Aconitic acid (propene-1,2,3-tricarboxylic acid) is the most prevalent 6-carbon organic acid that accumulates in sugarcane and sweet sorghum. As a top value-added chemical, aconitic acid may function as a chemical precursor or intermediate for high-value downstream industrial and biological applications. These downstream applications include use as a bio-based plasticizer, cross-linker, and the formation of valuable and multi-functional polyesters that have also been used in tissue engineering. Aconitic acid also plays various biological roles within cells as an intermediate in the tricarboxylic acid cycle (TCA) and in conferring unique survival advantages to some plants as an antifeedant, antifungal, and means of storing fixed pools of carbon. Aconitic acid has also been reported as a fermentation inhibitor, anti-inflammatory, and a potential nematicide.

1. Introduction

Aconitic acid, propene-1,2,3-tricarboxylic acid (

Figure 1), is listed as one of the top 30 value-added chemicals by the Department of Energy for its use in industry as a chemical building block and precursor to other important chemicals and polymers [

1]. Aconitic acid also plays a role in biological systems and has numerous applications that will be discussed herein [

2].

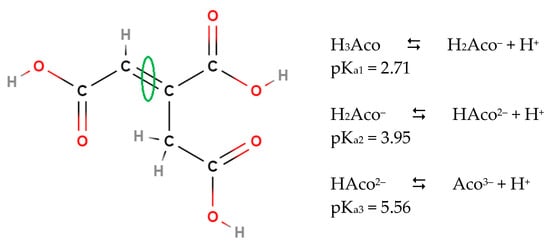

Figure 1. Chemical structure of

trans-aconitic acid (TAA) and its three stepwise carboxylic acid dissociation constants in aqueous solution.

Cis-aconitic acid (CAA) is obtained by rotation around the circled double bond. Dissociation constants [

3,

4].

2. Microbial Conversion of Aconitic Acid to Itaconic Acid

The production cost of itaconic acid remains high. However, economic feasibility may be improved through optimization of either fermentation or chemical synthesis methods. Some options may include using sugarcane molasses, a sugar- and aconitic acid-rich feedstock, for chemical or enzyme-based decarboxylation or for improved fermentation conditions. Optimized fermentation conditions may include the use of inexpensive feedstocks such as agricultural waste products or through metabolic engineering of microbial strains to eliminate unwanted pathways and directly increase carbon flux toward itaconic acid production.

Some fungi naturally convert aconitic acid to itaconic acid through decarboxylation. For example,

Aspergillus terreus is used in fermentations to produce itaconic acid [

43,

44,

45,

71]. In

A. terreus, CAA is first transported by a mitochondrial transporter, At_MttA, from the tricarboxylic acid (TCA) cycle in the mitochondria to the cytosol, where CAA is decarboxylated to itaconic acid by the

cis-aconitic acid decarboxylase Cad-A [

43,

46,

72]. Subsequently, itaconic acid is transported out of the mycelia by a specific transporter, belonging to the major facilitator superfamily (MFS) type transporter (MfsA) [

73]. The genes involved in itaconic acid production in

A. terreus also include a transcription factor, and the four genes are termed the “itaconate gene cluster” [

73]. However, in the corn smut basidiomycete,

Ustilago maydis, the mitochondrial transporter Um_Mtt1, also transports CAA from the mitochondria to the cytoplasm, but CAA is first isomerized to TAA by aconitate-Δ-isomerase, Adi1, then decarboxylated by

trans-aconitic acid decarboxylase, Tad1, to itaconic acid [

43,

46,

47,

74]. The “itaconate gene cluster” in

U. maydis is induced upon nitrogen limitation [

75]. Overall, the metabolic differences in itaconic acid production by these two fungi is notable because it demonstrates the possibility of producing itaconic acid from either the

trans or

cis isomer of aconitic acid in different organisms [

47]. Differential microbial conversions of CAA and TAA to itaconic acid may also provide insight into

ex vivo enzymatic conversion options with recombinantly expressed decarboxylases.

3. Microbial Use as a Carbon Source

Microorganisms such as the soil bacterium

Pseudomonas sp. WU-0701 encodes an aconitate isomerase that catalyzes the reversible isomerization between TAA and CAA, an intermediate in the conversion of citrate to isocitrate in the TCA cycle [

49]. This enables the organism to grow on TAA as a sole carbon source by isomerizing TAA to CAA, which feeds back into the TCA cycle. Interestingly, others have reported the presence of various

Pseudomonas species in the rhizosphere of sugar cane, while others have reported that some rhizosphere-associated bacteria may improve plant growth and photosynthesis under certain conditions [

76]. The utilization of TAA as a carbon source by some of these bacteria could suggest a possible symbiosis between sugar cane and microorganisms in the rhizosphere involving TAA.

4. Aconitic Acid as a Fermentation Inhibitor

There are some reports that aconitic acid may act as an inhibitor in the fermentation of sugar cane juice, syrup, molasses, and sweet sorghum syrup. When studying the fermentation of sweet sorghum juice as a function of harvesting time, Day and Sarkar [

77] noted that the yield of ethanol produced by sake and wine yeasts dropped later in the harvest season, even though the sugar content increased. They speculated that the aconitic acid was responsible for the reduction in ethanol yield. When increasing the fermentable sugars by concentrating sweet sorghum juice, Wu et al. [

78] reported that the fermentation efficiency decreased with increasing water removal and speculated that the increase in aconitic acid levels due to the water removal may have been the reason [

78]. In fermentation of sweet sorghum juice, Gibbons and Westby [

79] reported low ethanol yields by

Saccharomyces cerevisiae depending on sweet sorghum variety. They speculated that aconitic acid was partially responsible for the inhibition, as it varied between varieties. The inhibition also remained noticeable in the fermentation of mixtures of sweet sorghum juice with hydrolyzed cereal mash. More inhibition was noted with corn mash than with wheat mash. Another report showed that the fermentation rate decreased by 29% when comparing the production of ethanol from sweet sorghum juices containing 0.114 and 0.312% aconitic acid [

50]. These authors attributed the rate reduction to aconitic acid and showed that the intracellular acid concentration of the yeast increased by a factor of 2 and 4 when the pH is changed from pH 5.0 to pH 3.5 to pH 2.0. In a detailed study, Klasson [

52] showed that it was the undissociated form of aconitic acid that was responsible for inhibition of ethanol production by Distiller’s yeast,

S. cerevisiae, in the fermentation of sweet sorghum sugars. By controlling the pH during the fermentation, the inhibition could be overcome, and when the pH was controlled above 4.5, the presence of aconitic acid (5 g/L) became slightly advantageous, and ethanol titer (+4%) and yield (+3%) increased slightly, confirming results of a previous study in synthetic media [

51]. At a fermentation pH > 4.5, the fermentation of diluted sweet sorghum syrup to butanol by

Clostridium beijerinckii did not appear to be inhibited by aconitic acid [

52].

5. Nematocidal Activity of Trans-Aconitic Acid

Pathogenic nematodes can be a significant problem for some crops such as sugar beets and cotton. For instance, the beet cyst nematode,

Heterodera schachtii, is especially problematic for sugar beets, which supply about one-third of the world’s supply of sugar [

80]. Finding a sustainable, plant-based source of nematocide that is nontoxic to humans is of considerable interest. Interestingly, the soil bacterium,

Bacillus thuringiensis, produces TAA as a virulence factor against soil nematodes [

53]. Studies with the thuringiensin-producing strain,

B. thuringiensis CT-43 in particular, revealed a chemical product called CT-A, with nematocidal activity against the major pest root-knot nematode,

Meloidogyne incognita [

53]. Further study revealed that CT-A contains TAA and that TAA exhibits a significantly higher nematocide activity than the

cis isomer, CAA, in a survival bioassay with

M. incognita J2s after 72 h. A plasmid-encoded operon for TAA biosynthesis was described in

B. thuringiensis CT-43 that encodes an aconitate isomerase, named TAA biosynthesis-related gene A (tbrA), and a membrane-bound transporter

tbrB that transports TAA out of the cell [

53,

81].

6. Anti-Leishmanial Activity of Trans-Aconitic Acid

Anti-leishmanial activity has also been attributed to TAA against the protozoan pathogen,

Leishmania donovani, the causative agent of visceral leishmaniasis, also known as kala-azar, thirty years ago, which is potentially fatal and difficult to treat [

54,

55]. During the lifecycle of this protozoan, the promastigote form is present in the vector during disease transmission, while the amastigote form is found intracellularly within infected macrophages of the host. Anti-leishmanial drugs can be problematic due to toxicity. TAA was investigated as an alternative and in combination with conventional chemotherapy since TAA is an inhibitor of the aconitase enzyme in the TCA cycle [

56]. The

L. donovani amastigote relies on mitochondrial β−oxidation of fatty acids as an important energy source. During β-oxidation, fatty acids are converted to acetyl-CoA, which feeds into the TCA cycle to generate ATP for energy, so TAA was of particular interest as an inhibitor of aconitase in the TCA cycle [

57]. Interestingly, 20 mM TAA significantly attenuated promastigote replication that could be reversed by the addition of 20 mM CAA at 72 h, indicating divergent biological activity of the two aconitic acid isomers. Furthermore, 2 mM TAA reduced parasitic liver burden in infected hamsters in a dose-dependent manner [

54,

55]. A dose of 2 mM TAA reduced the number of amastigotes within a macrophage model by 60% [

54]. Five (5) mM TAA, together with anti-leishmanial drugs, sodium stibogluconate, pentamidine, or allopurinol, completely inhibited amastigote transformation to promastigote [

55]. These reports from

L. donovani may provide insight into the mechanism of action against other organisms such as nematodes.

7. Aconitic Acid Production Confers Survival Advantages

The production of TAA by sugarcane, sweet sorghum, and other plants may confer a survival advantage against pests and help to regulate metabolic processes during rapid plant growth. Stout et al. [

82] assayed 94 species of grasses and non-grasses from rangeland and found that 47% of grasses and 17% of non-grasses accumulated TAA to high levels. Furthermore, aconitic acid has also been detected in grasses such as oats, rye, wheat, barley, and maize [

83].

In higher plants,

trans-aconitate is produced and stored as a “tricarboxylic acid pool” [

7]. TAA is produced via two mechanisms connected to the TCA cycle. The first occurs via the citrate valve and citrate hydratase to form TAA [

7]. The second mechanism occurs with aconitase conversion of citrate to isocitrate via a

cis-aconitate intermediate, which can then be isomerized to TAA via aconitate isomerase [

7]. Accumulation of TAA may play a role in regulating the TCA cycle by inhibition of aconitase [

56]. Moreover, this inhibition can be alleviated by monomethyl esterification by

trans-aconitate methyltransferase TMT1, which has been described in

Escherichia coli,

Saccharomyces cerevisiae, and

Ashbya gossypii [

84,

85,

86].

7.1. Antifungal Defense

Aconitic acid may also play a role in antifungal defense in some plants. For example, TAA may accumulate in wheat as part of a protective mechanism against powdery mildew

Blumeria graminis f. sp.

Tritici [

58]. In particular, TAA and, to a much lesser extent, CAA can be induced to high levels of accumulation in wheat leaves by potassium sulfate [

87]. Moreover, later studies showed that in wheat plants experimentally infected and fed silicon, TAA was methylated to form methyl TAA, which acts as a phytoalexin to limit disease [

58].

Organic acid root exudates such as malic and tartaric acid also appear to inhibit fusarium wilt, caused by

Fusarium oxysporum f. sp.

fabae (FOF), in faba beans (

Vicia faba). TAA was only detected in root exudates under nitrogen limitation, while tartaric and malic acids were detected after nitrogen application. So far, it is unknown what role TAA may play in faba bean antifungal defense during limited nitrogen conditions [

88].

7.2. Antifeedant

TAA also appears to function as an antifeedant in some plants, such as barnyard grass against the brown planthopper (

Nilaparvata lugens) [

59]. Additional studies further demonstrated the resistance of barnyard grass and one resistant strain of rice “Babawee” to feeding by brown planthopper due to the presence of TAA, but not CAA. Furthermore, TAA was not detected in the susceptible rice strain “Koyonishiki” [

59,

60,

61,

62]. High levels of aconitic acid production may also play a role in the resistance of some cereal plants such as corn, sorghum, and barnyard grass to aphids [

89]. For instance, higher levels of TAA in sorghum leaves corresponded to decreased aphid burden and leaf damage, further implying that TAA functions as a defensive phytochemical [

89,

90,

91].

7.3. Defense against Aluminum Toxicity

Aconitic and oxalic acids are the predominant organic acids produced in maize. Aconitic acid appears to protect the maize against aluminum toxicity. The level of organic acids in maize is high during early harvest and decreases with each successive harvest [

5]. About 60% of the aconitic acid is the

trans isomer [

5]. TAA is found in both the shoots and roots of maize and may help protect the plant from Al toxicity through organic acid chelation [

6]. TAA was found to accumulate in the roots to higher levels in response to Al

3+ activity than in the shoots [

6].

Interestingly, since TAA-producing grasses such as sugar cane are often part of a crop rotation strategy with soybeans, and since sugar cane vinasse is sometimes applied to fields, the effect of TAA on soybean growth was investigated. TAA was found to inhibit soybean growth by inhibiting photosynthesis and increasing H

2O

2 in roots, which resulted in decreased water uptake [

69]. It is unknown whether any residual TAA remains in the soil after harvesting sugar cane or whether TAA rapidly dissipates to negligible levels, but it is worth considering the possible impact of TAA on crop rotations with soybean.

8. Biofilm Inhibition

Aconitic acid may be an inhibitor of biofilm formation. Pestana-Nobles et al. [

70] reported a computational study based on molecular docking and molecular dynamic simulation that screened 224,205 molecules from the natural products ZINC15 database. The results predicted TAA as a possible ligand and inhibitor of the PleD protein involved in bacterial biofilm formation. PleD and its homologs are diguanylate cyclases that contain a GGDEF domain involved in cyclic di-GMP second messenger formation, a critical signaling molecule involved in quorum sensing needed for biofilm formation. As such, PleD homologs are often the target of high-throughput screens for biofilm inhibitors [

92,

93]. While TAA was identified computationally as an inhibitory ligand for PleD, it has yet to be experimentally validated.

9. Anti-Inflammatory Treatment

TAA has also been reported as an anti-inflammatory treatment for conditions such as arthritis with mucoadhesive microspheres containing TAA [

63,

64]. For instance, the medicinal plant

Echinodorus grandifloras contains high levels of TAA and is used to treat rheumatoid arthritis in Brazil. TAA, along with other fractions extracted from

Echinodorus grandiflorus leaves, acts as an anti-inflammatory by inhibiting tumor necrosis factor-alpha (TNF-α) release during in vitro assay of lipopolysaccharide (LPS)-stimulated, THP-1 human monocyte cells [

65]. Furthermore, the lipophilicity of TAA can be improved by Fisher esterification with an alcohol to form mono- di- or tri-esters of TAA [

64]. Improving lipophilicity of TAA by esterification was used as a strategy to improve the pharmacokinetics and transport of TAA across biological membranes [

94]. The TAA esters were administered orally and tested in a mouse model of lipopolysaccharide (LPS)-induced arthritis. TAA diesters were found to be the most biologically active, and the anti-inflammatory activity increased the longer the aliphatic chain of the alcohol was used for esterification [

64].

This entry is adapted from the peer-reviewed paper 10.3390/foods11040573