Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Industrial

|

Engineering, Manufacturing

The wire harness assembly process is a complicated manufacturing activity, which is becoming more complex because of the evolving nature of mechatronic and electronic products that require more connectors, sensors, controllers, communication networking, etc.

- wire harness

- assembly

- collaborative robots

- ergonomics

1. Introduction

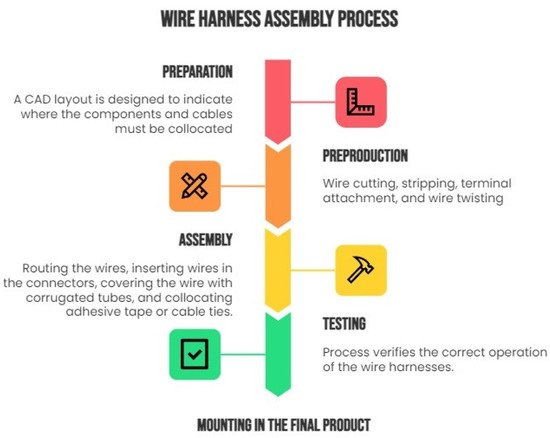

Wire harnesses join cables from different electrical equipment. Their assembly has not changed over time, even with the progress of manufacturing technology [1,2]. The wire harness assembly process is a complicated manufacturing activity, which is becoming more complex because of the evolving nature of mechatronic and electronic products that require more connectors, sensors, controllers, communication networking, etc. Moreover, most of their assembly tasks are done manually [2,3]. Heisler et al. [4] indicated that 90% of the wire harness assembly process tasks are done manually. The steps needed to manufacture a generic wire harness are presented in Figure 1. For the scope of this work, the process only focuses on manufacturing a wire harness, including tasks such as strapping its different wires to a supporting structure and adding plugs to its wires.

Figure 1. Steps in a Generic Wire Harnesses Assembly Process.

A collaborative robot (cobot) can perform multiple tasks to assist humans. Cobots work hand-to-hand with employees to achieve a job; for this reason, they are dependent on them in an industrial process [5,6]. Using a cobot could decrease the number of tasks that an employee will perform and improve the quality of the process at hand [7]. Cobots can reduce the physical and mental strains in human work. Moreover, a human–robot assembly process is a cost-effective solution between a manual and a completely automated assembly operation [8].

Assembly is a manufacturing process. It is a procedure for obtaining a final product through sequential tasks and sub-assemblies. An assembly process needs to be flexible, and humans are considered the optimal production resource for this kind of manufacturing process. However, with the new advances in (collaborative) robotics technology, the combination of humans and robots is now possible in assembly processes [9].

The advantages of a collaborative assembly process are mixing the flexibility, creativity, and skill of quickly making decisions of humans with cobots’ accuracy, repeatability, and payload [10,11,12]. Another advantage is the reduction in repetitive tasks that generate fatigue in humans producing a reduction in quality and increasing the cost of production [13].

When a collaborative assembly process is carried out, the essential objectives are obtaining operational efficiency, reducing production costs, and increasing the production rate. A critical element in this human–robot integration is selecting and allocating the tasks between humans and cobot(s) [9].

The main barrier to implementing automation solutions in the wire harness assembly process is that cobots have problems working with flexible materials, such as ‘cables’, because of the high variety of alternatives in their types, shapes, sizes, and lengths [7,14]. Moreover, the complexity, the high number of parts, and the absence of technological solutions are barriers to implementing automation solutions in the wire harness assembly process [2,15]. The disadvantages of manual work can mainly be related to low productivity, especially in large productions. In some cases, the effort required to teach a robot/cobot to perform a very complex task may not be worth it [4].

2. State-of-the-Art of the Wire Harness Assembly Process

2.1. Latest Advances in the Wire Harness Assembly Process Supported by Collaborative Robots

Heisler et al. [4] in their paper: “Optimization of Wire Harnesses using Human-Robot Collaboration”, did not find any automation solution covering the entireness of the wire harness assembly process for mass production, and they concluded that further research and technological developments are required in this manufacturing process. The only wire harness assembly tasks currently being supported by an automation solution are cable-routing and mating electric connectors.

The mating tolerance is the distance required for successful mating between the female and male connectors. In the paper: “Tolerance Dataset: Mating Process of Plug-in Cable Connectors for Wire Harness Assembly Tasks”, Yumbla et al. [17] presented a study of the mating tolerance for seventy different types of terminals for wire harnesses. Their objective was to determine the tolerance for different types of connectors. It is essential to know the number of pins, thicknesses, lengths, and shapes of the connectors for this purpose. They also determined that it is crucial to consider the corner shape. They developed a dataset that can be used to design and select the right robotic manipulator control for a robot. They concluded that their dataset, obtained using a CAD system, has a good tolerance [17]. A related study, titled: “Robotic Wire Pinning for Wire Harness Assembly Automation”, was developed by Tunstel et al. [13] using a cobot to establish a possible automation solution to insert a wire in an electrical terminal.

Another study by Yumbla et al. [18], titled: “Reposition and Alignment of Cable Connectors Using a Vibration Plate Manipulator for Wire Harness Assembly Tasks”, proposed using a vibrating plate to align the cable and the connector for the wire harness assembly process. Furthermore, they demonstrated that the proposed vibrating plate could move the connector to the desired position. The accurate pose is critical for a successful docking process in the wire harness assembly process.

Nguyen and Yoon [19], in “A Novel Vision-based Method for 3D Profile Extraction of Wire Harness in Robotized Assembly Process”, developed a method to determine a wire harness profile using a computer vision system to pick and collocate a wire harness in the correct position. Similar research was conducted by Kicki et al. [20] in “Tell Me, What Do You See?—Interpretable Classification of Wiring Harness Branches with Deep Neural Networks” to identify different types of wire harnesses with a computer vision system and neural networks to guide a cobot in the wire harness assembly process. They designed algorithms to classify the type of wire harness. Moreover, they obtain a colour map where the most illuminated regions are the critical parts where a wire harness is located in an assembly board, which could be used to guide a cobot. The third paper by Yumbla et al. [21], “Preliminary Connector Recognition System based on Image Processing for Wire Harness Assembly Tasks”, presents a computer vision system that identifies the final connectors of a wire harness, but they did not do any other task related to the wire harness assembly process.

Trommnau et al. [2], in their investigation: “Overview of the State of the Art in the Production Process of Automotive Wire Harnesses: Current Research and Future Trends”, concluded that the tasks with higher automation potential in the wire harness assembly process are wire routing, wire insertion, cable tie colocation, and adhesive taping. Nevertheless, these tasks need further research and technological developments to realise a viable and feasible automation solution for the industry.

Meanwhile, Heisler et al. [22], in “Automatization of the Cable-Routing-Process within the Automated Production of Wiring Systems”, made an automation solution where a cobot routed a cable in a wire harness assembly board. The wires were cut and crimped previously. Their process was the following: (a) to pick the first cable end; (b) to pick the second cable end; (c) to plug in the first contact; (d) to route the cable; and (e) to plug in the second contact. They concluded that integrating a collaborative robot in a cable-routing process is possible and that the process could be optimised.

When Román Ibáñez et al. [7] did their literature review on “Collaborative Robotics in Wire Harnesses Spot Taping Process”, they found no collaborative solution to incorporate a cobot in the wire harness assembly process. They proposed a solution where the employee can work on two-wire harness assembly boards simultaneously. His/her task is to collocate the wire harnesses on the board, and a cobot will collocate the spot taping. They proposed that a cobot makes the taping because it will not require moving the wire harness in this task. After all, it is challenging for a cobot to work with flexible materials. In this case, a cobot performed the repetitive task to find ergonomic improvements and reduce workers’ movements. They finally presented a simulation where an operator could work with a cobot doing the repetitive task of collocating the spot taping.

In addition, the paper from Gualtieri et al. [15] on “Design of Human-centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study” presents a conversion from a manual wire harness assembly workstation to a collaborative one they consider safer, more ergonomic, and more efficient. They conducted this development for a specific type of wire harness where they taped together three-wire groups using a taping pistol. They had the objective to reduce the awkward postures of the assembly workers. They placed a cobot at the back of a workstation while an operator worked in the front, reducing the possibilities of collision. The cobot worked in two stations, placed in the middle of these. They used the RULA (Rapid Upper Limb Assessment) method to evaluate ergonomics, getting a reduction from six (left arm) and seven (right arm) in the manual task to a value of three using a cobot in both arms. They concluded that using collaborative robotics can improve ergonomics because a cobot will do the most stressful task, that is, in their case, the taping colocation, reducing awkward postures, and the number of movements done by an operator.

2.2. Recent Advances in the Wire Harness Assembly Process without the Support of Collaborative Robots

In the study by Naijing et al. [23] on “Assembly Simulation of Multi-Branch Cables”, a simulation for the assembly of multiple wire harnesses was conducted. Specifically, it was attempted to model the junctions of a wire harness, considering its topological and anatomical characteristics. Therefore, their model can provide realistic simulations of wire harnesses deformation.

In contrast, Ruppert and Abonyi [24], in their work “Software Sensor for Activity-Time Monitoring and Fault Detection in Production Lines”, aimed to develop a sensor system that continuously estimates the time consumption of the different activities/tasks in the wire harness assembly process. Activity time was determined, and then compared to estimated activity times and generated alerts when the worker productivity decreased.

Sugiono et al. [25], in “Reducing Musculoskeletal Disorder (MSD) Risk of Wiring Harness Workstation using Workplace Ergonomic Risk Assessment (WERA) Method”, were looking for the best work posture for wire harness assembly employees using the WERA method. This method is used to evaluate ergonomics, and it considers the neck, the shoulders, the back, the wrists, and the legs. Initial results showed that all three analysed jobs were at the medium activity level, which means that these three jobs needed more research and changes or improvements. Risk factors values were elevated in the analysis of WERA for the shoulders and neck because the operator’s arm was raised but still below the chest limit, and the operator’s neck would have to bend to perform the activity.

2.3. Newest Advances in Collaborative Robots in Industry

In the paper of Sánchez Restrepo et al. [26] on “Toward an Intuitive and Iterative 6D Virtual Guide Programming Framework for Assisted Human-Robot Comanipulation”, they developed a virtual guideline, which is a software tool for offline programming of cobots. It is used to delimitate a cobot movement to avoid collisions between workers or objects in the environment. Moreover, it could improve the accuracy of the task at hand. The virtual guideline is a specific zone where a cobot could move. This zone could be delimited manually, moving the cobot to specific points.

Meanwhile, in the paper from Karaulova et al. [27] about “Lean Automation for Low-Volume Manufacturing Environment”, they analysed the advantages of integrating a cobot into the manufacturing operations of a small-sized enterprise. The result showed that using a collaborative robot could reduce manual work, improve ergonomics, and financial efficiency as well as increases competitiveness in the market.

Capitanelli et al. [14] in their work “On the Manipulation of Articulated Objects in Human-Robot Cooperation Scenarios”, explained the difficulties cobots have with working with flexible materials, such as cables.

The methodology presented in Mateus et al. [8], in their work on “A Structured Methodology for the Design of a Human-Robot Collaborative Assembly Workplace”, offers some guidelines on how integrating collaborative robots into an assembly workplace focused on safety, ergonomics, and time performance.

The paper of Malik and Bilberg [9] on “Collaborative Robots in Assembly: A Practical Approach for Tasks Distribution” presents a method for integrating cobots in an assembly process, which provides specific characteristics necessary to carrying out collaborative assembly tasks (i.e., cycle times, adaptability, and safety) between humans and cobots, working as a team according to their different abilities.

Gualtieri et al. [11], in their work “An Evaluation Methodology for the Conversion of Manual Assembly Systems into Human-Robot Collaborative Workcells”, presented a methodology to evaluate the conversion of a manual assembly workstation to a collaborative one.

The paper from Girbes-Juan et al. [28] on “Haptic and Visual Feedback Assistance for Dual-Arm Robot Teleoperation in Surface Conditioning Tasks” presents an architecture of teleoperation with tactile and visual feedback for tasks of surface treatment, such as wiping, polishing, sanding, etc. Teleoperation is useful when the worker and the robot cannot work in the same space because of the dangers this could represent, such as inaccessible locations or ergonomic problems. They significantly improve the surface treatment tasks, especially in the subtask that requires applying force in motion.

In contrast, the paper from Schmitt et al. [29] on “Assisted Human-Robot-Interaction for Industrial Assembly: Application of Spatial Augmented Reality (SAR) for Collaborative Assembly Tasks” shows an installation of a collaborative robot and a space augmented reality (SAR) system applied to the assembly of a toy truck with 17 pieces. They demonstrated how to divide the work sequence according to competencies between the human and the robot.

The second paper by Malik and Bilderberg [30] on “Complexity-based Task Allocation in Human-Robot Collaborative Assembly” develops a methodology to define the possibility of transforming a task from manual to collaborative.

Finally, Castro et al.’s [31] work on “Virtual Simulation of Human-Robot Collaboration Workstations” illustrates the development and use of an integrated digital human modelling and robot simulation tool, both intended to be a tool for engineers to create and adapt successful collaborative workstations.

2.4. Tabular Summary of the State-of-the-Art

Table 1 provides a tabular summary of the papers reviewed as part of this literature review to describe the state-of-the-art of the wire harness assembly process.

| Author(s) | Categories | Contribution | |

|---|---|---|---|

| State-of-the-Art | Topics of Interest | ||

| Heisler et al. [4] | SCR | CR | This paper presents an automation process that could be adapted for the assembly of wire harnesses. |

| Yumbla et al. [17] | SCR | CR | This paper offers a database of different tolerances of connectors used in wire harnesses. |

| Tunstel et al. [13] | SCR | CR | This paper presents a solution for the attachment of cables in the wire harnesses assembling process. |

| Yumbla et al. [18] | SCR | CR | This paper provides a solution for the alignment and manipulation of wire harnesses through vibrating plates. |

| Nguyen and Yoon [19] | SCR | CR and CV | This paper offers a solution for identifying the profile of a wire using a computer vision system for its later use in conjunction with a cobot in wire harnesses assembly procedures. |

| Kicki et al. [20] | SCR | CV | This paper presents a computer vision system and a neural network for identifying different types of wire harnesses for its later use as a navigation guide for a cobot. |

| Yumbla et al. [21] | SCR | CV | This paper proposes a computer vision system for the recognition of wire harness terminals. |

| Trommnau et al. [2] | SCR | CR | This paper reviews the state-of-the-art in wire harness assembly processes. |

| Heisler et al. [22] | SCR | CR | This paper presents an automation solution using a cobot for the routing task in a wire harness assembly process. |

| Román Ibáñez et al. [7] | SCR | CR | This paper proposes an automation solution using a cobot for the spot tapping task in a wire harness assembly process. |

| Gualtieri et al. [15] | SCR | CR and ER | This paper addresses the conversion of a manual workstation to a collaborative one for the wire harness assembly process’s spot tapping task. |

| Naijing et al. [23] | WCR | CR | This paper proposes a simulation model of a wire harness based on its physical properties by considering its topologies and anatomical characteristics. |

| Ruppert and Abonyi [24] | WCR | IM | This paper presents an alerting system using fixture sensors to notify when the productivity in a wire harness assembly process has been reduced. |

| Sugiono et al. [25] | WCR | ER | This paper evaluates the ergonomic conditions of workers in a wire harness assembly process using the WERA methodology. |

| Sánchez Restrepo et al. [26] | CRI | IM | This paper proposes an intuitively virtual guide for the easy programming of a robot without the need for an expert/expertise. |

| Karaulova et al. [27] | CRI | CR | This paper analyses the advantages that the integration of a cobot into an assembly process can offer in terms of flexibility and variability handling. |

| Capitanelli et al. [14] | CRI | CR | This paper details the difficulties that cobots can have when working with flexible materials and what solutions can be developed to handle these materials. |

| Mateus et al. [8] | CRI | IM | This paper presents a methodology to integrate a cobot in a sequential assembly process. |

| Malik and Bilberg [9] | CRI | CR | This paper develops a methodology that allows assigning the tasks that must be carried out by both a cobot and a human in a collaborative assembly process by optimizing for the best possible assembly sequence. |

| Gualtieri et al. [11] | CRI | IM | This paper provides a methodology for evaluating the transformation of a workstation from a manual to a collaborative semi-automated one. |

| Girbes-Juan et al. [28] | CRI | IM | This paper develops a teleoperation architecture for a cobot, which is responsible for conducting surface conditioning tasks. |

| Schmitt et al. [29] | CRI | IM | This paper offers a methodology for the design of a collaborative workstation focusing on its user acceptance. |

| Malik and Bilderberg [30] | CRI | IM | This paper develops a methodology for modifying a generic manual assembly task to a collaborative one. |

| Castro et al. [31] | CRI | IM | This paper offers a simulation model to design collaborative workstations optimizing for efficiency. |

Legend: SCR—Wire Harness Assembly Process supported by Collaborative Robots. WCR—Wire Harness Assembly Process without the Support of Collaborative Robots. CRI—Newest Advances in Collaborative Robots in Industry. CR—Collaborative Robots. ER—Ergonomics. CV—Computer Vision System. IM—Implementation Methodologies.

Table 1. Summary of the State-of-the-Art of the Wire Harness Assembly Process.

This entry is adapted from the peer-reviewed paper 10.3390/robotics11030065

This entry is offline, you can click here to edit this entry!