Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Operations Research & Management Science

Road lighting is essential to ensure the safety and comfort of its users, especially in preventing accidents and aiding visual tasks. The monumental shift from conventional road lighting technology to light-emitting diode (LED) lighting is driven by energy efficiency, associated cost savings, and environmental concerns in the road lighting system.

- light-emitting diode (LED)

- high-pressure sodium vapour (HPSV)

- data envelopment analysis (DEA)

1. Introduction

Street lighting is important to establish the safety and comfort of drivers, riders, and pedestrians. The safety aspects of street lighting include the prevention of accidents and injuries while also reducing the risk of crime and violence. In terms of comfort, street lighting can increase the quality of life when outdoor activities take place at night. Nowadays, street lighting also functions to beautify an area by creating beautiful scenery with landscape illumination. In recent progress, there has been a huge increase in the number of street users globally, and it has become increasingly important to ensure the safety and good visual performance of the users through reliable street lighting systems [1,2,3].

About 2.3% of the global electricity consumption is contributed by the public lighting particularly the street lighting [4]. However, there is also huge potential for energy savings in street lighting. Lobão et al. [5] predicted that there is more than 50% energy savings potential in street lighting, and they ascertained five criteria that influence the selection of efficient street lighting, namely price, power consumption, conductor loss depletion, beneficial life, and interest rate. Since it is critical to reduce the power usage as well as maintain good quality lighting surroundings and user safety, the major focus should be given on energy usage, production patterns, and energy efficiency programmes to promote energy efficiency of street lighting [6]. The earlier road lighting technologies included high-pressure sodium (HPS), low-pressure sodium (LPS), and metal halide (MH) lights [7,8]; however, more recent advances in lighting technology have enabled the development of solid-state lighting sources using LEDs. LEDs are preferable because of their high luminous efficacy, long lifetime, and high colour rendering index compared with conventional gas lights such as HPS and MH lights [9].

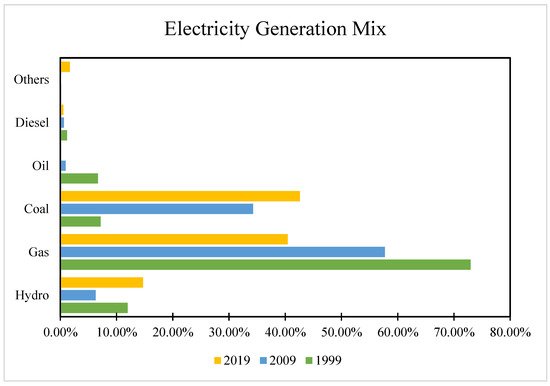

Malaysia has been using LED for road lighting illumination since 2012 [10,11]. Nonetheless, a local technical report by TEEAM [12] did not recommend LED adoption during that time after they found out that LED does not have advantages over the existing road lighting technology based on five criteria, namely energy-saving, cost-saving, maintenance cost over 20 years, safety and security, and environmental impact [12]. In addition, Mohd Yunin, Shabadin, Mohd Zulkifli and Syed Mohamed Rahim [11] remarked that the LED for road lighting should not be installed in areas prone to fog and rain since it leads to glare in the eyes of drivers. Nevertheless, Malaysia’s electricity demand is largely fuelled by gas and coal (refer to Figure 1) and the demand continues to rise for the past three decades [13]. In adition, the electricity’s share of the total energy consumption increased from 17.9% in 1998 to 20.3% in 2018 [13]. Hence, the Ministry of Energy and Natural previously known as the Ministry of Energy, Green Technology and Water targets a reduction of 10% in electricity consumption by 2025 from the energy efficiency sector [14].

Figure 1. Electricity generation mix in the years 1999, 2009, and 2019. Source: Energy Commission [13].

The energy price in Malaysia has also been increased as its price or electricity tariff is determined by Tenaga Nasional Berhad (TNB), the only electricity utility company in Peninsular Malaysia and the largest public-listed power company in Southeast Asia. The electricity tariff in Malaysia has been revised three times since 2008, and the latest revision took place in 2014. For street lighting use, there are two types of electricity tariffs; one that includes the maintenance work by TNB, which is currently at the current price of RM0.305/kWh after an increase from RM0.261/kWh, and the other rate that does not include the maintenance cost, which is currently priced at RM0.192/kWh from RM0.164/kWh [15].

With the increased price of energy, the recent development of LED lighting technology, and increased awareness of the encouraging environmental impact of adopting street lighting technology, there is a need to revisit the feasibility of LED for road illumination. To date, the existing literature has not come to an agreement on the need to switch from conventional lighting to LED lighting, as well as aspects regarding the energy, cost, and environmental concerns particularly in the Malaysian context [11,12,16,17]. These three aspects (energy, cost, and environmental concerns) are very crucial in adopting sustainable street lighting technology but lack of clear insights from these different perspectives would hinder the implementation of necessary measures. Therefore, more in-depth study is needed to apprehend the impact of adopting LED for road lighting in Malaysia.

2. Lamp Technologies

A light source is the most significant component of a lighting system because it merely defines visual value, cost, and efficiency of the lighting system [18]. Four important features in light source selection include illumination level required by a particular road according to codes and standards, colour rendering properties of the lamp, lamp lifetime and lamp efficacy [18]. Previously, the high intensity discharge (HID) lighting systems were widely used for road lighting as opposed to incandescent and fluorescent lighting. HPS, LPS, MH and MV lights are classified as the main road lighting technologies of HID lighting systems for road lighting use [19]. Table 1 presents the characteristic of five (5) main road lighting technologies which are HPS, LPS, MH, MV, and LED.

Table 1. Characteristics of main road lighting technologies.

| Lamp Type | CRI | Luminous Efficacy (lm/W) | Lifetime (Hours) |

|---|---|---|---|

| High-pressure sodium (HPS) | 30 | 50–150 | 15,000–24,000 |

| Low-pressure sodium (LPS) | 5 | 100–190 | 18,000–24,000 |

| Metal halide (MH) | 70–95 | 70–130 | 8000–12,000 |

| Mercury vapour (MV) | 50 | 50 | 10,000 |

| Light-emitting diode (LED) | 70–90 | Up to 160 | 40,000–100,000+ |

Source: Babatunde, Akinbulire, Oluseyi and Emezirinwune [18].

Table 1 compares colour rendering index (CRI) (an index to quantify the ability of a light source to render colour of surfaces accurately), luminous efficacy (a measure of how well a light source can produce visible light), which is measured in lumens per watt (lm/W), and lifetime (the life expectancy until the end-of-life) [18,19,20,21]. MH has the best colour rendering properties, and its luminous efficacy is considerably high, but the lifetime is relatively low. MV consumes high energy, and it also has poor lifetime. Among these HID lighting systems, the HPS lights are the most commonly used for conventional and high mast road lighting due to their excellent luminous efficiency, power usage, and long lifespan [19]. Nevertheless, LED has good CRI and efficacy, and the striking feature of LED is found through its highest lamp lifetime, which is ranging from 40,000 to over 100,000 h.

An HPS lamp commonly composed of four fundamental components, namely a sealed, translucent ceramic arc tube, main electrodes, an outer bulb, and a base. While a basic LED is made up of optical, electrical and mechanical, and thermal components [19,22]. An HPS lamp requires ballasts or capacitors to regulate the arc current flow and deliver the proper voltage to the arc, hence it is powered by an alternating current (AC) source [19]. LEDs utilise an electronic arrangement that converts the supply voltage to low-voltage direct current (DC), making it more energy efficient [18].

3. Concept of Efficiency in DEA

Data envelopment analysis (DEA) is a non-parametric approach that measures the performance of decision-making units (DMUs) in a single index value taking multiple inputs and multiple outputs. Pioneered by Charnes et al. [23] and developed from Farrell [24], DEA uses linear programming to estimate relative efficiency, a non-negative value, based on linear relationships between the inputs and outputs of DMUs under analysis. This data-driven performance measurement technique determines how efficient a DMU is in producing a certain level of output, based on the amount of input it uses as compared to other similar DMUs [25]. The Charnes, Cooper and Rhodes (CCR) DEA benchmarking model provides the information by locating and understanding the nature of inefficiencies of a DMU through comparisons with selected efficient DMUs of a similar profile.

Several studies have examined efficiencies in energy by adopting the DEA approach. Ashuri et al. [26] established the DEA energy benchmarking model by taking into account criteria such as total energy usage, building attributes, and local meteorological conditions for a more energy-efficient facility management work. In a large scale, Ervural et al. [27], who employed DEA to analyse renewable energy efficiencies of 81 cities in Turkey, discovered that regions with a high renewable energy potential can turn out to be efficient depending upon their regional technical advancement.

Nevertheless, the conventional efficiency formulation of the DEA tends to improve the performance of inefficient DMUs as soon as the efficient frontier is identified, by either increasing the current level of outputs or decreasing the current level of inputs. In the circumstances when the efficiency can be increased by maximising inputs or the efficiency can be reduced by minimising outputs [28,29]. These are usually referred to as ‘undesirable’ or ‘bad’ input and output variables. The production of ‘undesirable’ by-products such as pollutants and wastes are considered dangerous because of their negative impacts on the environment. Moreover, not considering the production of undesirable outputs in the DEA model development may result in biased efficiency measurement. During the evaluation process of the production performance, particularly when inefficiency exists, the desirable and undesirable outputs should be treated differently in order to improve the inefficiency [30].

There are four common methods to treat undesirable outputs [31]: neglecting undesirable outputs, treating undesirable outputs as inputs, treating the undesirable outputs in the nonlinear model, and applying necessary transformations to the undesirable outputs. An earlier study by Yang and Pollitt [32] showed that enforcing a technically correct disposability features on undesirable outputs makes a substantial impact on the final efficiency evaluation. Zhang et al. [33] established an eco-efficiency analysis on regional industrial systems in China by treating undesirable outputs as inputs. One of the nonlinear models developed for undesirable outputs is the directional distance function (DDF), which has been applied successfully on two separate occasions by Alfredsson et al. [34] and Halkos and Papageorgiou [35].

4. Input-Output Variables Selection

4.1. Techno-Economic Analysis of Road Lighting System

Techno-economic analysis (TEA) in general is a cost-benefit comparison resulting from the consideration of both technological and economic factors [36]. Zimmermann et al. [37] defined TEA as ‘a methodology framework to analyse the technical and economic performance of a process, product or service and includes studies on the economic impacts or research, development, demonstration, and deployment of technologies’. The TEA approach is used to conduct a cost-benefit analysis by utilising several methodologies to accomplish objectives such as determining the economic feasibility of a particular project, analysing cash flows over the duration of a project’s lifespan, determining the scales and applications of a technology, and comparing the economic quality of various technologies [38].

Net present value (NPV), internal rate of return (IRR), payback period, and return on investment (ROI) are some of the techniques. Several studies have employed these techniques to measure the efficiency of energy-efficient technology through their investments in lighting technology by techno-economic analysis. Yoomak et al. [39], for example, evaluated the performance of their investment in LED lighting to replace HPS road lighting in Thailand using the payback period and IRR. Their findings agreed that LED lighting meets the investment targets and has good potential quality, energy savings, and powerful lighting. Beccali et al. [40] carried out NPV and payback period for the return on investment by considering the on/off control and dimming control of LED retrofit funded through loan, self-funded, and incentive provided by the Italian Government. They found that LED retrofits with dimming control funded through the incentive provided by the Italian Government give the highest NPV value and a return time of 4 to 5 years.

There are two important types of cost to be considered in analysing the investment made on road lighting technology, namely the initial investment cost and operating cost. The initial investment cost is the installation cost [41], and this is one of the important aspects to consider in adopting LED lighting technology [42]. The fact that price of LED lighting is much higher compared to the conventional lighting, LED lighting systems would require a higher initial investment cost [43,44], which then could result in a low penetration rate of LED lighting.

The other fundamental segment of road lighting costing is the operation cost. Operation cost comprises energy consumption and maintenance cost. While the energy price makes up the consumption cost, the maintenance cost consists of the cost of cleaning and upkeeping of the lanterns [45,46]. Therefore, economic feasibility of the streetlight depends heavily on electricity prices [47], as revealed by Duman and Güler [48]. Meanwhile, Beccali et al. [49] found that the annual capital savings on a new LED lighting system could be attributed to maintenance cost and reduction in energy consumption.

4.2. Energy Consumption

Energy saving and efficiency have received high affinity among researchers specifically in road lighting installation. The literature on energy savings and efficiency for road lighting installation is analysed in three aspects, namely by optimising the design of road lighting system with the best parameter combination to ensure lighting regulating and installation efficiency, improving lamp and luminaire technology, and improving lamp and luminaire control systems [4,5,50]. Owing to these efforts, more sustainable road lighting technology has been developed and improved [2]. Previous studies also associated reduced energy consumption to energy savings with new LEDs’ design status. Djuretic and Kostic [51], for instance, underlined the need to choose similar photopic or mesopic luminance levels and they found that the high-quality LED luminaires could save 31 to 60% of energy as compared to the high-quality HPS luminaires applicable to multi-stage scenarios. Yoomak, Jettanasen, Ngaopitakkul, Bunjongjit and Leelajindakrairerk [39], on the other hand, studied power quality and energy savings of LED road lighting from the DIALux simulation programme, where the energy efficiency index difference was approximately 40%.

In a study on pedestrian street lighting, Juntunen et al. [52] developed smart LED luminaires with higher luminous efficacy to demonstrate energy savings without sacrificing user visual comfortability. In the passive mode, where the streetlights function without added intelligence, energy savings of 19 to 44% were achieved as compared to commercial luminaires. There is also huge potential for power consumption reduction in the LED lighting system with a control system [53,54]. Energy savings without comprising user visual comfortability has achieved a reduction of 38% energy consumption in an indoor experiment on the control of SPDs of LED lighting [55].

Pipattanasomporn, Rahman, Flory and Teklu [54] found that an intelligent lighting control system may reduce approximately 74% of energy usage. On the other hand, Bunjongjit, Ananwattanaporn, Ngaopitakkul, Jettanasen and Patcharoen [53] proposed a control circuit for LED luminaire based on the amount of daylight which has been able to reduce the lighting system’s power consumption while preserving lighting quality for the user. Smart Grid technology equally has the potential to further increase the efficiency and operational reliability of outdoor lighting systems as discussed by Filimonova et al. [56] on an LED outdoor lighting system for a university campus in Russia.

4.3. Lifetime of the Luminaire

Lifetime is the useful life of luminaire. LED advances have resulted in significant improvements in light source efficiency and lifetime [57]. In the market, the lifetime of LED lights involving LED drivers and source packages is regularly quoted as 25,000 to 50,000 h [58,59,60,61]. In general, the lifetime of LED lights is two to six times more than conventional lights which will reduce maintenance costs [49]. Nonetheless, poorly designed LED driver and high temperatures might shorten the lifetime of LED lights [62,63].

4.4. Environmental Concern in Road Lighting System

The assessment of environmental impact is the other well-researched topic in LED road lighting. Tannous et al. [64] utilised life cycle assessment (LCA) in measuring environmental impact to compare the usage of solar-LED and traditional-HPS road lighting. They considered LCA from the raw material extraction until the end-of-life, with two end-of-life scenarios modelled, landfilling and recycling. They concluded that the solar system has fewer overall environmental impacts than the traditional system for both landfilling and recycling scenarios. Many others looked into carbon dioxide emission reduction when assessing the environmental impact of the LED and conventional LED for road lighting illumination [4,18,44,48,49]. Carbon dioxide emission can be computed directly from electricity consumption by applying the multiplication of the carbon dioxide emission factor of a country.

This entry is adapted from the peer-reviewed paper 10.3390/en15134589

This entry is offline, you can click here to edit this entry!