One of the most effective ways to cover real estate development and renovation processes by improving functionality and energy efficiency is wooden additional floor construction. The scattered information is mapped out, organized, and collated on the current state of the art and the benefits of this practice including its different stages, focusing on the case of Finland. The topic is presented in an accessible and understandable discourse for non-technical readers. By highlighting the benefits and opportunities of this sustainable application, it will contribute to increasing the awareness of wooden additional floor construction, which has many advantages, and therefore to gain more widespread use in Finland and other countries.

- wood

- additional floor construction

- sustainability

- Finland

1. Introduction

References

- European Commission. Energy Roadmap 2050 Impact Assessment and Scenario Analysis, Brussels. 2011. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/roadmap2050_ia_20120430_en_0.pdf (accessed on 25 February 2022).

- Donoghue, H. 2050 Energy Roadmap: Energy Policy & Innovation: Energy Roadmap 2050. Eur. Energy Clim. J. 2012, 2, 32–37.

- Kuittinen, M.; Häkkinen, T. Reduced carbon footprints of buildings: New Finnish standards and assessments. Build. Cities 2020, 1, 182–197.

- Allard, I.; Nair, G.; Olofsson, T. Energy performance criteria for residential buildings: A comparison of Finnish, Norwegian, Swedish, and Russian building codes. Energy Build. 2021, 250, 111276.

- Energy Policies of The International Energy Agency (IEA) Countries: Finland 2018 Review. 2018. Available online: https://www.connaissancedesenergies.org/sites/default/files/pdf-actualites/situation_energetique_de_la_finlande.pdf (accessed on 25 February 2022).

- European Commission. Long-Term Renovation Strategy 2020–2050 Finland, Report According to Article 2a of Directive (2010/31/EU) on the Energy Performance of Buildings, as Amended by Directive 2018/844/EU. 10 March 2020. Available online: https://ec.europa.eu/energy/sites/default/files/documents/fi_2020_ltrs_en.pdf (accessed on 25 February 2022).

- Simson, R.; Fadejev, J.; Kurnitski, J.; Kesti, J.; Lautso, P. Assessment of Retrofit Measures for Industrial Halls: Energy Efficiency and Renovation Budget Estimation. Energy Procedia 2016, 96, 124–133.

- Kaasalainen, T.; Huuhka, S. Homogenous homes of Finland: ‘standard’ flats in non-standardized blocks. Build. Res. Inf. 2016, 44, 229–247.

- Hirvonena, J.; Jokisaloa, J.; Heljo, J.; Kosonena, R. Towards the EU emissions targets of 2050: Optimal energy renovation measures of Finnish apartment buildings. Int. J. Sustain. Energy 2019, 38, 649–672.

- The Housing Finance and Development Centre of Finland (ARA), The Suburban Innova Block of Flats Is Being Renovated into a Passive House. Available online: https://www.ara.fi/en-US/Housing_development/Development_projects/The_suburban_Innova_block_of_flats_is_be%2817681%29 (accessed on 25 February 2022).

- Soikkeli, A.; Sorri, L. A New Suburb Renovation Concept. Int. J. Archit. Environ. Eng. 2014, 8, 647–655.

- Soikkeli, A.; Hagan, H.; Karjalainen, M.; Koiso-Kanttila, J.; Kurnitski, J.; Viljakainen, M.; Hotakainen, T.; Jäntti, T.; Murtonen, N.; Sakki, R.; et al. Puun Mahdollisuudet Lähiöiden Korjauksessa. Oulu: Oulun Yliopisto, Arkkitehtuurin Osasto. Haettu Osoitteesta. 2011. Available online: https://www.oulu.fi/ark/tiedostot/puun_mahdollisuudet_lahioiden_korjauksissa_web.pdf (accessed on 25 February 2022). (In Finnish).

- The Finnish Timber of Council (Puuinfo). Available online: https://puuinfo.fi/?lang=enç (accessed on 25 February 2022).

- Huttunen, H.; Blomqvist, E.; Ellilä, E.; Hasu, E.; Perämäki, E.; Tervo, A.; Verma, I.; Ullrich, T.; Utriainen, J. The Finnish Townhouse as a Home. Starting Points and Interpretations. Habitat Components—Townhouse. Final Report. Aalto University Publication Series CROSSOVER 8/2017. Helsinki, Finland. 2017. Available online: https://aaltodoc.aalto.fi/bitstream/handle/123456789/30185/isbn9789526071220.pdf?sequence=1&isAllowed=y (accessed on 25 February 2022).

- United Nations Economic Commission for Europe United Nations Human Settlements Programme, Good Practices for Energy-Efficient Housing in the Unece Region, UNITED NATIONS, New York and Geneva. 2013. Available online: https://unece.org/fileadmin/DAM/hlm/documents/Publications/good.practices.ee.housing.pdf (accessed on 25 February 2022).

- Streimikiene, D.; Balezentis, T. Innovative Policy Schemes to Promote Renovation of Multi-Flat Residential Buildings and Address the Problems of Energy Poverty of Aging Societies in Former Socialist Countries. Sustainability 2019, 11, 2015.

- Paiho, S.; Abdurafikov, R.; Hoang, H.; Castell-Rüdenhausen, M.Z.; Hedman, Å.; Kuusisto, J. Business Aspects of Energy Efficient Renovations of Sovietera Residential Districts A Case Study from Moscow, VTT Technology 154 ISSN-L 2242-1211 ISSN 2242-122X (Online), VTT Technical Research Centre of Finland, Espoo, Finland. 2014. Available online: https://www.vttresearch.com/sites/default/files/pdf/technology/2014/T154.pdf (accessed on 25 February 2022).

- Official Statistics of Finland (OSF). Homeowners and Housing Companies Repaired by EUR 6.0 Billion in 2019. 2019. Available online: http://www.stat.fi/til/kora/2019/01/kora_2019_01_2020-06-11_tie_001_fi.html%20 (accessed on 25 February 2022).

- Soikkeli, A.; Sorri, L. A New Suburb Renovation Concept. In Proceedings of the ICAE 2014: XII International Conference on Architectural Engineering, Copenhagen, Denmark, 12–13 June 2014; International Science Index 90; World Academy of Science, Engineering and Technology: Paris, France, 2014; pp. 636–644.

- KTI Finland. The Finnish Property Market. 2019. Available online: https://kti.fi/wp-content/uploads/The-Finnish-Property-Market-2019.pdf (accessed on 25 February 2022).

- Farahani, A.S. Maintenance, Renovation and Energy Efficiency in the Swedish Multi-Family Housing Market; The Division of Building Services Engineering, Chalmers University of Technology: Gothenburg, Sweden, 2017; Available online: https://core.ac.uk/download/pdf/198056482.pdf (accessed on 25 February 2022).

- Ferrante, A.; Prati, D.; Fotopoulou, A. Triple A-Reno: Attractive, Acceptable and Affordable Deep Renovation by a Consumers Orientated and Performance Evidence Based Approach. In WP4–Task 4.2 Analysis and Design of the Business Module; Huygen Installatie Adviseurs: Maastricht, The Netherlands, 2018.

- Soikkeli, A.; Sorri, L.; Koiso-Kanttila, J. New Concept for User-Orientated Suburb Renovation. In Proceedings of the World SB14, Barcelona, Spain, 28–30 October 2014; pp. 1–7.

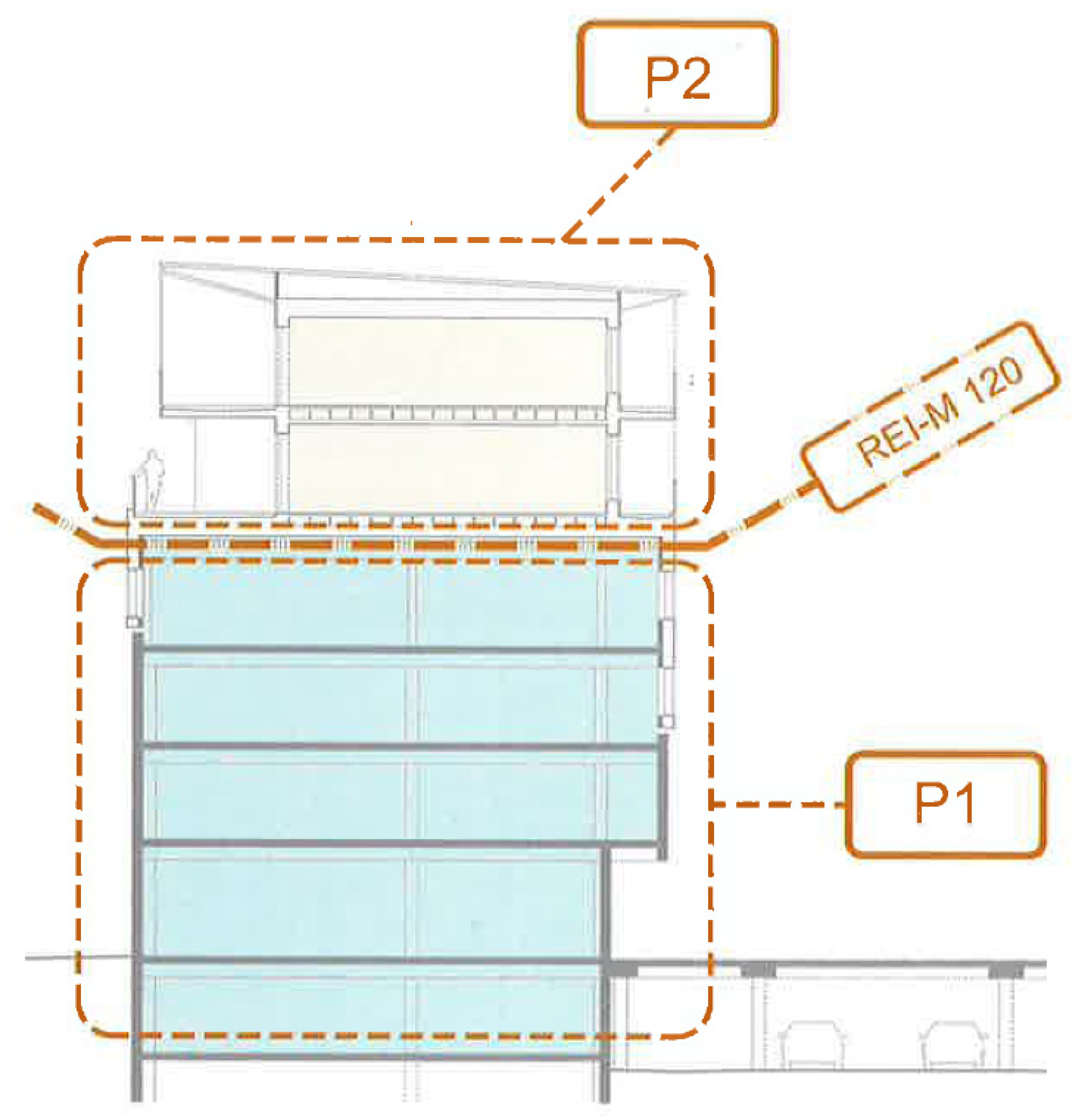

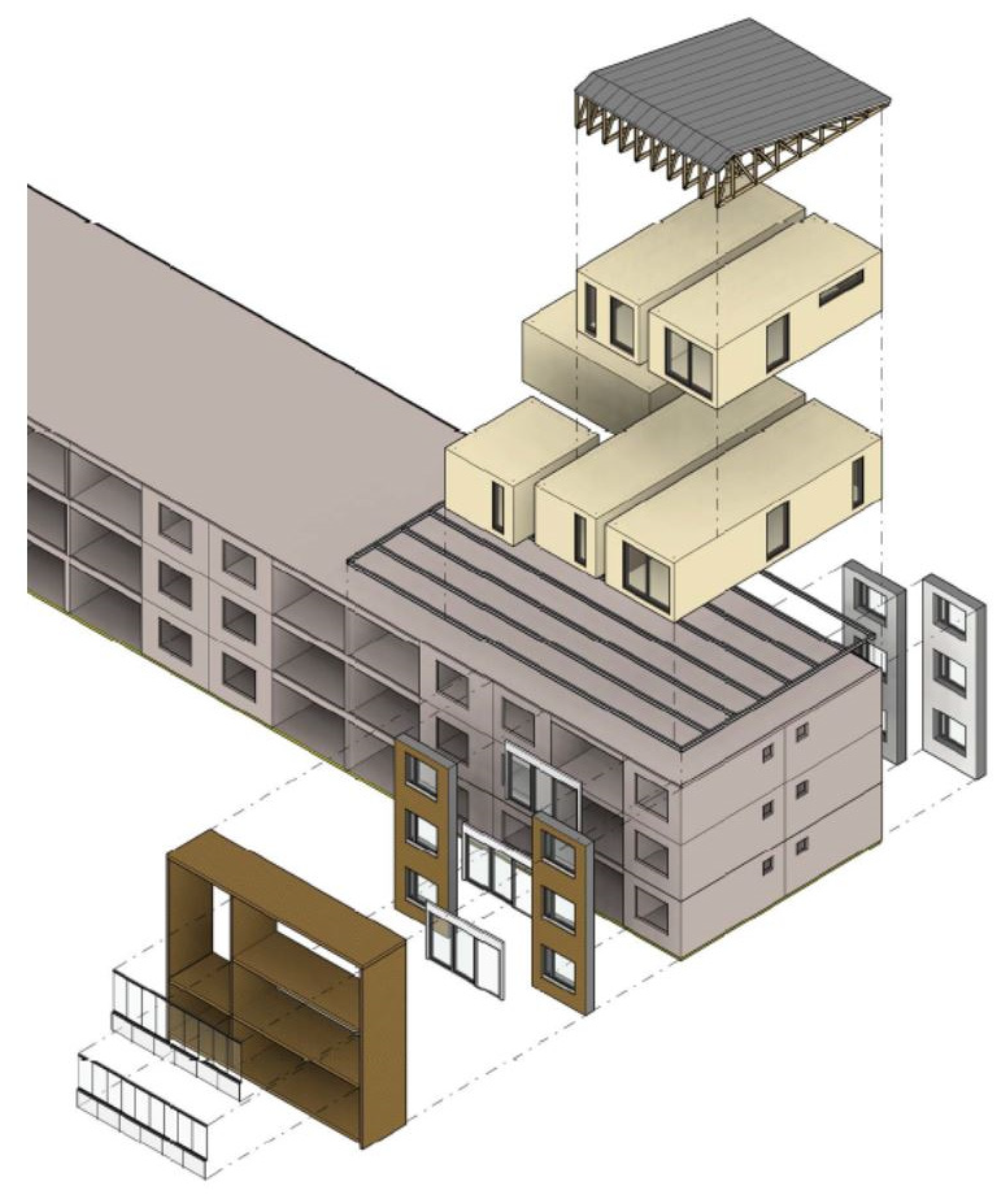

- Soikkeli, A. Additional floors in old apartment blocks. Energy Procedia 2016, 96, 815–823.

- Cronhjort, A.; Soikkeli, T.; Tulamo, T.; Junnonen, J. Urban Densification in Finland: Infill Development And Building Extensions With Timber Based Solutions. WIT Trans. Ecol. Environ. 2015, 193, 319–330.

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Residents’ Attitudes towards Wooden Facade Renovation and Additional Floor Construction in Finland. Int. J. Environ. Res. Public Health 2021, 18, 12316.

- Huuhka, S.; Vainio, T.; Moisio, M.; Lampinen, E.; Knuuttinen, M.; Bashmakov, S.; Köliö, A.; Lahdensivu, J.; Ala-Kotila, P.; Lahdenperä, P. To Demolish or to Repair? Carbon Footprint Impacts, Life Cycle Costs and Steering Instruments, Publications of the Ministry of the Environment 2021:9. Built Environment. 2021. Available online: https://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/162862/YM_2021_9.pdf?sequence=4&isAllowed=y (accessed on 25 February 2022).

- Bojić, M.; Miletić, M.; Malešević, J.; Djordjević, S.; Cvetković, D. Influence of additional storey construction to space heating of a residential building. Energy Build. 2012, 54, 511–518.

- Karjalainen, M.; Ilgın, H.E.; Somelar, D. Wooden Additional Floors in Old Apartment Buildings: Perspectives of Housing and Real Estate Companies from Finland. Buildings 2021, 11, 316.

- The National Building Code of Finland—Structural Fire Safety, Decree of the Ministry of the Environment. 2017. Available online: https://ym.fi/en/the-national-building-code-of-finland (accessed on 25 February 2022).

- Green, M. The Case for Tall Buildings: How Mass Timber Offers a Safe, Economical, and Environmentally Friendly Alternative for Tall Building Structures; MGB Architecture and Design: Vancouver, BC, Canada; Toronto, ON, Canada, 2012.

- Myers, F.; Fullera, R.; Crawford, R.H. The Potential to Reduce the Embodied Energy in Construction through the Use of Renewable Materials. In Proceedings of the ASA2012: The 46th Annual Conference of the Architectural Science Association (Formerly ANZAScA)—Building on Knowledge: Theory and Practice, Gold Coast, Australia, 14–16 November 2012.

- Construction Industry Progress towards Sustainability with Renewable Materials. Recycling Magazine. 2020. Available online: https://www.recycling-magazine.com/2020/04/14/construction-industry-progress-towards-sustainability-with-renewablematerials/ (accessed on 25 February 2022).

- Lammert, L. Circular Economy in Architecture—Sustainable Principles for Future Design. Master’s Thesis, Oulu School of Architecture, Faculty of Technology, University of Oulu, Oulu, Finland, 2018. Available online: https://figbc.fi/wpcontent/uploads/sites/4/2020/05/nbnfioulu-201811233096.pdf (accessed on 25 February 2022).

- Robati, M.; Oldfield, P.; Nezhad, A.A.; Carmichael, D.G.; Kuru, A. Carbon value engineering: A framework for integrating embodied carbon and cost reduction strategies in building design. Build. Environ. 2021, 192, 107620.

- Hart, J.; D’Amico, B.; Pomponi, F. Whole-life embodied carbon in multistory buildings: Steel, concrete and timber structures. J. Ind. Ecol. 2021, 25, 403–418.

- Soikkeli, A. Possibilities in the Renovation of Suburban Apartment Buildings. Case: Porvoonportti. In Improving the Quality of Suburban Building Stock; COST Action TU0701; Unifepress: Ferrara, Italy, 2012; pp. 127–140.

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276.

- Franzini, F.; Toivonen, R.; Toppinen, A. Why Not Wood? Benefits and Barriers of Wood as a Multistory Construction Material: Perceptions of Municipal Civil Servants from Finland. Buildings 2018, 8, 159.

- Geng, A.; Yang, H.; Chen, J.; Hong, Y. Review of carbon storage function of harvested wood products and the potential of wood substitution in greenhouse gas mitigation. For. Policy Econ. 2017, 85, 192–200.

- Hafner, A.; Schäfer, S. Comparative LCA study of different timber and mineral buildings and calculation method for substitution factors on building level. J. Clean. Prod. 2017, 167, 630–642.

- Dong, Y.; Qin, T.; Zhou, S.; Huang, L.; Bo, R.; Guo, H.; Yin, X. Comparative Whole Building Life Cycle Assessment of Energy Saving and Carbon Reduction Performance of Reinforced Concrete and Timber Stadiums—A Case Study in China. Sustainability 2020, 12, 1566.

- Bergman, R.; Puettmann, M.; Taylor, A.; Skog, K.E. The Carbon Impacts of Wood Products. For. Prod. J. 2014, 64, 220–231.

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise nonresidential construction: An LCA based comparative case study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862.

- Ritter, M.; Skog, K.; Bergman, R. Science Supporting the Economic and Environmental Benefits of Using Wood and Wood Products in Green Building Construction; General Technical Report FPL-GTR-206; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2011; pp. 1–9.

- Wang, L.; Toppinen, A.; Juslin, H. Use of wood in green building: A study of expert perspectives from the UK. J. Clean. Prod. 2014, 65, 350–361.

- Rinne, R.; Ilgın, H.E.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774.

- Skullestad, J.L.; Bohne, R.A.; Lohne, J. High-rise Timber Buildings as a Climate Change Mitigation Measure—A Comparative LCA of Structural System Alternatives. Energy Procedia 2016, 96, 112–123.

- CWC. Energy and the Environment in Residential Construction; Sustainable Building Series No.1; Canadian Wood Council: Ottawa, ON, Canada, 2007; Available online: https://cwc.ca/wp-content/uploads/publications-Energy-and-the-Environment.pdf (accessed on 25 February 2022).

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; Publications Office of the European Union: Luxembourg, 2018.

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S. Comparative life-cycle assessment of a mass timber building and concrete alternative. Wood Fiber Sci. 2020, 52, 217–229.

- Sandberg, K.; Orskaug, T.; Andersson, A. Prefabricated Wood Elements for Sustainable Renovation of Residential Building Façades. Energy Procedia 2016, 96, 756–767.

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build. 2010, 42, 230–242.

- Jussila, J.; Lähtinen, K. Effects of institutional practices on delays in construction—Views of Finnish homebuilder families. Housing Stud. 2020, 35, 1167–1193.

- Onyszkiewicz, J.; Sadowski, K. Proposals for the revitalization of prefabricated building facades in terms of the principles of sustainable development and social participation. J. Build. Eng. 2022, 46, 103713.

- Werner, F.; Taverna, R.; Hofer, P.; Richter, K. Carbon pool and substitution effects of an increased use of wood in buildings in Switzerland: First estimates. Ann. For. Sci. 2005, 62, 889–902.

- Kutnar, A.; Hill, C. Life Cycle Assessment—Opportunities for Forest Products Sector. Bioprod. Bus. 2017, 2, 52–64.

- Bergman, R.D.; Falk, R.H.; Gu, H.; Napier, T.R.; Meil, J. Life-Cycle Energy and GHG Emissions for New and Recovered Softwood Framing Lumber and Hardwood Flooring Considering End-of-Life Scenarios; Research Paper FPL-RP-672; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2013; p. 35.

- Karjalainen, M.; Ilgın, H.E. The Change over Time in Finnish Residents’ Attitudes towards Multi-Story Timber Apartment Buildings. Sustainability 2021, 13, 5501.

- Jagarajan, R.; Abdullah Mohd Asmoni, M.N.; Mohammed, A.H.; Jaafar, M.N.; Lee Yim Mei, J.; Baba, M. Green retrofitting—A review of current status, implementations and challenges. Renew. Sustain. Energy Rev. 2017, 67, 1360–1368.

- Östman, B. National Fire Regulations for the Use of Wood in Buildings—Worldwide Review 2020. Wood Mater. Sci. Eng. 2021, 1–4.

- Kincelova, K.; Boton, C.; Blanchet, P.; Dagenais, C. Fire Safety in Tall Timber Building: A BIM-Based Automated Code-Checking Approach. Buildings 2020, 10, 121.

- Xu, H.; Pope, I.; Gupta, V.; Cadena, J.; Carrascal, J.; Lange, D.; McLaggan, M.S.; Mendez, J.; Osorio, A.; Solarte, A.; et al. Large-scale compartment fires to develop a self-extinction design framework for mass timber—Part 1: Literature review and methodology. Fire Saf. J. 2022, 128, 103523.

- Östman, B. Fire Safety in Timber Buildings—Technical Guideline for Europe; SP Technical Research Institute of Sweden: Stockholm, Sweden, 2010; p. 19.

- Östman, B.; Brandon, D.; Frantzich, H. Fire Safety Engineering in Timber Buildings. Fire Saf. J. 2017, 91, 11–20.

- Su, L.; Wu, X.; Zhang, X.; Huang, X. Smart performance-based design for building fire safety: Prediction of smoke motion via AI. J. Build. Eng. 2021, 43, 102529.

- Siddiqui, A.A.; Ewer, J.A.; Lawrence, P.J.; Galea, E.R.; Frost, I.R. Building Information Modelling for performance-based Fire Safety Engineering analysis—A strategy for data sharing. J. Build. Eng. 2021, 42, 102794.

- Qiu, J.; Anwar Orabi, M.; Usmani, A.; Li, G. A computational approach for modelling composite slabs in fire within OpenSees framework. Eng. Struct. 2022, 255, 113909.

- Liu, K.; Chen, W.; Ye, J.; Jiang, J. Full-scale fire and post earthquake fire experiments of CFS walls with new configurations. Structures 2022, 35, 706–721.

- Medved, S. Buildings Fires and Fire Safety. In Building Physics; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 407–451.

- Liu, J.; Fischer, E.C. Review of large-scale CLT compartment fire tests. Construct. Build. Mater. 2022, 318, 126099.

- Gasparri, E. 9—Unitized Timber Envelopes: The future generation of sustainable, high-performance, industrialized facades for construction decarbonization. In Woodhead Publishing Series in Civil and Structural Engineering, Rethinking Building Skins; Gasparri, E., Brambilla, A., Lobaccaro, G., Goia, F., Andaloro, A., Sangiorgio, A., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 231–255.

- Tian, F.; Xu, D.; Xu, X. Synergistic Effect of APP and TBC Fire-Retardants on the Physico-Mechanical Properties of Strandboard. Materials 2022, 15, 435.

- Buchanan, A.H.; Östman, B.; Frangi, A. Fire Resistance of Timber Structures; NIST White Paper: Washington, DC, USA, 2014.

- Caniato, M.; Bettarello, F.; Ferluga, A.; Marsich, L.; Schmid, C.; Fausti, P. Thermal and acoustic performance expectations on timber buildings. Build, Acoust. 2017, 24, 219–237.

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332.

- Olsson, L. Moisture safety in CLT construction without weather protection—Case studies, literature review and interviews. E3S Web Conf. 2020, 172, 10001.

- Mjörnell, K.; Olsson, L. Moisture Safety of Wooden Buildings—Design, Construction and Operation. J. Sustain. Architect. Civil Eng. 2019, 24, 29–35.

- Renner, J.S.; Mensah, R.A.; Jiang, L.; Xu, Q.; Das, O.; Berto, F. Fire Behavior of Wood-Based Composite Materials. Polymers 2021, 13, 4352.

- Robert, J.; Bush, P.A.A. Changes and Trends in the Pallet Industry: Alternative Materials and Industry Structure. Memphis. Hardwood Mark. Rep. 1998, LXXVI, 11–14.

- Trouy, M.C.; Triboulot, P. Materiau bois: Structure et caractéristiques. Technol. Ingénieur Constr. Bois 2019, 253, 11–18.

- Upton, B.; Miner, R.; Spinney, M.; Heath, L.S. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Biomass Bioenergy 2008, 32, 1–10.

- Fast, P.; Jackson, R. A Case Study for Tall Timber. Struct. Mag. 2017, 50–52.

- Gohlich, R.; Erochko, J.; Woods, J.E. Experimental testing and numerical modelling of a heavy timber moment-resisting frame with ductile steel links. Earthq. Eng. Struct. Dynam. 2018, 47, 1460–1477.

- Andreolli, M.; Piazza, M.; Tomasi, R.; Zandonini, R. Ductile moment-resistant steel–timber connections. Proc. Inst. Civil Eng. Struct. Build. 2011, 164, 65–78.

- Li, Z.; Wang, X.; He, M. Experimental and analytical investigations into lateral performance of cross-laminated timber (CLT) shear walls with different construction methods. J. Earthq. Eng. 2020, 1–23.

- Yang, R.; Li, H.; Lorenzo, R.; Ashraf, M.; Sun, Y.; Yuan, Q. Mechanical behaviour of steel timber composite shear connections, Construct. Build. Mater. 2020, 258, 119605.

- Iqbal, A. Developments in Tall Wood and Hybrid Buildings and Environmental Impacts. Sustainability 2021, 13, 11881.

- Yang, X.; Tang, X.; Ma, L.; Sun, Y. Plastic composite sound insulation performance of structural wood wall integrated with wood. J. Bioresour. Bioprod. 2019, 4, 115–122.

- Zhang, Y.; Xie, L. Inspection and Evaluation of Wooden Frame Constructions; Chinese Academy of Forestry: Beijing, China, 2011.

- Ding, Y.; Zhang, Y.; Wang, Z.; Gao, Z.; Zhang, T.; Huang, X. Vibration test and comfort analysis of environmental and impact excitation for wooden floor structure. Bioresources 2020, 15, 8212–8234.

- Kankovsky, A.; Dedic, M. Wood flooring in combination with underfloor heating systems. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203, 22043.

- Sun, J.; Tu, K.; Büchele, S.; Koch, S.M.; Ding, Y.; Ramakrishna, S.N.; Stucki, S.; Guo, H.; Wu, C.; Keplinger, T.; et al. Functionalized wood with tunable tribopolarity for efficient triboelectric nanogenerators. Matter 2021, 4, 3049–3066.

- Song, Y.; Wang, H.B.; Cheng, X.L.; Li, G.K.; Chen, X.X.; Chen, H.T.; Miao, L.M.; Zhang, X.S.; Zhang, H.X. High-efficiency selfcharging smart bracelet for portable electronics. Nano Energy 2019, 55, 29–36.

- Parida, K.; Xiong, J.Q.; Zhou, X.R.; Lee, P.S. Progress on triboelectric nanogenerator with stretchability, selfhealability and bio-compatibility. Nano Energy 2019, 59, 237–257.

- Hao, S.F.; Jiao, J.Y.; Chen, Y.D.; Wang, Z.L.; Cao, X. Natural wood-based triboelectric nanogenerator as self-powered sensing for smart homes and floors. Nano Energy 2020, 75, 104957.

- Chandrasekhar, A.; Vivekananthan, V.; Khandelwal, G.; Kim, W.J.; Kim, S.J. Green energy from working surfaces: A contact electrification-enabled data theft protection and monitoring smart table. Mater. Today Energy 2020, 18, 100544.

- Tulonen, L.; Karjalainen, M.; Ilgın, H.E. Tall Wooden Residential Buildings in Finland: What Are the Key Factors for Design and Implementation? IntechOpen: London, UK, 2021.

- Zwerger, K. Recognizing the Similar and Thus Accepting the Other: The European and Japanese Traditions of Building with Wood. J. Tradit. Build. Archit. Urban. 2021, 2, 305–317.

- Ilgın, H.E.; Karjalainen, M.; Koponen, O. Dovetailed Massive Wood Board Elements for Multi-Story Buildings. In Proceedings of the LIVENARCH VII Livable Environments & Architecture 7th International Congress OTHER ARCHITECT/URE(S), Trabzon, Turkey, 28–30 September 2021; Volume I, pp. 47–60.

- Yusof, N.M.; Tahir, P.M.; Lee, S.H.; Khan, M.A.; James, R.M.S. Mechanical and physical properties of Cross-Laminated Timber made from Acacia mangium wood as function of adhesive types. J. Wood Sci. 2019, 65, 20.

- Karjalainen, M.; Ilgın, H.E.; Yli-Äyhö, M.; Soikkeli, A. Complementary Building Concept: Wooden Apartment Building: The Noppa toward Zero Energy Building Approach; IntechOpen: London, UK, 2021.

- Li, M.; Zhang, S.; Gong, Y.; Tian, Z.; Ren, H. Gluing Techniques on Bond Performance and Mechanical Properties of Cross- Laminated Timber (CLT) Made from Larix kaempferi. Polymers 2021, 13, 733.

- Ilgın, H.E.; Karjalainen, M. Preliminary Design Proposals for Dovetail Wood Board Elements in Multi-Story Building Construction. Architecture 2021, 1, 56–68.

- Bahrami, A.; Nexén, O.; Jonsson, J. Comparing Performance of Cross-Laminated Timber and Reinforced Concrete Walls. Int. J. Appl. Mech. Eng. 2021, 26, 28–43.

- Ilgın, H.E.; Karjalainen, M.; Koponen, O. Various Geometric Configuration Proposals for Dovetail Wooden Horizontal Structural Members in Multistory Building Construction; IntechOpen: London, UK, 2022.

- Sun, Z.; Chang, Z.; Bai, Y.; Gao, Z. Effects of working time on properties of a soybean meal-based adhesive for engineered wood flooring. J. Adhes. 2021, 1–20.

- Karjalainen, M.; Ilgın, H.E. A Statistical Study on Multi-Story Timber Residential Buildings (1995–2020) in Finland. In Proceedings of the LIVENARCH VII Livable Environments & Architecture 7th International Congress OTHER ARCHITECT/URE(S), Trabzon, Turkey, 28–30 September 2021; Volume I, pp. 82–94.

- Ilgın, H.E.; Karjalainen, M.; Koponen, O. Review of the Current State-of-the-Art of Dovetail Massive Wood Elements; IntechOpen: London, UK, 2021.

- Aaltonen, A.; Hurmekoski, E.; Korhonen, J. What about Wood?—“Nonwood” Construction Experts’ Perceptions of Environmental Regulation, Business Environment, and Future Trends in Residential Multistory Building in Finland. For. Prod. J. 2021, 71, 342–351.

- Ilgın, H.E.; Karjalainen, M. Perceptions, Attitudes, and Interest of Architects in the Use of Engineered Wood Products for Construction: A Review; IntechOpen: London, UK, 2021.

- Roos, A.; Woxblom, L.; McCluskey, D. The influence of architects and structural engineers on timber in construction—Perceptions and roles. Silva Fenn. 2010, 44, 871–884.

- Karjalainen, M.; Ilgın, H.; Tulonen, L. Main Design Considerations and Prospects of Contemporary Tall Timber Apartment Buildings: Views of Key Professionals from Finland. Sustainability 2021, 13, 6593.

- Hemström, K.; Gustavsson, L.; Mahapatra, K. The sociotechnical regime and Swedish contractor perceptions of structural frames. Constr. Manag. Econ. 2017, 35, 184–195.

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Suburban Residents’ Preferences for Livable Residential Area in Finland. Sustainability 2021, 13, 11841.

- Markström, E.; Kuzman, M.K.; Bystedt, A.; Sandberg, D.; Fredriksson, M. Swedish architects view of engineered wood products in buildings. J. Clean. Prod. 2018, 181, 33–41.

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Wooden Facade Renovation and Additional Floor Construction for Suburban Development in Finland; IntechOpen: London, UK, 2022.

- Ilgın, H.E.; Karjalainen, M.; Pelsmakers, S. Finnish architects’ attitudes towards multi-storey timber-residential buildings. Int. J. Build. Pathol. Adapt. 2021. ahead-of-print.

- Häkkänen, L.; Ilgın, H.E.; Karjalainen, M. The Current State of the Finnish Cottage Phenomenon: Perspectives of Experts. Buildings 2022, 12, 260.

- Gold, S.; Rubik, F. Consumer attitudes towards timber as a construction material and towards timber frame houses—Selected findings of a representative survey among the German population. J. Clean. Prod. 2009, 17, 303–309.

- Lähtinen, K.; Harju, C.; Toppinen, A. Consumers’ perceptions on the properties of wood affecting their willingness to live in and prejudices against houses made of timber. Wood Mater. Sci. Eng. 2019, 14, 325–331.

- Kylkilahti, E.; Berghäll, S.; Autio, M.; Nurminen, J.; Toivonen, R.; Lähtinen, K.; Vihemäki, H.; Franzini, F.; Toppinen, A. A consumer-driven bioeconomy in housing? Combining consumption style with students’ perceptions of the use of wood in multi-story buildings. Ambio 2020, 49, 1943–1957.

- Wang, Z.; Yin, T. Cross-Laminated Timber: A Review on Its Characteristics and an Introduction to Chinese Practices; IntechOpen: London, UK, 2021.

- Rahman, T.; Ashraf, M.; Ghabraie, K.; Subhani, M. Evaluating Timoshenko Method for Analyzing CLT under Out-of-Plane Loading. Buildings 2020, 10, 184.