Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Mechanical

The use of phase change material (PCM) as a thermal energy storage system integrated in new buildings, and as retrofits in old buildings, proved its merit as promising renewable energy source. Experimental investigations for the use of PCM in buildings gained attention where the experimental setups used are classified as: Large-scale, small-scale, retrofitting, and laboratory-based test facilities.

- phase change materials

- modular prototype

- heating

- cooling

- experimental studies

1. PCM Experiment Classification Criteria and Methodology

Studies are categorized based on the used prototypes and are classified according to their purpose, method, and volume. Experimental huts that simulate zones of real dimensions with a volume ≥5 m3 are classified as ‘large-scale prototypes’; Experimental huts utilizing conventional construction materials with a volume V such that: 1 m3 ≤ V ≤ 5 m3 are classified as ‘small-scale prototypes’; Experiments done on an already existing compartment of large scale by integrating PCM into its sections are grouped under the title ‘retrofitting in full-scale compartment’; and experimental facilities that represent a partition from a system containing PCM that does not simulate a complete model are classified as ‘laboratory-based building partitions’. Table 1 summarizes the criteria followed in classifying the studied literature according to test facility.

Table 1. Experimental studies classification based on test facility and the followed criteria.

| Classification Criteria | Classification Based on Test Facility | |||

|---|---|---|---|---|

| Large-Scale Prototype | Small-Scale Prototype | Retrofitting in Full-Scale Compartment | Laboratory-Based Test Facility | |

| Purpose | Test thermal behavior, heating/cooling load management, thermal comfort | Test thermal behavior, heating/cooling load management, thermal comfort | Test thermal behavior, heating/cooling load management, thermal comfort | Test thermal behavior |

| Method | Building up large hut subjected to real weather | Building up small hut subjected to real/artificial weather | Installing systems to already built full-scale buildings subjected to real weather | Building up systems (partitions) under controlled laboratory environment |

| Volume | V ≥ 5 m3 | 1 m3 ≤ V ≤ 5 m3 | V ≥ 5 m3 | No complete hut or V ≤ 1 m3 |

2. Large-Scale Prototype PCM Experimental Studies

2.1. Active Large-Scale Applications

Two full-scale cubicles designed and implemented by Mourid et al. [1] were tested under real weather conditions of the cold winter season. The test facilities’ walls were manufactured from double brick layers (72 mm each with an additional mortar of 10 mm) with an air cavity in between (116 mm) by which a PCM wallboard is installed on the internal layers. Experiments covered the investigation of the thermal performance of the rooms if the PCM was adhered to one wall internal layer, and if the PCM was installed in the ceiling. The main results showed that a 20% reduction in heat energy required can be reached. Comparing the effect of PCM position within the envelope, it is proved that placing the PCM in the ceiling is more efficient where 50% reduction in thermal losses across it is attained. Lu et al. [2] combined in their study the advantages of PCM integrated in floor with the conventional solar water heating system. The designed prototype was modeled on TRNSYS and the respective experimental and numerical results were compared to validate the model. 95.1% consistency was triggered. Experiments proved that for an indoor temperature of 20 °C, the PFCSS building is capable of saving 5.87% of energy consumption compared to the reference prototype.

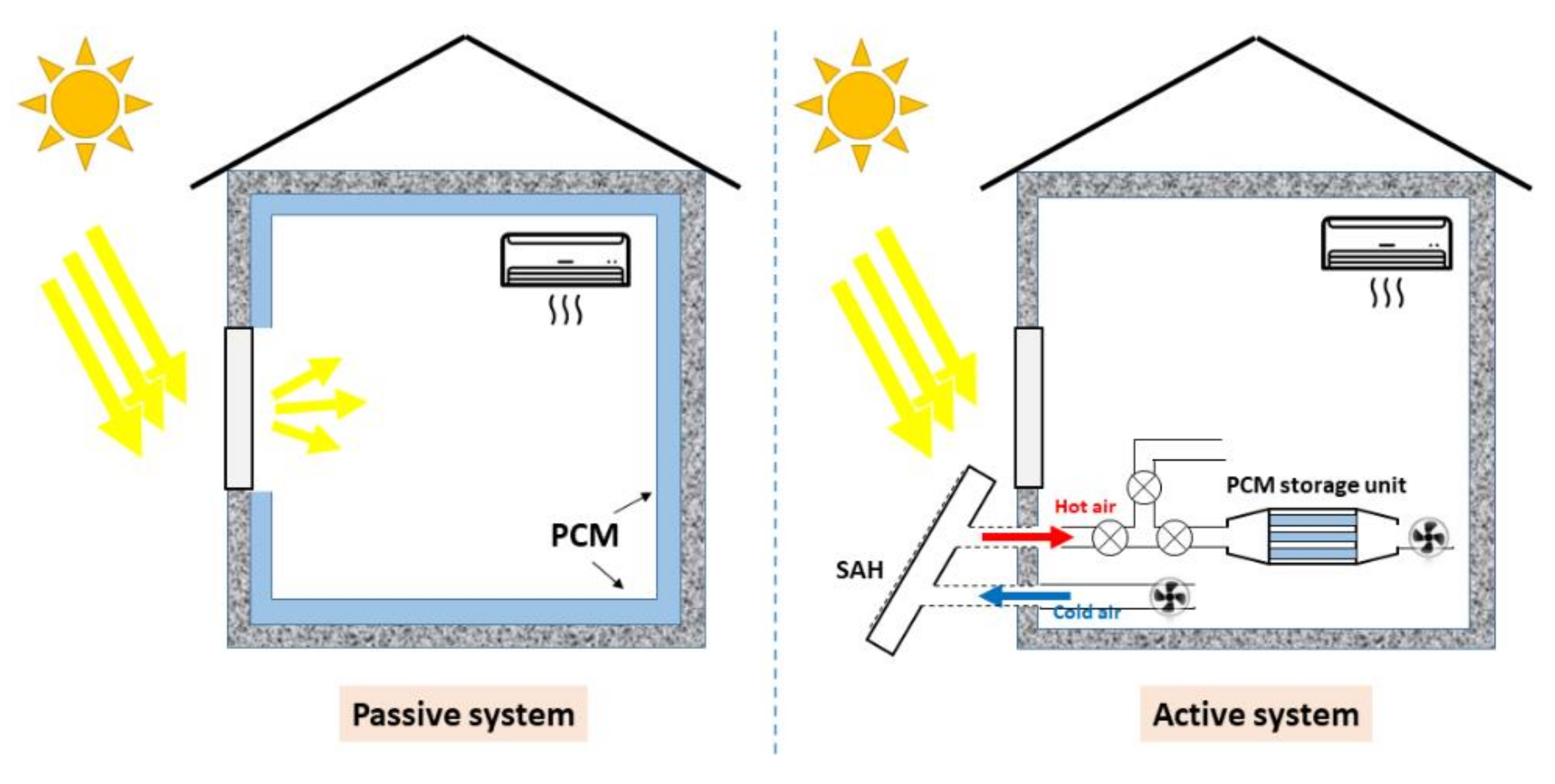

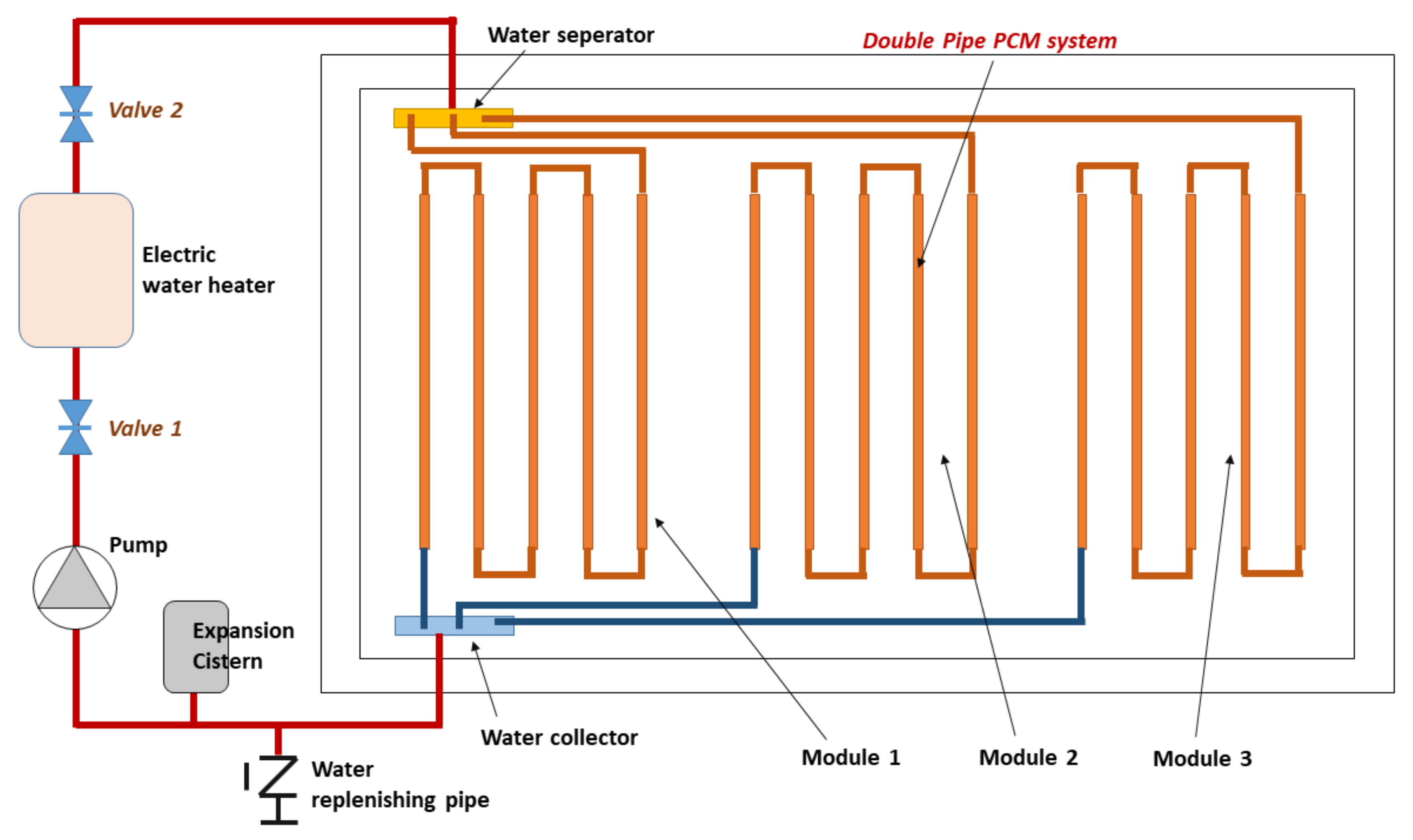

Figure 1 illustrates the differences in both systems. Results proved that the active system has more potential in load shifting (energy cost being 32% less than in passive system). For identical storage capacity of used PCM in both systems, an increase in the reduction of energy consumption by 22% was achieved when active system was used during winter. The passive system was more efficient for cooling purposes as the electricity consumption increased by 8% for active system.

Figure 1. Passive and active systems integrated in tested prototypes [3].

2.2. Passive Large-Scale Applications

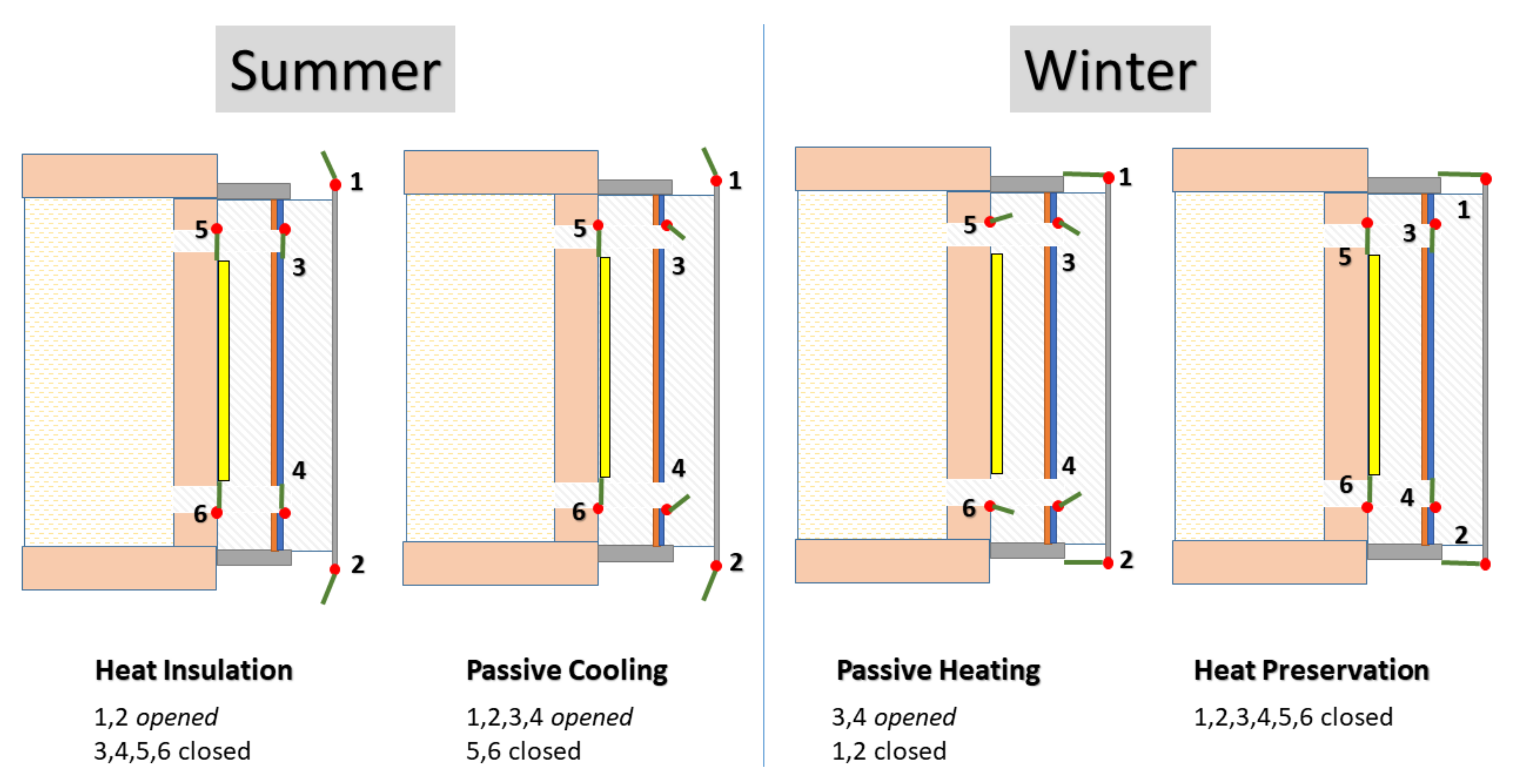

Figure 2 illustrates the mechanism of the solar Trombe wall studied within the research. Sun and Wang [4] studied the heat transfer performance of a solar wall with PCM for winter heating, using two identical test prototypes located in Jilin, China. Results indicated that the indoor temperature fluctuations are reduced and air circulation is enhanced. Indoor thermal comfort achieved by the proposed system indicates it to be an approach worth being optimized and commercialized.

Figure 2. Modified Trombe wall mechanism studied by Luo et al. [5].

3. Small-Scale Prototype PCM Experimental Studies

3.1. Active Small-Scale Applications

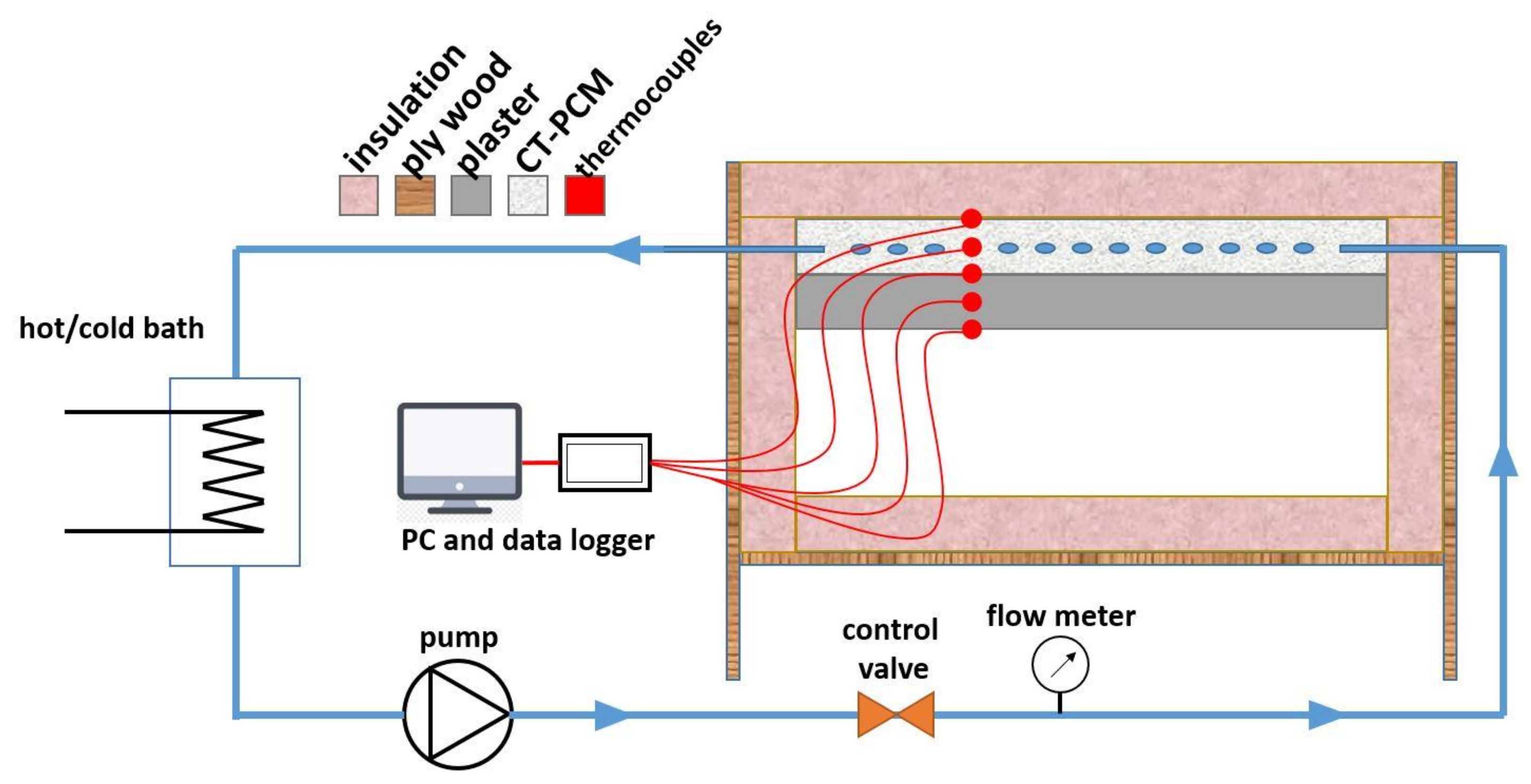

Small-scale prototypes are used for experimental investigations of specific application and are usually coupled with numerical models. The essence behind coupling both experiments and numerical analysis is to validate the numerical model to be used for full-scale building investigations. Another cause is the need for extending the studies for long-term periods which is tough and expensive as for experiments. Capillary tube embedded PCM component (CT-PCM)—installed in the wall and ceiling of a testing chamber—was investigated by Jobli et al. [6]. The authors proposed a numerical model that was validated by the experiments done. The system was composed of three main units: CT-PCM panel utilizing a 140 m long capillary tube for charging and discharging of PCM, dynamic thermal chamber and water bath system (see Figure 3). Results revealed that experimental data and numerical simulations agree for capillary flow rates above 800 mL/min, whereas varying correction factors (between 1.2 and 1.6) are applied for lower flow rates.

Figure 3. Thermally activated roof testing equipment [6].

Underfloor heating with electric radiant heating system equipped with PCM for energy saving purposes is a promising application. Fang et al. [7] prepared a novel eutectic PCM mixture of sodium acetate trihydrate-formamide and expanded graphite as a carrier. The thermophysical properties tests showed that the proposed PCM had favorable phase change enthalpy (187.6 kJ/kg), high thermal conductivity (3.11 W/m·K), suitable transitional temperature (38.54 °C), and improved shape stability and thermal reliability. The prepared PCMs were added into a test room above an electrical radiant heater. Experimental investigations revealed that the addition of the PCM layer enhances the thermal comfort greatly, where the total comfort time was 12.65 h for PCM room and 1.836 h for the room without PCM. Additionally, it was proven that the vertical temperature fluctuations were reduced effectively with PCM. The concept relies on pumping hot air into copper tubes that are located at the central layer of the floor. Results indicated that PCM distribution in the floor has a strong impact on the performance of the system.

3.2. Passive Small-Scale Applications

It was found that the encapsulation of PCM in the wall lead to reduction of indoor and wall inner surface temperatures by about 4.7 °C and a reduction of 23.84% in temperature fluctuation. Rathore and Shukla [8] constructed two identical small test cubicles in Mathura, India. One of the test cubicles was equipped with tubular macro-capsules filled with PCM at the walls and roof, whereas the other was considered a reference. The study performed by the authors focused on examining the thermal behavior of the passive PCM application for the tropical summer conditions. The test facilities were made from concrete, mortar of cement, and aluminum capsules such that the facilities are permanent in the structure. Results showed that the integration of macro-encapsulated OM37 PCM lead to a reduction in thermal amplitude in all walls and roof ranging between 40.67% and 59.79%, a delay ranging between 60 and 120 min in attaining the peak temperatures at different faces, and a reduction in cooling load that reached 38.76%, triggering a cost saving equivalent to ~0.4 US$/day. Khan et al. [9] prepared two models of composite walls to investigate the effect of using paraffin wax PCM on the wall heat transfer. The model was composed of rectangular layers insulated with wood and placed axially beside each other, ensuring complete thermal contact. Model 1 contained PCM and model 2 was deprived from PCM. Results showed that for cooling load reduction, PCM position is preferred to be near the heat source within the wall fragment. With the PCM used, a time shift was monitored for the process of achieving a given temperature compared with other building materials. Integrating double-layer shape stabilized PCM wallboards in building walls was investigated by Lu et al. [10] through two identical test rooms located in Wuhan, China. Exterior and interior layers were proved to be active in both summer and winter, respectively. Overheating in summer and undercooling in winter could be prevented using PCM.

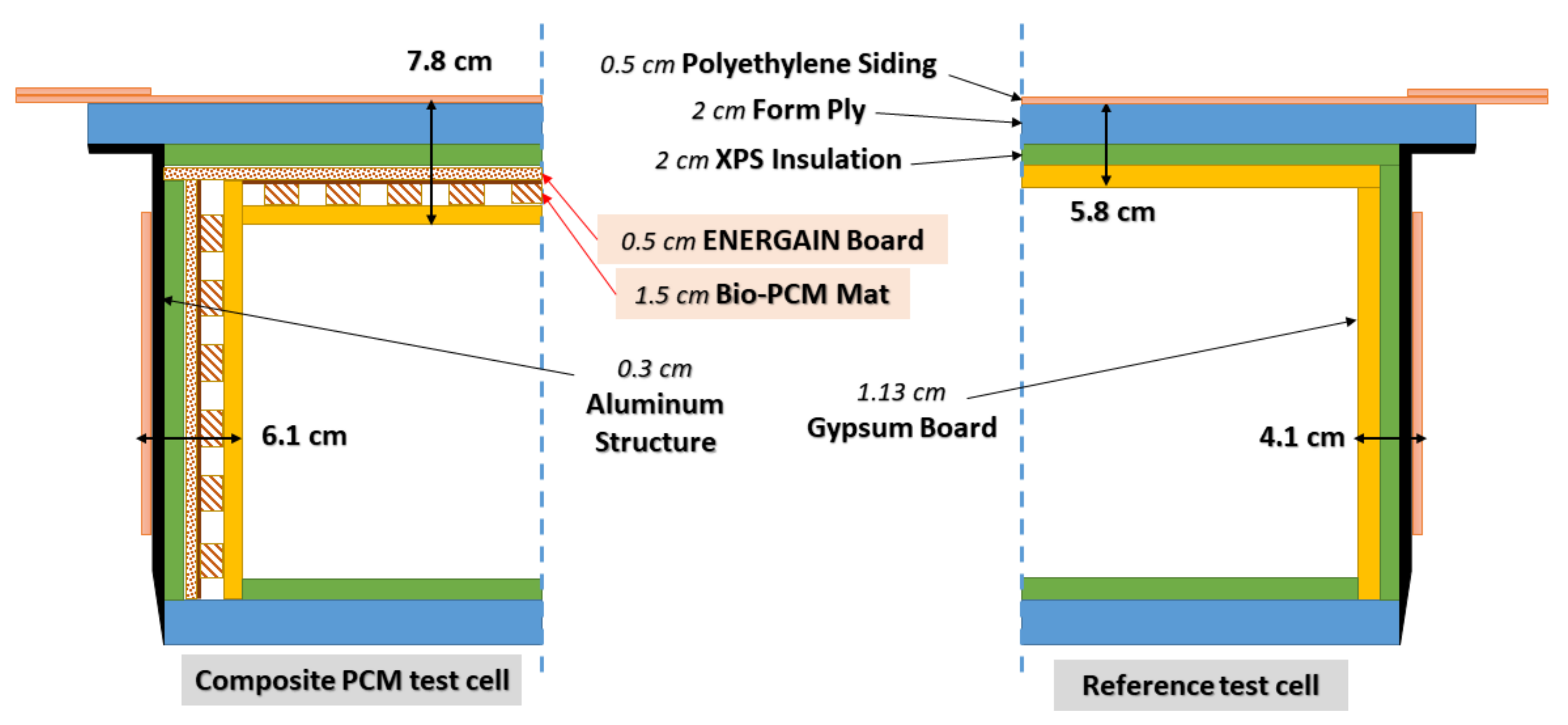

To manage the drawbacks behind high window to wall ratio (glazing walls) buildings, Berardi and Soudian [11] studied the effect of integrating passive PCM composites in walls and ceiling. The aim was to reduce the high heat gains due to solar radiation and minimize temperature swings within the cooling zone. Two test facilities were prepared (see Figure 4), one acting as a reference and the other as the one equipped with PCM in walls and ceiling. The system included composite PCM layers (Energain® and BioPCMTM) having different melting ranges that best suit indoor conditions during hot and cold seasons of Toronto, Canada. The hybrid system ensures thermal regulation through variable weather conditions (summer and winter). Results showed that using PCM decreased the indoor and surface temperatures by up to 6 °C. In addition, the low thickness of the double layered PCM system (2 cm) makes it favorable in retrofit projects for building thermal enhancement. Sun et al. [12] prepared residential building walls enhanced with pipe-encapsulated PCMs. The designed prototype was tested in the laboratory during summer season, with two main variables: pipe size and pipe depth (position) within the wall. It was shown that: (1) The reductions in heat fluxes through the PCM wall compared to control wall were 36.5% and 22.5% for the cases of middle depth and next to wallboard, respectively. However, in both cases the complete solidification of the PCM was not attained after the first experiment day. Moreover, it was proved that smaller pipe sizes with higher surface area to volume ratio are preferred. For 14 consecutive days of testing, Mehdaoui et al. [13] investigated the thermal performance of a PCM wall installed inside a small-scale prototype. Results showed that the installation of the PCM wall led to enhancement in thermal comfort by reducing the indoor temperature fluctuations. A numerical simulation was added to the study making a significant proof that PCM melting occurs at the upper side of the PCM wall more than the bottom.

Figure 4. Cross-section of composite PCM test facility and reference facility [11].

4. Compartments Retrofitting PCM Experimental Studies

4.1. Active Retrofits Applications

Underfloor heating thermal performance with enhanced thermal conductivity shape stabilized PCM was tested by Cheng et al. [14]. Paraffin, high density polyethylene, and expanded graphite were melt-mixed to form the SSPCM plates, which were placed above electrical mats in a conventional house room. The tested room located at the second floor of the house being located at Anhui province (subtropical weather) is 4 m long, 3 m wide, and 3 m high. Results proved that among the three studied heating systems, the phase change energy storage system has the lowest economic consumption and highest cost-effective performance. Lu et al. [15] performed an experimental study on double pipe PCM floor heating system for a testing house located in Zhangjiakou, China. PCM was encapsulated within the annulus of the double-pipe. Three modules of heat pipe loops were installed in the floor of the 6.4 m long, 4 m wide, and 2.7 m high room as shown in Figure 5. Results revealed that with the suitable operation strategy performed, thermal comfort could be achieved with fluctuations being reduced and controlled (average of 3 °C).

Figure 5. Underfloor double pipe PCM heating system studied by Lu et al. [15].

Stritih et al. [16] studied the effect of integrating PCM-LHTES at the termination of a solar air heater, mounted in a solar façade at the office building in Ljubljana, on the heating annual energy savings of the module. Operational cost savings have reached 24% using the PCM-LHTES compared to the system deprived from LHTES. Lamnatou et al. [17] investigated the performance of a novel building-integrated solar thermal system (BIST) equipped with myristic acid as PCM in Ajaccio, France. The system is composed of flat plate solar water heating collectors that are integrated into the building gutters. The study focused on performing life cycle assessment for two systems: with and without PCM to test the effect of PCM on environmental profile of the proposed system. Results showed that PCM has the highest impact related to ecosystem compared to the effect of other components in the system.

The effect of integrating a PCM component into conventional HVAC system was studied by Nada et al. [18]. A PCM module composed of SP-24E PCM plates was installed after the heating and cooling coil sections. Results showed that by increasing ambient temperature and the flow rate of fresh air, the number of required plates increases while the PCM discharge time decreases.

4.2. Passive Retrofits Applications

Wang et al. [19] performed an experimental study on the thermal behavior of disaster-relief prefabricated temporary houses (PTHs) equipped with PCM plates mounted on its internal faces. The aim of the study was to enhance the thermal environment of such houses that lack electrical thermal environmental control systems. Results were promising, by which both internal surface temperature and indoor temperature were monitored to be decreasing upon the integration of fixed PCM plates. Moreover, the authors concluded that using a movable PCM-based energy storage system is preferred so that the PCM is brought outdoor to benefit from low temperatures during night and thus ensure complete solidification. However, such a method full of hard continuous work (fixing and dismantling plenty of plastic net-shape containers) is inconvenient for victims that are already in disastrous conditions, and can no more withstand daily aggression. For that, the authors recommended a new practical design that permits the moving the PCM plates from indoor to outdoor to benefit from nocturnal cooling, and that is by manufacturing the conventional wall with PCM fixed to it being divided into several pieces that can rotate on its axis and turn inside faces outside. Lee et al. [20] introduced the concept of plug-and-play walls that allows testing several construction materials, for residential and commercial applications, easily and under full weather conditions. The insertion of a PCM layer allowed an average daily reduction of 27.4% and 10.5% in heat transferred through the south and west walls, respectively. It was also shown that an average delay of two to three hours with the integration of PCM. The integration of PCM plates as suspended ceiling and side wall was investigated by Vik et al. [21]. After studying five different scenarios, authors concluded that using PCM plates as suspended ceiling without being covered by aluminum ceiling panels attained the highest effect, and that the PCM proved to be able to decrease the energy consumption needed for mechanical cooling of the building.

Li et al. [22] prepared a novel PCM blind system and installed it within a double skin façade to minimize the overheating problem in summer season filling the gap in the present knowledge in such domain. The study was focused on diminishing the disadvantages behind such systems that are summarized to be: unpredictable heat transfer, night heat losses, and the thermosiphon phenomenon. Experimental results of the designed system showed high effectiveness regarding solar energy capturing and energy management.

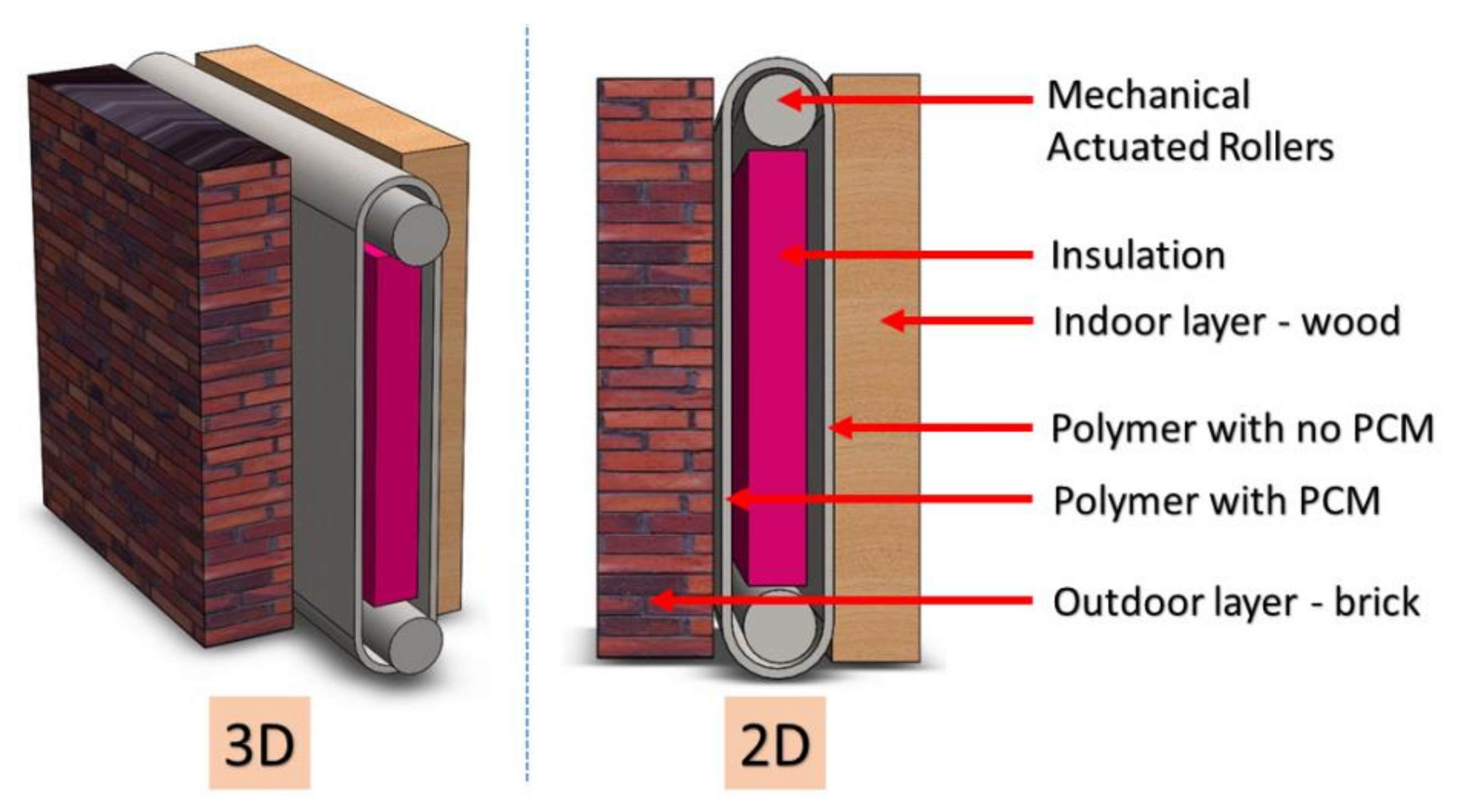

A novel design for a dynamic PCM layer incorporated in building envelopes was proposed Gracia et al. [23]. The system was concerned with removing the two main drawbacks of passive PCM applications in building envelopes: (1) the incomplete solidification of the PCM at night; and (2) the discharge of the absorbed internal gains (cooling load) back to indoors. The author proved the new concept by the promising results using a numerical tool that showed a cooling load reduction that can reach 379%. That means the system is able to provide cooling as well as being a thermal barrier. A schematic diagram for the proposed design is presented in Figure 6 below; The system is composed of two layers of plastic polymers containing an insulation wool layer in-between, where one side contains the PCM. It uses actuated rollers that can switch the position of the PCM from the near inside to the near outside, so that the discharge can be directed outdoors and the PCM will completely solidify.

Figure 6. Dynamic wall concept proposed by Alvaro Gracia [23].

5. Laboratory-Based PCM Building Partition Experimental Studies

6.1. Active Laboratory-Based Applications

Guo et al. [24] performed several experiments to assess the space heating performance and energy consumption characteristics; four ventilated blocks with different operation modes, and three blocks with different micro-encapsulated phase change material (PCM) distributions. The critical parameters under study where surface temperature of mortar block, the average temperature of space air, the temperature of black globe and the power consumption. The best result reached was a 41.5% increase in heating power consumption when PCM was concentrated on the upper part, and ventilation started at the same time as heating. In addition, the effect of some geometrical and operational parameters was also studied including the thickness of mortar block, air speed, and diameter of tube.

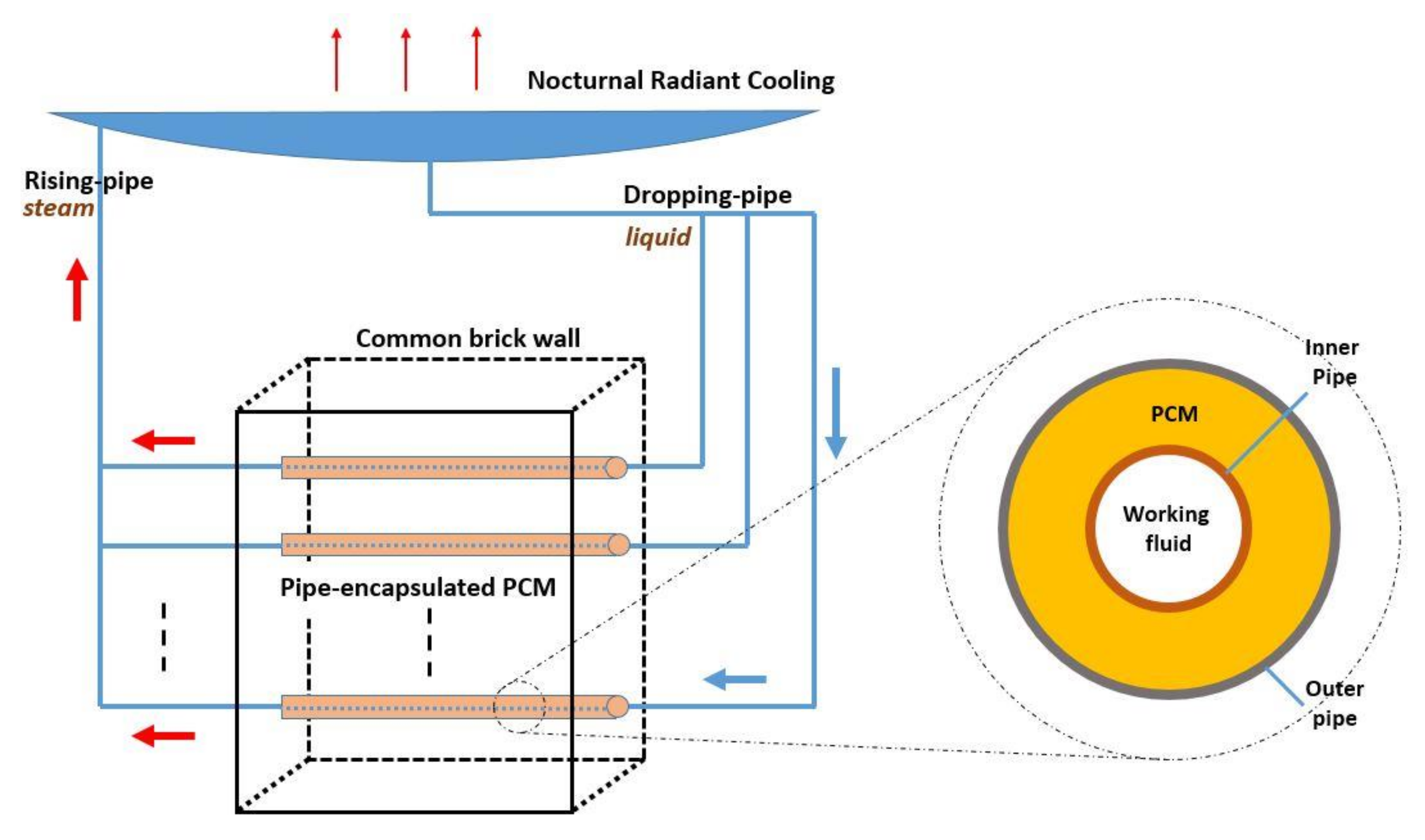

As an attempt for the removal of released heat during discharging of PCM in summer nights, Yan et al. [25] proposed a novel self-activated PCM wall utilizing gravity heat-pipes embedded into pipe-encapsulated PCM system, and linked to nocturnal radiative cooling. Figure 7 shows the mechanism of the system proposed were the working fluid used operates at its phase change temperature and pressure. During daytime, PCM stores heat by transforming into its liquid state with the working fluid being transformed into gaseous state completely. During night, the gas currying energy passes into the nocturnal radiator and releases its energy and condenses then returns into the PCM wall so that the PCM releases its stored energy into the working liquid that continues its cycle. By that, PCM will release its stored energy away from the internal zone and compete solidification is ensured. Results proved that, within a week of hot climate, a reduction of 74.5% in heat transferred accumulated at the interior surface of the novel PCM wall can be achieved, compared to a conventional wall.

Figure 7. Novel self-activated PCM wall mechanism [26].

Qiao et al. [26] established a personal cooling system (PCS) integrated with PCM heat exchanger (PCMHX) as an active cooling system for local residential zones. The system comprises a vapor compression cycle where an enhanced compressed expanded natural graphite (CENG) shell-and-tube heat exchanger, filled with organic PCM, is located between the compressor and the expansion valve serving as a condenser in the cooling cycle. Two sets of thermostatic expansion valves with necessary check valves and a reversing valve allow the cycle to be reversed so that the PCM can recharge while the PCMHX serves as an evaporator. Results showed that steady cooling, surrounding environment broad adaptive response, and enhanced recharging rate are achieved by the proposed PCM-PCS. Utilizing PCM cylindrical macro-capsules within an LHTES tank for heating load management in a mechanical heat pump system was studied by Xu et al. [27]. The study investigated the effect of tank orientation with specific parametric examinations. Results revealed that the temperature difference between HTF and melting PCM, and HTF flow rates are inversely proportional with PCM charging/discharging time in case of horizontal tank. Comparing the orientations, vertical tank shortens the charging/discharging time by 20% however the thermal capacity of PCM is decreased by 8.2%. A study by Saeed et al. [28] focused on investigating the effectiveness of plate type heat exchanger with phase change material as a thermal storage medium for load shifting. Results indicated that, compared to conventional systems, the prescribed design showed outstanding performance with an effectiveness reaching 83.1% regardless of poor thermal conductivity of used PCM. Sun et al. [29] designed and implemented a novel flat-heat-pipe heating system incorporating PCM and thermoelectric unit. The system was proven to be highly efficient in continuous intermittent heating. The thermoelectric unit was capable of supplying sufficient heat with a high coefficient of performance (exceeding 1.7) when the heat from the PCM is insufficient.

Sun et al. [30] prepared a small laboratory wind tunnel to investigate the thermal performance of ventilated slabs enhanced with paraffin-based PCM encapsulated with HDPE. The studied variables were the effect of wind speed, air temperature, and inclination angles. It was found that an increase in the charging rate of the PCM equivalent to 201.7% was achieved with the increase of inlet air temperature from 35 °C to 55 °C. However, with a unit increase in air speed (from 4 to 5 m/s), a small increase of 8.7% in the average charging speed was recorded.

Solar air heaters equipped with PCMs are studied by various researchers on a laboratory basis. Wadhawan et al. [31] analyzed the effect of using Lauric acid as PCM integrated in a thermal energy storage device (TESD) and installed in an active solar air heater module. The experimental set up used an electrical heater as a heating source while the whole setup was inside the lab. Results showed that the use of TESD yielded an average incremental rise of 86.47% regarding the output air temperature if compared to the system deprived from PCM. Abuska et al. [32] studied the effect of honeycomb core as PCM plate internal fin structure in a solar air heater. Three SAHs were used: (I) with PCM and honeycomb fins, (II) with PCM, and (III) without PCM. For different mass flow rates, results revealed that using the honeycomb matrix reduces the charge–discharge time of PCM with a slight reduction in instantaneous daily thermal efficiency. A recent study by Chen et al. [33] introduced the concept of closed collector-solar air heater system with PCM. The system was a closed loop that utilized a solar air collector with flat micro-heat pipe array linked to a duct that allows the circulation of air through a multichannel flat-tube thermal storage unit containing PCM. Results proved that the proposed system can quickly increase PCM temperature with a maximum attainable value that has been recorded to be 68.52 °C within 132 min.

6.2. Passive Laboratory-Based Applications

Fateh et al. [34] prepared a numerical dynamic model for investigating the effect pf PCM adoption in wall insulation layers. The model was validated by experiments done on a wall partition inside a laboratory insulated test facility simulating real environment. Results revealed that with the placement of PCM layer in positions 3 and 4 (i.e., in-between the layers of insulation at the wall center), a maximum reduction of 15% in heat energy consumption was achieved with a delay effect on the maximum heat flux of approximately 2 h. Evers et al. [35] tested the thermal performance of PCM-enhanced cellulose insulation placed as a wall partition in a dynamic wall simulator. The simulator was a small-scale cubicle that includes cavities in which different layers can be inserted. Two types of PCM were mixed with the insulation at 10% and 20% by weight of the wallboard: paraffin and salt-hydrate. Results proved that a reduction of 9.2% in the average peak heat flux was achieved by the wall containing paraffin, while no benefit was monitored regarding the salt-hydrate wall due to the hydroscopic behavior of unencapsulated hydrate salt. Ryms and Klugmann-Radziemska [36] compared the thermal performances of three different building bricks equipped with PCM: The first containing microencapsulated PCM powder (Micronal DS 5040 X), the second containing RT22 in the form of liquid and the third containing RT22 impregnated in building porous aggregate as a carrier. Results revealed that the third method is the most promising. The problem of high expenses following the integration of microencapsulated PCMs can be solved by the presence of aggregate carrier and RT22.

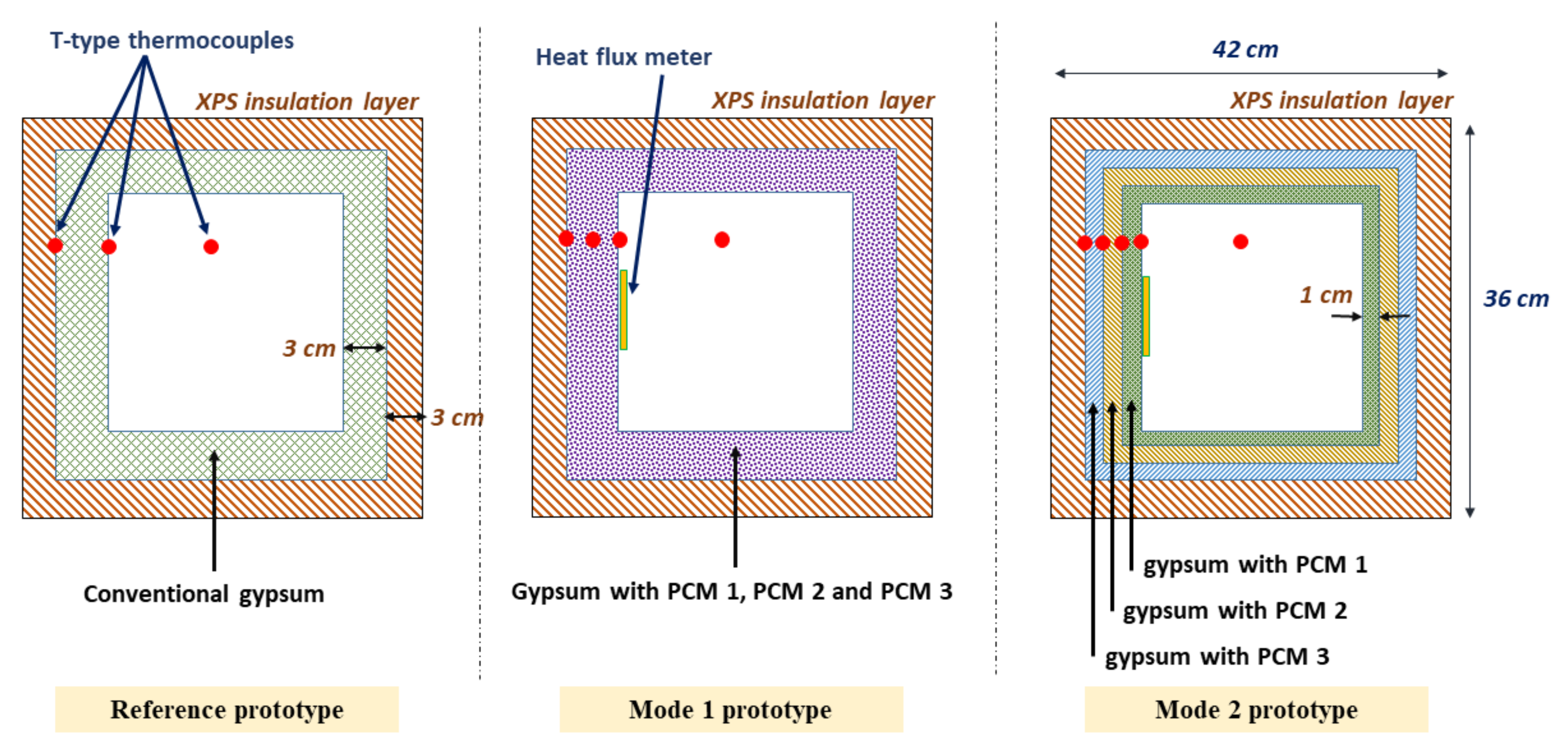

A study by Li et al. [37] focused on investigating the thermal performance of a novel PCM wallboard containing three types of PCMs having consecutive melting points of 12, 18, and 29 °C. The novelty behind the proposed wallboard is the ability to perform heat storage and enhance thermal comfort over a wide temperature range covering the whole year climates. Three identical reduced-scale test boxes were prepared and adopted with different wallboards: Mode 1 PCM wallboard, Mode 2 PCM wallboard, and gypsum wallboard as shown in Figure 8. Preliminary results proved that thermal comfort is achieved throughout the year. Additionally, it was found that Mode 2 is more suitable in regulating indoor temperature.

Figure 8. Experimental reduced-scale prototypes with PCM wallboards of different modes [37].

A study by Drissi et al. [38] covered the performance of a solar energy storage concrete panel equipped with PCM aggregates. The novel core–shell aggregates prevented the leakage of PCM and the overall concrete panels showed enhancement in their thermal performance. A reduction of 1 °C in peak temperature was monitored by means of the enhanced concrete panel ensuring a high potential for thermal comfort and electrical energy saving. Another study by Saxena et al. [39] investigated bricks embedded with PCM for building passive cooling. PCM bricks showed a reduction of 4–9.5 °C in temperature across their bodies compared to conventional ones. Enhancements in PCM wallboards have followed different scopes. Wang et al. [40] investigated the thermal performance of PCM honeycomb wallboard that was designed and fabricated using micro-encapsulated PCM and aluminum plate with honeycomb core. The preliminary results showed that indoor thermal conditions affect the performance of the wallboard, which proved to be capable of improving heat management the next day.

Li et al. [41] studied the effect of integrating PCM with nanoparticles in a window unit for increasing building thermal inertia. The used PCM was paraffin wax having low thermal conductivity that affects the optical performance of the window presenting a disadvantage that was removed by dispersed nanoparticles. Results revealed that the PCM-nanoparticles window system encountered favorable enhancements in thermal and optical performances compared to pure PCM window. Authors recommended CuO nanoparticles, a volume fraction < 1%, and a nanoparticle size < 15 nm.

This entry is adapted from the peer-reviewed paper 10.3390/en15041459

References

- Mourid, A.; El Alami, M.; Kuznik, F. Experimental Investigation on Thermal Behavior and Reduction of Energy Consumption in a Real Scale Building by Using Phase Change Materials on Its Envelope. Sustain. Cities Soc. 2018, 41, 35–43.

- Lu, S.; Zhao, Y.; Fang, K.; Li, Y.; Sun, P. Establishment and Experimental Verification of TRNSYS Model for PCM Floor Coupled with Solar Water Heating System. Energy Build. 2017, 140, 245–260.

- Gholamibozanjani, G.; Farid, M. A Comparison between Passive and Active PCM Systems Applied to Buildings. Renew. Energy 2020, 162, 113–123.

- Sun, D.; Wang, L. Research on Heat Transfer Performance of Passive Solar Collector-Storage Wall System with Phase Change Materials. Energy Build. 2016, 119, 183–188.

- Luo, C.; Xu, L.; Ji, J.; Liao, M.; Sun, D. Experimental Study of a Modified Solar Phase Change Material Storage Wall System. Energy 2017, 128, 224–231.

- Jobli, M.; Yao, R.; Luo, Z.; Shahrestani, M.; Li, N.; Hong, L. Numerical and Experimental Studies of a Capillary-Tube Embedded PCM Component for Improving Indoor Thermal Environment. Appl. Therm. Eng. 2019, 148, 466–477.

- Fang, Y.; Ding, Y.; Tang, Y.; Liang, X.; Jin, C.; Wang, S.; Gao, X. Thermal Properties Enhancement and Application of a Novel Sodium Acetate Trihydrate-Formamide/Expanded Graphite Shape-Stabilized Composite Phase Change Material for Electric Radiant Floor Heating. Appl. Therm. Eng. 2019, 150, 1177–1185.

- Kumar, P.; Rathore, S. An experimental evaluation of thermal behavior of the building envelope using macroencapsulated pcm for energy savings. Renew. Energy 2019, 149, 1300–1313.

- Khan, R.J.; Bhuiyan, Z.H.; Ahmed, D.H. Investigation of Heat Transfer of a Building Wall in the Presence of Phase Change Material (PCM). Energy Built Environ. 2020, 1, 199–206.

- Zhu, N.; Hu, N.; Hu, P.; Lei, F.; Li, S. Experiment Study on Thermal Performance of Building Integrated with Double Layers Shape-Stabilized Phase Change Material Wallboard. Energy 2018, 167, 1164–1180.

- Berardi, U.; Soudian, S. Experimental Investigation of Latent Heat Thermal Energy Storage Using PCMs with Different Melting Temperatures for Building Retrofit. Energy Build. 2019, 185, 180–195.

- Sun, X.; Medina, M.A.; Lee, K.O.; Jin, X. Laboratory Assessment of Residential Building Walls Containing Pipe-Encapsulated Phase Change Materials for Thermal Management. Energy 2018, 163, 383–391.

- Mehdaoui, F.; Hazami, M.; Messaouda, A.; Taghouti, H.; Guizani, A. Thermal Testing and Numerical Simulation of PCM Wall Integrated inside a Test Cell on a Small Scale and Subjected to the Thermal Stresses. Renew. Energy 2018, 135, 597–607.

- Cheng, W.; Xie, B.; Zhang, R.; Xu, Z.; Xia, Y. Effect of Thermal Conductivities of Shape Stabilized PCM on Under-Floor Heating System. Appl. Energy 2015, 144, 10–18.

- Lu, S.; Xu, B.; Tang, X. Experimental Study on Double Pipe PCM Floor Heating System under Different Operation Strategies. Renew. Energy 2020, 145, 1280–1291.

- Stritih, U.; Charvat, P.; Koželj, R.; Klimes, L.; Osterman, E.; Ostry, M.; Butala, V. PCM Thermal Energy Storage in Solar Heating of Ventilation Air—Experimental and Numerical Investigations. Sustain. Cities Soc. 2017, 37, 104–115.

- Lamnatou, C.; Motte, F.; Notton, G.; Chemisana, D.; Cristofari, C. Building-Integrated Solar Thermal System with/without Phase Change Material: Life Cycle Assessment Based on ReCiPe, USEtox and Ecological Footprint. J. Clean. Prod. 2018, 193, 672–683.

- Nada, S.A.; Alshaer, W.G.; Saleh, R.M. Experimental Investigation of PCM Transient Performance in Free Cooling of the Fresh Air of Air Conditioning Systems. J. Build. Eng. 2020, 29, 101153.

- Wang, C.; Huang, X.; Deng, S.; Long, E.; Niu, J. An Experimental Stydy on Applying PCMs to Disaster-Relief Prefabricated Temporary Houses for Improving Internal Thermal Environment in Summer. Energy Build. 2018, 179, 301–310.

- Lee, K.O.; Medina, M.; Sun, X. On the Use of Plug-and-Play Walls (PPW) for Evaluating Thermal Enhancement Technologies for Building Enclosures: Evaluation of a Thin Phase Change Material (PCM) Layer. Energy Build. 2015, 86, 86–92.

- Vik, T.A.; Madessa, H.B.; Aslaksrud, P.; Folkedal, E.; Øvrevik, O.S. Thermal Performance of an Office Cubicle Integrated with a Bio-Based PCM: Experimental Analyses. Energy Procedia 2017, 111, 609–618.

- Li, Y.; Darkwa, J.; Kokogiannakis, G.; Su, W. Phase Change Material Blind System for Double Skin Façade Integration: System Development and Thermal Performance Evaluation. Appl. Energy 2019, 252, 113376.

- Gracia, A. De Dynamic Building Envelope with PCM for Cooling Purposes—Proof of Concept. Appl. Energy 2019, 235, 1245–1253.

- Guo, J.; Zou, B.; Wang, Y.; Jiang, Y. Space Heating Performance of Novel Ventilated Mortar Blocks Integrated with Phase Change Material for Floor Heating. Build. Environ. 2020, 185, 107175.

- Yan, T.; Gao, J.; Xu, X.; Xu, T.; Ling, Z.; Yu, J. International Journal of Thermal Sciences Dynamic Simpli Fi Ed PCM Models for the Pipe-Encapsulated PCM Wall System for Self-Activated Heat Removal. Int. J. Therm. Sci. 2019, 144, 27–41.

- Qiao, Y.; Cao, T.; Muehlbauer, J.; Hwang, Y.; Radermacher, R. Experimental Study of a Personal Cooling System Integrated with Phase Change Material. Appl. Therm. Eng. 2020, 170, 115026.

- Xu, T.; Chiu, J.N.; Palm, B.; Sawalha, S. Experimental Investigation on Cylindrically Macro-Encapsulated Latent Heat Storage for Space Heating Applications. Energy Convers. Manag. 2019, 182, 166–177.

- Saeed, R.M.; Schlegel, J.P.; Sawafta, R.; Kalra, V. Plate Type Heat Exchanger for Thermal Energy Storage and Load Shifting Using Phase Change Material. Energy Convers. Manag. 2019, 181, 120–132.

- Sun, H.; Lin, B.; Lin, Z.; Zhu, Y. Experimental Study on a Novel Flat-Heat-Pipe Heating System Integrated with Phase Change Material and Thermoelectric Unit. Energy 2019, 189, 116181.

- Sun, X.; Chu, Y.; Medina, M.A.; Mo, Y.; Fan, S.; Liao, S. Experimental Investigations on the Thermal Behavior of Phase Change Material (PCM) in Ventilated Slabs. Appl. Therm. Eng. 2019, 148, 1359–1369.

- Wadhawan, A.; Dhoble, A.S.; Gawande, V.B. Analysis of the Effects of Use of Thermal Energy Storage Device (TESD) in Solar Air Heater. Alex. Eng. J. 2017, 57, 1173–1183.

- Abuşka, M.; Şevik, S.; Kayapunar, A. A Comparative Investigation of the Effect of Honeycomb Core on the Latent Heat Storage with PCM in Solar Air Heater. Appl. Therm. Eng. 2018, 148, 684–693.

- Chen, C.Q.; Diao, Y.H.; Zhao, Y.H.; Wang, Z.Y.; Liang, L.; Wang, T.Y.; Zhu, T.T.; Ma, C. Thermal Performance of a Closed Collector-Storage Solar Air Heating System with Latent Thermal Storage: An Experimental Study. Energy 2020, 202, 117764.

- Fateh, A.; Klinker, F.; Brütting, M.; Weinläder, H. Numerical and Experimental Investigation of an Insulation Layer with Phase Change Materials (PCMs). Energy Build. 2017, 153, 231–240.

- Evers, A.C.; Medina, M.A.; Fang, Y. Evaluation of the Thermal Performance of Frame Walls Enhanced with Paraf Fi n and Hydrated Salt Phase Change Materials Using a Dynamic Wall Simulator. Build. Environ. 2010, 45, 1762–1768.

- Ryms, M.; Klugmann-radziemska, E. Possibilities and Benefits of a New Method of Modifying Conventional Building Materials with Phase Change Materials (PCMs). Constr. Build. Mater. 2019, 211, 1013–1024.

- Li, C.; Yu, H.; Song, Y.; Tang, Y.; Chen, P.; Hu, H.; Wang, M.; Liu, Z. Experimental Thermal Performance of Wallboard with Hybrid Microencapsulated Phase Change Materials for Building Application. J. Build. Eng. 2019, 28, 101051.

- Drissi, S.; Ling, T.; Hung, K. Thermal Performance of a Solar Energy Storage Concrete Panel Incorporating Phase Change Material Aggregates Developed for Thermal Regulation in Buildings. Renew. Energy 2020, 160, 817–829.

- Saxena, R.; Rakshit, D.; Kaushik, S.C. Experimental Assessment of Phase Change Material (PCM) Embedded Bricks for Passive Conditioning in Buildings. Renew. Energy 2020, 149, 587–599.

- Wang, S.M.; Matiašovský, P.; Mihálka, P.; Lai, C.M. Experimental Investigation of the Daily Thermal Performance of a MPCM Honeycomb Wallboard. Energy Build. 2018, 159, 419–425.

- Li, D.; Wu, Y.; Liu, C.; Zhang, G.; Arıcı, M. Numerical Investigation of Thermal and Optical Performance of Window Units Filled with Nanoparticle Enhanced PCM. Int. J. Heat Mass Transf. 2018, 125, 1321–1332.

This entry is offline, you can click here to edit this entry!