Propylene is one of the most important building blocks in the petrochemical industry. It is industrially employed to produce polypropylene, which is used extensively to make packaging and labeling, textile products, laboratory equipment, loudspeakers, and automotive components. Propylene is also used for the manufacturing of acrylonitrile, propylene oxide derivatives, and other substances. Catalytic propane oxidative dehydrogenation (PODH) in the absence of gas phase oxygen is a promising approach for propylene manufacturing. PODH can overcome the issues of over-oxidation, which lower propylene selectivity. PODH has a reduced environmental footprint when compared with conventional oxidative dehydrogenation, which uses molecular oxygen and/or carbon dioxide.

1. Introduction

Propylene is one of the most important building blocks in the petrochemical industry [

1,

2,

3]. It is industrially employed to produce polypropylene, which is used extensively to make packaging and labeling, textile products, laboratory equipment, loudspeakers, and automotive components. Propylene is also used for the manufacturing of acrylonitrile, propylene oxide derivatives, and other substances [

4,

5]. The current global propylene demand is the range of 90 million metric tons (MMT) per year, according to the IHS Chemical World Analysis. It is estimated that this demand will rise up to 130 MMT per year by 2023 [

6,

7].

The traditional olefin production involves steam cracking, fluid catalytic cracking (FCC), and catalytic dehydrogenation (DH) [

1,

3,

8,

9,

10]. Typical feedstocks for ethane steam cracking are LPG (light petroleum gas) and naphtha. These olefin production processes involve homogeneous reactions where the hydrocarbon species are steam cracked into smaller olefins [

3]. For FCC, commonly used feedstocks are vacuum gas oil, refinery hydrocarbon residues, and de-asphalted oil, which are converted into light and higher value products, such as gasoline. Cracking processes are endothermic and, thus, consume large amounts of heat. To accomplish this, these processes require reactor designs that can be operated at high temperatures [

9]. Additionally, significant undesirable amounts of coke are formed, imposing severe operating constraints with frequent plant shutdowns [

1,

10,

11].

Catalytic dehydrogenation (CDH) is an economical route for upgrading low-cost saturated alkanes, such as ethane and propane, into the more valuable olefin feedstocks (e.g., ethylene, propylene) [

12]. Furthermore, and given the recent increase of shale gas availability [

13,

14,

15], there is a renewed interest in efficient and economical routes to convert alkanes into olefins. One should note that CDH is thermodynamically limited [

3,

8,

16]. At the present time, CDH is mainly considered for propane and butane dehydrogenation. In this respect, one can list the several industrial scale processes [

8,

17] for propane dehydrogenation. These include CATOFIN from ABB Lummus, OLEFLEX from UOP, Fluidized Bed Dehydrogenation (FBD) from Snamprogetti, and Steam Active Reforming (STAR) from Phillips Petroleum. These technologies differ with respect to the catalyst type used, the reactor design employed, and the selected operating conditions. These processes include a dehydrogenation section and a catalyst regeneration section [

18,

19]. However, CDH displays similar constraints as steam cracking and FCC, with these being, as follows: a) they involve endothermic reactions and b) they require operating temperatures in the 450–700 °C range. At these high temperatures, cracking and coking can occur, which limits the use of potentially valuable catalysts, such as Cr

2O

3/Al

2O

3 and Pt/Sn/Al

2O

3. Existing processes are insufficient to satisfy increasing olefin market demands due to these issues, and given that in catalytic cracking (FCC) olefins are only by-products [

8,

14].

2. Propane Dehydrogenation (DH) and Oxidative Dehydrogenation (PODH) Reactions: Stoichiometry and Thermodynamics

At chemical equilibrium, a reacting system achieves a condition where the total Gibbs Free Energy is minimized [

69]. Two approaches are possible for assessing chemical equilibrium: (a) stoichiometric and (b) non-stoichiometric [

70,

71]. The “stoichiometric” approach requires a defined stoichiometry, involving all reactants and products with their molecular formulae. This stoichiometric approach is the one considered for PODH.

Table 1 reports both the ΔGR and the ΔHR, at the reference condition of 298K, for the various reactions that are involved in propane ODH, under both O2-rich and O2-free atmospheres. Thus, one can observe that the PODH reactions with gaseous oxygen are more exothermic than the catalytic PODH reactions using the lattice oxygen. Thus, there is in principle, a valuable strategy if PODH reactions are driven by lattice oxygen. These based lattice oxygen reactions can likely provide conditions for the better management of temperature runaways and better control of undesired reactions.

Table 1. Gibbs Free Energy and Enthalpy Changes for Propane Dehydrogenation (DH) and Oxidative Dehydrogenation (ODH) Reactions.

Propane can be converted under the absence of oxygen in the gas phase (e.g., cracking and dehydrogenation relations), as described in Equations (5)–(9). However, these reactions are negligible in the 500–550 °C range and under short reaction times (<20 s). Thus, one can ignore them in equilibrium calculations [

59].

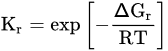

However, and if oxygen is co-fed with propane, several reactions can take place as described in Equations (10)–(19). If one examines the negative ΔGR298 for all these reactions, one can observe that chemical equilibrium favors various postulated reactions. The equilibrium constant Kr for each of these reactions can be related to the ΔGr, according to the following equation:

where, R is the universal gas constant with a 8.314 J/(mol K) value.

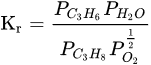

As an example, when considering Equation (10), at 550 °C and with pressures close to atmospheric, one can see that the activities of the chemical species involved in oxy-dehydrogenation can be approximated with their respective partial pressures, as follows:

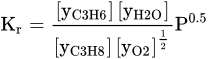

Chemical species partial pressures can be further expressed in terms of the system total pressure P and the gases mole fractions, as follows:

In the case of Equation (10) in

Table 1, and given that all the other K

823 equilibrium constants for oxy-dehydrogenation with oxygen being co-fed (Equations (11)–(19) in

Table 1) exceed the value of 1 by far, one can see that these gas phase reactions are not limited by chemical equilibrium. The anticipated product molar fractions for gas phase PODH led to limited propylene selectivity with significant yields of the undesirable CO

2 and ethylene [

29,

30].

Thus, given these facts, the discovery of alternative catalytic pathways for PODH to improve the homogenous PODH is a requirement. One possible promising avenue is the one of using V2O5 supported on γ-alumina.

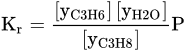

One can see that the PODH, as shown in Table 1 for a V2O5 catalyst, might occur via a network of possible reactions (Equations (20)–(24)). For Equation (20) of Table 1, the following relation is anticipated under chemical equilibrium:

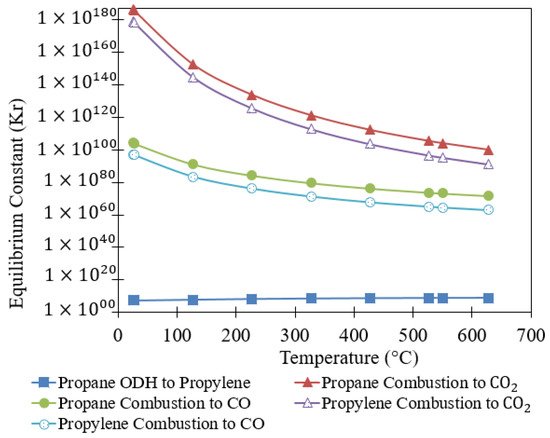

Equation (20) (refer to Table 1) displays a ΔGR,298 = −41.5 KJ/mol and a K823K = 5.88×108, as reported in Figure 1. This shows that the PODH is unconstrained by chemical equilibrium at the anticipated selected process conditions. While this is favorable, one can also see that there is a host of other undesirable secondary reactions with even larger ΔGR,298 competing with Equation (20).

Figure 1. Chemical Equilibrium Constants as a Function of Temperature for Propane ODH under an O2-free Atmosphere. Total pressure: 1 atm.

Thus, thermodynamic equilibrium analysis for catalytic PODH oxy-dehydrogenation is valuable. It shows the promise of PODH via Equation (20) while pointing to the need of new catalysts to achieve high propylene selectivities.

Finally, and regarding the ODH process under an O2-free atmosphere, the catalyst regeneration reaction (2V2O4 + O2 = 2V2O5), which can be calculated by Equation (25) in Table 1, can be effected in a separate regenerator unit. This catalyst regeneration is both spontaneous and exothermic. Therefore, the energy for the PODH under an O2-free atmosphere with a high selectivity for propylene being endothermic can be recovered from the catalyst regeneration reaction.

This entry is adapted from the peer-reviewed paper 10.3390/catal10040418