In the present work, the contemporary exhaust gas treatment systems (EGTS) used for SOx, PM, and NOx emission mitigation from shipping are reviewed. Specifically, after-treatment technologies such as wet scrubbers with seawater and freshwater solution with NaOH, hybrid wet scrubbers, wet scrubbers integrated in exhaust gas recirculation (EGR) installations, dry scrubbers, inert gas wet scrubbers and selective catalytic reduction (SCR) systems are analyzed. The operational principles and the construction specifications, the performance characteristics and the investment and operation of the reviewed shipping EGTS are thoroughly elaborated. The SCR technology is comparatively evaluated with alternative techniques such as LNG, internal engine modifications (IEM), direct water injection (DWI) and humid air motor (HAM) to assess the individual NOx emission reduction potential of each technology. Detailed real data for the time several cargo vessels spent in shipyards for seawater scrubber installation, and actual data for the purchase cost and the installation cost of seawater scrubbers in shipyards are demonstrated. From the examination of the constructional, operational, environmental and economic parameters of the examined EGTS, it can be concluded that the most effective SOx emission abatement system is the closed-loop wet scrubbers with NaOH solution which can practically eliminate ship SOx emissions, whereas the most effective NOx emission mitigation system is the SCR which cannot only offer compliance of a vessel with the IMO Tier III limits but can also practically eliminate ship NOx emissions.

- exhaust gas treatment systems

- IMO 2020 global sulfur cap: IMO NOx Tier II/III limits

- scrubbers

- selective catalytic reduction (SCR)

1. Introduction

|

Year of Issue |

Permitted Fuel Sulfur Content (% m/m) |

|

|---|---|---|

|

SECAs |

Worldwide |

|

|

2000 |

1.5% |

4.5% |

|

2010.07 |

1.0% |

|

|

2012 |

3.5% |

|

|

2015 |

0.1% |

|

|

2020 |

0.5% |

|

2. Operational Principles and Key Characteristics of Marine Exhaust Gas Treatment Systems

2.1. General Description

-

Aqueous—wet exhaust gas treatment and SOx and PM curtailment systems, or wet scrubbers.

-

Dry flue gas treatment and SOx mainly reduction systems (dry scrubbers).

-

The aqueous SOx and PM mitigation systems are divided into three categories [30]:

-

Open circuit or open-loop aqueous scrubbing systems, usually based on the use of seawater as flue gas scrubbing and SOx and PM mitigating medium in specially designed counterflow heat exchangers that are called scrubbers [31].

-

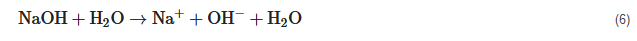

Closed circuit or closed-loop aqueous scrubbing systems usually based on the use of an aqueous solution of fresh water and alkaline medium (usually sodium hydroxide (caustic soda), NaOH) as exhaust gas scrubbing, and SOx and PM mitigation medium in specially designed counterflow heat exchangers [32].

-

Aqueous hybrid scrubbing systems which can function as either open-loop systems with seawater or closed-loop systems with aqueous solution of NaOH [33].

-

The aqueous exhaust gas treatment and scrubbing systems (scrubbers) that operate as sub-systems of exhaust gas recirculation (EGR) installations in marine engines. As known, EGR is used in marine engines for the reduction of the in-cylinder NOx formation rate. Hence, the integrated EGR systems equipped with wet scrubbers are primarily used to mitigate NOx formation inside the cylinders through exhaust gas recirculation, and they employ wet scrubbers to curtail SOx and PM emissions. The employment of the aqueous gas treatment systems of this category, besides SOx and PM mitigation, result in the curtailment of the fouling and corrosion phenomena of the marine diesel due to aqueous exhaust gas cleaning [34,35].

-

Inert gas aqueous systems that use small-size aqueous SOx and PM mitigation systems to clean and convert exhaust gas to inert gas can further be used for tanker evacuation [36].

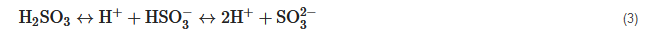

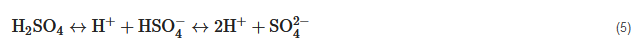

2.2. Wet Exhaust Gas Cleaning and SOx Reduction Systems with Seawater or with Caustic Soda (SOx Scrubbers)

-

The preservation of exhaust gas buoyancy phenomenon (i.e., the avoidance of excess temperature reduction of exhaust gases during their scrubbing process by the aqueous medium).

-

The simultaneous minimization of the space captured and the weight and the energy consumption by the SOx and PM mitigation aqueous gas treatment system.

-

The minimization of the pressure drop of the exhaust gas stream.

-

Hot corrosion avoidance of the SOx scrubber constructional elements from exhaust gases that contain sulfur and possibly acid sulfate roots.

-

The avoidance of exhaust gas vapor condensation and appearance of water droplets at the SOx and PM scrubber outlet.

-

The effluent water from the scrubber which is either ejected to the sea or guided to an on-board wastewater treatment plant.

-

The heavy residues that are rejected from the on-board wastewater treatment plant or from the freshwater recirculation process.

-

The flue gases that contain the remaining pollutant species which were not captured from the aqueous flue gas treatment process.

-

The impure water rejection rate from a SOx scrubber with seawater as the scrubbing medium is 45 m3/MWh.

-

The impure water rejection rate from a SOx scrubber with caustic soda varies from 0.1 to 0.3 m3/MWh (The indicative recirculation rate is 20 m3/MWh).

-

Exhaust gases that are generated from marine diesel engines (Exhaust gases are produced from the combustion of intake air with fuel. Lubricant oil can also be present in exhaust gases depending on the engine status and the operational conditions).

-

Seawater or fresh water with NaOH which are used for scrubbing exhaust gases.

-

Impure water which may contain combustion products and chemical additives.

-

A total of 2 kg CO2/GJ of fuel heating energy can be produced from the neutralization/inactivation process.

-

A total of 1.6 kg CO2/GJ of fuel heating energy can be generated from the flue gases scrubbing process in the aqueous scrubber.

2.3. SOx and PM Mitigation Wet Scrubbers Integrated in EGR Systems

2.4. Inert Gas SOx Scrubbers

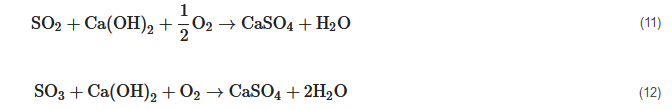

2.5. Dry Exhaust Gas Treatment and SOx Capture Systems

2.6. Marine Selective Catalytic Reduction (SCR) Systems

3. Applications of Marine Exhaust Gas Treatment Systems

3.1. Wet Closed-Loop and Open-Loop SOx Scrubbers

-

Quantity of 11 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 2.9% sulfur in fuel oil.

-

Quantity of 8 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 2.4% sulfur in fuel oil.

-

Quantity of 4 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 1.4% sulfur in fuel oil.

-

Quantity of 1 L caustic soda with 50% w/w NaOH/MWh achieves SOx emissions equivalent to 0.9% sulfur in fuel oil.

3.2. Wet SOx and PM Scrubbers Integrated in Marine EGR Systems

3.3. Inert Gas Wet SOx Scrubbers

3.4. Dry SOx Scrubbers

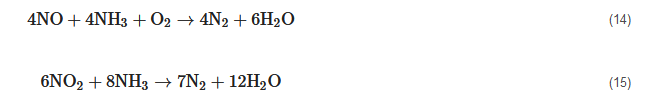

3.5. Marine Selective Catalytic Reduction (SCR) Systems

This entry is adapted from the peer-reviewed paper 10.3390/en15103638

References

- Heywood, J.B. Internal Combustion Engine Fundamentals, 1st ed.; McGraw-Hill: New York, NY, USA, 1988.

- Dieselnet. IMO Marine Engine Regulations. 2020. Available online: https://dieselnet.com/standards/inter/imo.php (accessed on 2 April 2022).

- IMO. Sulfur Oxides (SOx) and Particulate Matter (PM)—Regulation 14. Available online: http://www.imo.org/en/OurWork/ Environment/PollutionPrevention/AirPollution/Pages/Sulfur-oxides-(SOx)-%E2%80%93-Regulation-14.aspx (accessed on 2 April 2022).

- European Commission. Report from the Commission to the European Parliament and the Council on Implementation and Compliance with the Sulfur Standards for Marine Fuels Set Out in Directive (EU) 2016/802 Relating to a Reduction in the Sulfur Content of Certain Liquid Fuels, Brussels. 16 April 2018. Available online: https://op.europa.eu/en/publication-detail/-/ publication/9050f35b-4155-11e8-b5fe-01aa75ed71a1/language-en/format-PDF (accessed on 2 April 2022).

- IMO. Nitrogen Oxides (NOx)—Regulation 13. Available online: http://www.imo.org/en/OurWork/Environment/ PollutionPrevention/AirPollution/Pages/Nitrogen-oxides-(NOx)-%E2%80%93-Regulation-13.aspx (accessed on 2 April 2022). 6. Deniz, C.; Zincir, B. Environmental and economical assessment of alternative marine fuels. J. Clean. Prod. 2016, 113, 438–449. [CrossRef]

- Notteboom, T.; Delhaye, E.; Vanherle, K. Analysis of the Consequences of Low Sulfur Fuel Requirements. University of Antwerpen Transport and Mobility. 2010. Available online: https://www.schonescheepvaart.nl/downloads/rapporten/doc_1361790123.pdf (accessed on 2 April 2022).

- Guo, M.; Fu, Z.; Ma, D.; Ji, N.; Song, C.; Liu, Q. A short review of treatment methods of marine diesel engine exhaust gases. Procedia Eng. 2015, 121, 938–943. [CrossRef]

- Lu, X.; Geng, P.; Chen, Y. NOx Emission reduction technology for marine engine based on Tier-III: A Review. J. Therm. Sci. 2020, 29, 1242–1268. [CrossRef]

- Lion, S.; Vlaskos, I.; Taccani, R. A review of emissions reduction technologies for low and medium speed marine Diesel engines and their potential for waste heat recovery. Energy Convers. Manag. 2020, 207, 112553. [CrossRef]

- Ni, P.; Wang, X.; Li, H. A review on regulations, current status, effects and reduction strategies of emissions for marine diesel engines. Fuel 2020, 279, 118477. [CrossRef]

- Deng, J.; Wang, X.; Wei, Z.; Wang, L.; Wang, C.; Chen, Z. A review of NOx and SOx emission reduction technologies for marine diesel engines and the potential evaluation of liquefied natural gas fuelled vessels. Sci. Total Environ. 2021, 766, 144319. [CrossRef]

- Ushakov, S.; Stenersen, D.; Einang, P.-M.; Ask, T.-O. Meeting future emission regulation at sea by combining low-pressure EGR and seawater scrubbing. J. Mar. Sci. Technol. 2020, 25, 482–497. [CrossRef]

- Hämäläinen, E. Estimated impacts of the sulfur directive on the Nordic industry. Eur. Transp. Res. Rev. 2015, 7, 8. [CrossRef]

- Lindstad, H.; Sandaas, I.; Strømman, A.H. Assessment of cost as a function of abatement options in maritime emission control areas. Transp. Res. Part D Transp. Environ. 2015, 38, 41–48. [CrossRef]

- Panasiuk, I.; Turkina, L. The evaluation of investments efficiency of SOx scrubber installation. Transp. Res. Part D Transp. Environ. 2015, 40, 87–96. [CrossRef]

- Hirata, K.; Niki, Y.; Kawada, M.; Iida, M. Development of Marine SCR System and Field Test on Ship. International Symposium on Marine Engineering (ISME) BEXCO, Busan, October 2009. Available online: https://www.nmri.go.jp/oldpages2/power-sys/ center/hirata/184_Koichi_Hirata.pdf (accessed on 2 April 2022).

- Magnusson, M.; Fridell, E.; Ingelsten, H.H. The influence of sulfur dioxide and water on the performance of a marine SCR catalyst. Appl. Catal. B Environ. 2012, 111, 20–26. [CrossRef]

- Cimino, S.; Lisi, L.; Tortorelli, M. Low temperature SCR on supported MnOx catalysts for marine exhaust gas cleaning: Effect of KCl poisoning. Chem. Eng. J. 2016, 283, 223–230. [CrossRef]

- Fridell, E.; Salo, K. Measurements of abatement of particles and exhaust gases in a marine gas scrubber. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230, 154–162. [CrossRef]

- Brynolf, S.; Magnusson, M.; Fridell, E.; Andersson, K. Compliance possibilities for the future ECA regulations through the use of abatement technologies or change of fuels. Transp. Res. Part D Transp. Environ. 2014, 28, 6–18. [CrossRef]

- Ammar, N.R.; Seddiek, I.S. Eco-environmental analysis of ship emission control methods: Case study RO-RO cargo vessel. Ocean. Eng. 2017, 137, 166–173. [CrossRef]

- Seddiek, I.S.; Elgohary, M.M. Eco-friendly selection of ship emissions reduction strategies with emphasis on SOx and NOx emissions. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 737–748. [CrossRef]

- Viana, M.; Hammingh, P.; Colette, A.; Querol, X.; Degraeuwe, B.; de Vlieger, I.; van Aardenne, J. Impact of maritime transport emissions on coastal air quality in Europe. Atmos. Environ. 2014, 90, 96–105. [CrossRef]

- Nikopoulou, Z. Incremental costs for reduction of air pollution from ships: A case study on North European emission control area. Marit. Policy Manag. 2017, 44, 1056–1077. [CrossRef]

- Boscarato, I.; Hickey, N.; Kašpar, J.; Prati, M.-V.; Mariani, A. Green shipping: Marine engine pollution abatement using a combined catalyst/seawater scrubber system. 1. Effect of catalyst. J. Catal. 2015, 328, 248–257. [CrossRef]

- Lindstad, H.; Eskeland, G.S.; Psaraftis, H.; Sandaas, I.; Strømman, A.H. Maritime shipping and emissions: A three-layered, damage-based approach. Ocean. Eng. 2015, 110, 94–101. [CrossRef]

- Dulebenets, M.A. Green vessel scheduling in liner shipping: Modeling carbon dioxide emission costs in sea and at ports of call. Int. J. Transp. Sci. Tech. 2018, 7, 26–44. [CrossRef]

- ABS. Exhaust Gas Scrubber Systems: Status and Guidance. 2013. Available online: https://ww2.eagle.org/content/dam/eagle/ publications/2013/Scrubber_Advisory.pdf (accessed on 2 April 2022).

- EGC Handbook 2012. A Practical Guide to Exhaust Gas Cleaning Systems for the Maritime Industry. 2012. Available online: https://www.egcsa.com/wp-content/uploads/EGCSA-Handbook-2012-A5-size-.pdf (accessed on 2 April 2022).

- Macdonald, F.; Rojon, I. (Eds.) Fathom Maritime Intelligence. Marine Scrubbers: The Guide 2015. 2015. Available online:

- http://www.fathommaritimeintelligence.com/uploads/2/5/3/9/25399626/scrubber_guide_sample_pages.pdf (accessed on 2 April 2022).

- Gregory, D.; West, M. EGCSA Handbook; Exhaust Gas Cleaning Systems Association: London, UK, 2010.

- Watanabe, Y.; Koyanagi, S. Development and installation of marine-use hybrid SOx scrubber system that complies with IMO SOx emission regulations. Mitsubishi Heavy Ind. Tech. Rev. 2016, 53, 48.

- MAN Diesel & Turbo. Tier III NOx Technologies—Comparison of EGR with SCR, Presentation; MAN Diesel & Turbo: Augsburg, Germany, 2013.

- MAN Diesel & Turbo. Marine Engine IMO Tier II and Tier III Programme 2015; Report. May 2022. Available online: https: //mandieselturbo.com/docs/default-source/sales-force-package/marine_engine_programme_2015.pdf?sfvrsn (accessed on 2 April 2022).

- Kjølholt, J.; Aakre, S.; Jürgensen, C.; Lauridsen, J. Assessment of Possible Impacts of Scrubber Water Discharges on the Marine Environment. Environmental Project No. 1431, Danish Ministry of Environment, Environmental Protection Agency. 2012. Available online: https://www2.mst.dk/Udgiv/publications/2012/06/978-87-92903-30-3.pdf (accessed on 2 April 2022).

- Krystallon, H. Sea Water Scrubbing—Does It Contribute to Increased Global CO2 Emission? Danish Ministry of the Environment:

- Littlehampton, UK, 2007.

- Hamworthy. Moss Flue Gas System, Inert Gas Systems; Hamworthy: Moss, Norway, 2007.

- Henriksson, T. SOx scrubbing of marine exhaust gases. Wartsila Tech. J. 2007, 55–58.

- Høy-Petersen, N. Answers to Specific Questions and General Information from Clean Marine, Oslo, Norway 2011. Available online: www.cleanmarine.com (accessed on 2 April 2022).

- Hufnagl, M.; Liebezeit, G.; Behrends, B. Effects of Sea Water Scrubbing; Final Report; BP Marine: Navi Mumbai, India, 2005.

- Kircher, D.; Stotz, T. Holland America Line Sea water scrubber demonstration project. In Proceedings of the Faster Freight, Cleaner Air Northwest Conference, Seattle, WA, USA, 17 September 2008.

- Kullas-Nyman, B.-M. Exhaust gas scrubbing systems: Technical and economic aspects. In Proceedings of the Wärtsilä Presentation, Maritime Stakeholder Event, Brussels, Belgium, 1 June 2011.

- Lloyd’s Register. Understanding Exhaust Gas Treatment Systems: Guidance for Shipowners and Operators. June 2012. Available online: https://www.rtu.lv/writable/public_files/RTU_understanding_exhaust_gas_treatment_systems.pdf (accessed on 2 April 2022).

- Oikawa, K.; Yongsiri, C.; Takeda, K.; Harimoto, T. Seawater flue gas desulfurization: Its technical implications and performance results. Environ. Prog. 2004, 22, 67–73. [CrossRef]

- Reynolds, K. Exhaust gas cleaning systems selection guide. In Ship Operations Cooperative Program; U.S. Department of Transportation: Elliot City, MD, USA, 2011.

- Ritchie, A.; de Jonge, E.; Hugi, C.; Cooper, D. Service Contract on Ship Emissions: Assignment, Abatement and Market-Based Instruments, Task 2c-SO2 Abatement; European Commission Directorate General Environment: Brussels, Belgium, 2005.

- Scala, F.; Lancia, A.; Nigro, R.; Volpicelli, G. Spray-dry desulfurization of flue gas from heavy oil combustion. J. Air Waste Manag. Assoc. 2005, 55, 20–29. [CrossRef]

- Wärtsilä. Wärtsilä Low-Speed Engines NOx—Emission—Tier III Solutions. INTERTANKO Annual Event, Technical Workshop—Air Emissions NOx Tier III; Wärtsilä: Athens, Greece, 2015.

- Wärtsilä. Wärtsilä Environmental Technologies, Wartsila Environmental Product Guide; Wärtsilä: Athens, Greece, 2015.

- Sun, X.; Meng, F.; Yang, F. Application of seawater to enhance SO2 removal from simulated flue gas through hollow fiber membrane contactor. J. Membr. Sci. 2008, 312, 6–14. [CrossRef]

- Tasin, A. Introduction to Scrubber Technologies; Wärtsilä Presentation: Newark, NJ, USA, 2015.

- Kouremenos, D.A.; Hountalas, D.T.; Binder, K.B.; Raab, A.; Schnabel, M.H. Using advanced injection timing and EGR to improve DI diesel engine efficiency at acceptable NO and soot levels. SAE Trans. 2001, 110, 55–68. [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 1: Effect of reducing inlet charge oxygen. SAE Trans. 1996. [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 2: Effects of carbon dioxide. SAE Trans. 1996. [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 3: Effects of water vapour. SAE Trans. 1997. [CrossRef]

- Ladommatos, N.; Abdelhalim, S.; Zhao, H.; Hu, Z. The dilution, chemical and thermal effects of exhaust gas recirculation on diesel emission—Part 4: Effects of carbon dioxide and water vapour. SAE Trans. 1997, 106, 1844–1862. [CrossRef]

- Ladommatos, N.; Balian, R.; Horrocks, R.; Cooper, L. The effect of exhaust gas recirculation on soot formation in a high-speed direct-injection diesel engine. SAE Trans. 1996. [CrossRef]

- Couple Systems. The Very New Exhaust Gas Cleaning System; Couple Systems: Bardowick, Germany, 2010.

- Azzara, A.; Rutherford, D.; Wang, H. Feasibility of IMO Annex VI Tier III Implementation Using Selective Catalytic Reduction. The International Council on Clean Transportation (ICCT) 2014, Working Paper 2014-4. Available online: https://theicct.org/ sites/default/files/publications/ICCT_MarineSCR_Mar2014.pdf (accessed on 2 April 2022).

- International Association for Catalytic Control of Ship Emissions to Air (IACCSEA). 2020. Available online: https://www.

- iaccsea.com/wp-content/uploads/2018/12/IACCSEA-Marine-SCR-Technical-and-operational-capabilities-2013.pdf (accessed on 2 April 2022).

- Kang, X.; Ma, X.; Yin, J.; Gao, X. A study on simultaneous removal of NO and SO2 by using sodium persulfate aqueous scrubbing. Chin. J. Chem. Eng. 2018, 26, 1536–1544. [CrossRef]

- ABS, Global Sulfur Cap—2020. Available online: https://ww2.eagle.org/content/dam/eagle/advisories-and-debriefs/ABS_ Debrief_Global_Sulfur_Cap_16385.pdf (accessed on 2 April 2022).

- Caiazzo, G.; Langella, G.; Miccio, F.; Scala, F. An experimental investigation on seawater SO2 scrubbing for marine application. Environ. Progress Sustain. Energy 2013, 32, 1179–1186. [CrossRef]

- Chevron, Marine Lubricants White Paper, The 2020 Global Sulfur Cap and the Role of Cylinder Oil Lubricants. Available online: https://www.chevronmarineproducts.com/content/dam/chevron-marine/white-papers/2020%20Global%20Cap% 20Whitepaper%20DESKTOP.pdf (accessed on 2 April 2022).

- Ülpre, H.; Eames, I. Environmental policy constraints for acidic exhaust gas scrubber discharges from ships. Mar. Pollut. Bull. 2014, 88, 292–301. [CrossRef]

- Flagiello, D.; Erto, A.; Lancia, A.; Di Natale, F. Experimental and modelling analysis of seawater scrubbers for sulfur dioxide removal from flue-gas. Fuel 2018, 214, 254–263. [CrossRef]

- Abadie, L.-M.; Goicoechea, N.; Galarraga, I. Adapting the shipping sector to stricter emissions regulations: Fuel switching or installing a scrubber? Transp. Res. Part D Transp. Environ. 2017, 57, 237–250. [CrossRef]

- International Chamber of Shipping. Guidance to Shipping Companies and Crews on Preparing for Compliance with the 2020 ‘Global Sulfur Cap’ for Ships’ Fuel Oil in Accordance with MARPOL Annex VI, 1 July 2019. Available online: https://www.ics-shipping.org/docs/default-source/resources/guidance-for-compliance-with-the-2020-global-sulfur-capjuly-2019.pdf?sfvrsn=24 (accessed on 2 April 2022).

- Rass, K.; Affolter, S.; Mader, R.; Rozmyslowicz, B.; Stark, M.; Weber, M.F. Impact of Sulfur Cap 2020 on Two-Stroke Engine Tribology Aspects. 19th CIMAC Congress, Paper 437, Vancouver, Canada, 10–14 June 2019. Available online: https://www.wingd.com/ en/documents/general/papers/impact-of-sulfur-cap-2020-on-2-stroke-engine-tribology-cimac2019-paper-437-k-rass/ (accessed on 2 April 2022).

- Marocco, L. Modeling of the fluid dynamics and SO2 absorption in a gas–liquid reactor. Chem. Eng. J. 2010, 162, 217–226. [CrossRef]

- Brown, K.; Kalata, W.; Schick, R. Optimization of SO2 Scrubber using CFD Modeling. Procedia Eng. 2014, 83, 170–180. [CrossRef]

- Tang, X.-J.; Li, T.; Yu, H.; Zhu, Y.-M. Prediction model for desulfurization efficiency of on-board magnesium-base seawater scrubber. Ocean Eng. 2014, 76, 98–104. [CrossRef]

- Kim, A.-R.; Seo, Y.-J. The reduction of SOx emissions in the shipping industry: The case of Korean companies. Mar. Policy 2019, 100, 98–106. [CrossRef]

- Gu, Y.; Wallace, S.W. Scrubber: A potentially overestimated compliance method for the Emission Control Areas. The importance of involving a ship’s sailing pattern in the evaluation. Transp. Res. Part D Transp. Environ. 2017, 55, 51–66. [CrossRef]

- Makkonen, T.; Inkinen, T. Sectoral and technological systems of environmental innovation: The case of marine scrubber systems. J. Clean. Prod. 2018, 200, 110–121. [CrossRef]

- Schinas, O.; Stefanakos, C.N. Selecting technologies towards compliance with MARPOL Annex VI: The perspective of operators. Transp. Res. Part D Transp. Environ. 2014, 28, 28–40. [CrossRef]

- Darake, S.; Hatamipour, M.S.; Rahimi, A.; Hamzeloui, P. SO2 removal by seawater in a spray tower: Experimental study and mathematical modeling. Chem. Eng. Res. Des. 2016, 109, 180–189. [CrossRef]

- Jiang, L.; Kronbak, J.; Christensen, L.-P. The costs and benefits of sulfur reduction measures: Sulfur scrubbers versus marine gas oil. Transp. Res. Part D Transp. Environ. 2014, 28, 19–27. [CrossRef]

- Lindstad, H.E.; Rehn, C.-F.; Eskeland, G.S. Sulfur abatement globally in maritime shipping. Transp. Res. Part D Transp. Environ. 2017, 57, 303–313. [CrossRef]

- Endres, S.; Maes, F.; Hopkins, F.; Houghton, K.; Mårtensson, E.M.; Oeffner, J.; Quack, B.; Singh, P.; Turner, D. A new perspective at the ship-air-sea-interface: The environmental impacts of exhaust gas scrubber discharge. Front. Mar. Sci. 2018, 5, 139. [CrossRef]

- Turkina, L.; Panasiuk, I. Optimization of production of ship hull parts. In Proceedings of the 15th International Conference Transport Means 2011, Kaunas, Lithuania, 20–21 October 2011.

- Turner, D.R.; Edman, M.; Gallego-Urrea, J.-A.; Claremar, B.; Hassellov, I.-M.; Omstedt, A.; Rutgersson, A. The potential future contribution of shipping to acidification of the Baltic Sea. Ambio 2018, 47, 368–378. [CrossRef]

- Ma, H.; Steernberg, K.; Riera-Palou, X.; Tait, N. Well-to-wake energy and greenhouse gas analysis of SOx abatement options for the marine industry. Transp. Res. Part D Transp. Environ. 2012, 17, 301–308. [CrossRef]

- Kackur, J. Wartsila, Shipping in the 2020 Era—Selection of Fuel and Propulsion Machinery, Business White Paper. Available online: https://www.motorship.com/__data/assets/pdf_file/0036/986319/White-Paper_Shipping-in-the-2020-era_Pre-final. pdf (accessed on 2 April 2022).

- An, S.; Nishida, O. New application of seawater and electrolyzed seawater in air pollution control of marine diesel engine. JSME Int. J. Ser. B Fluids Therm. Eng. 2003, 46, 206–213. [CrossRef]

- Andreasen, A.; Mayer, S. Use of seawater scrubbing for SO2 removal from marine engine exhaust gas. Energy Fuels 2007, 21, 3274–3279. [CrossRef]

- Caiazzo, G.; Di Nardo, A.; Langella, G.; Scala, F. Seawater scrubbing desulfurization: A model for SO2 absorption in fall-down droplets. Environ. Prog. Sustain. Energy 2012, 31, 277–287. [CrossRef]

- Caiazzo, G.; Miccio, F.; Scala, F. Modeling Heat and Mass Transfer in a Seawater Scrubber for Marine Application: Some Improvements Based on a CFD Simulation. XXXVI Meeting of the Italian Section of the Combustion Institute. 2013. Available online: http://www.combustion-institute.it/proceedings/XXXVI-ASICI/papers/36proci2013.VI1.pdf (accessed on 2 April 2022). 90. Rakopoulos, C.D.; Giakoumis, E.G.; Hountalas, D.T.; Rakopoulos, D.C. The Effect of Various Dynamic, Thermodynamic and Design Parameters on the Performance of a Turbocharged Diesel Engine Operating under Transient Load Conditions; SAE Technical Paper 2004-01-0926; SAE International: New York, NY, USA, 2004. [CrossRef]

- Kosmadakis, G.M.; Rakopoulos, D.C.; Rakopoulos, C.D. Methane/hydrogen fueling a spark-ignition engine for studying NO, CO and HC emissions with a research CFD code. Fuel 2016, 185, 903–915. [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Kosmadakis, G.M. Numerical and experimental study by quasidimensional modeling of combustion and emissions in variable compression ratio high-speed spark-ignition engine. ASCE J. Energy Eng. 2021, 147, 04021032. [CrossRef]

- Papagiannakis, R.G.; Hountalas, D.T.; Rakopoulos, C.D.; Rakopoulos, D.C. Combustion and Performance characteristics of a Di Diesel Engine Operating from Low to High Natural Gas Supplement Ratios at Various Operating Conditions; SAE Technical Paper No.

- 2008-01-1392; SAE International: New York, NY, USA, 2008. [CrossRef]

- Papagiannakis, R.G.; Krishnan, S.R.; Rakopoulos, D.C.; Srinivasan, K.K.; Rakopoulos, C.D. A combined experimental and theoretical study of diesel fuel injection timing and gaseous fuel/diesel mass ratio effects on the performance and emissions of natural gas–diesel HDDI engine operating at various loads. Fuel 2017, 202, 675–687. [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Papagiannakis, R.G. Evaluating oxygenated fuel’s influence on combustion and emissions in diesel engines using a two-zone combustion model. ASCE J. Energy Eng. 2018, 144, 04018046. [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kosmadakis, G.M.; Papagiannakis, R.G. Experimental comparative assessment of butanol or ethanol diesel-fuel extenders impact on combustion features, cyclic irregularity, and regulated emissions balance in heavy-duty diesel engine. Energy 2019, 174, 1145–1157. [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Mavropoulos, G.C.; Kosmadakis, G.M. Investigating the EGR rate and temperature impact on diesel engine combustion and emissions under various injection timings and loads by comprehensive two-zone modeling. Energy 2018, 157, 990–1014. [CrossRef]

- Rakopoulos, D.C. Effects of exhaust gas recirculation under fueling rate or air/fuel ratio–controlled strategies on diesel engine performance and emissions by two-zone combustion modeling. ASCE J. Energy Eng. 2021, 147, 04020079. [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Kosmadakis, G.M.; Giakoumis, E.G. Exergy assessment of combustion and EGR and load effects in DI diesel engine using comprehensive two-zone modeling. Energy 2020, 202, 117685. [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Development of cumulative and availability rate balances in a multi-cylinder turbocharged indirect injection diesel engine. Energy Convers. Manag. 1997, 38, 347–369. [CrossRef]

- Giakoumis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Combustion noise radiation during dynamic diesel engine operation including effects of various biofuels blends: A review. Renew. Sust. Energy Rev. 2016, 54, 1099–1113. [CrossRef]

- Rakopoulos, C.D.; Mavropoulos, G.C. Experimental instantaneous heat fluxes in the cylinder head and exhaust manifold of an air-cooled diesel engine. Energy Convers. Manag. 2000, 41, 1265–1281. [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kyritsis, D.C.; Andritsakis, E.C.; Mavropoulos, G.C. Exergy evaluation of equivalence ratio, compression ratio and residual gas effects in variable compression ratio spark-ignition engine using quasi-dimensional combustion modelling. Energy 2022, 244, 123080. [CrossRef]

- Tingas, E.A.; Im, H.G.; Kyritsis, D.C.; Goussis, D.A. The use of CO2 as an additive for ignition delay and pollutant control in CH4/Air autoignition. Fuel 2018, 211, 898–905. [CrossRef]

- Tingas, E.-A.; Kyritsis, D.C.; Goussis, D.A. H2/Air autoignition dynamics around the third explosion limit. ASCE J. Energy Eng. 2019, 145, 04018139. [CrossRef]

- Konstandopoulos, A.G.; Zarvalis, D.; Chasapidis, L.; Deloglou, D.; Vlachos, N.; Kotrba, A.; Anderson, G. Investigation of SCR catalysts for marine diesel applications. SAE Int. J. Engines 2017, 10, 1653–1666. [CrossRef]

- Liang, X.; Xiao, J.; Xu, Y.; Liu, S.; Men, X. CFD simulations to research the control rules with gate leaves in SCR-DeNOx facility for marine diesel engines. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015.

- Chen, Y.; Lv, L. Design and evaluation of an integrated SCR and exhaust muffler from marine diesels. J. Mar. Sci. Technol. 2015, 20, 505–519. [CrossRef]

- Zhu, Y.; Xia, C.; Shreka, M.; Wang, Z.; Yuan, L.; Zhou, S.; Feng, Y.; Hou, Q.; Abdu Ahmed, S. Combustion and emission characteristics for a marine low-speed diesel engine with high-pressure SCR system. Environ. Sci. Pollut. Res. 2020, 27. [CrossRef]

- Park, T.; Sung, Y.; Kim, T.; Lee, I.; Choi, G.; Kim, D. Effect of static mixer geometry on flow mixing and pressure drop in marine SCR applications. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 27–38. [CrossRef]

- Guo, Y.; Deng, Y.; Zhang, J.; Shen, Y.; Wilson, C. Experimental and numerical analysis of NOx reduction in marine urea-SCR system. In Proceedings of the 4th International Conference on Information, Cybernetics and Computational Social Systems (ICCSS), Dalian, China, 24–26 July 2017; pp. 450–455.

- Ayre, L.S.; Johnson, D.R.; Clark, N.N.; England, J.A.; Atkinson, R.J.; McKain, D.L., Jr.; Ralston, B.A.; Thomas, H.; Balon, T.H., Jr.; Moynihan, P.J. Novel NOx emission reduction technology for diesel marine engines. In Proceedings of the ASME 2011 Internal Combustion Engine Division Fall Technical Conference, ICEF2011, Morgantown, WV, USA, 2–5 October 2011. ICEF2011-60182.

- Xiao, Y.; Zhao, H.; Tian, X.; Tan, W. Investigation on the control strategy for marine selective catalytic reduction system. ASME Trans. J. Dyn. Sys. Meas. Control 2019, 141, 011005. [CrossRef]

- Foteinos, M.I.; Konstantinidis, S.K.; Kyrtatos, N.P.; Busk, K.-V. Simulation of the transient thermal response of a high pressure selective catalytic reduction aftertreatment system for a Tier III two-stroke marine diesel engine. ASME Trans. J. Eng. Gas Turbines Power 2019, 141, 071001. [CrossRef]

- Xi, H.; Zhou, S.; Zhou, J. New experimental results of NO removal from simulated marine engine exhaust gases by Na2S2O8/urea solutions. Chem. Eng. J. 2019, 362, 12–20. [CrossRef]

- Choi, C.; Sung, Y.; Choi, G.-M.; Kim, D.-J. Numerical analysis of NOx reduction for compact design in marine urea-SCR system. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 1020–1033. [CrossRef]

- Zhu, Y.; Zhang, R.; Zhou, S.; Huang, C.; Feng, Y.; Shreka, M.; Zhang, C. Performance optimization of high-pressure SCR system in a marine diesel engine. Part I: Flow optimization and analysis. Top. Catal. 2019, 62, 27–39. [CrossRef]

- Zhu, Y.; Zhang, R.; Zhou, S.; Huang, C.; Feng, Y.; Shreka, M.; Zhang, C. Performance optimization of high-pressure SCR system in a marine diesel. Part II: Catalytic reduction and process. Top. Catal. 2019, 62, 40–48. [CrossRef]

- Kleinhenz, M.; Fiedler, A.; Lauer, P.; Döring, A. SCR coated DPF for marine engine applications. Top. Catal. 2019, 62, 282–287.

- [CrossRef]

- Ha, T.-H.; Nishida, O.; Fujita, H.; Wataru, H. Simultaneous removal of NOx and fine diesel particulate matter (DPM) by electrostatic water spraying scrubber. J. Mar. Eng. Technol. 2014, 8, 45–53. [CrossRef]

- Zis, T.; Psaraftis, H.N. Operational measures to mitigate and reverse the potential modal shifts due to environmental legislation. Marit. Policy Manag. 2019, 46, 117–132. [CrossRef]

- Lehtoranta, K.; Aakko-Saksa, P.; Murtonen, T.; Vesala, H.; Ntziachristos, L.; Rönkko, T.; Karjalainen, P.; Kuittinen, N.; Timonen, H. Particulate mass and nonvolatile particle number emissions from marine engines using low-sulfur fuels, natural gas, or scrubbers. Environ. Sci. Technol. 2019, 53, 3315–3322. [CrossRef] [PubMed] 123. Greek Shipowner. Personal communication, 2020.

- DNV GL. Global Sulfur Cap 2020, Compliance Options and Implications for Shipping—Focus on Scrubbers. Available online: https://www.dnvgl.com/maritime/publications/global-sulfur-cap-2020.html (accessed on 2 April 2022).

- Yang, Z.L.; Zhang, D.; Caglayan, O.; Jenkinson, I.D.; Bonsall, S.; Wang, J.; Huang, M.; Yan, X.P. Selection of techniques for reducing shipping NOx and SOx emissions. Transp. Res. Part D Transp. Environ. 2012, 17, 478–486. [CrossRef]

- Claremar, B.; Haglund, K.; Rutgersson, A. Ship emissions and the use of current air cleaning technology: Contributions to air pollution and acidification in the Baltic Sea. Earth Syst. Dyn. 2017, 8, 901–919. [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [CrossRef]

- Williams, P.J. Use of seawater as makeup water for wet flue gas desulfurization systems. In Proceedings of the EPRI-DOE-EPA Combined Utility Air Pollutant Control Symposium, Atlanta, GA, USA, 16–20 August 1999.

- International Maritime Organization. Investigation of Appropriate Control Measures (Abatement Technologies) to Reduce Black Carbon Emissions from International Shipping 2015. Available online: http://www.imo.org/en/OurWork/Environment/ PollutionPrevention/AirPollution/Documents/Air%20pollution/Black%20Carbon.pdf (accessed on 2 April 2022).

- DNV GL. Global Sulfur Cap 2020. Get Insights on Compliance Options and Implications for Shipping. Focus on Scrubbers; DNV GL: Bærum, Norway, 2019.

- DNV GL. Global Sulfur Cap 2020. Know the Different Choices and Challenges for On-Time Compliance; DNV GL: Bærum, Norway, 2020. 132. The Swedish Club, Sulfur Guide, Dealing with the Sulfur Cap 2020 and Beyond. Available online: https://www.swedishclub. com/media_upload/files/Publications/Loss%20Prevention/Sulfur-Guide%202019%20www.pdf (accessed on 2 April 2022).

- Cho, B.K.; Lee, J.H.; Crellin, C.C.; Olson, K.L.; Hilden, D.L.; Kim, M.K.; Kim, P.S.; Heo, I.; Oh, S.H.; Nam, I.-S. Selective catalytic reduction of NOx by diesel fuel: Plasma-assisted HC/SCR system. Catal. Today 2012, 191, 20–24. [CrossRef]

- Liu, B.; Wu, X.; Liu, X.; Gong, M. Assessment of ecological stress caused by maritime vessels based on a comprehensive model using AIS data: Case study of the Bohai Sea, China. Ecol. Indic. 2021, 126, 107592. [CrossRef]

- Zhang, Y.; Yang, X.; Brown, R.; Yang, L.; Morawska, L.; Ristovski, Z.; Fu, Q.; Huang, C. Shipping emissions and their impacts on air quality in China. Sci. Total Environ. 2017, 581–582, 186–198. [CrossRef]