The synthesis of tailored and highly engineered multifunctional pharmaceutical nanocarriers is an emerging field of study in drug delivery applications. They have a high surface-area-to-volume ratio, aiding the targeted drug’s bio-distribution and pharmacokinetic properties. Therefore, the characterization of nanocarriers is critical for understanding their physicochemical properties, which significantly impact their molecular and systemic functioning. To achieve specific goals, particle size, surface characteristics, and drug release properties of nanocarriers must be managed. This mini review provides an overview of the applications of non-destructive testing techniques (NDTT) to reveal the characteristics of nanocarriers, considering their surface charge, porosity, size, morphology, and crystalline organization. The compositional and microstructural characterization of nanocarriers through NDTT, such as dynamic light scattering, X-ray diffraction, confocal laser scanning microscopy, ultraviolet-visible spectroscopy, scanning electron microscopy, atomic force microscopy, and nuclear magnetic resonance spectroscopy, have been comprehensively reviewed. Furthermore, NDTT is only used to characterize physicochemical parameters related to the physiological performance of nanocarriers but does not account for nanocarrier toxicity. Hence, it is highly recommended that in the future, NDTT be developed to assess the toxicity of nanocarriers. In addition, by developing more advanced, effective, and precise techniques, such as machine vision techniques using artificial intelligence, the future of using NDTT for nanocarrier characterization will improve the evaluation of internal quality parameters.

1. Introduction

In recent years, nanotechnology has gained considerable application in the field of medicine and engineering. It studies and manages matter at the nanoscale level with diameters ranging from 1 to 100 nanometers [

1]. It deals with different nanoparticles derived from polymers, metals, non-metals, or combinations [

1]. These nanoparticles are employed in various applications, from electronics to drug delivery [

2].

The nanoparticles used for drug delivery, known as nanocarriers, offer several benefits, such as the ability to deliver hydrophobic and hydrophilic drug molecules, precision regarding the target, and a high level of stability [

3]. Nanocarriers are colloidal chemicals (drugs, pesticides, fertilizers, and plant growth promoters) that can modify their bioactivation and properties [

4]. They have a high surface-to-volume ratio, which can aid in the biodistribution and pharmacokinetics of the targeted compounds [

4]. Nanoparticles, nanospheres, nanoemulsions, nanocapsules, and nano-sized vesicular carriers, such as niosomes and liposomes, can all be considered as nanocarriers [

5]. Nanospheres are matrix particles in which pharmaceuticals are uniformly distributed, whereas nanocapsules contain a distinct polymeric membrane surrounding the chemicals of interest, such as drugs, proteins, and additives [

4,

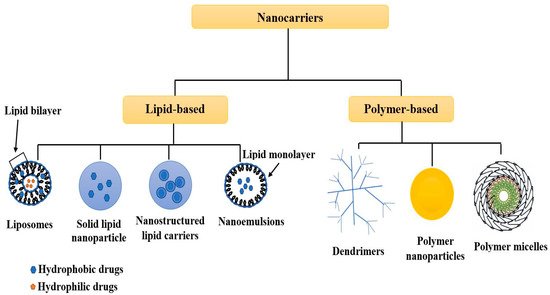

6]. Moreover, nanocarriers can be categorized into two types, as shown in

Figure 1, based on the constituents used for their manufacture: polymer-based or dendritic and lipid-based nanocarriers. Solid lipid nanoparticles, nanoemulsions, nanostructured lipid carriers, and liposomes are examples of lipid-based nanocarriers. On the other hand, nano-colloids, polymer micelles, dendritic branches, polymer vesicles, and polymer nanoparticles are polymer and dendritic branch-based nanocarriers [

4].

Figure 1. Schematic representation of different lipid-based and polymer-based nanocarriers.

Furthermore, it is essential to comprehend how our biological system will respond to nanocarriers. As particle size shrinks, surface area relative to volume increases, allowing for increased particle interaction with its surroundings [

7]. Consequently, nanocarrier size and surface area strongly influence the fate of nanoparticles within the body. When it comes to nanocarrier retention, distribution, absorption, and elimination, the lymphatic system and the blood capillaries play a significant role [

8]. The lymph nodes detect any foreign substance moving through the body as the fluids are reabsorbed into the blood. If the particles are larger, the immune system identifies them as foreign, and the macrophages consume them before expelling them from the body [

9]. This is a challenge for nanosized drug delivery systems; nevertheless, the clearance of the medication is also influenced by the drug’s particle size and surface features, which are equally as essential as the formulation of the drug. Hence, nanocarriers must regulate proper drug release properties, surface properties, and particle size to achieve specified goals. So, researchers need to use advanced characterization methodologies in the early stages of product development to correlate the product’s effects with their biological implications and to forecast the outcomes of therapeutic interventions [

10].

When it comes to pharmaceutical development, traditional characterizing methods, such as reverse phase high-performance liquid chromatography (RP-HPLC), typically necessitate destructive extraction procedures on small, nominally random product samples to document the product’s quality [

11,

12]. Such techniques are time consuming and frequently ineffective at ensuring zero-defect product quality because they fail to identify the effect of crucial process parameters on product quality features [

13]. Therefore, researchers proceeded forward and began characterization using non-destructive testing approaches.

Non-destructive testing techniques (NDTT) involve inspection, testing, or evaluation of materials, assemblies, or components for discontinuities or changes in attributes without altering their quality [

10]. Therefore, NDTT techniques do not destroy the sample being characterized, unlike destructive testing. However, in many circumstances, detecting a flaw or characterization of any sample necessitates the application of a combination of NDTTs [

14]. In order to safeguard the effectiveness of the evaluation, it is essential to have a good understanding of the background, benefits, and limitations of each NDTT [

15]. The NDTT commonly used to characterize nanocarriers are X-ray diffraction, ultraviolet-visible spectroscopy, scanning electron microscopy, dynamic light scattering, atomic force microscopy, confocal laser scanning microscopy, and nuclear magnetic resonance spectroscopy.

Table 1 represents different non-destructive techniques used to characterize nanocarriers and their attributes.

Table 1. Different non-destructive techniques used to characterize nanocarriers.

As previously mentioned, nanotechnology is a fast-increasing field of study, and many published works on nanocarrier characterization exist. However, just a few mention the NDTT. Most researchers have concentrated on their fundamentals instead of emphasizing the application of characterization approaches.

2. Non-Destructive Testing Techniques

The following section presents the compositional and microstructural characterization of nanocarriers through NDTT along with their working principles, such as X-ray diffraction, dynamic light scattering, confocal laser scanning microscopy, ultraviolet-visible spectroscopy, scanning electron microscopy, atomic force microscopy, and nuclear magnetic resonance spectroscopy.

2.1. X-ray Diffraction

2.1.1. Working Principle

X-ray diffraction (XRD) is an analytical technique that discloses important details about a crystalline substance’s lattice structure, such as crystallographic structure, chemical composition, bond angles, and unit cell diameters in natural and synthetic materials [

34]. The principle of constructive interference of X-rays is used in XRD, which requires a crystalline sample [

34]. A beam of X-rays is passed through the specimen and is scattered or diffracted by the atoms in the X-rays’ path. Using an appropriately positioned detector, the interference generated by X-ray scattering is seen, and the crystalline structure properties of the material are determined using Bragg’s law [

7]. According to Bragg’s law, the scattering angle is inversely proportional to the interplanar distance at a given wavelength [

35].

Using Bragg’s Law, the characteristics of dispersed X-rays reveal the crystalline material’s arrangement:

where n is an integer, θ is the scattering angle, d is the interplanar, and λ is the wavelength.

For crystalline and amorphous materials, sharp and broad diffraction peaks can be seen, with smaller crystallites forming broader peaks [

35]. The information obtained from an XRD pattern, as compared to the information obtained from other characterization techniques, allows researchers to determine whether their nanocarriers are uniformly sized or not. To confirm the identity of any analyte, the generation of a specific XRD pattern with characteristic peaks can be compared with XRD patterns from existing literature [

36].

2.1.2. Application

Sabbagh et al. [

37] published a work that used XRD (along with other techniques) to evaluate nanocarriers loaded with metronidazole (MET) made from chitosan (CS) and alginate (AlgNPs). The authors were able to gather a large amount of morphological data by overlaying the patterns of the XRD for CS-AlgNPs, pure MET, and MET-CSAlgNPs. The XRD pattern for pure MET revealed peaks at 2θ = 11.0° and 22.3°. The unloaded CSAlgNPs XRD pattern showed two large peaks at 2θ = 14.9° and 21.6°, suggesting the nanocarriers were amorphous. When these two patterns were compared to the MET-CS-AlgNPs pattern, it is clear that the peaks shown in the pure MET pattern were not present in the MET-CS-AlgNPs pattern. Sabbagh et al. [

37] determined that MET was effectively laden in the amorphous portion of the nanocarriers.

Similarly, in another study, XRD was used by Rachmawati et al. [

38] to characterize polylactic acid-based nanocarriers loaded with curcumin. The researchers overlaid the XRD patterns obtained for unloaded polylactic acid nanocarriers, pure curcumin, and polylactic acid nanocarriers loaded with curcumin. Pure curcumin’s XRD pattern showed sharp, high-intensity peaks, representing significant crystallinity. The peak intensities of nanocarriers were dramatically reduced, indicating lower crystallinity and a probable transfer into an amorphous phase of curcumin. From the results, the authors could determine that curcumin was successfully loaded into their produced polylactic acid nanocarriers.

2.2. Ultraviolet-Visible Spectroscopy

2.2.1. Working Principle

An ultraviolet-visible (UV-Vis) spectrophotometer is used to determine the absorption or transmission of light in opaque or transparent liquid substances [

39]. It compares the intensity of light reflected by a sample to the intensity of light reflected by a reference material. This is accomplished by passing a light beam through the particles dispersed in the liquid medium and then measuring the amount of light that remains in a detector [

39].

Nanocarriers are characterized by evaluating their unique absorption peaks caused by a phenomenon known as surface plasma resonance. Each constituent used to create a given nanocarrier will absorb a precise amount of light, like any other matter [

40]. A specific spectrum can be formed by utilizing this procedure for a particular fabrication, which may vary depending on the chemicals and contaminants found in the analyte [

40]. As a result, the nanocarriers’ purity or characteristics can be determined by comparing the obtained spectrum to reference spectrums in other literature.

2.2.2. Application

Pang et al. [

41] used a UV-Vis spectrophotometer to characterize starch-maleate nanocarriers loaded with curcumin (CurSM). They obtained spectra for each component used in their studies, such as CurSM, free curcumin, and starch malate. The author states that the peaks confirmed the presence of starch-maleate and free curcumin at 250 nm and 420 nm. Furthermore, because distinct absorption peaks for free curcumin were found to rely on the utilized solvent, the authors concluded that free curcumin attained tautomeric equilibrium with keto-enol and diketo forms.

Similarly, by observing a distinctive peak at 520 nm, Hung et al. [

42] proved the usefulness of UV-Vis spectroscopy in demonstrating the favorable loading of an anticancer drug into gold nanocarriers based on collagen. The UV-Vis technique was also beneficial for the characterization of gelatin-stabilized copper nanocarriers, according to Musa et al. [

43]. The authors reported that the intensity of the peak at 583 nm grew steadily when the concentration of gelatin used was increased. When the spectral profiles of gelatin-stabilized copper nanocarriers with different gelatin concentrations were superimposed, a noticeable red shift from 583 nm to 590 nm was observed, implying that the size of the copper nanocarriers increased with gelatin concentration.

2.3. Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy

2.3.1. Working Principle

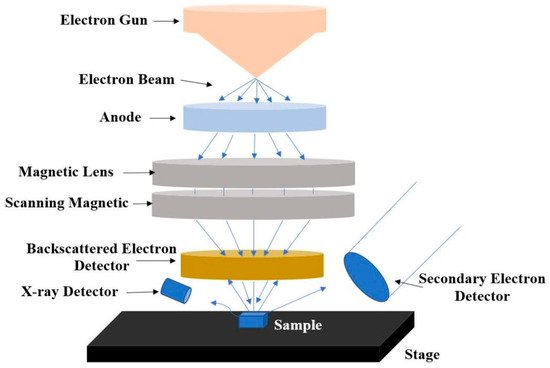

A scanning electron microscope (SEM) images a sample by scanning it in a raster scan pattern with a high-energy electron beam [

34]. The interaction of those electrons with the atoms in the sample produces signals that carry information about the sample’s composition, surface topography, and other qualities, such as electrical conductivity [

44]. SEM photographs of a sample surface can be very high resolution, revealing features as small as 1 to 5 nm [

39]. Electrons created by a source are accelerated in a field gradient under a vacuum. The beam is focused onto the specimen via electromagnetic lenses. The specimen emits several signals because of its reaction with the electron beam. A detector catches the secondary electrons, and the intensity of these secondary electrons is compared to the scan of primary electron beam to create an image of the sample surface. Finally, the image is displayed on a computer monitor [

39].

Figure 2 shows the major components of an SEM.

Figure 2. Schematic representation of a scanning electron microscope.

The elemental analysis or chemical characterization of a material is performed using energy-dispersive X-ray spectroscopy (EDS or EDX). It is a type of X-ray fluorescence spectroscopy that investigates a sample through interactions between electromagnetic radiation and matter, examining X-rays generated by the matter as a result of hitting the charged particles [

34]. It provides a wide range of characterization capabilities because of the fundamental premise that each element has a unique atomic structure, which allows X-rays indicative of an element’s atomic structure to be separated from others. Researchers can learn a lot about the elemental composition of nanocarriers from the combined results of a single SEM-EDX investigation [

45].

2.3.2. Application

Rezaei et al. [

46] used SEM to investigate the structural properties of nanocarriers derived from hyaluronic acid-functionalized with lipoic acid and chitosan (HACSLA-NPs). These nanocarriers had a diameter ranging from 50 to 130 nm and an orderly distribution and arrangement. The identity of HACSLA-NPs was revealed by further EDX microanalysis, which revealed distinct peaks in the EDX spectra, indicating the existence of NO and hydrogen components. Lipoic acid is made up of Sulphur (S), which was confirmed by peaks and the favorable loading of lipoic acid. The authors were able to describe nanoparticles using SEM-EDX without inflicting any damage to the materials.

Similarly, Musa et al. [

43] reported SEM photos of gelatin-based copper nanoparticles. According to the author’s SEM image analysis, the gelatin matrix securely sustained the copper nanoparticles. These results demonstrated that as the concentration of the gelatin was increased, the mean diameters of the nanoparticles gradually dropped, resulting in the particles becoming smaller. This is an anticipated result based on the findings obtained from the various characterizations carried out on the copper nanoparticles.

This entry is adapted from the peer-reviewed paper 10.3390/biophysica2030016