Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Mechanics

Thin-walled composite plates have been widely used as structural components in various engineering applications to bear static and dynamic loads. The vibrations caused by the dynamic loads are transmitted to passengers and precision equipment, which reduces the crew’s comfort, affects normal operations, and shortens the service life of high-precision equipment. There is a rising demand to design optimal composites that have a superior combination of high stiffness and exceptional vibration mitigation capability.

- concurrent topology optimization

- damping composite materials

- dynamic compliance

- homogenization

- composite plates

1. Introduction

Thin-walled composite plates have been widely used as structural components in various engineering applications to bear static and dynamic loads. The vibrations caused by the dynamic loads are transmitted to passengers and precision equipment, which reduces the crew’s comfort, affects normal operations, and shortens the service life of high-precision equipment [1]. There is a rising demand to design optimal composites that have a superior combination of high stiffness and exceptional vibration mitigation capability. Over the past few decades, active and passive methods have been developed to improve the dynamic performance of composite structures [2][3][4][5]. Among these methods, incorporating a passive damping material layer into the base plates (i.e., free-layer [6] or constrained-layer [7][8]) is one of the most efficient, robust, and low-cost methods. Intrinsically, the vibration performance of the composite plates is determined by the properties of the damping materials and their topological arrangements on the base plates. Conventional design practices for damping composite architectures are focused on parameter analysis, in which only a few design variables are considered (i.e., the thickness or the size of the damping layer) [9][10]. However, these rely heavily on the designers’ intuition and it is hard to obtain the optimal configurations. These challenges are more notable when optimal microstructural damping configurations and macroscopic arrangements are simultaneously pursued.

Topology optimization (TO) [11][12] is a powerful inverse design technique that does not require predefined shapes. It can be used to generate a free-form optimal configuration that fulfills the functional requirements quantified by the objective functions and constraints. A series of TO methods have been developed to design damping composite structures, which can be broadly classified into two categories: one is to optimize the macrostructure layout of the damping material on the plates [13][14][15][16], while the other is focused on optimizing the composite architectures in microscale [17][18][19][20] using the homogenization method [21][22][23][24]. However, most existing works focus on either the macro- or micro-scale TO. Recent studies show that combining the macrostructure topology optimization with microscale composite material design can significantly improve structural performance. Zhu [25] proposed a concurrent TO strategy to optimize the layout of damping material and the beam size of the lattice core; however, they did not consider the microstructure design problems of the damping layer. Zhang [26] proposed a concurrent TO method to design the free-layer damping structures with a maximum structural modal loss factor. In addition to the damping performance, the vibration response of the structures controlled by dynamic stiffness is equally important. To the authors’ knowledge, so far, limited researches have focused on the multi-scale topology optimization of composite plate structures in a frequency range. In this case, dynamic compliance is often used as the design objective for vibration response design [27][28][29][30][31][32][33]. In these studies, dynamic compliance is calculated using proportional damping, which cannot accurately consider the variation of damping due to the change of damping material configurations.

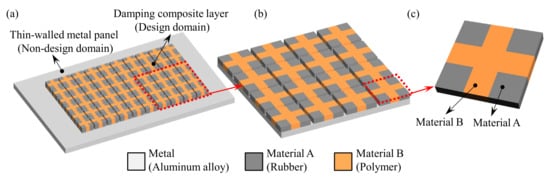

Figure 1. Two-scale composite plate design. (a) A composite plate consists of a metal panel and periodic damping composite. (b) Periodic damping composite. (c) Microstructure of the periodic damping composite.

2. Dynamic Compliance of the Composite Plate

2.1. The Complex Stiffness Model for the Damping Material

A complex stiffness model [26] is used to describe the dynamic characteristic of the damping material, which can be stated as:

where E′ and E″ are the storage and loss modulus of the damping material, respectively. η is the loss factor of the damping material. ζ is the imaginary unit, ζ=−1−−−√.

2.2. Complex Frequency Response of the Composite Plate

The momentum equation of a structural system under harmonic excitation can be written as:

where M and K are the global mass and stiffness matrices, respectively. K is the complex when the structure contains a damping material with a complex stiffness shown in Equation (1). u is the displacement vector of the macrostructure, f is the magnitude of the harmonic force, ω is the excitation frequency of the harmonic force, and t is time.

The damping characteristic of the metal panel is ignored in this paper since it is negligibly small compared with that of the damping material. The global stiffness matrix of structure K is expressed as:

where the superscript “R” and “I” represent the real and imaginary parts, respectively. The subscripts “p” and “v” denote the metal panel and the damping composite layer, respectively.

Considering the free vibration of the composite structure, the complex eigenvalue λr and the eigenvector Φr can be expressed as:

where ωr and ηr are the r-th real eigenvalue and loss factor of the macrostructure. ΦrR and ΦrI are the real and imaginary parts of the complex eigenvector, respectively. The eigenvector Φ is normalized to ϕ = {ϕ1, ϕ2,…ϕr,…}.

Converting the governing equation shown in Equation (2) to the frequency domain leads to:

The solution of Equation (6) is:

Based on the mode superposition method, the response of structure u is equal to H(ω) when the magnitude of the harmonic force is a unit load. Then the response can be described as:

where j is the DoFs of the excitation position, and k is the DoFs of the response position. Λ is the number of eigenfrequencies/eigenmodes that are used to calculate the response. Note that the more eigenmodes used, the more accurate results obtained. In this study, Λ = 20 is used.

Using the non-normalized eigenvector Φ, Equation (8) can also be expressed as:

where mr is the r-th mode mass.

2.3. Dynamic Compliance of the Composite Plate

If the response of the composite plate is obtained, the dynamic compliance can be stated as:

where F is the vector of the applied external load. Due to the complex stiffness matrix, the displacement vector u is complex, which is expressed as . Then the dynamic compliance is given by:

where CR and CI are the real and imaginary parts of the dynamic compliance, respectively. The 2-norm of the dynamic compliance of the composite structures can be defined as:

According to Equations (6) and (10), compliance can be stated as:

The displacement vector is complex, so Equation (13) can be rewritten as:

Finally, dynamic compliance C can be stated as:

According to Equation (15), CR and CI are expressed as:

This entry is adapted from the peer-reviewed paper 10.3390/ma15020538

References

- Li, B.; Huang, C.; Xuan, C.; Liu, X. Dynamic stiffness design of plate/shell structures using explicit topology optimization. Thin-Walled Struct. 2019, 140, 542–564.

- Nakra, B. Vibration Control in Machines and Structures Using Viscoelastic Damping. J. Sound Vib. 1998, 211, 449–466.

- Qatu, M.S.; Sullivan, R.W.; Wang, W. Recent research advances on the dynamic analysis of composite shells: 2000–2009. Compos. Struct. 2010, 93, 14–31.

- Rao, M.D. Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. J. Sound Vib. 2003, 262, 457–474.

- Zhou, X.; Yu, D.; Shao, X.; Zhang, S.; Wang, S. Research and applications of viscoelastic vibration damping materials: A review. Compos. Struct. 2016, 136, 460–480.

- Danti, M.; Vigè, D.; Nierop, G.V. Modal Methodology for the Simulation and Optimization of the Free-Layer Damping Treatment of a Car Body. J. Vib. Acoust. 2010, 132, 021001.

- Alvelid, M.; Enelund, M. Modelling of constrained thin rubber layer with emphasis on damping. J. Sound Vib. 2007, 300, 662–675.

- Balmès, E.; Corus, M.; Baumhauer, S.; Jean, P.; Lombard, J.-P. Constrained viscoelastic damping, test/analysis correlation on an aircraft engine. Conf. Proc. Soc. Exp. Mech. Ser. 2011, 3, 1177–1185.

- Alvelid, M. Optimal position and shape of applied damping material. J. Sound Vib. 2008, 310, 947–965.

- Zheng, H.; Cai, C.; Pau, G.; Liu, G. Minimizing vibration response of cylindrical shells through layout optimization of passive constrained layer damping treatments. J. Sound Vib. 2005, 279, 739–756.

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224.

- Bendsøe, M.P.; Sigmund, O. Material interpolation schemes in topology optimization. Ingenieur-Archiv 1999, 69, 635–654.

- Alfouneh, M.; Tong, L. Maximizing modal damping in layered structures via multi-objective topology optimization. Eng. Struct. 2017, 132, 637–647.

- Kim, S.Y.; Mechefske, C.K.; Kim, I.Y. Optimal damping layout in a shell structure using topology optimization. J. Sound Vib. 2013, 332, 2873–2883.

- Yamamoto, T.; Yamada, T.; Izui, K.; Nishiwaki, S. Topology optimization of free-layer damping material on a thin panel for maximizing modal loss factors expressed by only real eigenvalues. J. Sound Vib. 2015, 358, 84–96.

- Ding, H.; Xu, B. Optimal design of vibrating composite plate considering discrete–continuous parameterization model and resonant peak constraint. Int. J. Mech. Mater. Des. 2021, 17, 679–705.

- Chen, W.; Liu, S. Microstructural topology optimization of viscoelastic materials for maximum modal loss factor of macrostructures. Struct. Multidiscip. Optim. 2016, 53, 1–14.

- Huang, X.; Zhou, S.; Sun, G.; Li, G.; Xie, Y.M. Topology optimization for microstructures of viscoelastic composite materials. Comput. Methods Appl. Mech. Eng. 2015, 283, 503–516.

- Zhang, H.; Ding, X.; Wang, Q.; Ni, W.; Li, H. Topology optimization of composite material with high broadband damping. Comput. Struct. 2020, 239, 106331.

- Ding, H.; Xu, B. Material microstructure topology optimization of piezoelectric composite beam under initial disturbance for vibration suppression. J. Vib. Control. 2021, 2021.

- Andreassen, E.; Andreasen, C.S. How to determine composite material properties using numerical homogenization. Comput. Mater. Sci. 2014, 83, 488–495.

- Liang, X.; Du, J. Concurrent multi-scale and multi-material topological optimization of vibro-acoustic structures. Comput. Methods Appl. Mech. Eng. 2019, 349, 117–148.

- Fang, Z.; Yao, L.; Tian, S.; Hou, J. Microstructural Topology Optimization of Constrained Layer Damping on Plates for Maximum Modal Loss Factor of Macrostructures. Shock. Vib. 2020, 2020, 1–13.

- Banh, T.T.; Luu, N.G.; Lee, D. A non-homogeneous multi-material topology optimization approach for functionally graded structures with cracks. Compos. Struct. 2021, 273, 114230.

- Zhu, J.-H.; Liu, T.; Zhang, W.-H.; Wang, Y.-L.; Wang, J.-T. Concurrent optimization of sandwich structures lattice core and viscoelastic layers for suppressing resonance response. Struct. Multidiscip. Optim. 2021, 64, 1801–1824.

- Zhang, H.; Ding, X.; Li, H.; Xiong, M. Multi-scale structural topology optimization of free-layer damping structures with damping composite materials. Compos. Struct. 2019, 212, 609–624.

- Olhoff, N.; Du, J. Generalized incremental frequency method for topological designof continuum structures for minimum dynamic compliance subject to forced vibration at a prescribed low or high value of the excitation frequency. Struct. Multidiscip. Optim. 2016, 54, 1113–1141.

- Takezawa, A.; Daifuku, M.; Nakano, Y.; Nakagawa, K.; Yamamoto, T.; Kitamura, M. Topology optimization of damping material for reducing resonance response based on complex dynamic compliance. J. Sound Vib. 2016, 365, 230–243.

- Xu, B.; Jiang, J.S.; Xie, Y.M. Concurrent design of composite macrostructure and multi-phase material microstructure for minimum dynamic compliance. Compos. Struct. 2015, 128, 221–233.

- Yang, X.; Li, Y. Topology optimization to minimize the dynamic compliance of a bi-material plate in a thermal environment. Struct. Multidiscip. Optim. 2012, 47, 399–408.

- Kang, Z.; Zhang, X.; Jiang, S.; Cheng, G. On topology optimization of damping layer in shell structures under harmonic excitations. Struct. Multidiscip. Optim. 2012, 46, 51–67.

- Olhoff, N.; Niu, B. Minimizing the vibrational response of a lightweight building by topology and volume optimization of a base plate for excitatory machinery. Struct. Multidiscip. Optim. 2016, 53, 567–588.

- Zhang, X.; Kang, Z. Dynamic topology optimization of piezoelectric structures with active control for reducing transient response. Comput. Methods Appl. Mech. Eng. 2014, 281, 200–219.

This entry is offline, you can click here to edit this entry!