Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Olive oil production processes usually generate large amounts of high load polluted wastewater known as Olive Mill Wastewater (OMW), locally known as “Zibar”. Most of these olive oil-producing processes are found in the Mediterranean countries, where olive trees are planted to produce both olives and olive oil.

- olive mills wastewater

- circular economy

- polyphenols

- wastewater treatment

1. Introduction

These days, environmental sustainability should be considered in all industrial and agro-industrial sectors [1]. It can be promoted by producing cleaner products with less waste and by reusing and recovering all valuable components present in wastewater [2]. Some of these industrial sectors generate large amounts of different types of wastewater, such as textile [3], petroleum refining [4], carwash [5], and food [6] industries. Olive oil production processes usually generate large amounts of high load polluted wastewater known as Olive Mill Wastewater (OMW), locally known as “Zibar”, [6]. Most of these olive oil-producing processes are found in the Mediterranean countries, where olive trees are planted to produce both olives and olive oil. These countries produce more than 15 M m3/year or about 98% of the world’s olive oil production [7][8]. The largest olive oil-producing countries are Spain, Italy, Greece, Turkey, Tunisia, Portugal, Morocco, and Algeria [9]. In addition, olive trees are planted in the Middle East countries, USA, Australia, and Argentina [10].

In Jordan, olive trees are abundant, especially on the country’s northern part, where the weather is favorable for this type of tree. Consequently, the olive tree is considered an essential agro-industrial cost-effective contributor to the local economy. However, a relatively large amount of 300,000 m3 of Zibar is produced every season in addition to the production of 120,000 tons of olive mill solid wastes, locally known as “Jift”. These produce liquid and solid waste and impose a serious environmental challenge that needs sustainable management [11][12][13][14]. Accordingly, researchers will focus on the properties of OMW constituents. It will consider the most relevant research published in the last two decades related to OMW treatment using single and combined processes. Then it will compare two main approaches for OMW management, namely; the conventional and the sustainable treatment processes. In the conventional approach, the treatment process’s main objective is to treat OMW to meet environmental regulations. On the other hand, the sustainable approach uses a treatment process that compromises the recovery of valuable ingredients found in OMW followed by treatment of the residual wastewater of OMW. In addition, these processes will be analyzed and compared according to their benefits.

2. OMW Composition

The composition and characteristics of OMW usually vary depending on many factors, including the geographic location and climate, type, the degree of maturity of olive fruits, the processing procedures, and the method of oil extraction, such as batch or continuous [10]. In addition, the classical processes for olive oil extraction from fruits use continuous processes of two and three-phase centrifugation to affect the composition of OMW, as shown in Table 1 [15].

Table 1. Portuguese OMW characterization from 6 olive mills in the campaign. Adapted from Reference [15].

| Factors | OMW I | OMW II | OMW III | OMW IV | OMW V | OMW IV |

|---|---|---|---|---|---|---|

| pH | 6.85 | 5.02 | 4.24 | 5.02 | 4.92 | 5.50 |

| COD (kgm−3) | 9.08 | 44.6 | 20.6 | 134.0 | 135.0 | 23.0 |

| BOD (kgm−3) | 4.75 | Nd | 11.0 | 40.0 | 42.0 | 7.90 |

| PhC * (kgm−3) | 0.03 | 2.54 | 0.61 | 5.40 | 6.16 | 0.25 |

| TS (kgm−3) | 7.30 | 33.1 | 15.1 | 117 | 106 | 18.8 |

| VS (kgm−3) | 7.10 | 28.4 | 9.80 | 94.3 | 79.2 | 12.9 |

* PhC phenolic compounds, Nd—not determined.

The color of OMW effluent varies from black to dark brown. It is characterized by a high organic load of different compounds, including sugars, lipids, pectin, tannins, polyphenols, and polyalcohols [15][16]. Table 2 shows the details of different components found in untreated and treated OMW.

Table 2. Physiochemical characteristics of untreated and treated OMW. Adapted from Reference [17].

| Characteristics | Untreated OMW | Treated OMW |

|---|---|---|

| pH at 25 °C | 5 ± 0.2 | 8.1 ± 0.2 |

| Electrical conductivity (25 °C) (dS m−1) | 8.2 ± 0.1 | 14.2 ± 0.1 |

| Chemical oxygen demand (g L−1) | 53.3 ± 4.8 | 4.5 ± 0.41 |

| Biochemical oxygen demand (g L−1) | 13.42 ± 1.21 | 1.8 ± 0.16 |

| COD/BOD5 | 4 ± 0.72 | 2.5 ± 0.45 |

| Salinity (g L−1) | 6.23 ± 0.56 | 12.1 ± 1.1 |

| Water content (g L−1) | 960.6 ± 19.2 | 984 ± 19.7 |

| Total solids (g L−1) | 39.55 ± 1.98 | 15.9 ± 0.8 |

| Mineral matter (g L−1) | 6.5 ± 0.33 | 10.15 ± 0.51 |

| Volatile solid (g L−1) | 33 ± 1.65 | 4.8 ± 0.24 |

| Total organic carbon (g L−1) | 17.6 ± 0.88 | 3.2 ± 0.16 |

| ortho-diphenols (g L−1) | 8.6 ± 0.86 | 0.77 ± 0.08 |

| Total nitrogen Kjeldhal (g L−1) | 0.5 ± 0.05 | 0.25 ± 0.03 |

| Carbon/Nitrogen | 35.2 ± 7.04 | 12.8 ± 2.56 |

| Toxicity by LUMIStox (% I B) | 99 ± 9 | 30 ± 3 |

| P (mg L−1) | 36 ± 3.6 | 15 ± 1.5 |

| Na (g L−1) | 0.8 ± 0.08 | 0.86 ± 0.09 |

| Cl (g L−1) | 1.45 ± 0.15 | 1.3 ± 0.13 |

| K (g L−1) | 8.6 ± 0.8 | 5.34 ± 0.5 |

| Ca (g L−1) | 0.9 ± 0.09 | 3.2 ± 0.3 |

| Fe (mg L−1) | 23.4 ± 2.3 | 38.3 ± 3.8 |

| Mg (mg L−1) | 186.9 ± 18.7 | 281 ± 28.1 |

It is clear from Table 2 that OMW contains various components, including organic and inorganic compounds or ions. The most important compounds are polyphenols, volatile acids, sugars, polyalcohols, and some nitrogen compounds. The concentration of phenolic compounds could reach 10 g/L, a value that makes OMW toxic with high antibacterial activity [17]. Fortunately, most of these components have economic value. However, even recently, most of the treatment processes for OMW aim to treat the wastewater without getting the benefits of its valuable components.

The annual production rate of OMW effluents in all the Mediterranean region is over 30 × 106 m3 [18]. This sizeable seasonal production rate of wastewater represents a considerable hazard to the environment due to the high load of pollutants, which needs an intensive management protocol [19]. Unfortunately, the treatment of OMW is still a crucial issue in the Mediterranean region that needs to be resolved due to the severe negative impact on the environment, especially land and water resources. This fact still challenges researchers and industries to present their research findings and technologies to solve OMW problems [20]. Intensive research is needed not just to treat OMW but for clean production of the olive oil industry from one side and the sustainable treatment of the OMW [21].

It is clear from Table 2 that OMW contains various components, including organic and inorganic compounds or ions. The most important compounds are polyphenols, volatile acids, sugars, polyalcohols, and some nitrogen compounds. The concentration of phenolic compounds could reach 10 g/L, a value that makes OMW toxic with high antibacterial activity [17]. Fortunately, most of these components have economic value. However, even recently, most of the treatment processes for OMW aim to treat the wastewater without getting the benefits of its valuable components.

The annual production rate of OMW effluents in all the Mediterranean region is over 30 × 106 m3 [18]. This sizeable seasonal production rate of wastewater represents a considerable hazard to the environment due to the high load of pollutants, which needs an intensive management protocol [19]. Unfortunately, the treatment of OMW is still a crucial issue in the Mediterranean region that needs to be resolved due to the severe negative impact on the environment, especially land and water resources. This fact still challenges researchers and industries to present their research findings and technologies to solve OMW problems [20]. Intensive research is needed not just to treat OMW but for clean production of the olive oil industry from one side and the sustainable treatment of the OMW [21].

3. Valorization Constituents of OMW and Sludge

Sustainable utilization of wastes produced by the food-industry is becoming a hot environmental issue due to the polluting properties of the byproducts, both liquids, and solids, generated during the preparation and production of food [22][23]. For instance, considerable amounts of solid and liquid wastes are produced during olive oil extraction; these wastes are collectively known as olive mill wastes [24]. Around 20 million tons of fresh water is needed for olive oil processing in the Mediterranean area, resulting in up to 30 million tons of liquid-solid waste per year.

In the Middle East, it was reported in 2017 that around 175,000 m3 of OMW were produced from 209,000 tons of olives in the olive pressing industry. This quantity of OMW roughly contains 3069, 7956, 149, 2.07, 3753, and 4.2 tons of BOD5, COD, residual olive oil, phenols, total suspended solids, and phosphorous respectively. Therefore, the OMW content is high with organic matter expressed as BOD5 and COD [25]. The produced OMW usually contains lipids, fats, carbohydrates, nitrogenous compounds, organic acids, polyalcohols, and some inorganic constituents. Other compounds found in OMW include a wide variety of phenolic compounds, tannins, and organic halogenated pollutants. In addition, OMW is characterized by its high suspended solids content, high turbidity, and a low pH of 3.5 to 5.5 [26].

Based on its high pollutants load, OMW is considered as a significant source of environmental pollution. Due to the high-cost obstacles, no treatment processes are currently available at the mills; therefore, OMW is usually discharged into the environment, causing significant environmental pollution such as: coloring and pollution of ground and surface waters, soil surface, and foul odors problems. However in other cases, like in Jordan, OMW is transferred in tankers to certain basins found in the northern side of the country [27].

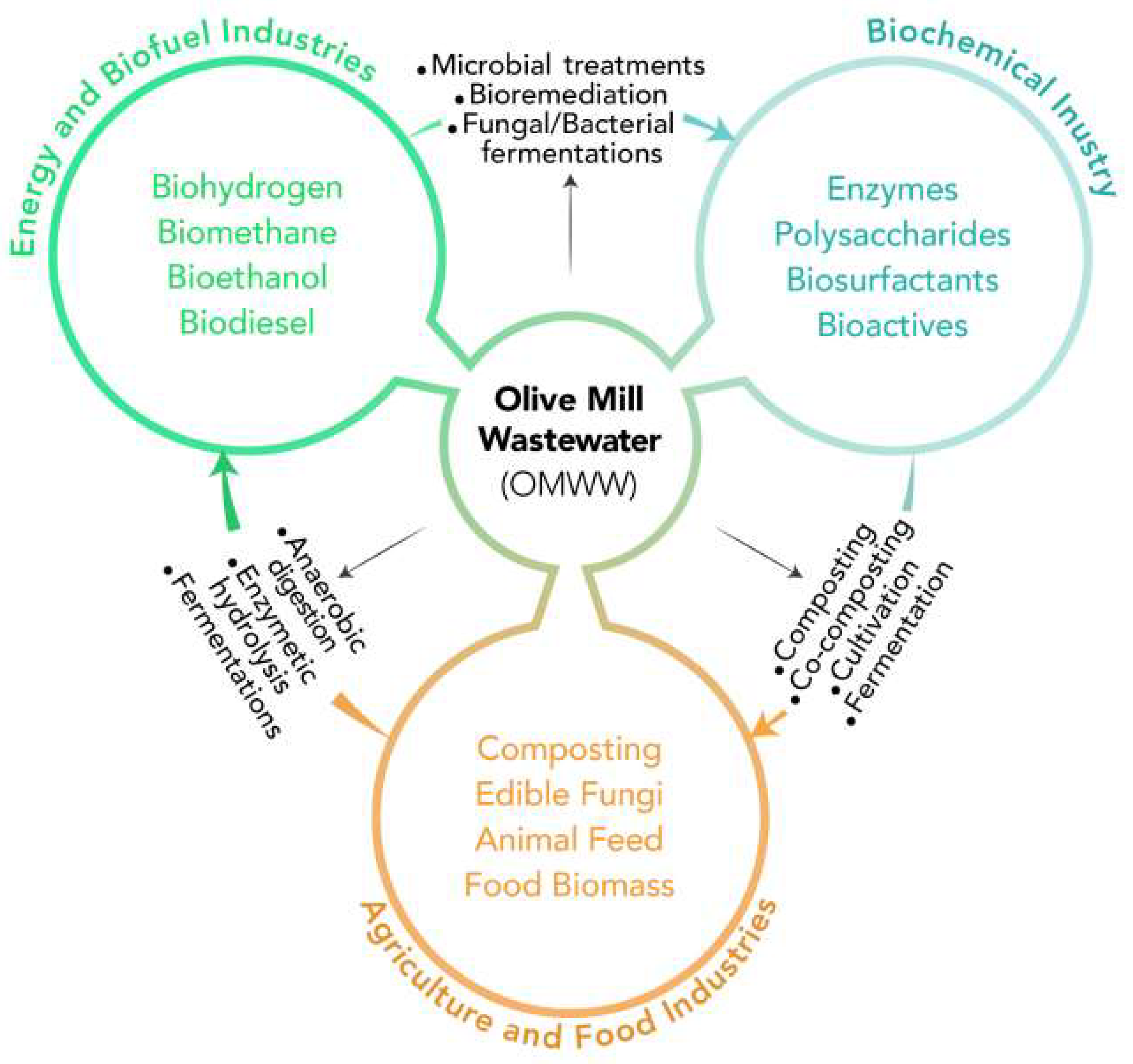

Fortunately, many OMW constituents have high economical values and can be extracted, purified, and used in many applications. The main valuable components that can be extracted from OMW wastewater were summarized by [8] and shown in Figure 1 [8].

Figure 1. Microbial valorization and potential uses of OMW [9].

This entry is adapted from the peer-reviewed paper 10.3390/w14111695

References

- Vuppala, S.; Bavasso, I.; Stoller, M.; Di Palma, L.; Vilardi, G. Olive mill wastewater integrated purification through pre-treatments using coagulants and biological methods: Experimental, modelling and scale-up. J. Clean. Prod. 2019, 236, 117622.

- El Abbassi, A.; Kiai, H.; Raiti, J.; Hafidi, A. Application of ultrafiltration for olive processing wastewaters treatment. J. Clean. Prod. 2014, 65, 432–438.

- Buthiyappan, A.; Abdul Raman, A.A. Energy intensified integrated advanced oxidation technology for the treatment of recalcitrant industrial wastewater. J. Clean. Prod. 2019, 206, 1025–1040.

- Lin, S.; Mackey, H.; Hao, T.; Guo, G.; van Loosdrecht, M.C.; Chen, G. Biological sulfur oxidation in wastewater treatment: A review of emerging opportunities. Water Res. 2018, 143, 399–415.

- Emamjomeh, M.M.; Jamali, H.A.; Naghdali, Z.; Mousazadeh, M. Efficiency of electrocoagulation, sedimentation and filtration hybrid process in removing chemical oxygen demand and turbidity from carwash industrial wastewater: Optimization by response surface methodology. J. Maz. Univ. Med. Sci. 2019, 29, 106–120.

- Mousazadeh, M.; Niaragh, E.K.; Usman, M.; Khan, S.U.; Sandoval, M.A.; Al-Qodah, Z.; Bin Khalid, Z.; Gilhotra, V.; Emamjomeh, M.M. A critical review of state-of-the-art electrocoagulation technique applied to COD-rich industrial wastewaters. Environ. Sci. Pollut. Res. 2021, 28, 43143–43172.

- Callegari, A.; Cecconet, D.; Molognoni, D.; Capodaglio, A. Sustainable processing of dairy wastewater: Long-term pilot application of a bio-electrochemical system. J. Clean. Prod. 2018, 189, 563–569.

- Chatzisymeon, E.; Foteinis, S.; Mantzavinos, D.; Tsoutsos, T. Life cycle assessment of advanced oxidation processes for olive mill wastewater treatment. J. Clean. Prod. 2013, 54, 229–234.

- Ahmed, P.; Fernández, P.M.; Figueroa, L.I.C.; Pajot, H. Exploitation alternatives of olive mill wastewater: Production of value-added compounds useful for industry and agriculture. Biofuel Res. J. 2019, 6, 980–994.

- Harwood, J. Handbook of Olive Oil: Analysis and Properties; Aparicio, R., Ed.; Aspen Publishers, Inc.: Gaithersburg, MD, USA, 2013.

- Al-Qodah, Z.; Al-Shannag, M.; Bani-Melhem, K.; Assirey, E.; Alananbeh, K.; Bouqellah, N. Biodegradation of olive mills wastewater using thermophilic bacteria. Desalination Water Treat. 2015, 56, 1908–1917.

- D’Annibale, A.; Quaratino, D.; Federici, F.; Fenice, M. Effect of agitation and aeration on the reduction of pollutant load of olive mill wastewater by the white-rot fungus Panus tigrinus. Biochem. Eng. J. 2006, 29, 243–249.

- Yesilada, O.; Sik, S.; Sam, M. Biodegradation of olive oil mill wastewaterby Coriolus versicolor and Funalia trogii: Effects of agitation, initial COD concentration, inoculum size and immobilization. World J. Microbiol. Biotechnol. 1998, 14, 37–42.

- Dourou, M.; Kancelista, A.; Juszczyk, P.; Sarris, D.; Bellou, S.; Triantaphyllidou, I.-E.; Rywinska, A.; Papanikolaou, S.; Aggelis, G. Bioconversion of olive mill wastewater into high-added value products. J. Clean. Prod. 2016, 139, 957–969.

- Davies, L.C.; Vilhena, A.M.; Novais, J.M.; Martins-Dias, S. Olive mill wastewater characteristics: Modelling and statistical analysis. Grasas Aceites 2004, 55, 233–241.

- Benavente, V.; Fullana, A.; Berge, N.D. Life cycle analysis of hydrothermal carbonization of olive mill waste: Comparison with current management approaches. J. Clean. Prod. 2016, 142, 2637–2648.

- Mekki, A.; Dhouib, A.; Aloui, F.; Sayadi, S. Olive wastewater as an ecological fertiliser. Agron. Sustain. Dev. 2006, 26, 61–67.

- Al-Qodah, Z.; Al-Bsoul, A.; Assirey, E.; Al-Shannag, M. Combined ultrasonic irradiation and aerobic biodegradation treatment for olive mills wastewaters. Environ. Eng. Manag. J. 2014, 13, 2109–2118.

- El Hanandeh, A. Energy recovery alternatives for the sustainable management of olive oil industry waste in Australia: Life cycle assessment. J. Clean. Prod. 2015, 91, 78–88.

- Stoller, M.; Ochando-Pulido, J.M.; Vilardi, G.; Vuppala, S.; Bravi, M.; Verdone, N.; Di Palma, L. Technical and economic impact of photocatalysis as a pretreatment process step in olive mill wastewater treatment by membranes. Chem. Eng. Trans. 2017, 57, 1171–1176.

- Haddar, W.; Baaka, N.; Meksi, N.; Elksibi, I.; Mhenni, M.F. Optimization of an ecofriendly dyeing process using the wastewater of the olive oil industry as natural dyes for acrylic fibres. J. Clean. Prod. 2014, 66, 546–554.

- Shahamat, Y.D.; Khani, M.R.; Mahdizadeh, H.; Kannan, K.; Kalankesh, L.R.; Kamarehei, B.; Baneshi, M.M. Olive Mill Wastewater (OMW) Treatment by Hybrid Processes of Electrocoagulation/Catalytic Ozonation and Biodegradation. Environ. Eng. Manag. J. 2020, 19, 1401–1410.

- Khedkar, R.; Singh, K. Food industry waste: A panacea or pollution hazard? In Paradigms in Pollution Prevention; Springer: Cham, Switzerland, 2018; pp. 35–47.

- Šafranko, S.; Ćorković, I.; Jerković, I.; Jakovljević, M.; Aladić, K.; Šubarić, D.; Jokić, S. Green Extraction Techniques for Obtaining Bioactive Compounds from Mandarin Peel (Citrus unshiu var. Kuno): Phytochemical Analysis and Process Optimization. Foods 2021, 10, 1043.

- Al Bsoul, A.; Hailat, M.; Abdelhay, A.; Tawalbeh, M.; Jum’H, I.; Bani-Melhem, K. Treatment of olive mill effluent by adsorption on titanium oxide nanoparticles. Sci. Total Environ. 2019, 688, 1327–1334.

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An overview on olive mill wastes and their valorisation methods. Waste Manag. 2006, 26, 960–969.

- Halalsheh, M.; Kassab, G.; Shatanawi, K. Impact of legislation on olive mill wastewater management: Jordan as a case study. Water Policy 2021, 23, 343–357.

This entry is offline, you can click here to edit this entry!