This paper aims to assess the relationship between Industry 4.0 (I4.0) and the circular economy that could contribute to supply chain management performance. To achieve this, a combination of the interpretative structural modelling (ISM) and (cross-impact matrix multiplication applied to classification) MICMAC approach was used to establish the interrelationships between these topics. The developed analysis reveals that there are 19 constructs capable of elucidating this relationship and that there is a hierarchy between these constructs, which are presented in a structural model. Further, the different levels of dependency and driving power are compared in a cluster diagram. As the main result, it was found that there is a strong mutual relationship between the basic technologies. The use of Internet of Things and cloud computing technologies influences the collection of large amounts of data, leading to big data, which in turn influence the use of data analytics tools to obtain competitive advantages. These outcomes may contribute to managers’ more assertive decision-making regarding the selection, implementation, and evaluation of projects adopting Industry 4.0 technologies and circular economy approaches in supply chains. Moreover, our study could be the basis for future empirical research to investigate how companies incorporate Industry 4.0 technologies into their processes and how this influences the quest for sustainable supply chains.

1. Introduction

The vertical disintegration of companies has increased the complexity of management in terms of time and quality and increased uncertainty in the markets, making it impossible today for companies to compete effectively if they are isolated from their suppliers and other stakeholders [

1,

2]. In this context, adopting the concept of supply chains (SCs) is increasingly essential for a company’s performance. Moreover, two themes are being increasingly discussed in the context of SCs, the circular economy (CE) and Industry 4.0 (I4.0) [

3]. The CE paradigm consists of a possible way to achieve environmental objectives and economic sustainability by developing systemic changes that go beyond the individual company and involve the other actors in the SC, contributing to adding value to a product and/or service [

4,

5]. On the other hand, I4.0 refers to an industrial revolution based on the deployment of automation technologies and information and communication technologies, which can be helpful to meet current SC needs, such as flexibility, increased productivity, reducing waste, resource optimisation, and more sustainable production processes [

2]. Consequently, the CE can be used to minimise resource usage and decrease waste generation in a high-tech manufacturing environment, integrating sustainable resource management and transforming SCs in the I4.0 [

6,

7].

Previous research has assessed the relationship between these themes. For example, some researchers have linked the CE to I4.0 [

7,

8], while others have linked, separately, the implementation of I4.0 or the CE to SC performance [

1,

2,

9,

10,

11]. However, a systematic analysis from the perspective of experts concerning the relationship between these three topics is still missing. Many articles do not provide insight into the realization of initiatives to introduce Sustainable Industry 4.0 in the supply chain context. Our paper uses combined Interpretive structural modelling (ISM) and the MICMAC approach was used as a systematic methodology to establish the interrelationships between these topics. However, there is still a lack of studies that analyse this relationship more deeply, to create a consensus between the relationships between the different strategies of I4.0 and CE in the supply chain [

12,

13].

This study aims to identify the relationship between I4.0 technologies and the CE and present the effect of adopting both approaches concerning SC performance. Then, this research is an attempt to fill this gap and aims to answer the two research questions: (1) what are the relationships between I4.0 technologies and the CE? (2) What is the potential effect of these constructs on SC performance? As a starting point, a systematic literature review (SLR) was developed, resulting in 19 constructs. Subsequently, the interactions between these constructs and the strength of the driving and dependence power of this relationship were proposed using a combined interpretive structural modelling (ISM) and fuzzy MICMAC (Matrice d’Impacts Croisés Multiplication Appliqués à un Classement (cross-impact matrix multiplication applied to classification) analysis.

2. Theoretical Background

Although much work has been done on sustainable SCs, the relationship between the CE and SCs still needs to be explored, especially to identify the methods and tools that need to be adopted across the SC to support efficient CE adoption, enabling a “complete” transition from a linear to a circular SC due to its increased complexity [

5]. In this context, I4.0 technologies can be of great value [

2,

7]. Some proposals for relationships between these two approaches can be found in the literature, with ReSOLVE [

16] being one of the most cited methods. However, empirical studies are scarce, resulting in the effect of this relationship on companies’ performance, especially in the SC, is poorly studied. It is this gap that the present study aims to address. The intersection literature between these areas is presented.

3. Research Method

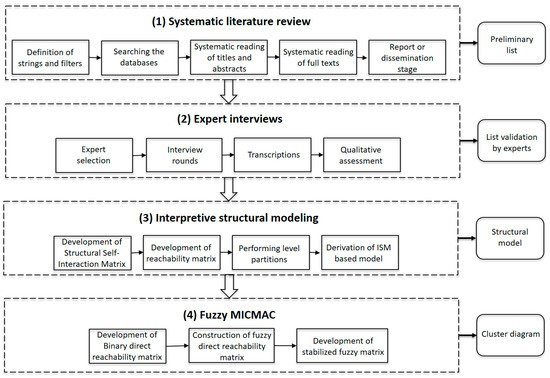

This research aims to identify the relationships between I4.0 technologies, CE approaches, and SC performance. For this, the ISM approach was chosen to identify and classify relationships between variables [

10]. This methodology involves four steps [

10,

31,

32]: (1) identification of elements that relate the three research topics through a systematic literature review (SLR), and this generated a preliminary list; (2) data collection through expert interviews to validate this list from an empirical perspective; (3) elaboration of the structural model; and (4) fuzzy MICMAC development with a cluster diagram showed the elements driver and dependence power. The following subsections describe these steps, as summarised in

Figure 1.

Figure 1. Research method.

4. Conclusions

The main contribution of this research is to present the relationships between the different constructs of the studied themes. The ISM model, the reachability matrix, and the strength matrix of relationships are, together, valuable tools for understanding the direction, order, and power of the complex relationships between I4.0, the CE, and SC performance. Using these tools, managers can make more proactive and consistent decisions regarding implementing I4.0 technologies and CE approaches. They can also select the main performance measures associated with this implementation, allowing the evaluation of the performance of projects with greater accuracy.

This entry is adapted from the peer-reviewed paper 10.3390/su14052772