Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The chitosan shows interesting and unique properties, thus it can be used for different purposes which contributes to the design and development of sustainable novel materials. This helps in promoting sustainability through the use of chitosan and diverse materials based on it.

- chitosan

- sustainable development

- circular economy

1. Chitosan as a Renewable Material

1.1. Chitosan as a Biomaterial

Chitosan is obtained through the deacetylation of chitin, which is one of the most abundant biomaterials after cellulose. This one is a polysaccharide which can be found in crustaceans, insects, or fungi (Table 1) [1]. Chitin is considered a linear long-chain homopolymer which is composed of N-acetyl glucosamine, and can develop three polymorphic forms known as α-, β-, and γ-chitin [2].

Table 1. Some of the main chitin sources and percentages [1].

| Source | Percentage (%) |

|---|---|

| Shrimps | 30–40% |

| Squids | 20–40% |

| Krill | 20–30% |

| Crabs | 15–30% |

| Fungi | 10–25% |

| Insects | 5–25% |

| Oysters | 3–6% |

| Clams | 3–6% |

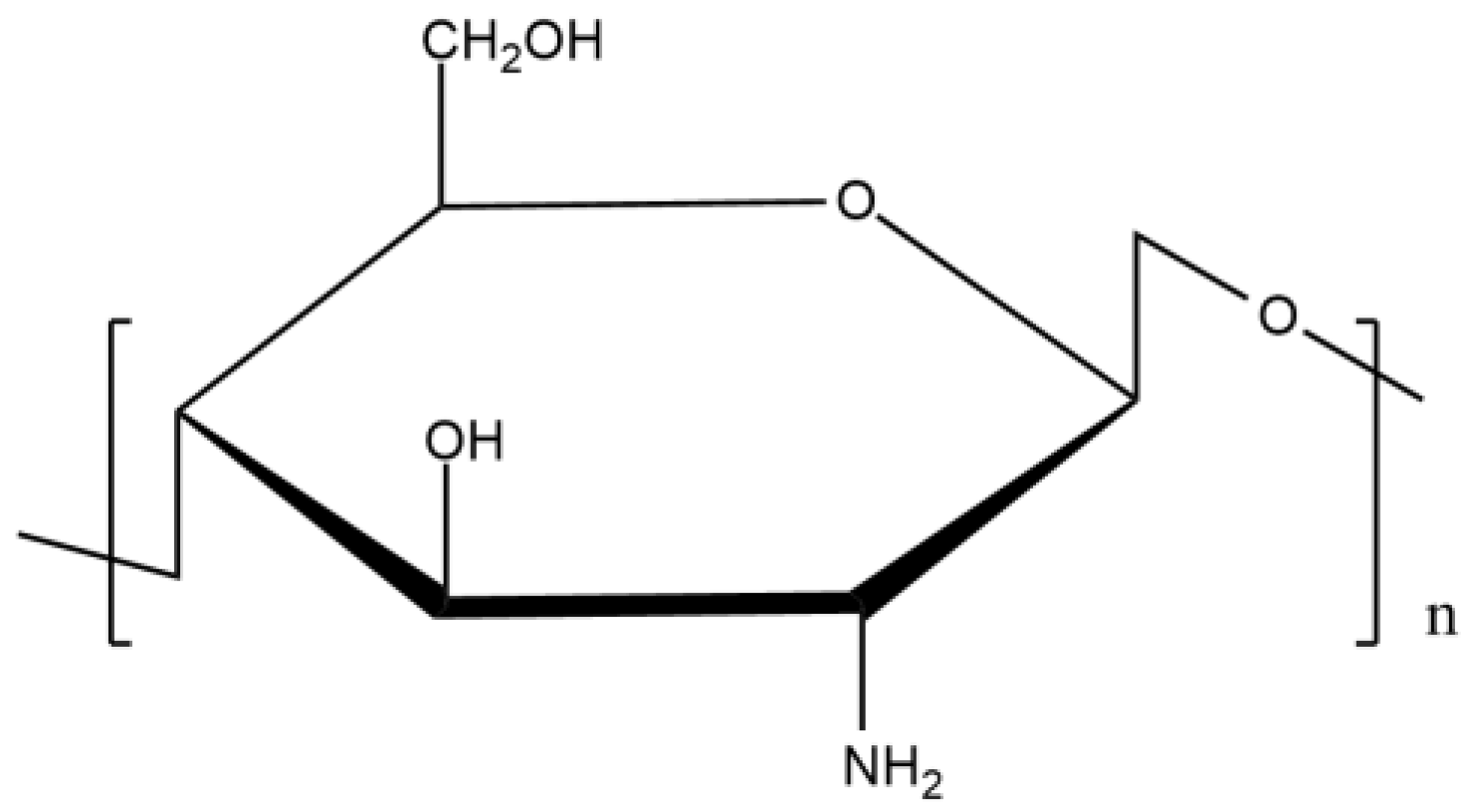

Commercial chitosan (Figure 1) is composed of D-glucosamine and N-acetyl glucosamine and is produced by the partial deacetylation of chitin. This reaction carries out the change of acetamido groups into amino groups. There are three kinds of this biopolymer depending on its molecular weight: low molecular weight, high molecular weight, and oligochitosans [3].

Figure 1. Chemical structure of chitosan.

1.2. General Features and Properties of Chitosan

The main properties which can contribute to a sustainable development that are exhibited by the chitosan are non-toxicity, biodegradability, and biocompatibility. Nevertheless, there are other interesting properties and characteristics which explain its versatility which can be deduced from Table 2.

Table 2. General properties of chitosan [4][5].

| Property | Conditions | Use | References |

|---|---|---|---|

| Solubility | Dilute acids (pH < 6). Insoluble in organic solvents and water | Water treatment | [6][7] |

| Activity | Antibacterial, antifungal mucoadhesive analgesic, and hemostatic properties | [8][9][10] | |

| Degradation | Depends on molecular weight and deacetylation degree | [6][11] | |

| Biocompatibility | Physiological medium | Biomedical applications | [12][13] |

| Chelating properties | Capability to bind and adsorb diverse ions | The removal of heavy metals and dyes from wastewater | [14][15] |

| Biodegradability | Biodegradable to normal body constituents | [13][16][17] | |

| Hemostatic | Stop a hemorrhage | [18][19] | |

| Catalyst | Accelerates the formation of osteoblast | [20] | |

| Fungicide | Stopping the development of fungi | [21][22] | |

| Spermicidal | Reduce the mobility of spermatozoa | [23] | |

| Anticholesteremic | Reducing agent cholesterol | [24][25] | |

| Anticancer | Inhibiting the development of cancer cells | [26] | |

| Conductivity | Ionic conductivity | [27][28] | |

| Flocculating agent | Interactions with negatively charged molecules | Water treatment | [29] |

| Thickener | Increase the viscosity | [30] | |

| Polyelectrolytes | Acidic medium | [31] | |

| Adsorption | Separation and filtration | [32][33][34] | |

| Clarifying agent | Immobilization of enzymes | [35] |

From the presentation of Table 2, it can be deduced that chitosan is a sustainable material as it is biodegradable and non-toxicity [36]. Another important reason for using chitosan is the presence of a large number of hydroxyl and amino groups in its structure which are suitable for chemical modifications [37]. This fact and the wide versatility of chitosan makes this material especially interesting for the preparation of suspensions, composites, functionalized materials, or (nano)hybrids for diverse eco-friendly purposes and applications. The interesting polymorphic behavior exhibited by the chitosan [38], together with the molar mass and degree of deacetylation, mainly defines its mechanical properties. The molar mass will also play an important role for other properties such as degradation degree or antibacterial activity as these are strongly affected by the changes in molar mass.

On the other hand, the degree of deacetylation is associated with the content of acetamide groups of polymeric chains. These groups will strongly affect the final features and properties of the chitosan, in particular its capacity to be biodegradable and its immunological activity. The deacetylation degree is defined between 50 and 99%, its content depends on the preparation methods. The deacetylation degree must be higher than 50% for the chitosan; below that value, it is considered chitin [6]. Some of the most important uses of chitosan are associated with biomedical applications. Nevertheless, new developments related to chitosan focus on agriculture, food packaging, textiles, or environmental applications [39]. The solubility of the chitosan depends on the medium being used to dissolve it; in acid mixtures with water, it is soluble, but it is insoluble in common organic solvents [40][41]. The reason for its solubility can be explained due to the presence of amino groups that transforms chitosan into a base, whose protonation produces a polyelectrolyte [42]. The presence of different functional groups is responsible for the reactivity and the flexibility of this polycationic polymer [43]. Chitosan biofilms show a semi-crystalline behavior, together with high hydrophobicity and little flexibility [44].

1.3. Chitosan as an Ecofriendly Biopolymer and Its Applications

Chitosan is considered a natural biopolymer; it has received remarkable attention from the scientific community due to the fact that it can be easily biodegraded. Its residues are not toxic and can be easily eliminated and biodegraded by nature [12]. One of the most important problems associated with the raw materials is that these are limited, but chitosan is the most abundant biopolymer after cellulose. Furthermore, chitosan exhibits a great biocompatibility, limited by its low solubility which can be solved through chemical modifications and hydrolysis. Chitosan is a bioactive material which can be modulated and used in many applications [45]. Some of these applications are associated with biomedical purposes such as drug delivery systems, scaffolds, or membranes. Nevertheless, there are other important uses such as in the textile industry, wastewater treatments, agriculture, food, packaging, personal care, and biotechnology, among others. The adsorbent properties of chitosan are very useful for removing different heavy metal ions accumulated in water and derived from industrial processes such as Pb2+, Hg2+, and Cu2+, among others [46]. These can be accumulated inside the body and produce numerous diseases [47]. Chitosan can contribute to the agriculture by improving the harvest and productivity, being an ecofriendly material. It is used as a coating for seeds, enhancing the properties of the plants and the obtained products in terms of shelf life. This use as fertilizer is especially useful for plant protection as it can stimulate the plant defense, but it can also act as an antibacterial and antimicrobial agent [48]. Thus, chitosan acts as a plant growth-promoting agent and plant protector [49]. For that reason, it is considered a pesticide by several countries. The antioxidant properties of chitosan, together with its antimicrobial features, are suitable for the production of films for food packaging. The preparation of hybrid materials with chitosan allows modifying the permeability of those films depending on the requirements [50]. The chitosan can also be used as a food additive, dietary fiber, and functional ingredient [51][52].

2. Applications of Chitosan for Sustainable Development

Chitosan can contribute to sustainable development through its applications and uses. This entry tries to expose some of the most important applications related to the contribution of chitosan to a circular economy and sustainability. Figure 2 depicts the diversified application of chitosan.

Figure 2. Different uses of chitosan.

2.1. Sustainable Use of Chitosan for Food Packaging and in Agriculture

Many biopolymers are being implemented in different coating materials due to their excellent properties in terms of degradability and compatibility; these biopolymers include gums, starch, proteins cellulose, lipids, and their derivatives [53][54][55][56][57][58][59]. In this sense, chitosan is a promising material for that purpose due to several reasons associated with its biocompatibility and abundance [60][61]. The use of the chitosan in films can also provide other superiorities because of its antibacterial and antioxidant properties [62][63][64][65]. In general, chitosan is used in combination with other polymers due to some of its drawbacks associated with its low mechanical properties. Another important problem associated with chitosan is related to its water sensitivity [66]. The preparation of blends can diminish these problems, thus obtaining films with a wide range of properties. The miscibility problems between the mixtures of polymers can reduce the spectra of possibilities, but in general, the preparation of these films is easy and cheap. The preparation of these systems could be a good alternative regarding traditional films based on oil derivatives [67]. There are other mixtures with synthetic polymer of chitosan that are not included in this entry, as those do not fit the sustainability criteria of the present entry. Numerous composites of chitosan have been fabricated with graphene, carbon nanotubes, activated carbon, and metal nanoparticles [68][69][70][71]. One study suggests that poly(L-lactic acid)-ZnO multilayered with cationic chitosan and anionic β-cyclodextrin can be used as a promising material in applications for the active packaging of food [72]. A novel bilayer food packing film of Ag-Metal−organic framework loaded p-coumaric acid modified chitosan (P-CS/Ag@MOF) or chitosan nanoparticles (P-CSNPs/Ag@MOF) and polyvinyl alcohol/starch (PVA/ST) was fabricated. The bilayer composite film revealed a relatively smooth surface and higher tensile strength (27.67 MPa). The P-CS/Ag@MOF bilayer films displayed better oil resistance and oxidation resistance, and the bilayer film had good UV-blocking properties and transparency [73]. The diverse blend composites of chitosan have been developed with various natural antimicrobial compounds and have been applied for antimicrobial food packaging; such antimicrobial compounds include thyme oil, spirulina, oregano essential oil, nisin, apple peel polyphenols, bamboo vinegar, cinnamon essential oil, custard apple leaves, plum peel extract, etc. [74][75][76][77][78][79][80]. The antibacterial nanofiber films were fabricated using gelatin, chitosan, and 3-phenyllactic acid (PLA) by electrospinning. Under acidic conditions, chitosan and PLA interacted and formed hydrogen bonds, which decreased the crystallinity of the nanofiber films. The nanofiber film had the best thermal stability, water stability, water vapor permeability, and more effective antibacterial effects against Salmonella enterica Enteritidis and Staphylococcus aureus, suggesting that the nanofiber film mat can be used as an active food packaging [81]. Similarly, Wang et al. discussed various chitosan and gelatin edible films, their synthesis strategies including casting, electrospinning, and thermoplastic method, and their properties in their review, thus highlighting importance of chitosan-based food packing films [82]. In Argentina, chitosan is produced from the waste of the shrimp industry; the synthesized chitosan has similar physicochemical properties to those of analytical grade chitosan. The chitosan coatings applied to processed lettuce at harvest increased nutritional quality and reduced microbiological contaminants in minimal processed lettuce [83]. Panda et al. fabricated ferulic acid-modified water-soluble chitosan and poly(γ-glutamic acid) polyelectrolyte multilayers films. These film surfaces possessed a reduced amount of protein adsorption; thus, these can be used as a potential good biomaterial for biomedical purposes to intensify the bio-active surface [84], thus prompting the concept of circularity and sustainability.

The chitosan can act as protector, coating material, stimulator of the growth, nutrient, fertilizer, or pesticide in agriculture. It was also observed that the use of chitosan can increase productivity. Furthermore, the use of chitosan could replace some dangerous chemicals used as compounds of fertilizers in agriculture, protecting soil, aquifers, and ecosystems [85]. It was reported that excellent antimicrobial activity was observed in chitosan against many viruses, bacteria, and fungi. Nevertheless, its activity is higher against fungi than bacteria. In general, the chitosan seems to inactivate the replication of viruses [86]. Moreover, it is considered a potent elicitor which can induce plant defense against diseases [87].

2.2. Sustainable Applications of Chitosan in Purification of Water, Paper-Making, and Green Chemistry

The chitosan is a good flocculant for water treatment, especially indicated for organic matter, suspended solids, and ions (metals). Furthermore, the deposition rate is stimulated when chitosan is used [88]. It is used over oil spills as it can preserve the integrity of the oil mass. Its properties are also indicated for anionic waste where the chitosan can remove the metal ions of the acid solutions. Some of the most attractive features of chitosan regarding other flocculants are associated with its biodegradability and its adsorption and flocculating ability, which show excellent results with oils [12]. Chitosan and its composites demonstrate excellent adsorption properties for diversified environmental contaminates ranging from organic pollutants to metal ions [36][89][90][91][92][93]. The mechanism for the adsorption of toxic pollutants by chitosan and its composites involves various types of interactions such as electrostatic, hydrogen bonding, π-π bonding, etc. The chitosan and its composites had several hydroxyls and amino and carboxylic groups which are very helpful for such interactions, thus making it more adsorbent.

This entry is adapted from the peer-reviewed paper 10.3390/polym14071475

This entry is offline, you can click here to edit this entry!