Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Materials Science, Coatings & Films

当今世界,“白色污染”问题越来越严重,许多国家都特别关注这个问题,减少聚合物废物和保护环境已成为最重要的任务之一。由于可生物降解包装膜材料的降解性、安全性、经济性和实用性,生物降解包装膜材料已成为包装行业取代传统包装膜材料的主要趋势,前提是满足包装性能要求。

- degradable

- packaging film materials

- degradation mechanism

- modified

1. Introduction

Plastic was once hailed as one of the greatest inventions of the 20th century, because of its light weight, good processing performance, low price and many other advantages that make the global plastic industry has been rapid development [1]. According to statistics, the total global production of plastic products exceeds 300 million tons [2,3,4], with 13 million tons entering the water [5]. However, only 6–26% of plastic products are recycled, which means that at least 74% of plastic waste ends up in landfills or enters the environment every year [3,6], of which about 46% comes from the packaging industry, especially food packaging films, which are largely non-recyclable [7]. Since most plastics are now made from non-biodegradable materials, it often takes one to two hundred years to degrade these plastic products [8,9,10,11,12,13].

Plastic is the most commonly used packaging material [14,15], especially packaging film material. However, the packaging industry generates about 141 million tons of plastic waste each year [16], and most of the packaging film materials are composed of non-degradable materials, which obviously leads to many environmental problems, such as “white pollution” [17,18,19]. General purpose plastic packaging films such as polyethylene (PE), polypropylene (PP), polystyrene (PS) and polyvinyl chloride (PVC) [20,21] film materials undergo a long period of aging under the current common waste disposal method of sanitary landfill conditions. Under the action of abiotic factors (such as solar radiation, high temperature, wave impact, gravel abrasion) or biotic factors (such as ingestion, colonization, degradation) [22,23], physical or chemical property changes, molecular weight reduction and molecular weight distribution changes, but its decomposition is not complete, the majority of decomposition into microplastics (particle size < 5 mm) or nanosized-plastics (particle size < 0.1 μm) [24,25]. At present, microplastics have been widely detected in oceans [24,26], sediments [27], rivers [28,29,30], lakes [20], atmosphere [31,32,33], soil [34,35] and organisms [36], disrupting the normal metabolism and energy balance in organisms, thus affecting the normal growth and reproduction of organisms and causing potential harm to human health [37,38].

To solve these problems, it has become important for biodegradable packaging film materials to replace traditional packaging film materials [39,40]. However, biodegradable plastics currently account for less than 1% of total plastics production [41]. Compared with traditional packaging film materials, biodegradable packaging film materials are more expensive to produce and have poor mechanical properties and their barrier properties, which are the main reasons for their limited applications [42].

2. Degradation Mechanism of Degradable Packaging Film Materials

Degraded plastics are plastics that have been subjected to defined environmental conditions for a period of time and contain one or more steps that result in significant changes in the chemical structure of the material resulting in loss of certain properties (such as integrity, molecular mass, structure or mechanical strength) and/or fragmentation [43,44]. As shown in Table 1, the degradation degree can be divided into complete and incomplete degradation, and different degradation mechanisms can be divided into photodegradation, water degradation, thermal oxidative degradation and biodegradation [45].

Table 1. The classification and characteristic of degradable plastics.

| Classification | Category | Features |

|---|---|---|

| By degradation principle | Biodegradable plastics | Similar performance to traditional plastics, good degradability, high safety |

| Photodegradable plastics | Simple and low cost production process | |

| Thermal oxidative degradation plastics | Requires oxygen and heat | |

| Hydrodegradable plastics | Short degradation time, no trace, no pollution, low cost | |

| By degradation characteristics | Fully degradable plastics | Completely disintegrates and leaves no trace |

| Incomplete degradable plastics | Partial degradation |

2.1. Photodegradation

Photodegradable materials are degraded to low molecular weight compounds that are relatively safe for the environment by photo-initiated fracture and free radical oxidative fracture reactions under the action of sunlight (mainly UV light) [46]. Photodegradable film materials can be mainly divided into photodegradable materials obtained by copolymerization and photodegradable materials with composite photosensitizers [47].

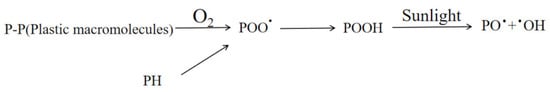

In sunlight, UV light with a wavelength of 290 nm–400 nm only accounts for about 5%, and it is the UV light that causes photodegradation of the film. Figure 1 shows the photodegradation mechanism. The molecular chains react under certain conditions of oxygen, temperature and humidity, and the long molecular chains are decomposed into peroxides and eventually achieve photodegradation [48].

Figure 1. The mechanism of photodegradation.

Christensen et al. [49] investigated the photodegradation properties of polymers with a 1:1 mass ratio of polycaprolactone to polyvinyl chloride by monitoring CO2 emissions during UV exposure. The results showed that the interaction of the two components in the polymer reduced the photodegradability. Najaf et al. [50] used polyaniline modified TiO2 as a photocatalyst and then combined it with polyvinyl chloride to make photodegradable films. The results showed that the quality of polyaniline decreased by 67% when the molar ratio of polyaniline to TiO2 was 10:1 under the condition of 30W UV lamp irradiation for 720 h, decreased by 12% compared with the pure polyvinyl chloride (PVC) film, and its photodegradation performance was greatly improved.

Photodegradable materials must be exposed to light and have a long degradation period, while most film materials are not exposed to natural light for a long time after disposal and it is difficult to ensure the degradation conditions required for photodegradable film materials, which greatly limits the large-scale application of photodegradable film materials.

2.2. Hydrodegradation

Hydrodegradable plastic is a kind of plastic that can self-degrade by hydrolysis. The essence is the presence of hydrolyzable covalent bonds in degradable plastics, such as esters, ethers, anhydrides, amides, carbamides or ester-amide groups [45], which can achieve dissolution when the plastic encounters water [51,52]. Water activity, temperature, pH and time are the key factors affecting the efficiency of hydrolysis [53].

Polyvinyl alcohol (PVA) is a water-soluble polymer with a carbon chain as the main chain and a large number of hydroxyl groups on the side chain [54,55]. It is non-toxic, easily processed, biodegradable, has good mechanical properties [56,57], and can be mixed with natural polymeric materials such as polysaccharides and proteins to improve its properties [58,59,60]. Mainly used in the packaging of water-soluble products, the buyer can do not touch the product in the process of using the product, safe and at the same time make the use of the product more convenient. However, the resistance of PVA film to water is very low, usually in a very short period of time can be completely dissolved [61]; therefore, if it is widely used in the field of packaging needs, it needs to be modified for water resistance.

Lv et al. [62] investigated the time-dependent hydrolysis behavior of polylactic acid (PLA) and starch/PLA composites. The results showed that the presence of starch may induce hydrolysis to occur at the interface between starch and PLA. In addition, starch can slightly slow down PLA hydrolysis without affecting the degree of PLA hydrolysis. Table 2 shows the water degradation of several common biodegradable polyesters in different water environments.

Table 2. Hydrologic degradation of several typical biodegradable polyesters in different water environments. Data from [63].

| Material | Conditions | Weight Loss % | Number-Average Molecular Weight (Mn) | Mechanical Properties |

|---|---|---|---|---|

| Polylactic acid (PLA) | Seawater | <2 | 96.60 × 103 to 83.85 × 103 | No significant change |

| Germicidal water | <2 | 96.60 × 103 to 67.98 × 103 | ||

| Poly (butyleneadipate-co-terephthalate) (PBAT) | Seawater | <2 | 46.67 × 103 to 20.31 × 103 | Total loss |

| Germicidal water | <2 | 46.67 × 103 to 16.02 × 103 | ||

| Poly (butylene succinate) (PBS) | Seawater | <2 | 41.56 × 103 to 30.11 × 103 | Total loss |

| Germicidal water | <2 | 41.56 × 103 to 18.63 × 103 | ||

| Polycaprolactone (PCL) | Seawater | 32 | 77.79 × 103 to 77.09 × 103 | Total loss |

| Germicidal water | <2 | 77.79 × 103 to 14.82 × 103 |

2.3. Thermal Oxidative Degradation

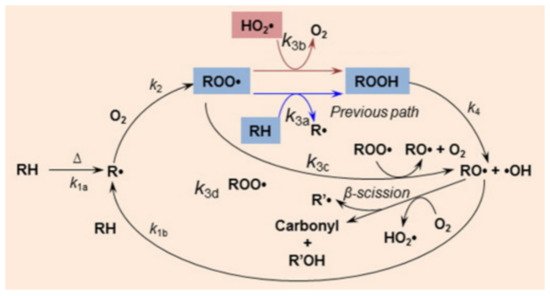

Thermally oxygen degraded plastic is that subjected to heat and/or oxidation over a period of time and contains one or more steps that result in significant changes in the chemical structure of the material, resulting in loss of certain properties (such as integrity, molecular mass, structure or mechanical strength) and/or fragmentation [64,65]. Heat can change the oxidation mechanism of plastics, and higher temperatures can improve the degradation of plastics [66,67]. Figure 2 shows the mechanism of thermal oxidative degradation. Thermally oxygen degraded plastic is also very difficult to degrade completely in most cases due to the conditions.

Figure 2. Auto-oxidation scheme of polymer. Reprinted from Ref. [68]. Copyright (2016), with permission from Elsevier.

Gaurav et al. [69] prepared two high-density polyethylene/polylactic acid blends with and without the addition of a compatibilizer and a pro-oxidant using a melt blending technique. The results showed that the addition of the compatibilizer led to a significant improvement in the mechanical properties of the blends and the addition of the pro-oxidant led to an improvement in their oxidative degradation properties.

2.4. Biodegradable

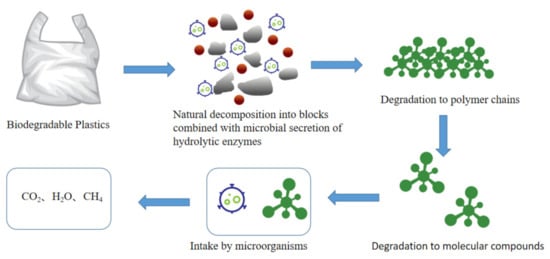

Biodegradable plastics are those degraded by naturally occurring microorganisms under natural conditions such as soil and/or sand, and/or specific conditions such as composting or anaerobic digestion or aqueous cultures, and ultimately degrade to environmentally benign biomass, CO2, CH4 and H2O [70,71,72]. Figure 3 shows the biodegradation mechanism. Biodegradable plastics have stable performance and can be completely degraded and returned to nature in a short period of time under composting conditions [73].

图 3.生物降解的机制。

目前的研究表明,动物、植物、微生物和酶都具有降解塑料的能力[74,75]。表3显示了普通塑料的生物降解。在改变塑料性能的众多途径中,塑料的生物降解是塑料进入环境不可避免的环境过程之一,也是一种原位、绿色、相对低成本、低技术的塑料垃圾处理方式。

在各种可降解机理中,生物降解比其他降解机理更完整、更快速,降解产物无害。可生物降解的塑料可以与有机废物一起堆肥,从而与一般塑料废物相比,消除了人工分拣步骤,大大方便了废物的收集和处置,从而使堆肥和有机废物的无害化处置成为现实[80]。与传统薄膜材料相比,生物降解包装膜材料具有绿色、环保、资源节约等特点,从而逐渐成为包装行业的研究热点,发展可生物降解包装膜是从根本上解决“白色污染”的有效途径。

This entry is adapted from the peer-reviewed paper 10.3390/membranes12050500

This entry is offline, you can click here to edit this entry!