Chemical vapor deposition (CVD) and flame hydrolysis deposition (FHD) techniques fall in the category of the gas-phase deposition method, which is discussed below:

A.1. CVD techniques

CVD is a deposition process that produces high-performance solid materials, usually under a vacuum. In this technique, chemical reactions between organometallic or halide compounds and other gases form the nonvolatile solid thin films that are deposited on substrates. The key difference between this method and PVD is that the material deposition on the substrate is multidirectional, while PVD is a line-of-site impingement. CVD is widely used in microfabrication processes to deposit materials in numerous forms such as epitaxial, amorphous, monocrystalline, and polycrystalline. Unlike PVD, a definite chemical reaction between a mixture of gases and the bulk surface of the material occurs in CVD, allowing the chemical decomposition of some of the components of the gas, establishing a solid coating on the surface of the substrate. In addition, this enables the structures and properties of the resulting products to be tuned [

83], and several cutting-edge CVD systems and their alternates, for instance, plasma-enhanced CVD (PECVD) [

84] and metal-organic CVD (MOCVD) [

85], have been industrialized. Typically, high-vacuum working environments are not needed for CVD, enabling a predominant technology for electronics, optoelectronics, and biomedical applications. There are several reports on high-quality waveguide films deposited via CVD or its alternates [

86,

87,

88]. A recently published brief review on CVD [

88] should be studied for more details.

PECVD is a technique for depositing thin films of different materials on substrates at a lower temperature than traditional CVD. It is a hybrid coating technique in which energetic electrons trigger CVD processes (100–300 eV) inside the plasma rather than thermal energy, as in traditional CVD techniques. It is a vacuum-based deposition process that works at pressures as low as 0.1 Torr, permitting film deposition at substrate temperatures as low as 350 °C. There are several publications on the PECVD technique for the deposition of fine optical layers [

89,

90,

91]. Since PECVD needs comparatively low substrate temperatures and offers high deposition rates, the films can be deposited onto large-area substrates that cannot survive the high temperatures needed by conventional CVD techniques. Thick coating >10 μm can be deposited with a different thermal expansion coefficient without stresses developing during the cooling [

92].

MOCVD is a commonly used technique for a wide variety of materials, including electronic, optoelectronic, piezoelectric, ferroelectric, and multiferroic. Precursors made up of complex metal-organic ligands of metal ions are treated as a deposition source in this method. As opposed to PVD methods, one of the major benefits of MOCVD is that the precursors are held outside the deposition chamber and can thus be refilled continuously during long deposition runs. Several precursor mixtures with varying amounts of dopants can also be made quickly and effectively. Furthermore, superconductor film growth has been achieved at high deposition rates of more than 0.5 μm/min. Additionally, numerous mixtures of various precursors can be made with varying levels of dopants very quickly and effectively. Likewise, high deposition rates of more than 0.5 μm/min have been achieved in superconductor film growth [

93]. MOCVD of other materials uses rates of about 1 μm/h, so such high rates are rare. Since MOCVD precursors can be deposited over a wide area at high deposition rates, high throughput is possible, which is crucial for large-scale manufacturing.

A.2. Flame hydrolysis deposition (FHD)

An FHD process is widely used to depose the WG films since it can provide an elevated deposition rate resulting in minimal optical losses and low-stress thin films [

33]. In this deposition process, vapor precursors are added in a flame and experience chemical reactions to create soot particles which are afterward thermophoretically collected to form a porous layer on a substrate. To obtain a WG core, the porous soot deposited on the substrate must form a dense glass. To prevent the mixing of the layers, sintering temperatures are preferred such that the layers adjacent to the substrate have higher viscosities for the given temperatures. These temperatures are, sadly, often sufficient to allow the dopants to volatilize on the deposit surfaces. Consequently, in the densified glass layer, dopant concentration gradients and compositional inhomogeneities are formed, producing substandard optical properties. Such issues can be reduced or eliminated if the layers can be pre-sintered during deposition. In [

32], pre-sintered WG glass films are created, allowing straight WG losses to diminish from ~0.3 dB/cm to ~0.05 dB/cm. To minimize layer mixing, sintering temperatures are adjusted so that the layers closest to the substrate have greater viscosities for a specific temperature. The FHD method offers the benefits of depositing glass films at high rates with minimal losses and producing films with low strain. However, the sintering temperatures for these layers are still high enough to induce the dopants to volatilize at the deposit’s surfaces, which is a concern. As a result, in the densified glass layer, dopant concentration gradients and compositional inhomogeneities form, resulting in poor optical characteristics. These issues might be lessened or eliminated if the layers could be placed pre-sintered during laydown. Several studies on the formation of low-loss planar WGs utilizing the FHD process have already been reported [

33,

94,

95,

96].

- B.

-

Liquid-phase deposition

Liquid-phase deposition (LPD) is a distinctive soft solution process achieved by uncomplicated techniques. The two most widely used methods are discussed in this section: spray pyrolysis and the sol-gel method.

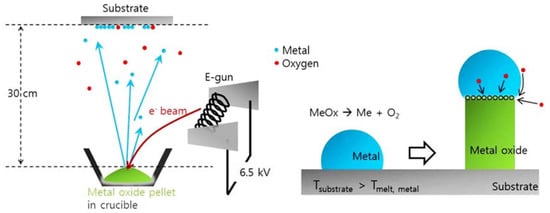

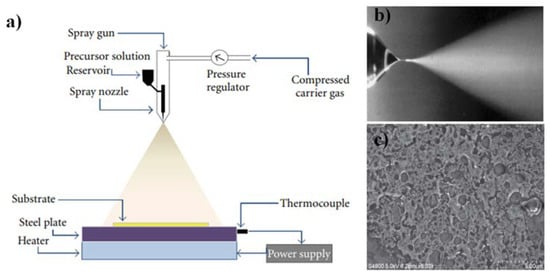

B.1. Spray pyrolysis method

Spray pyrolysis is a method for preparing thin and thick films, ceramic coatings, and powders currently being researched [

97]. Unlike many other film deposition techniques, it represents a very simple and relatively cost-effective processing method, especially concerning equipment costs. In this method, a thin film is deposited by spraying a solution on a heated surface where the constituents react to form a chemical compound [

98]. Chemical reactants are chosen so that products other than the compounds required are volatile at the deposition temperature. It provides an incredibly simple technique to prepare films of any composition. Researchers have used this method to develop high-quality thin films which can be employed in different optical components [

99,

100,

101,

102]. Spray pyrolysis, on the other hand, has the fatal flaw of forming porous and/or hollow-structured particles [

103,

104]. A lot of research has gone into solving this problem [

105,

106]. The impact of salt solubility and physical properties on the morphology of zirconia particles made from five different salts was examined, finding that those made from precursor solutions with lower initial relative solution saturations established solid ZrO

2 particles, while others formed hollow ones [

107]. The inclusion of H

2O

2 in the ZrO

2 particle preparation process aided solid particle production by slowing the breakdown reaction and preventing the development of the surface crust [

108]. By introducing a stable colloidal solution into spray pyrolysis, multicomponent oxide particles with a spherical and dense shape were formed, in which the colloidal seed triggered the volume precipitation of droplets by serving as nucleation seeds [

109].

Spray pyrolysis does not necessitate the use of costly substrates or chemicals. Instead, the process has been used for depositing thick films, porous films, and powder products. Using this flexible approach, even multilayered films can be effortlessly prepared. In the glass industry and solar cell production, spray pyrolysis has been used for many decades [

98]. An atomizer, precursor solution, substrate heater, and temperature controller are all typical components of spray pyrolysis equipment. The schematic illustration of the spray pyrolysis process is shown in

Figure 3a [

99]. For the readers interested in a detailed study of this method, please consult [

98]. The magnified image of the spray nozzle spraying methanol containing a small amount of HCL is shown in

Figure 3b [

110]. In [

99], a homemade spray pyrolysis technique is used to prepare SnO

2 thin films by utilizing aqueous solutions of SnCl

4·5H

2O. The FESEM micrograph of SnO

2 thin film is shown in

Figure 3c. The deposited thin film shows pores on the surface containing nanoparticles.

Figure 3. (

a) The schematic of the spray pyrolysis setup [

99], (

b) Cone-jet spraying of methanol containing a small amount of HCL. Reprinted with permission from [

110], (

c) FESEM micrograph of SnO

2 thin film [

99].

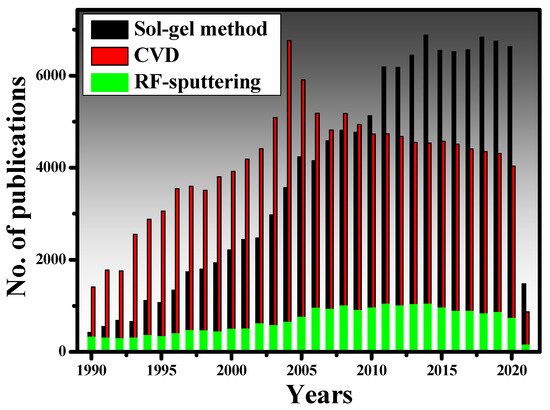

B.2. Sol-gel method

The sol-gel method, which involves a suspension of colloidal particles, was invented at the dawn of chemistry. The groundbreaking work of Ebelmen (a French chemist) in the 1800s is credited with establishing a sol-gel synthesis of silicon tetra isoamyl oxide from silicon tetrachloride and isoamyl alcohol [

111]. The latter study included the synthesis of boron amyloxide, boron ethoxide, and boron methoxide using isoamyl alcohol, ethanol, and methanol, respectively, with boron trichloride [

111]. The sol-gel method is a wet chemical method for creating thin-film coatings. Its key benefits are the overall low cost of the procedure relative to more conventional processes such as CVD and PVD, as well as the ability to adapt the composition and properties of thin films to adjust the requirements of the anticipated application [

112].

Thin-film coating methods must fulfill the requirements of complete control of film thickness to be successfully used in integrated optics. As a result, thickness management is critical for thin-film development processes in general, and sol-gel is no exception. It has been indicated that the final thickness is primarily determined by coating speed, angle of inclination, and sol concentration. Besides, sol viscosity, density, and liquid-vapor surface tension can also influence the final heat-treated thickness [

113]. According to [

114], the coating process must be carried out in a cleanroom environment to acquire sol-gel thin films of high optical quality. In [

115], a three-step sol-gel process was established to make organic dye-doped thin films with customized porosity for applications in chemical sensing and optoelectronics. Moreover, sol-gel-derived ceramic films are also presented in [

116]. More significant works on the sol-gel method can be found here [

117,

118,

119,

120,

121,

122,

123,

124,

125,

126]. To understand the popularity of the sol-gel and other traditional methods, we have plotted the number of research papers published on the sol-gel method, CVD, and RF-sputtering from the year 1990 to 2021, as shown in

Figure 4. The data has been taken from the Scopus database, which is one of the authentic databases like Web of Science and Google Scholar. From 1990 to 2004, quite intensive research was conducted on CVD while the sol-gel method was still growing. After 2004, the sol-gel method gained more recognition for the deposition of high-quality thin films. The RF-sputtering method is also widely used in research but does not seem to be as prevalent as the other two methods.

Figure 4. The number of publications related to CVD, RF-sputtering, and sol-gel method, indexed in the Scopus database. The keywords “sol-gel dip coating method”, “Chemical vapor deposition” and “RF-sputtering” were used during the search.

2. Refractive Index Modification Methods

The refractive index (RI) of a material is a number that describes how the light will propagate through it. Light travels at different speeds in the materials having different RI, which can be changed by modifying the density of the material.

2.1. Ion Exchange Process

Ion exchange is a primeval method focused on replacing an ion existing in the glass (typically Na

+) with another ion (e.g., Ag

+, K

+, and Li

+) typically provided by a salt melt [

127]. It dates to the first era as a technique for painting glass: it seems that Egyptians previously utilized it in the sixth century to embellish plates and vessels with a brownish-yellow color. The Moors used this method to dye the window glass of their palaces in Spain a few centuries later. In the 1960s, the solidification of the glass surface by ion-exchange transformed into a routine industrial procedure. Since the early 1970s, the appropriateness of ion exchange technology for the development of optical WGs in glass has been known as the groundbreaking works of Izawa and Nakagome [

128] and Giallorenzi et al. [

129] demonstrated techniques to benefit from the upsurge in the RI of integrated optics created by replacing the Na

+ with another ion having higher electronic polarizability, for instance, silver (Ag).

Glass is a well-known optical medium, and glass WGs offer several benefits, notably inexpensive material costs, compliance with optical fibers, low propagation loss and birefringence, and good stability and durability. Ion exchange as a fabrication method offers convenience and cost savings because it does not require complex production equipment. It supports batch processing making it adaptable to a wide range of applications. The ion exchange method has also been shown to be suitable for the industrial manufacture of WG components; however, unique fabrication criteria for modules that will be used in the field must be met. After more than 10 years into ion-exchanged WGs, interest has steadily evolved, and basic demonstrations of the practicability of single-mode devices and the process’ adaptability have laid the groundwork for the technology’s prospects, such as a serious commercial production possibility frontier. Findakly examined the state of ion-exchanged glass WG available technology [

130].

2.2. Ion Implantation

Ion implantation has shown to be an effective method for manufacturing optical WGs in different substrates [

141,

142]. In the instance of light ions being inserted, the physical density of the substrate is decreased by the damage instigated by nuclear collisions during implantation. As a result, the region with a RI lower than the substrate can function as an optical barrier that allows the light confinement in a thin layer between the surface of the substrate and the optical barrier. However, this optical confinement can be somewhat weak, and the alleged tunneling effect may occur, resulting in the energy leakage of the propagating light. To diminish light leakage to the substrate through the optical barrier, multiple-energy implants are frequently employed to extend the barrier width [

143]. Heavy ions, on the other hand, may upsurge the physical density and polarizability of the substrate, which raises the RI of the implanted region bounded by the region with a lower RI, resulting in a typical optical WG. The exact precision of implantation depth and the number of doped ions employed are two main benefits of employing ion implantation. The implantation depth is proportional to the acceleration voltage, which is generally 10–100 keV, while the ion current may be used to measure the number of ions (called the dosage). The ion implantation process is complicated, and the readers who seek in-depth knowledge on this topic are referred to [

144].

2.3. Femtosecond-Laser Writing

Integrated optics can be more readily miniaturized and incorporated with micro-electronics resulting in accurate and exceedingly integrated systems, contrary to many optical fiber technologies. In 1996, femtosecond (fs) laser writing was first established and had been thoroughly investigated ever since [

147]. Due to its ability to swiftly and flexibly direct the inscription of the complex structures with satisfactory accuracy, fs-laser WG writing in the glass is an encouraging method for integrated optics [

148]. Photolithography and FIB micromachining, on the other hand, are slower. In addition, materials, including glasses [

149,

150], crystals [

19,

151], and polymers [

152,

153], WG structures can now be written on directly. Compared to the most popular techniques for the development of WG, fs-laser writing has the advantages of quick production, versatility in WG design, high three-dimensional accuracy, and easy integration of the resulting WG structures with optical fiber E-beam lithography and PECVD.

It is interesting to develop integrated photonics WG sensors that do not involve any etching or complex fabrication procedures. For that reason, the WG should be written near the surface of the substrate. In most previous studies [

154,

155,

156], the WGs were embedded inside the glass substrate via fs-laser writing. However, there are still a few reported studies on the laser-written WGs near the surface of the substrate [

157,

158,

159]. This situation is mostly due to the ablation of glass that happens near the surface while focusing. Writing near-surface WGs is inspired by the desire to allow light to interact with the ambient medium to create integrated sensors in glass chips. Fast fabrication, flexibility in WG design, high spatial precision (i.e., limited by beam quality, wavelength, and polarization), and simple integration of the manufactured WGs with fiberized modules are all advantages of fs-laser direct writing over the most common methods, EBL and PECVD.