Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Materials Science, Coatings & Films

|

Materials Science, Composites

|

Nanoscience & Nanotechnology

Flexible electrode technology is the key to the wide application of flexible electronics. However, flexible electrodes will break when large deformation occurs, failing flexible electronics. It restricts the further development of flexible electronic technology. Flexible stretchable electrodes are a hot research topic to solve the problem that flexible electrodes cannot withstand large deformation. Flexible stretchable electrode materials have excellent electrical conductivity, while retaining excellent mechanical properties in case of large deformation.

- flexible stretchable electrodes

- flexible electronics

- electrode material

1. Concept

The ordinary electrode belongs to a rigid physical form and does not have flexibility or extensibility; the structure of the flexible electrode is integrated, which is flexible, but not stretchable; the flexible stretchable electrode is flexible and stretchable. Ordinary electrodes are generally prepared by mixing active materials, adhesives, and conductive agents, grinding them evenly, and then coating metal collectors with them. Due to the heterogeneous interface between the collector and the active material layer, such electrodes are prone to fall off or powder when folded or bent, leading to failure of the electrodes [8]. The development of flexible electronics requires high capacity, high stability, and high flexibility of the electrode materials. Flexible electrodes are mainly made up of conductive flexible self-supporting electrodes or by loading active materials onto flexible conductive materials [9]. Morphologically, the perception of multidimensional space is characterized by repeated stretching, compression, folding and torsion. Flexible electronics are required to maintain their original functions in any of the above-mentioned shapes, and it is not enough for electrodes to be flexible only.

The flexible electrodes that retain their function despite a strain of 10% are referred to as flexible stretchable electrodes, based on the elastic limit of the human skin [10]. In addition to being highly flexible, conductive, and loaded with active materials, flexible stretchable electrodes also need to meet the requirements of stretchability, strong adhesion, surface modifiability, and biocompatibility [11]. In the future, our perception will be greatly expanded by electronics built into our clothes and accessories, attached to our skin, and even implanted into our bodies, enabling us to blend highly efficiently with the perceived information. In addition, due to advances in flexible materials and flexible electronic products, great progress has been made in bioheuristic flexible robot technology [12,13,14,15,16,17].

From a biomedical perspective, this biocompatible electronic product, including wearable electronic devices [18,19], epidermal devices [20,21,22,23,24], and implantable electronic devices [25,26,27,28], plays an increasingly important role in human health monitoring, which will significantly change the future of health care and our relationship with electronics; from the perspective of smart robots, a biomimetic soft robot with skin-like sensors and soft actuators is expected to interact with human beings and their surroundings, significantly enhancing security, sensitivity, and adaptive responses, to achieve a complete human-machine cycle; from the perspective of the future industrial internet, it can achieve the multidimensional and high-fidelity representation of production feature data, and ultimately achieve the accurate construction and free regulation of the Internet through the establishment of the model database, the classification of production elements, and the correlation between each model and each other.

2. Performance

Conductivity is one of the key indices of the electrical properties of flexible stretchable electrodes, which is related to the composition and structure of the material itself. The flexible stretchable electrode with good performance should show low resistance under the maximum operating strain, and the resistance value is almost unchanged during the cycle. Generally, the square resistance is the resistance value on the unit thickness and unit area of conductive materials, and the unit is Ω/sq or Ω/□. For a thin square film electrode with side length l and thickness d, the square resistance can be expressed as: RS=ρlld=ρd. Where the resistance RS (Ω/sq) is equal to the volume resistivity ρ (Ω·m) divided by thickness d, conductivity σ (S/m) is the reciprocal of volume resistivity. It can be seen from the above formula that the block resistance is independent of the sample size, directly proportional to the resistivity and inversely proportional to the thickness of the film sample. It is a parameter comprehensively reflecting the conductivity of the film. Among them, “square” has no practical significance, but is used to distinguish it from the resistance between two points.

The deformation types of flexible electronics in different use scenarios can be divided into bending, twisting, uniaxial tensile deformation, biaxial tensile deformation, circumferential tensile deformation, etc. As an indispensable part of flexible electronics, electrode materials can also withstand external forces and resist deformation, which we call the mechanical properties of materials. Under the action of external forces, the shape and size of the material change, which is called deformation. When a material is deformed, the relative positions and distances between molecules or ions within it change, and additional internal forces between atoms and molecules will be generated to resist external forces, and an attempt is made to restore to the state before the deformation. When the balance is reached, the additional internal forces are equal in size, and opposite in direction, to the external forces. The additional internal force on a material’s unit area is called stress, and its value is equal to the external force on a unit area; that is, σ = F/A, where σ is stress, F is external force, and A is area. In the International System of Units, the unit of stress is N/m2, which is also written as Pa. If the area before the material is stressed is A0, then σ0 = F/A0 is the nominal stress. If the material is compressed by force and the area is A, σT = F/A is the true stress. Nominal stress is commonly used in practice, and there is little difference in numerical values between materials with small deformation.

Strain is used to characterize the relative displacement of particles within a material under stress. For isotropic materials, there are three basic types of strain: tensile strain ε, shear strain γ and compression strain Δ. For ideal elastic materials, elastic deformation occurs under stress. The relationship between stress and strain obeys Hooke’s law, that is, the stress σ is proportional to the strain ε: σ = E⋅ε. The scale factor E in the formula is called the elastic modulus. Elastic modulus is the stress at which a material undergoes unit strain, which indicates the resistance of the material to deformation. The larger the E, the less likely the material will be to deform, indicating greater stiffness of the material. The unit of elastic modulus is the same as the unit of stress, both N/m2.

3. Functional Adjustment

Flexible electrodes can be divided into three levels according to their mechanical properties. The lowest level is bendable and coileable, the second level is plastic stretchable, and the highest level is flexible stretchable. As far as the degree of preparation difficulty, the higher a material is in the hierarchy, the more difficult the preparation. Concerning application requirements, the higher a material is in the hierarchy, the broader the scope of application. The development of flexible stretchable electrodes is a hotspot and difficult point in current research. A large stretching range (>1%) requires higher performance and structure of materials [40]. Flexible stretchable materials are usually prepared by two methods: one is to develop a new type of flexible stretchable material [41], and the other is to process the material into a geometric structure with scalability. As shown in Table 1, the process complexity of the two methods is different and the flexible stretchable materials prepared have different mechanical properties.

Table 1. Comparison of two different types of flexible stretchable electrodes.

| Type | Flexible Form | Patterning | Stretch Direction | Fatigue Resistance |

Process Complexity and Cost |

|---|---|---|---|---|---|

| Flexible stretchable material | Flexible material | Easily | Multiple Directions | Moderate | Simple, large-area preparation and low cost |

| Structural design of stretchable materials | Structural deformation |

Difficulty | Uniaxially/Biaxially | Good | Complex, small size, high cost, and high equipment requirements |

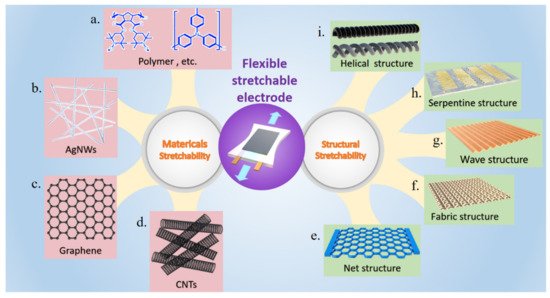

Flexible stretchable electronic materials can be divided into two categories: flexible stretchable materials and flexible stretchable composite materials. Flexible stretchable materials refer to materials that have certain stretchability when conductive polymers (Figure 3a), metal nanostructures (Figure 3b), graphene (Figure 3c), and carbon nanotubes (Figure 3d) are processed into thin films, fibers, and blocks. Flexible stretchable composite materials refer to the preparation of stretchable composite materials by loading the active materials which are not stretchable on the flexible stretchable materials. Electrodes made of flexible stretchable electronic materials have excellent stretchability and tensile restorability, but their shortcomings are limited by the material itself, and their conductivity and energy density are low.

Figure 3. Flexible stretchable materials: (a) conductive polymers, (b) metal nanostructures, (c) graphene and (d) carbon nanotubes, and stretchable structures: (e) mesh, (f) fabric, (g) wavy, (h) snake, and (i) spiral.

It is difficult for flexible stretchable materials to maintain absolute stability of resistance during stretching, and it is unavoidable that conductive materials undergo micro-structure fracture when they recover from stretching. Due to the low electrical stability of flexible stretchable materials, scientists have proposed geometric structures to achieve the stretchability of materials [42,43]. Conductors are fabricated into scalable geometries such as mesh [44] (Figure 3e), fabric [45] (Figure 3f), wavy [46] (Figure 3g), snake [47] (Figure 3h), and spiral [48] (Figure 3i) to form flexible stretchable electrodes. When an electrode with a stretchable structure is stretched, the conductor material can cleverly use its geometric shape to buffer the external stress, thus maintaining a stable conductivity at a larger stretch length and even lower than the resolution limit.

After the requirement of flexible stretchability was achieved in mechanical performance, with further research on flexible stretchable electrodes it was applied to epidermal electronic devices and implantable electronic devices [49,50], which puts forward new requirements for flexible stretchable electrodes. To achieve a close skin fit, flexible stretchable materials need to have a lower Young’s modulus (<260 kPa [51]) than the human epidermis. In addition, long-time wear puts higher requirements on the biocompatibility and wearing comfort of the materials.

This entry is adapted from the peer-reviewed paper 10.3390/coatings12050558

This entry is offline, you can click here to edit this entry!