Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Mechanical

Fiber-reinforced plastic (FRP) composite laminates are widely used in the aerospace field, automotive industry, wind power generation, and civil infrastructure because of their lightweight and relatively high strength characteristics. Interlaminar fracture toughness (ILFT) is a quantitative measure of the ability of composite laminates to resist crack extension and an estimate of material toughness.

- FRP

- delamination damage

- interlaminar fracture toughness (ILFT)

- short fiber toughening

1. Introduction

Fiber-reinforced plastic (FRP) composite laminates are widely used in the aerospace field [1], automotive industry [2], wind power generation [3], and civil infrastructure [4] because of their lightweight and relatively high strength characteristics. However, as the laminates are bonded by resin only in the thickness direction, they are prone to cracking and eventually delamination under the action of external forces [5]. Delamination damage limits the development of composite materials as it seriously affects their safety performance and service life. Much work has been carried out to suppress delamination and increase damage tolerance, including Z-directional toughening (3D braiding [6,7,8,9], Z-pinning [10], laminate stitching [11], and 3D integrated woven spacer sandwich composites [12,13]), matrix modification [14], and interlaminate toughening [15]. Z-directional toughening, which introduces a separate yarn system in the Z-direction of the composite, has been shown to significantly improve interlaminar fracture toughness [16], but this may come at the cost of compromising the in-plane properties and is difficult to operate. Interlayer toughening and resin modification requires only minor changes to conventional processes for toughening purposes but use materials such as nanofilms and nanoparticles, which require high costs.

Short fibers are a variety of sources, excellent performance, and inexpensive materials that can be added to laminate plies alone for interlaminar toughening or mixed in resin to modify the resin matrix, which can simply and effectively improve the interlaminar strength of composites.

2. Interlaminar Fracture Toughness Characterization and Testing of Composite Laminates

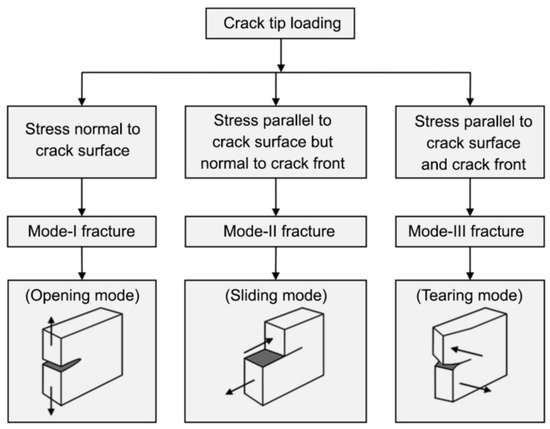

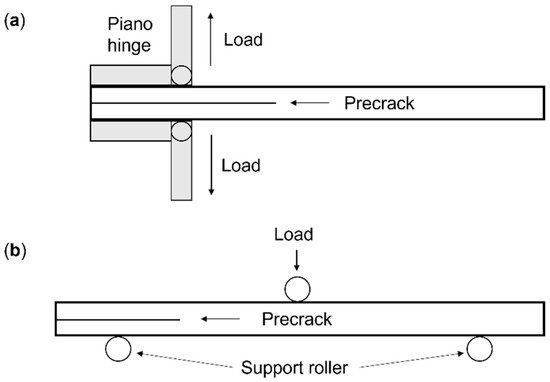

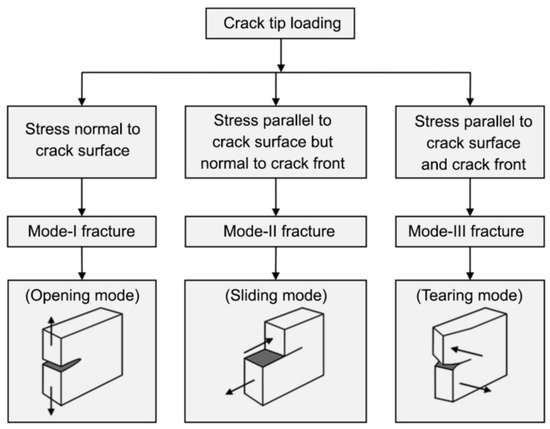

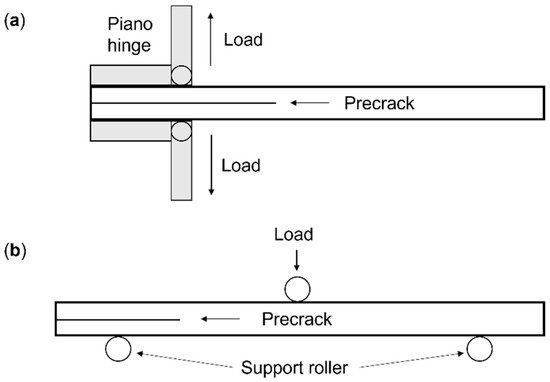

According to the different forms of load, the composite laminate delamination mainly has the types: opening mode (mode I), sliding mode (mode II), and tearing mode (mode III). The three forms of delamination, as shown in Figure 1, of which mode III delamination is less studied, account for a negligible fraction [17,18]. Interlaminar fracture toughness (ILFT) is a quantitative measure of the ability of composite laminates to resist crack extension and an estimate of material toughness. The stress-based stress intensity factor K [19] and the strain-based strain energy release rate G [20] are often used to characterize delamination extension. Since composites are materials with anisotropic mechanical properties, the calculation of the stress intensity factor K for interlaminar cracks is particularly complicated, so most of the studies are conducted using the strain energy release rate G as the control parameter for delamination expansion. The strain energy release rate is the strain energy released per unit area of crack growth of the deformed object, and its critical value is called the critical strain energy release rate, expressed by the symbol GC, which indicates the energy required for crack expansion per unit area; generally, there is the mode I (GIC) and mode II (GIIC) [21]. From the ASTM standard, it is known that the mode I and mode II ILFT of composites is mainly obtained by the double cantilever beam (DCB) test [22] and end notched flexure (ENF) test [23], with the test setup diagram in Figure 2. The ILSS testing [24] is a popular method for characterizing the interfacial strength of composite materials. Composites are very sensitive to low-velocity impact loading in practical applications, so the low-velocity impact test [25] and compression after impact (CAI) test [26] are also often used together to characterize the resistance of composites to delamination when subjected to low-velocity impacts.

Figure 1. Modes of fracture [18].

Figure 2. Schematic diagrams of (a) double cantilever beam (DCB) test and (b) end notch flexure (ENF) test.

3. Short Fiber Toughening

3.1. Short Fiber Interlayer Toughening

In the 1990s, Sohn and Hu covered the surface of carbon fiber prepreg with chopped aramid fibers that accounted for 0.4% to 0.8% of the weight of the laminate and then cured it according to the conventional process. It was found that the addition of short fibers could produce fiber bridging during delamination extension to improve the mode I (GIC) and mode II (GIIC) interlaminar fracture toughness of the laminate by up to more than two times [27]. Since then, more scholars have begun to study short fibers as interlaminar toughening materials to improve the interlaminar fracture toughness of composites [28,29,30,31,32]. Liu et al. investigated the effect of three basic factors on the interlaminar fracture toughness of CF/EP composites using three-factor four-level orthogonal tests, as in Table 1, which are short fiber type, length, and density [33]. The results showed that the effects of each factor on the ILFT were in the order of fiber type, fiber density, and fiber length. The addition of Kevlar fiber most significantly enhanced GIC and GIIC; with the increase of short fiber density, GIC showed a positive correlation, and GIIC showed a decreasing and then increasing trend. Both GIC and GIIC tend to increase as the length of the staple fiber increases and tend to decrease when the length is too long. This provides some reference for future studies in terms of material selection and dosage, but the authors do not further analyze how length and density affect the interlaminar fracture properties.

Table 1. Orthogonal test table (Data from [33]).

| Number | Fiber Length (mm) |

Fiber Density (g/m2) |

Fiber Type |

|---|---|---|---|

| 1 | 3 | 5 | Kevlar |

| 2 | 3 | 10 | carbon fiber |

| 3 | 3 | 15 | glass fiber |

| 4 | 3 | 20 | basalt fiber |

| 5 | 7 | 5 | Kevlar |

| 6 | 7 | 10 | carbon fiber |

| 7 | 7 | 15 | glass fiber |

| 8 | 7 | 20 | basalt fiber |

| 9 | 11 | 5 | Kevlar |

| 10 | 11 | 10 | carbon fiber |

| 11 | 11 | 15 | glass fiber |

| 12 | 11 | 20 | basalt fiber |

| 13 | 15 | 5 | Kevlar |

| 14 | 15 | 10 | carbon fiber |

| 15 | 15 | 15 | glass fiber |

| 16 | 15 | 20 | basalt fiber |

Aramid fibers (AF) have the characteristics of high toughness, high elongation at break, and easy fibrillation on the surface [34]. Under the action of fiber bridging, the deformation and longitudinal tear of the fiber itself can absorb a lot of energy, which plays a very good role in toughening effect [35]. Wang et al. studied the interfacial toughness of CFRP reinforced by short aramid fibers with different lengths and areal densities based on the double cantilever beam test [36]. The results showed that the short aramid fibers with a length of 3 mm and an areal density of 24 g/m2 had the best toughening effect, the ultimate load, and the mode I interlaminar fracture toughness can be increased by 292.87% and 168.59%, respectively. To ensure the feasibility and effectiveness of aramid fiber interlaminar toughening CFRP, they adopted wettability treatment technology with resin pre-coating to treat short aramid fiber tissues (6 mm, 24 g/m2), and the peak load and GIC of CFRP were increased by 112%, and 160%, respectively. The pre-coating contributed 37% and 56% improvement, respectively [37]. This explains that the toughening ability of short Kevlar fibers of 3 mm is stronger than 6 mm at the same surface density. This provides a simple way to improve the interfacial compatibility of fibers and resins and also demonstrates that modification of short fibers can further improve the toughening effect.

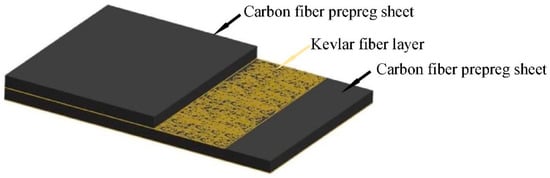

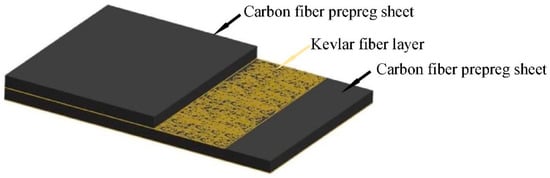

To enable the short fibers to be evenly dispersed between the layers, Hu et al. impregnated chopped Kevlar fibers in the resin and uniformly coated them on the mid-plane of the laminate. The laminate structure is shown in Figure 3. The effect of chopped Kevlar fiber toughening on the low-speed impact performance of CFRP through drop-weight impact test and compression after impact (CAI) test was studied [38]. The test results showed that the damage resistance of the toughened laminate did not show significant advantages at lower impact energies, and the effect of short fiber toughening was shown only at higher energy impacts. However, the CAI strength and damage strain values increased at all energy levels because the pullout of the chopped fibers consumed part of the energy in delamination expansion under compressive loading, slowing down the yielding process and increasing the CAI strength. The authors considered that short Kevlar fiber toughening is very effective in increasing the damage tolerance when the damage is dominated by mode I fracture toughness.

Figure 3. Structure of composite laminate with Kevlar-fiber toughening. The sandwich structure was adopted, with a carbon fiber prepreg sheet at the top and bottom and a Kevlar-fiber layer in the middle [38].

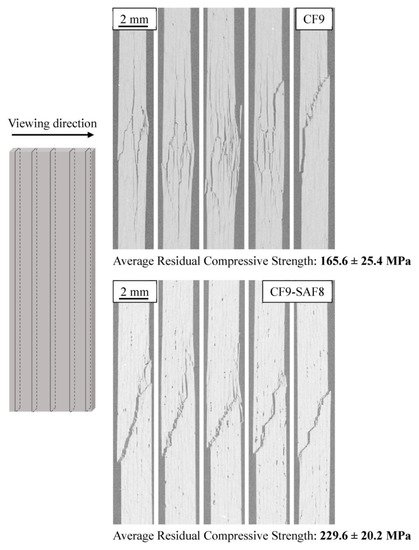

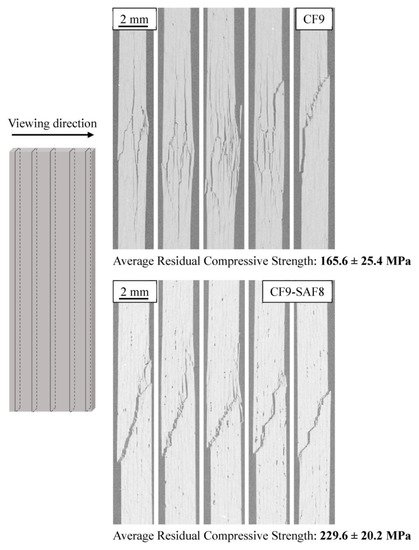

It is believed that adding short fibers to the interlayer is only beneficial to post-impact properties. Still, the interfacial staggering leads to a decrease in the flexural properties of CFRP. Yuan et al. placed an ultra-thin nonwoven short aramid fiber veil (UTNWSAFV) at the interface of all layers of CFRP laminates and found that not only the impact resistance of CFRP could be improved, but also the flexural strength and modulus were improved accordingly [39]. They prepared a toughened prepreg by interweaving the unbonded UTNWSAFV to the surface of the carbon fiber layer in the prepreg production process [40]. Impact tests and compression after impact tests showed that adding UTNWSAFV can effectively suppress out-of-plane deformation and layered expansion. The CAI failure pattern of the laminate with SAFV was changed from delamination damage to shear damage, as seen in Figure 4. The addition of short fibers to the prepreg production process to create short fiber toughened prepreg is a promising technology that focuses on how the short fibers are added to the prepreg in large quantities and uniformly, as this has a major impact on the stability of the composite properties.

Figure 4. CAI test failure morphology of CF9 and CF9-SAF8 (X-ray µCT) [40].

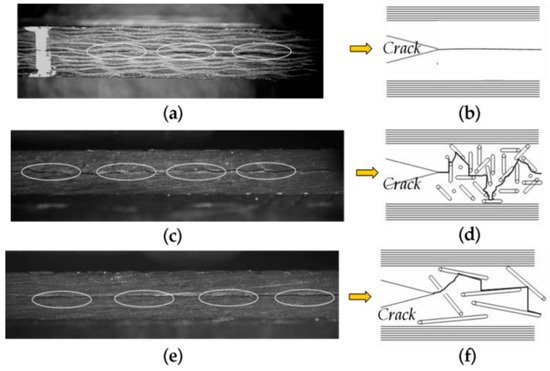

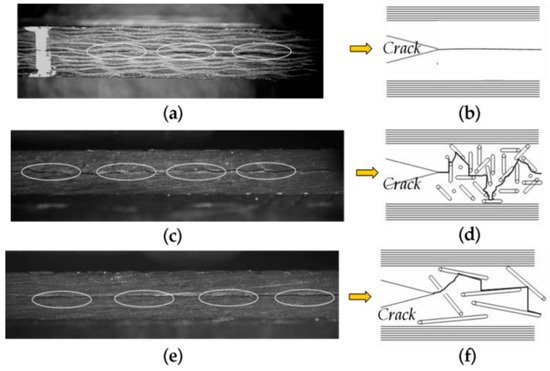

Carbon fibers (CF) have high strength and modulus and are often used to make composite materials. Due to their excellent properties, chopped carbon fibers are also used as interlaminar toughening materials to improve the fracture toughness of composites. Xu et al. compared the interlaminar fracture toughness and bending properties of CF/EP composites toughened with two lengths of chopped carbon fibers [41]. It showed that the shorter (0.8 mm) carbon fiber performed better than the longer (4.3 mm) carbon fiber in improving mode I fracture toughness. The longer carbon fiber contributed more to mode II fracture toughness, which was achieved without compromising the bending mechanical properties. Short carbon fibers easily form a three-dimensional interwoven network structure in the epoxy resin of the middle layer of the laminate, and this structure can play a better role in obstructing cracks, as shown in Figure 5. Moreover, due to the addition of short carbon fibers, the electrical conductivity in the thickness direction of the carbon fiber laminates has been improved. According to this conclusion, different lengths of staple fibers can be selected for selective toughening, depending on the form of loading the laminate is subjected to.

Figure 5. The crack propagation path in the mid-layer of laminates during Mode I DCB tests: (a,b) pure; (c,d) SCFs (7.8 mg/cm2) and (e,f) LCFs (7.8 mg/cm2) [41].

To improve the lightning strike resistance of composite materials, Liu et al. bonded chopped nickel-coat carbon fibers (NiCF) together with adhesive to make a NiCF veil, which was used as a multifunctional toughening layer for CFRP [42]. It is shown that the multifunctional NiCF veil can not only improve the interlayer fracture toughness of CFRP, which can increase the GIC by 74.75% and GIIC by 36.22%, but also improve the electrical conductivity in the thickness direction by 220.49%. Its toughening mechanisms include debonding and fracture of NiCF, as well as flaking and splitting of the nickel coating. The above study shows that the rupture and debonding of the coating absorbs additional energy to improve the interlaminar fracture toughness of the composite without losing the interfacial compatibility of the short fibers and the resin. Du et al. used CNT grafted short carbon fibers as interlaminar toughening materials for CF/EP composites, and the type I interlaminar fracture energy of CFRP could be increased by 125% when the density of CNT-SCF was 10 g/m2 [43]. Of particular note, he investigated the crack damage sensing ability of toughened CFRP composites using a simple electrical response method using an experimental setupand the results showed that the change in resistance increased monotonically with cracking, which provides a new method for measuring crack extension.

This entry is adapted from the peer-reviewed paper 10.3390/su14106215

This entry is offline, you can click here to edit this entry!