1. Introduction

Biocatalysis can be defined in a broad sense as the mediation of chemical reactions by means of biological systems, including isolated enzymes, whole cells or cell-free extracts [

1]. As recently stated by Sheldon and Brady [

2], biocatalysis agrees with ten of the twelve principles of green chemistry, thus being the most sustainable and environmentally friendly approach for the preparation of high added value molecules [

3,

4,

5], even at industrial scale [

6,

7].

Among the six different types of biocatalysts according to the type of reaction they catalyze, oxidoreductases (EC 1) are, together with hydrolases, the most employed family of enzymes with synthetic purposes. This large group of enzymes, with 22 types of oxidoreductase subtypes, are involved in all type of redox reactions, catalyzing oxidation and reductions processes [

8,

9,

10,

11]. The application of oxidoreductases to obtain valuable building blocks is a current area of interest in organic synthesis, due to the mild reaction conditions and oxidants/reductants required for their function, combined with the generally exquisite stereoselectivity afforded by this type of catalysts.

Water is the natural medium in which enzymes perform their activity. Due to its unique properties, water can be considered an environmentally friendly solvent, which represents an advantage over other solvents, but sometimes its use in organic syntheses catalyzed by enzymes presents some drawbacks. Firstly, water is a very high polar solvent, so the application of enzymes for synthetic purposes is often hindered by the low solubility of many organic substrates and products in aqueous buffers, leading to substrate concentration restrictions [

12]. In addition, water can lead to undesired side reactions (hydrolysis), which also leads to lower yields than in absence of water.

In order to circumvent these problems, different non-conventional media have been applied in biocatalysis, since the discovery in the 1980s [

13,

14] that biocatalysts can perform their activity in organic solvents [

15], with some advantages over the use of aqueous medium. Thus, organic solvents have been widely exploited in reaction catalyzed by enzymes, but it has to be considered that their application presents several environmental disadvantages, due to their inherent toxicity and the problems derived from their flammability or explosion risks. For these reasons, green solvents approaches are required [

16] in order to minimize the negative impact of the solvent media in the

E factor of the biocatalytic process [

17]. One way to reduce the toxicity of organic (co)solvents has been developed by using biobased solvents [

18,

19,

20,

21], that is, solvents obtained from natural renewable sources which present unique characteristics. Typical examples shown in this review are cyclopentyl methyl ether (CPME), as well as 2-methyltetrahydrofuran (2-MeTHF), which are well established as valuable (co)solvents in several biotransformations, including those catalyzed by redox enzymes. Moreover, Guajardo and Domínguez de María have also demonstrated last year that Cyrene

TM is a promising biosolvent in lipase-catalyzed transformations [

22], but the development of more environmentally friendly reaction media is not only circumscribed to organic solvents, as other solutions have also been applied. Thus, supercritical solvents (CO

2) have appeared as a promising alternative to organic solvents [

23,

24,

25], but almost all the examples using liquid CO

2 in biocatalyzed processes have been performed in reactions using hydrolases. Matsuda et al. have recently started to use CO

2-expanded biobased liquids as a green alternative for lipase-catalyzed biotransformations [

26]. Finally, neoteric solvents have appeared as valuable reaction media. Thus, several reviews cover the application of ionic liquids (ILs) as (co)solvents in biocatalysis [

27,

28,

29,

30]. These compounds are salts containing poorly coordinated ions that are liquid below 100 °C, normally at room temperature, the so-called room temperature ionic liquids (RTILs). RTILs have been used for biocatalysis purposes since the 2000s. They present low or no vapor pressure, low flammability, thermal robustness and are able to stabilize enzymes and solubilize most of the substrates. But RTILs presents some drawbacks, due to their environmental effect, accumulation in the medium and toxicity. By this reason, a more environmentally approach has been developed in the last few times by using deep eutectic solvents (DESs), compounds formed by the combination of a hydrogen-bond donor with a hydrogen-bond acceptor [

31,

32,

33].

2. Biocatalyzed Redox Processes at Neat Conditions

An attractive approach towards sustainable biocatalytic processes is to carry out enzymatic reactions directly in the substrate(s) without the addition of any solvent, since high productivity, competitiveness and reduced waste can be achieved [

12]. There are several solvent-free systems including redox enzymes described in literature, using either whole-cells or isolated biocatalysts [

34,

35,

36,

37]. In all these examples, both the immobilization of isolated enzymes and/or the addition of a small amount of water (‘structural water’) were required to maintain the activity and flexibility of the biocatalysts. In some cases, the hydrophility of the (co)substrate showed a strong effect on enzyme catalysis, causing the stripping of the essential enzyme-bound water [

38].

Alcohol dehydrogenases (ADHs) are oxidoreductases that catalyze the reversible reaction between alcohols and carbonyl compounds (aldehydes and ketones) through a redox process. In order to achieve these reactions, a nicotinamide cofactor, NAD(P)H, is required to perform the electron transfer from/or to the substrate or electron source [

39,

40,

41]. ADHs can be employed as free enzymes or as whole-cells systems, which present some advantages as they are cheaper than isolated enzymes, easier to handle and present an efficient internal cofactor regeneration system. In contrast, lower yields and selectivities can be obtained due to competitive processes in the cell system and solubility and productivity issues can also occur. Whole-cells expressing ADHs have been demonstrated to work on micro-aqueous systems in organic solvents [

42] and neat substrates [

43] for the reduction of a series of ketones.

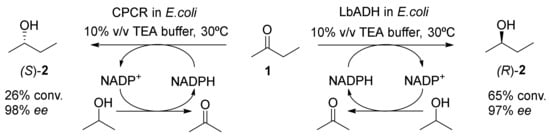

The applicability of ADHs in neat substrate systems has also been proved in the enantioselective synthesis of 2-butanol (

2) in which a continuous micro-aqueous system was applied to minimize the time-dependent racemization of the process (

Scheme 1) [

44]. In this case, the reaction medium consisted on a mixture of the substrate 2-butanone (

1) and the 2-propanol used for NADPH cofactor regeneration. The system was tested with two stereocomplementary enzymes expressed in

Escherichia coli, the ADH from

Lactobacillus brevis (LbADH) and from

Candida parapsilosis (CPCR), enabling the production of both enantiomers (

R)- and (

S)-

2, respectively. Optimizing the flux and so the residence time, the enantiomeric excess (

ee) of the product could be increased while reducing the substrate conversion.

Scheme 1. Enantioselective biocatalytic synthesis of (R)- and (S)-2-butanol with E. coli cells expressing ADHs in a continuous micro-aqueous solvent-free reaction system.

On the one hand, E. coli cells expressing LbADH yielded the (R)-2 with a 65% conversion starting with 0.1 M of ketone 1, attaining a 97% ee and high space-time yields of 2278 g/L day. On the other hand, using CPCR a 26% conversion of (S)-2 with 98% ee was achieved from 5.0 M of 1, leading to a space-time yield of 461 g/L day.

The use of isolated biocatalysts was also tried in the reduction of

1 in neat substrate by using the ADH evo-1.1.200 and 1,4-butanediol (1,4-BD) as a sacrificial electron donor [

38]. However, although a linear product formation of

2 over 10 days was observed, very low conversion rates (<1%) were achieved. This fact was attributed to the high hydrophility of 1,4-BD making the enzyme to lose flexibility and more apolar solvents, such as methyl

tert-butyl ether and toluene, were required to achieve higher conversions.

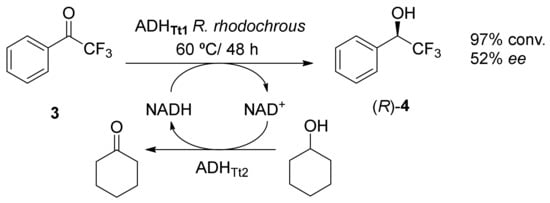

Rhodococcus rhodochrous cells harboring ADHs were also proved to work in neat substrate as reported in the reduction of 2,2,2-trifluoroacetophenone (

3) to α-(trifluoromethyl)benzyl alcohol (

4), using cyclohexanol (1:1

v/

v) for cofactor regeneration (

Scheme 2) [

45]. In this case, the expression of a thermophile enzyme enabled the heat-pretreatment of cells and the performance of reactions at 60 °C, resulting higher conversions due to an increase in the membrane permeability and the inactivation of other indigenous enzymes. Overall, high product concentration (3.6 M) and productivity (190 mol

4/kg cells h) were achieved in 48 h, although with low stereoselectivity (52%) in the formation of (

R)-

4.

Scheme 2. Whole-cell bioconversion of 2,2,2-trifluoroacetophenone (3) to α-(trifluoromethyl) benzyl alcohol (R)-4 using ADHs and cyclohexanol oxidation for cofactor recycling.

Besides bioreduction processes catalyzed by ADHs, other reactions employing neat conditions have been developed employing oxidative enzymes. Thus, recent examples with the newly discovered fungal unspecific peroxygenases (UPOs) have also been reported by Hollmann’s group [

46,

47]. UPOs are promising enzymes able to perform a wide set of oxyfunctionalization reactions acting as ‘self-sufficient’ monooxygenases only requiring H

2O

2 for activation [

48,

49]. These enzymes are functionally similar to the well-known P450-monooxygenases, but their higher stability due to their extracellular nature and the non-necessity of expensive cofactors and auxiliary enzymes for catalysis, make peroxygenases more attractive for synthetic chemistry. However, the dosage of H

2O

2 is one of the limiting factors in the peroxygenase-catalyzed reactions, since a high concentration of this oxidant can inactivate the biocatalysts. For that reason, the peroxide needs to be continuously supplied or

in situ generated to keep its concentration in limits enough to get a good activity without negative impact in their stability [

50,

51]. UPOs present also the advantage of being able to work with organic peroxides as co-substrates, thus expanding their catalysis to non-aqueous reaction media. These extracellular enzymes required immobilization to be applied as isolated biocatalysts and the low activity recovery after this procedure is the major challenge on this kind of processes.

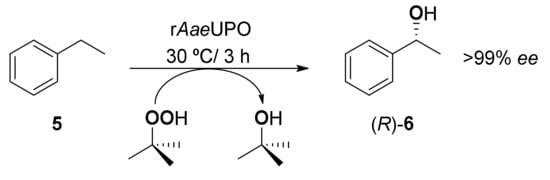

The first evidence of the use of peroxygenases in neat conditions was in the selective hydroxylation of ethylbenzene (

5) using the recombinant peroxygenase from

Agrocybe aegerita (r

AaeUPO) (

Scheme 3) [

46].

tert-Butyl hydroperoxide (

tBuOOH) was used as co-substrate and oxygen donor due to the higher solubility in hydrophobic media, and was found to be a milder oxidant compared to H

2O

2. The system was demonstrated on semipreparative scale (250 mL) yielding 1.25 g of the enantioenriched (

R)-phenylethanol (

6, 98%

ee) within 3 h of reaction where the

tBuOOH was continuously supplied to avoid enzyme inactivation. Under these conditions, authors claimed that the biocatalyst was able to perform 90,000 total turnover numbers (TTN).

Scheme 3. Stereoselective hydroxylation of ethylbenzene to (R)-phenylethanol using the recombinant peroxygenase from Agrocybe aegerita (rAaeUPO) and tert-butyl hydroperoxide in neat substrate.

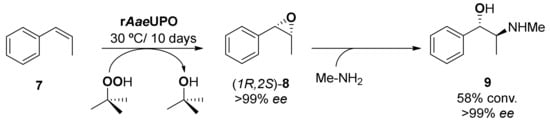

The same enzyme was later proved to selectively epoxidize a set of styrene derivatives in the neat substrates [

47]. Thus, it was applied to build an interesting chemoenzymatic process to afford the valuable drug (pseudo)ephedrine

9 (

Scheme 4). A first epoxidation step of

cis-β-methylstyrene (

7), with a high stereoselectivity (>99%) and product concentration (360 mM), yielded (

1R,2S)-

8, that was chromatographically purified. The oxirane-ring was chemically opened with methyl amine to form the desired compound

9 with a good overall yield (58%).

Scheme 4. Chemoenzymatic process for the synthesis of (pseudo)ephedrine starting by enzymatic epoxidation of cis-β-methylstyrene in neat substrate and following by the spontaneous oxirane ring-opening employing methylamine.

3. Application of Bio-Based Solvents in Redox Reactions Catalyzed by Enzymes

The ideal implementation of solvent-free chemical processes is not always possible and usually (co)solvents are needed to improve mass and heat transfer, reaction rates, selectivities or even the position of the chemical equilibria. However, the concern about their high environmental impact and waste generation is driving the attention to search for greener alternatives, such as solvents derived from biomass. In this context, cyclopentyl methyl ether (CPME), 2-methyltetrahydrofurane (2-MeTHF) and other solvents have emerged as promising ecofriendly solution in redox enzyme catalysis, replacing other traditional solvents in biocatalytic processes [

18,

19,

20,

21]. It has to be considered that these solvents present nowadays some drawbacks, as their high price and scarce availability, a not assessed toxicology and that they are still unknown solvents with a lack of data about them. Bio-based solvents have been widely employed with hydrolases, but only examples with CPME and 2-MeTHF have been found in reactions catalyzed by oxidoreductases.

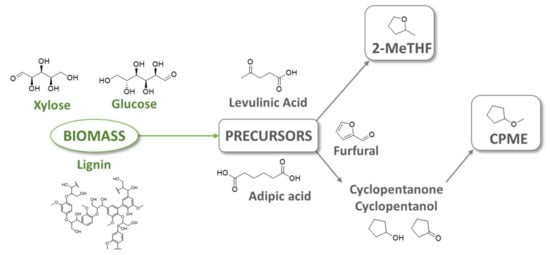

Very recently, the suitability of CPME as solvent for biotransformations has been pointed out. This solvent presents advantages such as a low solubility in water (1.1 g CPME/100 g) allowing two liquid phase systems, low toxicity and negligible peroxide formation rate. Moreover, it presents manageable boiling point (106 °C), narrow explosion ranges and stability to harsh acid or basic reaction conditions. Although nowadays the synthesis of CPME is based on petrochemicals, a biogenic synthetic pathway could be contemplated through the use of biosynthesized precursors (cyclopentanone or cyclopentanol) obtained from biomass-derived furfural or adipic acid (

Figure 1) [

19,

52].

Figure 1. Biogenic pathways options for the synthesis of bio-based CPME and 2-MeTHF.

However, these biogenic routes do not assure a sustainable process in the synthesis of these solvents and life-cycle assessment (LCA) are necessary to study the impact of each particular example. In addition, it has to be taken into account that processes performed in mixtures CPME/aqueous buffer occur in biphasic systems, which can present some inconveniences due to mass transfer issues between the two reaction phases.

In 2015, CPME was employed as cosolvent in the reduction of a set of activated alkenes catalyzed by different enoate reductases [

53]. These flavin-dependent enzymes are able to catalyze the asymmetric hydrogenation of C=C double bonds, yielding the corresponding chiral reduced compounds [

54,

55] and requiring nicotinamides as cofactors in order to perform their activity. Unfortunately, poor conversions (<10%) were achieved when using CPME at 20%

v/

v during the optimization of reaction conditions for the reduction of six compounds, where the enzyme did not show a sufficient stability towards solvent such as 1-butanol and ethers. Successful examples of the use of CPME as solvent in bioredox processes have been reported for the selective synthesis of chiral valuable amines by the novel imine reductases (IREDs). IREDs are NADPH-dependent oxidoreductases that catalyze the asymmetric reduction of imines and iminium ions to the corresponding chiral secondary and tertiary amines, employed in biocatalysis since 2010 [

56,

57].

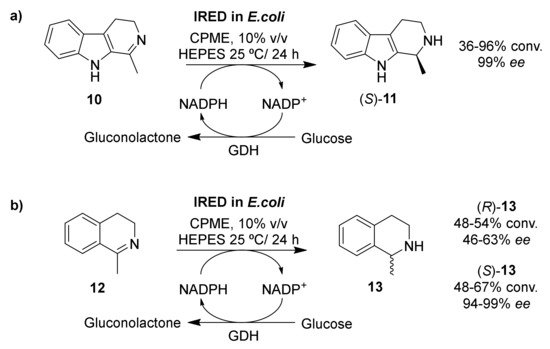

E. coli cells expressing IREDs have been employed in micro-aqueous systems for the selective reduction of β-carboline harmane (

10) and 1-methyl-3,4-dihydroisoquinoline (

12,

Scheme 5) [

58]. The biocatalysts only showed activity in methyl

iso-butyl ketone and CPME among the organic solvents tested and the buffer concentration was optimized to 10%

v/

v. Overall results showed that most of the screened IREDs achieved moderate (>46%) to excellent (>94%) enantioselectivities in the synthesis of (

S)-

11 and both enantiomers (

R)- and (

S)-

13. This system opens the possibility to expand the substrate scope of IREDs towards more hydrophobic molecules.

Scheme 5. Micro-aqueous systems in CPME using E. coli cells expressing IREDs for the asymmetric reduction of: a) β-carboline; and b) isoquinoline.

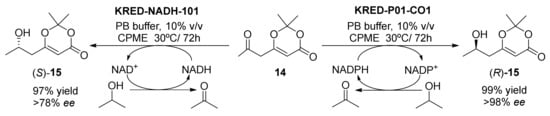

Moreover, CPME has also been applied as cosolvent in ADH-catalyzed reductions, where a higher yield and stereocontrol in the reactions were achieved compared to their traditional synthetic alternatives. One of these examples is the synthesis of the building block molecule β-hydroxydioxinone

15 by the ADH-catalyzed enantioselective reduction of β-ketodioxinone

14 (

Scheme 6) [

59]. Interestingly, the use of ethereal solvents such as THF, 2-MeTHF, CPME and MTBE in 5–25%

v/

v proportions, increased the yield of the process from 68% in buffer phosphate pH 7 to the highest 98% achieved with 10% CPME. In addition, using this cosolvent the catalyst loaded could be reduced from 5% weight to 1%, while maintaining the same high yields. Both (

R)- and (

S)-enantiomers where accessible to a large scale (20 g) with high 97–99% yield and stereoselectivities using stereocomplementary commercial engineered ADHs from the Codexis Ketoreductase Screening Kit in 10%

v/

v CPME. In addition, the system could be expanded to the synthesis of more than 20 other β-hydroxydioxinones with overall excellent yields (>90%) and enantioselectivities (>90%

ee), widening the substrate scope and giving access to new molecules whose synthesis was not possible before in a stereoselective manner.

Scheme 6. Enantioselective reduction of β-ketodioxinones by ADHs to both enantiomers of β-hydroxydioxinones using isopropanol as sacrificial electron donor.

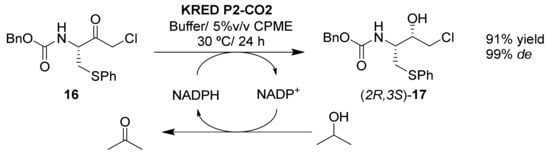

CPME has also been selected as cosolvent due to the higher yield achieved in the bioreduction step of the chemoenzymatic synthesis towards the anti-HIV drug Nelfinavir [

60]. The process consisted on the chemical preparation of an α-chloroketone

16 and its subsequent stereoselective reduction catalyzed by ADHs to (2

R,3

S)-chlorohydrin

17 (

Scheme 7), which is a key-intermediate in the synthesis of Nelfinavir. Among the commercial enzymes tested, two showed the desired stereoselectivity towards the enantiomer of interest and the addition of 5%

v/

v CPME as cosolvent maximized both conversion (99%) and stereoselectivity (99%

de). The higher yield and stereocontrol of this biocatalytic method is the main advantage over the classical reduction methodologies.

Scheme 7. Stereoselective bioreduction of α-chloroketone to (2R,3S)-chlorohydrin 17 by KREDs in the presence of 5% CPME as cosolvent. Cofactor recycling was performed using the isopropanol-acetone oxidative cycle.

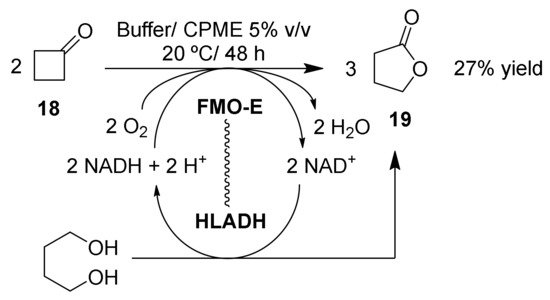

Another example of micro-aqueous system in CPME is the convergent cascade affording γ-butyrolactone

19 as a model lactone product, starting from cyclobutanone (

18) and butane-1,4-diol (

Scheme 8) [

61].

Scheme 8. Convergent cascade reaction for the synthesis of γ-butyrolactone by fused FMO-E and HLADH using CPME as cosolvent.

Herein, an elegant solution to make enzyme-coupled cofactor regeneration possible in low-water media by fusing two enzymes (monooxygenase FMO-E and alcohol dehydrogenase HLADH) to minimize the “cofactor travel distance” avoiding the nicotinamide cofactor degradation by organic solvents is proposed. A study of the solvent effect showed that the ethereal solvents such as MTBE and CPME were suitable solvents resulting in about 27% yield, while in other lower log P value solvents tested (acetonitrile, isopropyl alcohol and THF) there was not product formation after long reaction times. This is another example in which the higher hydrophilicity of the solvent strongly affected the substrate conversion due to the stripping of the essential enzyme-bound water and decreasing protein flexibility.

In line with CPME, 2-MeTHF has also been proposed as an eco-friendly solvent for different biocatalyzed redox processes, since it usually performs like traditional solvents such as THF but with better characteristics. Besides its attractive physical and chemical properties such as its low miscibility with water, low boiling point and the possible biosynthesis from biomass-derived furfural or levulinic acid (

Figure 1), preliminary studies shown also its fast (bio)degradation and low toxicity and it has already been approved for its use in the pharmaceutical industry [

18,

62].

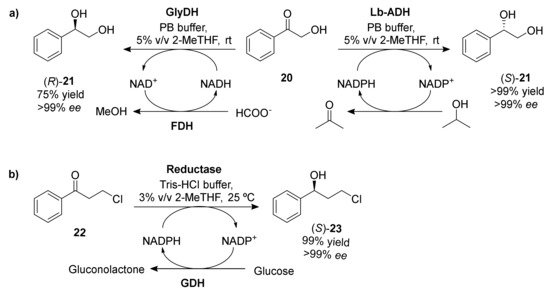

The use of 5%

v/

v of 2-MeTHF in phosphate buffer pH 8 was demonstrated to be an efficient alternative to DMSO and MTBE in the lyase-catalyzed reaction towards chiral α-hydroxy ketones, leading to a diminished

E factor in the process [

63]. This biocatalyzed reaction was later combined in a one-pot cascade procedure with ADHs and glycerol dehydrogenase (GlyDH) for the synthesis of α-aryl vicinal diols (

Scheme 9a) [

64]. After optimization, high yields (75–99%) and excellent enantioselectivity (>99%

ee) for both the (

R)- and (

S)-

21 were achieved in the bioreduction of the α-aryl-2-oxo-1-hydroxy ketone

20, using LbADH and the glycerol dehydrogenase from

Cellulomonas sp. (GlyDH), respectively. In addition, the methodology was extended to more challenging aromatic aldehydes like furfural, for the synthesis of chiral furan-1,2-diols again with high yield (87%) and enantioselectivity (>99%

ee). The suitability of using 2-MeTHF as cosolvent (3%

v/

v) in whole-cell biotransformations was also demonstrated in the conversion of 3-chloro-1-phenyl-1-propanone

22 to (

S)-3-chloro-1-phenylpropanol

23 [

65], employing recombinant

E. coli cells containing the

Saccharomyces cerevisiae YOL151W reductase and glucose dehydrogenase for the NADPH cofactor regeneration in Tris-HCl buffer (pH 7.5) (

Scheme 9b). The system showed high efficiency with a 99% yield and complete enantioselectivity for the formation of (

S)-

23.

Scheme 9. Biocatalyzed enantioselective reductions of a) 2-hydroxy-1-phenyl-1-ethanone (20), and b) 2-chloro-1-phenyl-1-propanone (22) in presence of 3–5% (v/v) 2-MeTHF as cosolvent.

Table 1 summarized the biocatalysts employed in presence of CPME and 2-MeTHF for bioreduction and biooxidation processes.

Table 1. Overview of biotransformations catalyzed by oxidorreductases in the presence of different proportions of CPME and 2-MeTHF.

|

Biocatalyst

|

Solvent (% v/v)

|

Yield (%)

|

ee (%)

|

Reference

|

|

Enoate reductases

|

CPME 20% v/v

|

<10

|

0–99

|

[53]

|

|

Imine reductases

|

CPME 90% v/v

|

36–96

|

46–99

|

[58]

|

|

ADH

|

CPME 10% v/v

|

>90

|

>90

|

[59]

|

|

ADH

|

CPME 5% v/v

|

99

|

99

|

[60]

|

|

Monooxygenase + ADH

|

CPME 5% v/v

|

27

|

-

|

[61]

|

|

Alcohol and glycerol dehydrogenases

|

2-MeTHF 5% v/v

|

75–99

|

>99

|

[64]

|

|

Saccharomyces cerevisiae YOL151W Reductase

|

2-MeTHF 3% v/v

|

99

|

>99

|

[65]

|

4. Deep-Eutectic Solvents in Bioreductions/Biooxidations

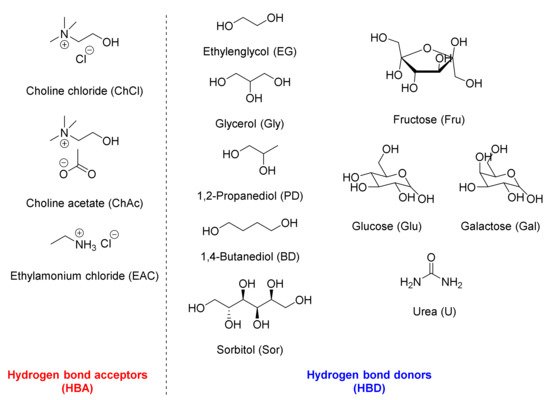

Deep eutectic solvents (DESs) are liquid compounds obtained by mixing a hydrogen bond donor (HBD) with a hydrogen bond acceptor (HBA) at a determined molar ratio at high temperature (50–80 °C). After stirring for some hours a liquid is formed, which maintains this state even after cooling down at room temperature. The hydrogen bonds formed reduced the overall melting point, forming the eutectic mixture which can be employed without further purification, representing an advantage as the synthesis of DESs is a waste-free procedure. HBAs more typically employed are quaternary ammonium salts, as choline or ethylamonium salts, whereas different types of hydrogen bond donors can be employed in the preparation of these liquids (Figure 2), typically including polyols as ethylenglycol (EG), glycerol (Gly), xylitol or sorbitol (Sor); organic acids such as oxalic, malic, levulinic or malonic acid; sugars as glucose (Glu), fructose (Fru) or galactose (Gal), and other compounds such as urea (U) or acetamide. When the DESs are formed by natural components, including sugars, aminoacids or polyols, they can be also called Natural Deep Eutectic Solvents (NADESs).

Figure 2. Structure of the components of the (NA)DESs described in the present revision.

Apart from their easy preparation, DESs present a wide set of advantages, including a high biodegradability, non-volatility, non-flammability and low toxicity [

66,

67]. By these reasons, DESs have constituted a greener alternative as (co)solvents to develop asymmetric catalytic transformations. In addition, it is possible to modify the structure of these solvents in order to tune their physico-chemical properties, thus being in principle possible to design DESs for specific applications.

Seminal work in the field of biocatalyzed reactions in presence of DESs was developed by Kazlauskas et al. in 2008 [

68], employing a set of choline chloride-based solvents in different processes catalyzed by hydrolases. Since them, DESs have been widely employed as solvents or cosolvents in enzymatic catalysis [

69,

70,

71]. As usual, most of the examples of biocatalyzed reactions involving DESs have been catalyzed by hydrolases, as this type of enzymes are able to carry out their activity in several non-aqueous media. But the application of DESs is not only restricted to hydrolysis or synthetic processes, being described some other examples with dehalogenases [

72], lyases [

73] and also with oxidoreductases [

74,

75].

Apart from the inherent positive effect of employing DESs as (co)solvent in catalytic processes, due to their environmentally friendly properties, these compounds usually can present a further benefit on the biocatalyzed reactions, by increasing the activity and/or the selectivity of the processes.

This entry is adapted from the peer-reviewed paper 10.3390/molecules25133016