Electrochemical behaviors, advantages, and disadvantages of existing electrospun nanofiber anode materials were thoroughly reviewed by classifying into four groups according to the lithium storage principles.

- Li-ion battery anode

- electrospun nanofiber

- rechargeable battery

1. Introduction

Lithium-ion batteries are a portable power source with a high energy density and stable electrochemistry that have changed our daily lives. Thanks to technological developments in areas such as smartphones and electric vehicles, there is an increased demand for high energy density and fast-charging lithium-ion batteries that can provide greater power capacity. Recent battery fires and explosions have also led to a desire to improve the safety of energy storage systems [1,2]. The design of a novel negative electrode material can address the energy density, safety, and rate performance issues of conventional graphite electrodes that cause unsatisfactory electrochemical performances such as low theoretical capacity (372 mAh/g) [3], irreversible electrolyte and lithium consumption based on solid electrolyte interphase (SEI) formation [4], slow lithium intercalation [5], and dendrite formation during fast charging [6]. Resolving these issues has been the focus of publications on novel lithium-ion battery anodes.

Despite positive results seen in the literature, conventional lithium-ion batteries still use graphite anodes. The two main factors preventing most novel technologies from being implemented in commercial lithium-ion batteries are (i) a need to reduce battery prices rapidly (targeting $125/kWh by 2022) [7] and (ii) a large number of specification requirements for commercial battery anode materials such as areal capacity (4 mAh/cm2) [8], electrode density (1.6 g/cm3) [9], electrode volume change (15%) [10], initial coulombic efficiency (90% to 95%) [11], and various target cycling and rate performance specifications dependent on purpose. Implementing major existing anode material research innovations into a commercial lithium-ion battery and designing novel anode materials and structures should be simultaneously pursued to meet the future demands for high energy density, high safety, and fast-charging lithium-ion batteries.

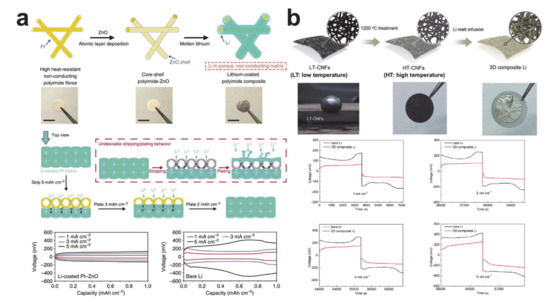

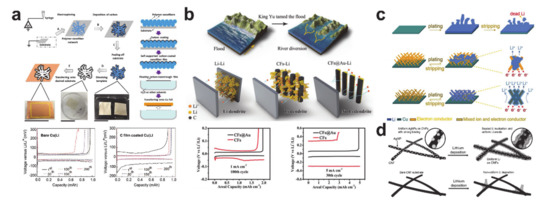

Electrospinning has been identified as the most promising route for designing novel anode materials and structures, owing to the simple process setup and wide variety of electrospinnable materials. The electrospinning process can encourage the implementation of existing anode material research based on the process being able to mass-produce anodes [12,13,14]. Although nanofiber anode material research has mainly focused on developing carbon-, silicon-, and tin-based materials to replace graphite anodes, there have been numerous publications on a wide variety of anode materials thanks to the merits of the electrospinning process. Here, examples to design the advanced anode materials based on the electrospun nanofibers are presented. Heteroatoms and pores were employed to increase the specific capacity of carbon anode [15,16]. Carbon composited and nanostructured metal and metal oxide anode materials were designed to improve cycling and rate performances [17,18]. Lithiophilic nanofiber was fabricated to enhance the reversibility of lithium plating and stripping [19]. It is necessary to review previous research into electrospun nanofiber-based anode materials to establish better strategies for implementing nanofiber anode materials in commercial lithium-ion batteries and designing novel nanofiber anode materials for next-generation batteries.

There have been two types of typical review articles on the electrospun nanofiber anode materials: (i) focusing on specific materials and structures (e.g., reviews of carbon, silicon, tin, and their composite nanofibers and nanostructures for lithium rechargeable batteries [20,21,22,23,24] and hollow, porous, and hierarchical structured nanofibers for energy applications [25,26,27]) and (ii) providing a broad overview of recent research and developments [28,29,30,31]. Regardless of the review types, the electrospun nanofiber anode materials in the previous review articles were mostly categorized into the material classes, for example, carbon, metals, and metal oxides, and so on [28,29]. The electrochemical behaviors of the anode materials are, however, not simply classified into the material classes as follows: TiO2 stores lithium by insertion, FeOx is lithiated by conversion reaction, and SnOx electrochemically mainly reacts with the lithium by alloying mechanism. In addition, some anode materials have multiple lithium storage mechanisms. As such, it is important to classify the anode materials into the categories of the main lithium storage principle for better understanding of the anode materials. This review focuses on the lithium storage principles and accordingly categorizes the electrospun nanofiber anode materials into the principles. This review aimed to provide inspiration to those working to improve conventional lithium-ion battery performances and pioneering novel routes to next-generation battery success.

2. Basic Lithium Storage Principles

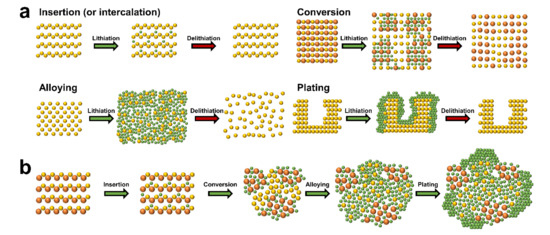

It is crucial to understand the various mechanisms, advantages, and disadvantages of lithium storage in each anode material when designing high performance anodes. Figure 1a shows the anode materials of lithium rechargeable batteries categorized into four main groups based on electrochemical reactions. The first group is that of insertion (or intercalation) anode materials. Lithium-ions are reversibly inserted into and extracted from the periodic microstructure with little or no microstructural change resulting from the insertion/extraction (or intercalation/ deintercalation) mechanism. Representative insertion anode materials such as graphite and Li4Ti5O12 have been successfully commercialized based on their common strengths (e.g., small volume change during the electrochemical reaction and long lifespan based on the structural stability). However, low theoretical specific capacities (e.g., graphite (372 mAh/g) [32] and Li4Ti5O12 (175 mAh/g) [33]), which are the major drawback of insertion materials, have encouraged the development of alternative anode materials such as conversion and alloying anode materials. The second group is that of conversion reaction-based anode materials. These materials store lithium by altering the ionic bonding from a metallic cation and anion to a lithium-ion and anion in ionic compounds such as metal oxides, metal sulfides, and metal selenides. Microstructural changes that occur to the conversion anode materials during the electrochemical reactions separate the materials into small grains consisting of metal and lithium-anion complexes, which provide higher specific capacities in comparison with the insertion anode materials. However, poor kinetics, large volume changes, and the large redox potential hysteresis prevent commercialization of conversion anode materials. The third group is that of alloying anode materials that provide an increase in specific capacity. This is achieved when the lithium atoms form an alloy with the host metallic phase by breaking the inter-atomic bonds of the host material. However, the large volume changes driven by the insertion and extraction of the large amount of lithium cause pulverization, solid electrolyte interphase (SEI) growth, and electrical contact loss. The fourth group is that of plating anode materials. A vast amount of lithium can be stored by the plating mechanism as the lithium is stored in a free volume. The lithium-ions are deposited on the inactive lithium surface by electrochemical reduction and the lithium atoms are stripped from the surface by electrochemical oxidation. However, critical issues such as dendrite growth, severe SEI growth, and dead lithium formation need to be addressed before plating anode materials can be incorporated into commercial lithium rechargeable batteries.

The electrochemical behaviors of single element anode materials, such as graphite and crystalline silicon, can be mostly understood from the lithiation mechanisms. For example, lithium storage in artificial graphite is achieved using insertion and plating mechanisms [34]. However, the lithiation behaviors of ceramic anode materials consisting of multiple elements are very complex because of the multiple electrochemical reactions. For instance, tin oxide (SnO2) is lithiated via insertion (SnO2 + xLi+ + xe− ↔ LixSnO2), irreversible conversion (SnO2 + 4Li+ + 4e− → Sn + 2Li2O), and alloying (Sn + xLi+ + xe− ↔ LixSn (0 ≤ x ≤ 4.4)) [35]. When focusing on the microstructural change of specific regions during lithiation, the lithiation mechanism follows a sequential order. The schematic showing the microstructural changes of a virtual ceramic material is shown in Figure 1b to show the sequential order of lithiation: (i) a small amount of lithium atoms stored in the lattice from insertion (or intercalation), (ii) the lithium-ions are bonded to the anions by altering the reduced metallic cations through conversion, (iii) the lithium atoms form an alloy with the fully reduced metallic atoms via alloying, and (iv) the lithium-ions are reduced and deposited on the electrically conductive surface of the ceramic material owing to the fully lithiated microstructure being inactive.

3. Plating/Stripping-Based Storage Materials

4. Current Limitations and Prospects

5. Concluding Remarks

Electrospun anode materials were designed to improve the desired properties and to reduce the negative properties based on the electrochemical reaction type being studied. Some of the more prominent achievements are already at a high technology-readiness level and are ready to be implemented in commercial lithium-ion battery production; furthermore, forming a graphite composite with the existing electrode can reduce the difficulty barrier to introducing nanofiber-based anode materials. More effort is required with regard to promoting the use of anode materials for lithium metal batteries and solid-state batteries, in order to accelerate next-generation battery development.

This entry is adapted from the peer-reviewed paper 10.3390/polym12092035