronan alone, which is due to the highly charged glycosaminoglycan segments on the aggrecan core protein [79]. In addition, the friction forces between damaged human cartilage can be reduced by self-assembled structures formed by hyaluronan and phospholipids [80]. The favorable interfacial lubrication properties of hyaluronan associated with phospholipids have also been observed in model systems [81,82,83]. The results of the friction force measurements between model silica surfaces coated with supported DPPC bilayers in the presence of hyaluronan have clearly indicated that the aggregates of hyaluronan/phospholipids are able to achieve low friction up to the pressure of 56 MPa, [81] which is higher than the pressure (25 ± 5.2 MPa) [84] that leads to the damage of the hyaline cartilage. Recently, multilayers have been prepared by the co-adsorption of HA and DPPC vesicles by Raj et al. [82], and the investigation showed that the friction coefficient between the layers was below 0.01 up to the pressure of 20 MPa. Over the last decade, Dedinaite and co-workers have investigated the intermolecular synergistic mechanism of the bio-lubricants in synovial fluid such as synergy pairs of hyaluronan and phospholipids [77,81,82,83,84,85,86,87]. Their studies indicate that synergistic lubrication can be achieved by the bio-lubricants working together. We summarize some of the observed synergistic effects of bio-lubricants regarding their interfacial lubricating properties in Table 1.

Table 1. The lubrication performance of the bio-lubricant aggregates. The table provides data for the effective friction coefficient, µeff, and the highest pressure, P, investigated.

| Compositions | Substrate | Interfacial Lubricating Properties | Ref. |

|---|---|---|---|

| HA + DPPC liposomes | Damaged human cartilage | The reduction in friction was 69.5%, P = 1.3 MPa |

[79] |

| HA + Aggrecan | Mica | μeff = 0.01, P = 1.6 MPa | [78] |

| HA + DPPC vesicles | Macroscopic glass surfaces | μeff = 0.1, P = 210 MPa | [77] |

| HA + DPPC bilayer | Silica | μeff = 0.03, P = 56 MPa | [80] |

| HA + DPPC vesicles | Silica | μeff < 0.01, P = 23 MPa | [81] |

| COMP + lubricin | PMMA | μeff = 0.06, P = 7 MPa | [85] |

| cross-linked HA + DOPC | Mica | μeff > 0.5, P = 2 MPa | [88] |

| HA + Lubricin | Mica | μeff = 0.09–0.4, P = 4 MPa | [89] |

| HA + Lubricin + Type II collagen |

Gold versus SiO2 | μeff = 0.01, P = 0.013 MPa | [90] |

This entry is adapted from the peer-reviewed paper 10.3390/polym14132724

This entry is offline, you can click here to edit this entry!