2.1. Dairy Cattle Breeds

Since the creation of dairy farms, the sector has worked on and improved several breeds, in order to be able to produce huge amounts of milk. Holstein/Holstein–Friesian, Jersey, Brown Swiss, Guernsey, and Ayrshire are the main dairy breeds worldwide [

5]. Jersey cows are specialized in milk with a high content of solids (more 0.57% of total protein and, above all, more 1.37% of total fat, when compared to Holstein–Friesians), and show high reproductive performance [

34]. However, out of all the breeds, McClearn et al. [

35] showed that Holstein–Friesian cows are the most efficient and profitable (5720 vs. 5476 kg per cow of total milk yield, from Holstein–Friesian vs. Jersey × Holstein–Friesian, respectively) breed for mass milk production, when compared to crossbreeds with dairy aptitude.

Due to these traits, the Holstein is the dairy breed of choice for worldwide farmers [

36]. The origin of the Holstein breed dates back 2000 years ago, in The Netherlands, where Germanic tribes needed to obtain animals capable of making the best value of their lands [

37]. Therefore, they crossed black animals, “Batavians”, with white animals, “Friesians”, obtaining more efficient animals with greater productive capacities [

38]. In 1852, the first specimens of this breed arrived in Boston. It was in USA that the main genetic improvement took place, transforming the Holstein cows into that what we currently have [

38,

39]. Diverse reproductive biotechnologies, such as artificial insemination (AI) and embryo transfer, have allowed the genetic improvement of the breed, as well as its dissemination all over the world [

36].

2.2. Genetic Improvement of Dairy Cattle

All of the improvements made at the genetic level of dairy breeds enabled farms to improve their production levels [

40]. These improvements began to be realized at the beginning of the 20th century, through the selection of animals with higher production traits, and with a higher content in milk solids [

41]. This trend was observed throughout the 20th century, thus the genetic choice fell, mainly in productive traits and conformational traits [

41,

42]. An example of this is that, in 1920, Holstein cows produced on average 2000 kg of milk annually (305 days in milk). In comparison, 100 years later, Holstein cows on average produce over 10,000 kg of milk annually, with the same content of solids [

41]. Through artificial insemination techniques, it was possible to disseminate and cross bulls of superior genetic value all over the world [

42]. This cross-breeding resulted in genetic improvement through the production of in genetically superior offspring [

43].

This fast genetic improvement, mainly focused on increasing milk yield in the Holstein cattle [

32], has led to associated problems, such as poor fertility, inadequate health, and shorter longevity. As a result, from the beginning of the 21st century onwards, genetic improvement underwent a radical transformation, with a greater focus on reproductive traits (fertility), health (average SCC), and sustainability traits (alimentary efficiency) [

40].

The genetic evaluation of the sires can be performed in a traditional way, evaluating the animal’s pedigree and progeny testing [

44]. Progeny testing is based on the performance of the offspring, which, when superior to the parental generation, leads to genetic improvement [

42,

44]. Recent technologies have made it possible to evaluate genetic merit or value through genomic prediction [

45], whereby, through the analysis of the genome of the animals, the predicted breeding values (EBV) can be estimated [

44]. Due to the high amount of data available, as well as pedigree information, and phenotypes information, the estimation of the breeding values of the selected animals is highly reliable [

46]. In addition to being a better tool for the selection of the desired traits and breed conservation, it restricts inbreeding, which negatively impacts reproduction and production traits [

47].

Furthermore, producers started, in some parts of the world, to crossbreed [

48]. Crossbreeding occurs when two different lines, breeds, or populations are crossed [

49]. This technique brings some benefits, such as introducing greater genetic variability of desired characteristics, especially when there is a high inbreeding depression [

48]. Crossbred dairy cattle have been considered more robust (10 to 15% of expected heterosis for longevity in Danish models) and more fertile (about 10% of expected heterosis), as well as economically efficient, when compared to full breeds [

49,

50,

51]. According to Dezetter et al. [

52], Montbéliarde and Normandé have been the most frequently used breeds in the EU to cross with Holstein cows. These breeds, originating from France, show higher resilience, better fertility, produce milk with more solids, and have dual purpose, providing an additional income for farmers when these animals are culled and sold for beef [

52]. Nevertheless, high-yielding cows have also been selected for many years, for other genetic traits, related to health, longevity, reproduction, and other positive characters besides yield capacity [

43,

53], and can also show high fertility rates [

54]. Moreover, improving nutritional, welfare, and reproductive management appears to be the key to sustain fertility in dairy farms [

55]. Moreover, new methodologies (e.g., genetic selection of best adapted animals) are being currently tested to improve breed health and resilience and reduce the footprint of production [

32,

56,

57].

As such, a new focus is on more sustainable and balanced production, with a reduction in the ecological footprint of farms [

58]. Thus, in response to the current needs of industries and consumers, genetic selection has begun to give greater emphasis to animal welfare, health, longevity, resilience, and environmental efficiency (methane emission and food efficiency) traits [

58].

2.3. Rearing Calves and Heifers

Similar to the evolutionary process, the process of rearing has experienced several substantial changes in the last decades, in terms of housing and feeding calves and heifers based, again, on increased knowledge concerning the physiology, pathology, and requirements of the animals at each life stage [

59]. Although rearing is the most sensitive sector of a dairy herd [

60], on many farms, the poor management of calves leads to high mortality and morbidity rates [

61].

Heifer rearing represents, on average, 15 to 20% of the total costs of a farm, bringing no immediate economic benefit, as heifers do not produce milk until the first calving [

62]. A recent study (2020) calculated the cost of rearing a heifer from birth to first calving, with automatic feeders, but in different housing systems. It concluded that rearing costs are higher in confinement (USD 1920 on average) than in pasture (USD 1335 on average) [

63]. In The Netherlands (2015), a similar cost was estimated to be around EUR 1790 [

64]. Higher costs (2017) were reported in the UK (GBP 1819 ± 387; up to less than GBP 407.83 in herd sizes ≥100 milking cow) [

65].

Nonetheless, these animals are subjected to a very high risk of morbidity and mortality, due to poor management concerning the rearing [

66]. Neo-natal diarrhea and bovine respiratory disease (BRD), are the two main diseases that affect calves [

67,

68,

69]. These conditions are complex and of multifactorial origin, which makes it control difficult for both farmers and veterinarians [

69]. To reduce these incidences, several management protocols are advised [

70,

71]. The passive transfer of immunity from cow to calf, through colostrum, is an example of one of the key points of these improved management protocols.

Colostrum is the first milk produced by the dam, and this is characterized by being rich in proteins and antibodies [

72]. The ingestion of this highly important and rich nourishment during the first 6 h of life [

60] reduces the risk of infection for many pathologies [

73]. However, colostrum supply is not a simple process, and it must be rigorous, since poor colostrum management is frequent, and leads to failure in the transfer of immunity [

73]. Good and clean colostrum management is essential for the survival and vitality of calves [

72]. These good practices are characterized by providing high quality colostrum (rich in immunoglobulin G (IgG), i.e., a minimum of 50 mg/mL IgG), in an adequate volume [

74], and provided within the optimal range for IgG absorption during the first 6 h and up to 24 h after birth. Beyond 24 h of life, the IgG absorption is very limited [

72], and, when possible, colostrum should be pasteurized [

75].

Furthermore, current guidelines advise that, from the first week of age, calves should be provided with

ad libitum clean water, starter concentrate, good quality straw or hay, and milk supply three times a day, with a total of 7 to 10% of body weight [

76,

77,

78].

Ad libitum clean water supply is fundamental immediately after the birth of the calves, as it stimulates the ingestion of dry food or concentrate, which is vital for rumen development, rapid growth, and vitality [

77]. A recent study [

78] concluded that calves reared with the practices mentioned presented bigger hip height, larger body length, and better digestion. These animals continued to present better growth rate and better health five months later [

78]. Recent works have evaluated the supplementation of fatty acids in milk and concentrate [

79], or the use of cobalt-lactate [

80], with the objective of reducing the use of antibiotics, and increase the health status of calves. These studies showed that the animals had greater efficiency, better health, and an increased growth rate.

In addition, improvement in calves’ housing and implementation of preventive protocols based on vaccines have been developed [

67,

73]. The most common type of calf housing in the EU and in the USA is the individual housing of the new-born calf based, on observed good health results and weight gain [

81,

82]. This is a biosecurity measure, since this type of housing reduces the transmission of respiratory and gastrointestinal diseases, albeit limiting the animal’s natural behavior [

61]. A recent study compared the risk of contamination by diarrheal viral agents, and there was a lower risk in individual housing when compared to group housing [

83]. Despite this, individual housing is considered as restraint for calves’ welfare. Recent studies have demonstrated that group rearing is better for calves’ social and behavioral development [

84]. Pairing housing systems, being the current recommended practice for rearing, improves calves’ health and welfare [

82,

85]. These systems increase positive social behavior, promoting the intake of solid feed, higher average daily gain, and reducing fearfulness of animals [

86,

87]. Rearing calves even in groups from a very young age is now being considered, since this practice allows for less labor, distress, and the adoption of new feeding technologies [

88]. One important technical advancement with rearing has been the automated milk feeders (AMF) [

59,

67]. These automated systems make it possible to increase the frequency with which calves are milk fed, increase animal welfare, and reduce the workload of producers [

89]. The increase in milk intake by calves allows them to grow at a faster rate, and allows for a reduction in the incidence of diseases such as diarrhea [

28].

Vaccination programs have been carried out to increase the passive immunity of calves against neo-natal diarrhea via the vaccination of dams in the prepartum period [

60]. Vaccinating calves against the agents causing bovine respiratory complex, or directly in calves during the first three weeks of age with intranasal vaccines [

68], is another common suggestion. Thus, all of these advances in the knowledge about rearing management have allowed farmers to improve their work, increased animal welfare, and reduced the incidence of the two main diseases that affect cattle at these young ages. The calves and heifers are the future of the farm, and those not affected by diarrhea or respiratory diseases early on become healthier and more productive adult cows, bringing more income to farmers [

90].

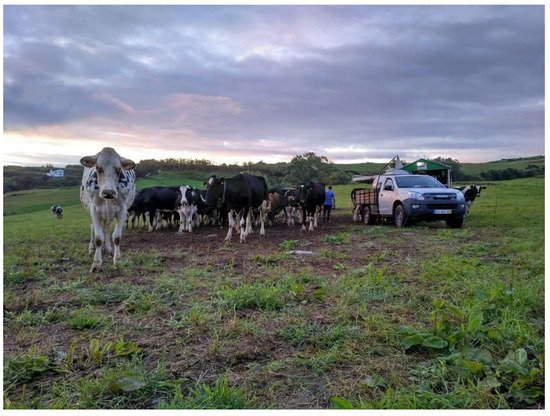

2.4. Pasture-Based Systems versus Indoor Systems

Since the first dairy farms came into production, the sector has undergone an intense transformation. In the beginning, farms were pasture-based, with grassland being the main constituent of cattle feed [

5]. Currently, this system is still implemented in regions of great preponderance in the dairy sector, and in available pastures, such as New Zealand [

7], Ireland [

6], Uruguay [

91], and the Azores [

8] (

Figure 1). These regions allow the cultivation of annual rich pastures [

5,

8], due to the mild climate and abundant rainfall throughout the year.

Figure 1. Grassing production system of dairy cattle (Azores).

In dry and very hot regions, where the soils are poor, such as the west coast of the USA, Mexico, south of Europe, and the Middle East, dairy farms are permanently indoors, with production based on stored forage and external cereal systems [

5].

Thus, we observe two main production systems, depending on the main source of feeding: the traditional pasture-based system, and the indoor-system with indoor feeding.

In general, pasture-based farms report better animal welfare indicators [

92,

93,

94,

95], showing lower incidence of pathologies, such as lameness, hoof injuries, uterine diseases, and lower mortality rates, than the rates from indoor farms [

96]. Cows are grazing animals, with pastures being their natural environment, where they can express their physiological behavior, reducing distress and immunological depression [

97]. This system is also known for being low-cost, benefiting from natural resources [

98].

However, systems exclusively using pasture have limitations as well. Cows fed exclusively or mostly grazing may not meet their nutritional needs, thus reducing their yield [

99], and the supplementation of their diets is quite complicated in grasslands. This reinforces the need to supply feed, so that they can cover their nutritional needs for health and yield [

100]. Another limitation of pasture-based systems is the dependence of grass growth on climate conditions, making it much more difficult to provide a homogenous daily feed (

Figure 2) [

101]. The implementation of mechanized systems is still more difficult and less common in grazing farms [

102]. All of this makes the pasture-based systems low output systems, as compared to the indoor systems [

98].

Figure 2. Transhumance of dairy cattle between non-contiguous grasslands (Azores).

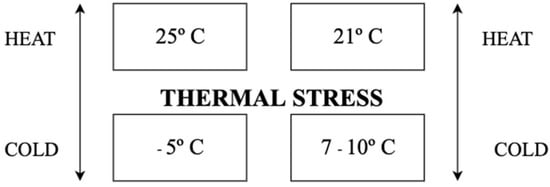

The thermal stress that animals are subjected to outdoors causes discomfort, decreased performance, and decreased milk production [

103]. To assess the thermal comfort of the cows, a temperature–humidity index (THI) was established, with a maximum limit of 72 (25 °C and 50% relative humidity). When this limit is exceeded, milk production declines, since animals are under heat stress [

104]. Heat has a bigger negative effect on cows than cold [

67]. Despite this, cold stress can be also a common problem, especially in pasture-based farms or in farms with inappropriate facilities.

Cows experience cold stress with temperatures below −5 °C, with a reduction in milk production as a consequence [

105]. Cold stress is primarily a major problem in calves, due to their natural inability to control their own body temperature [

67]. According to [

67,

103,

104,

105,

106], and represented in

Figure 3, there is a representation of the temperatures limits, from which adult cows and calves start to suffer from thermal stress (heat and cold).

Figure 3. Thresholds of thermal stress in adult cows and calves.

In an effort to solve thermal stress, indoor systems arose as a solution to the outdoor thermal stress. Nevertheless, indoor heat stress is still a major problem if farms do not implement appropriate methods to produce forced convention and evaporative cooling, such as fans and misting fans [

107]. The creation of stables dates back to the beginning of the 20th century, using extremely laborious, individual barns [

5]. From 1970 onwards, large feedlots were created, which were spread throughout the dairy world, with the advantage of allowing the handling of animals in groups, depending on their production stage [

108]. All of this has driven a great evolution in the management and practices of the dairy sector [

5,

108].

On the other hand, indoor systems are linked to higher productivity, boosted by a better nutritional control, and improved reproductive management [

97,

99]. These systems also have the advantage of protection against extreme weather conditions [

99] (

Figure 2). Animals reared indoors were also less susceptible to gastrointestinal parasitism, such as

Fasciola hepatica and gastrointestinal nematodes [

93,

104,

109]. As example, a higher proportion of dairy herds with access to pasture presented strongyle (94% vs. 40%;

p < 0.01),

Nematodirus (82% vs. 20%;

p < 0.01) and

Moniezia (12% vs. 0%;

p < 0.01) diagnosis, when compared with farms with indoor systems, exclusively [

110]. However, in this study [

110],

Trichuris diagnosis was more frequent in confined farm systems (65% vs. 100%;

p < 0.05).

Despite having improved several aspects, indoor systems have also shown varied constraints. Animal density must be taken into account when stabling the animals. Many farmers end up having too many animals per surface space to maximize the use of their facilities [

111], which leads to great losses [

112]. Animals in a high stocking density are more stressed and become more aggressive, especially due to less manger space and lying space disputes [

113]. Farms with a lower or appropriate stocking density have animals with normal behavior, which lie down for longer periods, and show greater ruminative comportment [

114,

115]. In addition, the concentration of disease-causing micro-organisms or particles in the environment is inversely proportional to the space available to animals [

116]. The incidence of pathologies such as lameness, mastitis, and uterine disorders also increases with stocking density [

96].

Lameness is one of the three most prevalent disease in dairy farms, leading to large economic losses, with reduced yield and reproductive performance, and an important animal welfare constraint [

117]. Cows with hoof diseases, especially in postpartum, have longer calving intervals, and a higher number of inseminations per conception [

118]. Lameness is also related with lower body conditions scores [

119] and poor indexes of animal welfare, which can be mitigated by preventive measures such as regular claw trimming [

120]. A case of lameness can represent losses of between EUR 100–190 per case per year [

121].

The increase in production diseases, such as acidosis and ketosis, and infections is another negative impact of intensive production systems, being a major problem in high-producing dairy cows [

122]. They are mainly related with intense negative energy balance due to high yielding [

123,

124].

Table 1 summarizes the main advantages and disadvantages associated with each production system.

Table 1. List of main advantages and disadvantages related with pasture-based or indoor systems production.

| Pasture-based farms: |

Advantages:

- (a)Better animal health and welfare indicators (Crump et al. [93]).

- (b)Lower pathologies incidence, such as lameness (Arnott et al. [96]).

- (c)Low-cost production (Macdonald et al. [98]).

- (d)Consumer perspective: positive (Armbrecht et al. [125]).

Disadvantages:

- (a)Limited protection against extreme weather conditions and predators (Charlton et al. [99]).

- (b)Higher propensity to thermal stress (Legrand et al. [104]).

- (c)Higher risk of gastrointestinal parasitosis (Crump et al. [93]).

- (d)Nutritional deficiency (Charlton et al. [99]; Crump et al. [93]).

- (e)Lower productivity (Charlton et al. [97]).

- (f)Weather dependence for grass growth (Wilkinson et al. [101]).

|

| Indoor farms: |

Advantages:

- (a)Higher productivity (Charlton et al. [97]).

- (b)Protection against extreme weather conditions (Charlton et al. [99]).

- (c)Lower propensity against thermal stress (Legrand et al. [104]).

- (d)Better nutritional control (Charlton et al. [99]).

Disadvantages:

- (a)Higher incidence of production diseases such as lameness and uterine disorders (Arnott et al. [96]).

- (b)Occurrence of new production diseases, such as acidosis and ketosis (Steeneveld et al. [122]).

- (c)Stocking density problems (Charlton et al. [111]; Talebi et al. [113]).

- (d)Worse animal health and welfare (Crump et al. [93]).

- (e)Consumer perspective: negative (Armbrecht et al. [125]).

|

The best system varies from region to region, and several factors should be taken into account. Climate conditions, the availability and prices of land and raw feed materials, and production costs are all factors that influence the adoption of a system. Consumers’ perspective is a mean driver of market frames and, independently of which level of excellence we achieve with one system or another, according to the society, pasture-based farms provide animals with better conditions, enhancing health and welfare [

125].

Therefore, grassland systems have an intrinsic worth in markets which are able to give value to this, as is the case for example in the Dutch market, where farms with grazing cows receive an increase in the final price of milk, compared to indoor farms [

108].

2.5. Nutritional and Feeding Management

The nutritional and food management of animals has also undergone a huge evolution, as a result of new science developments and new knowledge [

126]. These changes correlate with the availability and cost of raw materials. Moreover, the continuous raise in feed costs constitutes a threat to nutritional management and to farms’ profitability [

127]. The feeding management verified in each farm, invariably depends on the mode of feeding, i.e., pasture-based or indoor cattle, and also depends on the size of the herd [

128]. Dairy farms in poor landscapes, or where the lands have a high purchase or lease cost, can only buy external forages and food supplies [

129,

130].

Furthermore, when a nutritionally balanced diet is provided with less variability and higher precision, producers are able to extract the full potential of their animals [

131]. The diet of these animals is highly controlled, and consists of energy rich foods, such as concentrated feed, corn silage, grass, and soy cuts, amongst others [

132,

133]. On the other hand, pasture-based farms have lower production costs, but with lower yields [

98,

131]. However, the need for the owners of these farms to increase productivity has led to the supplementation of forage (e.g., corn silage), and concentrated feed, thus increasing the dry matter (DM) intake [

100,

134].

The DM is the final mass of a food or product, after subtracting the water [

135]. The evaluation of this parameter has been a very important tool for increasing the performance of animals. Through ingested DM, producers and nutritionists can calculate the required and actual intake, and how efficiently they are transforming it [

136]. To increase and optimize DM intake, automatic feeding systems (AFS) were created [

137]. These systems make it possible to reduce the farm’s management costs, reduce the workload, and above all, allow for an increase in the frequency at which the food is distributed by stall [

138]. This increase in frequency allows the animals to distribute food intake more evenly, instead of having feeding spikes, with the advantage that the cows have a regular ruminal pH, throughout the day [

139]. Lactating cows are usually ad libitum fed, in order to optimize DM intake (

Figure 4).

Figure 4. Feeding management using a total mixed ration system in confined in a low-sized farm (<200 lactating cows; Azores).

According to Phillips et al. [

140], increasing feeding frequency enhances the amount of milk produced, as well as the concentration of fat in milk; however, a similar study carried out in Finland [

141] concluded that, although the animals boosted their efficiency in food conversion, there were no changes in the amount or concentration of the constituents of the milk produced.

On the other hand, Mattachini et al. [

138] concluded that an excessive increase in food distribution can affect the resting time of animals, and also affect behavior. Farms with AMS, such as those already described, together with AFS, allow animals to show their natural behavior [

139]. In fact, appropriate nutritional assessment and management are essential for animal welfare, productivity, and reducing the prevalence of pathologies, such as mastitis and reproductive problems [

142,

143].

2.6. The Milking Process

The historical evolution of the dairy sector is closely linked to the evolution of milking. The milking routine is one of the most laborious and precise processes that make up a dairy farm, corresponding to approximately 33% to 57% of the total work carried out daily on the farms [

144]. Milking cows manually was hard work, and required a lot of labor, constituting an obstacle to farmers, who wanted to increase their herds and yield [

5]. The necessity to raise productivity was driven by the need and demand for more products to feed the growing population at that time. All of these factors, but also the requirement for more secure and hygienic products, led to the appearance of the first mechanized milking systems at the beginning of the 20th century. Those systems were known as “milking catheters” [

145].

Despite being a great advancement for that time, it caused distress [

146], but also many problems of infections of the mammary gland, and the spread of mastitis due to bad milking practices, which at the time were little studied or known [

145]. With the development of vacuum around the mid-20th century, great technological advances in milking systems were achieved, such as the “Rotolactor” in 1930 [

5], and the Herringbone parlors in New Zealand [

145].

From 1954 to 1964, several studies were conducted to know and understand not only the main causative factors of mastitis, but also to control bacterial infections in the udder. Such knowledge has allowed for an improvement in milk quality and an upgrade in udder health [

147]. This brought enormous benefits to farmers, who were able to increase yield and milk quality. In the early 1990s, the first automatic milking systems (AMS), or milking robots, were presented in The Netherlands, being one of the greatest advances that the dairy industry had witnessed until then [

11]. This responded to the need not only to optimize the time of farmers, but also to address the lack of labor for agriculture, which exists in many regions of the world [

10,

11].

The AMS offer greater flexibility in terms of the milking time, and allow for an increase in individual milking frequency, instead of the two or three milking/day normally carried out in the conventional system [

148]. Since then, a lot of discussion between farmers and specialists in the area has arisen. Studies carried out indicate that the farms that have AMS register greater quantity and better bacterial quality of milk produced, as well as saving labor [

148,

149]. In turn, these systems imply higher repair and maintenance costs, as well as the need for specialized staff [

150]. A recent study conducted on a farm in the United Kingdom found that after installing an AMS, there was a 13% increase in yield and a 28% reduction in somatic cell count (SCC) [

151], with variations depending on farms. The enormous ability of the robot to provide varied data on the health and productivity of animals, is noteworthy [

152].

The particular experience in the Azores is that many farms have mobile milking systems to milk in the pastures [

8], and the implementation of AMS is not yet common. These mobile milkking systems are particularly and traditionally seen in smaller farms. Traditionally in the Azores, cows are milked in the pastures twice a day; the milk is transported in non-refrigerated milk tanks, and placed in the collection point of the local dairy industries (

Figure 5) [

8]. On the other hand, bigger Azorean farms are abandoning the pasture-based systems, opting for full indoor or semi-indoor production systems with milking parlors.

Figure 5. Mobile non-refrigerated bull tank milk (Azores).

Regardless of the choice of milking systems, it is essential to have an adequate regulation of the pressure and vacuum systems [

144], as well as the adoption of good milking practices and hygiene [

153]. In line with this progress, improved milking practices have been introduced. Simple practices, such as wearing gloves, cleaning the udder, drying teats, use of post-dipping, and teat disinfection, among others [

154], significantly control the spread of many pathogens inside farms [

155]. As a result, a lower incidence of clinical mastitis, lower mammary gland infection rates, and decreased SCC are some of the benefits that come from adherence to these programs, which encompasses good milking practices, hygienic practices, and the strategic use of antibiotic therapy at dry-off [

156].