Nanotechnology is defined as a new technology for making applicable matters, systems and devices using nanosized materials, as well as new phenomena and properties at the nanoscale (1–100 nanometers) [1]. Adding certain Nanoparticles (NPs) to injection solutions can significantly benefit enhanced oil recovery (EOR), with advantages such as wettability alternation, changes in fluid properties, improving the trapped oil mobility, enhancing the consolidation of sands and decreasing the interfacial tension (IFT)

- interfacial tension

- NPs

- nanotechnology

- wettability

- EOR

- nanofluids

1. Introduction

Nanoparticles (NPs) are known as important nanomaterials for a broad range of commercial and research applications owing to their physical characteristics and properties. Currently, the demand for NPs for use in enhanced oil recovery (EOR) is very high. The use of NPs can drastically benefit EOR by changing the wettability of the rock, improving the mobility of the oil drop and decreasing the interfacial tension (IFT) between oil/water.

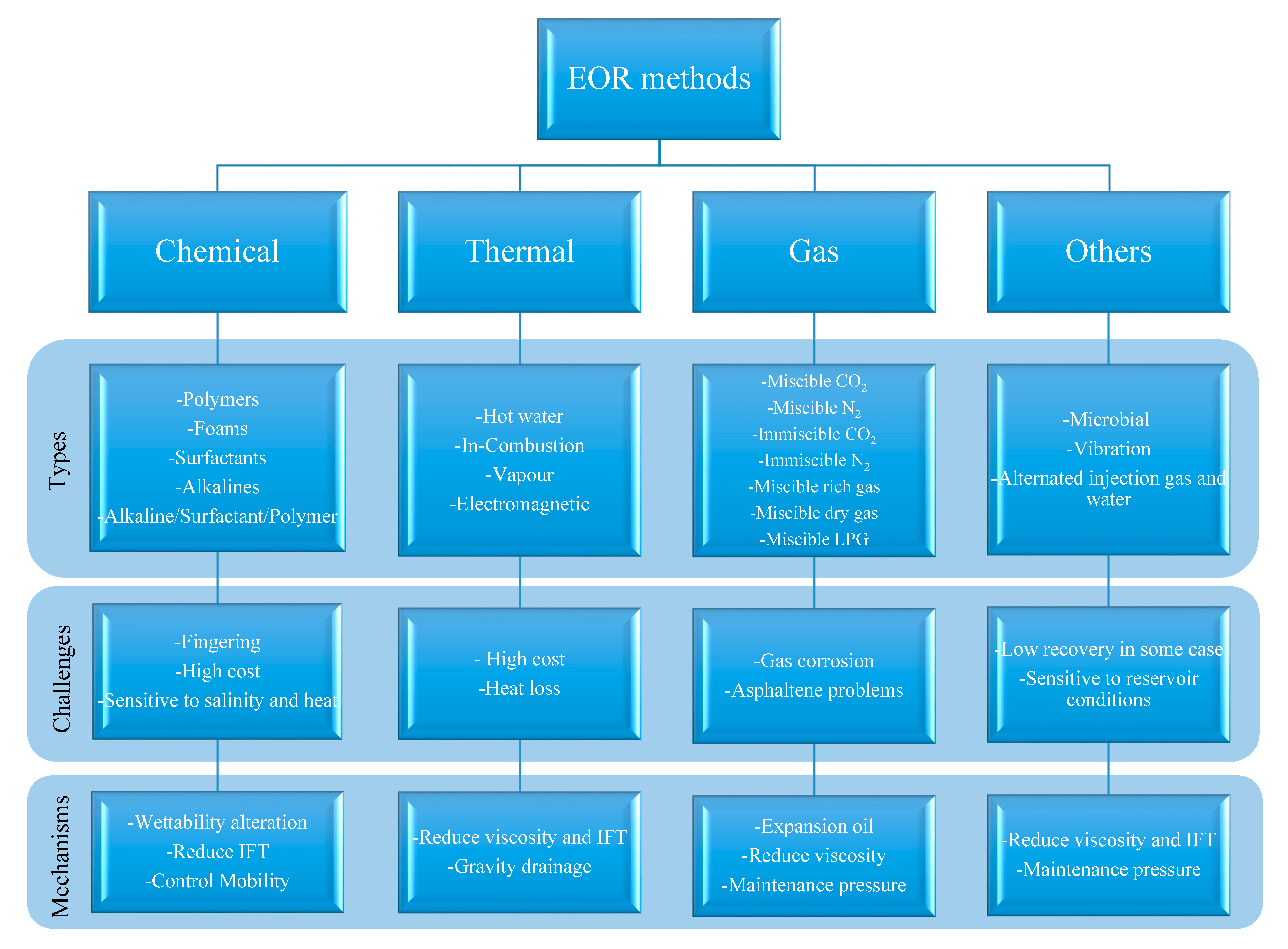

Nanomaterials are novel alternative methods to be applied as new EOR techniques and solve residual oil problems in heavy and semi-heavy oil reservoirs in last decade[1][2][3][4][5]. Figure 1 shows different EOR methods categorized into four major groups[6][7][8]. Nanoparticles and nanofluids, as interdisciplinary sciences, have great significance in the fields of thermal engineering, materials and nanoscience come across. Over the last decade, they have developed greatly and uncloaked their potential applications in EOR[9][10][11][12][13]. There are many studies that have indicated improved EOR processes by NPs and nanofluids in the past decade[2][4][14][15][16]. In several works, nano- and microspheres have been used for mobility control and have indicated excellent results in decreasing water cut, improving sweep efficiency and oil recovery[17][18][19]. In addition, micro and nanospheres can reduce the capillary force and water relative permeability and finally change the water flow path in porous media[19]. Moreover, NPs have suitable resistance to degradation at high salinity and temperature in oil and gas reservoirs. Some studies also investigated surfactant solutions with NPs as nanofluids for improving oil recovery in harsh reservoir conditions[18].

Figure 1. Flow sheet of enhanced oil recovery methods, mechanisms and challenges.

Figure 1. Flow sheet of enhanced oil recovery methods, mechanisms and challenges.

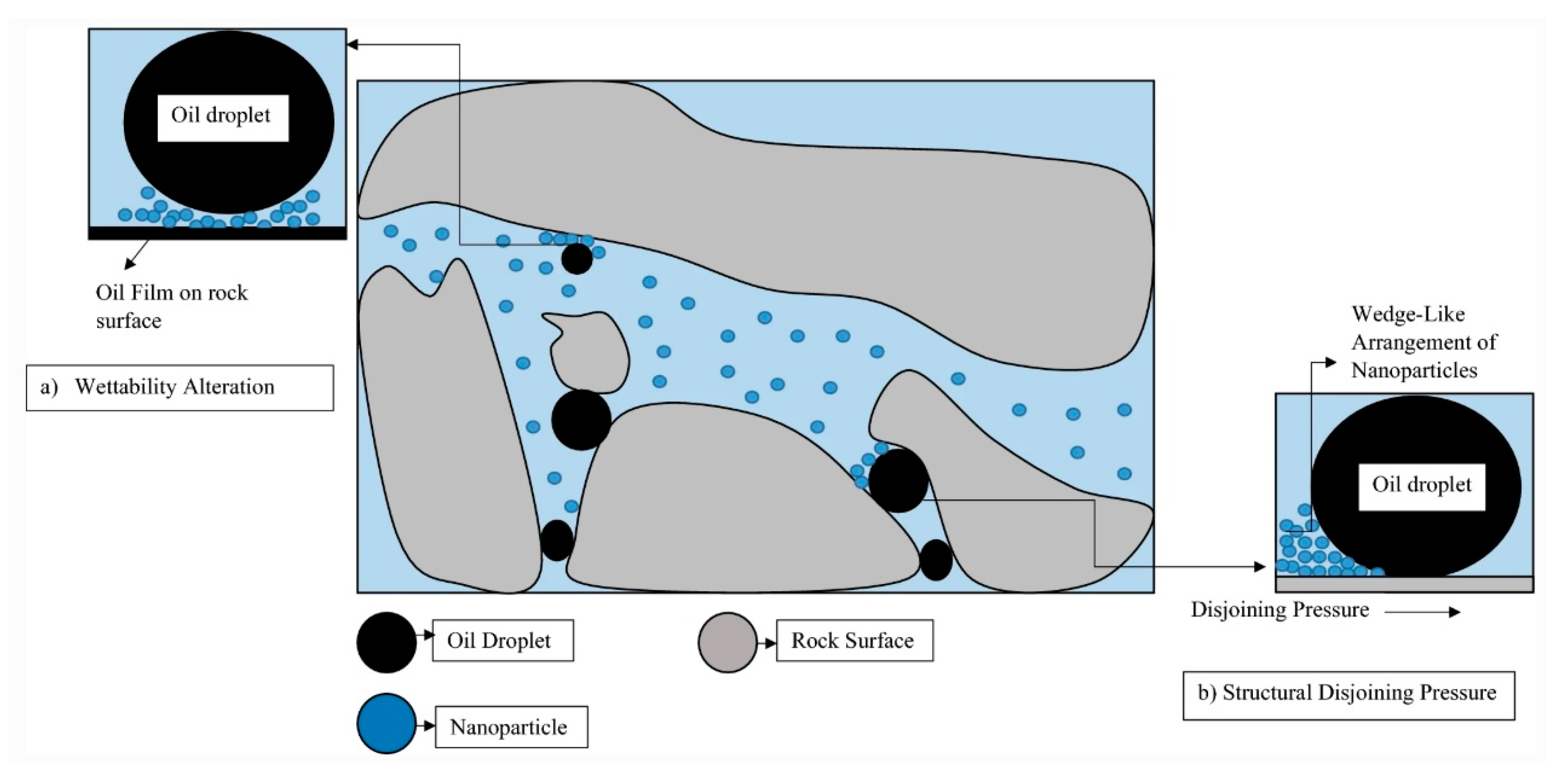

Many researchers have used nanomaterials to reduce the viscosity of bitumen and heavy and semi-heavy oil. Based on some experimental results, NP concentration, size and type are different parameters that affect the reduced viscosity mechanism of heavy oil[20][21][22][23][24][25][26]. In addition, much research has shown that wettability alteration and IFT reduction between fluids and rocks are two main mechanisms that NPs have great potential to enable on micro- and nanoscales (Figure 2)[27].

Figure 2. Mechanism of NPs EOR. (a) Changing wettability and (b) structural pressure by NPs[28].

Figure 2. Mechanism of NPs EOR. (a) Changing wettability and (b) structural pressure by NPs[28].

2. Effects of Nanoparticles on Oil Recovery

A combination of surfactants and NPs causes the release of oil drops, which are trapped in thin throats and microchannels of the reservoir rock. These phenomena are related to some agents that lead to an increase in oil recovery; these include parameters such as the wettability alteration of reservoir rocks, spontaneous emulsion formation, changing IFT between reservoir fluids and flow properties of porous media[29][30][31][32].

Over the years, various NPs were evaluated to improve oil recovery. For instance, Ehtesabi et al.[33] found that the TiO2 NPs achieved an 80% increase in oil recovery in oil-wet sandstone. Shah [34] investigated the performance of oil recovery with CuO nanoparticles. The results showed that CuO nanoparticles lead to a 71% increase in oil recovery. Kanj et al.[35] studied the flooding performance of modified carbon nanoparticles. They found that carbon-based fluorescent NPs increase the oil recovery factor in carbonate reservoir by more than 96%.

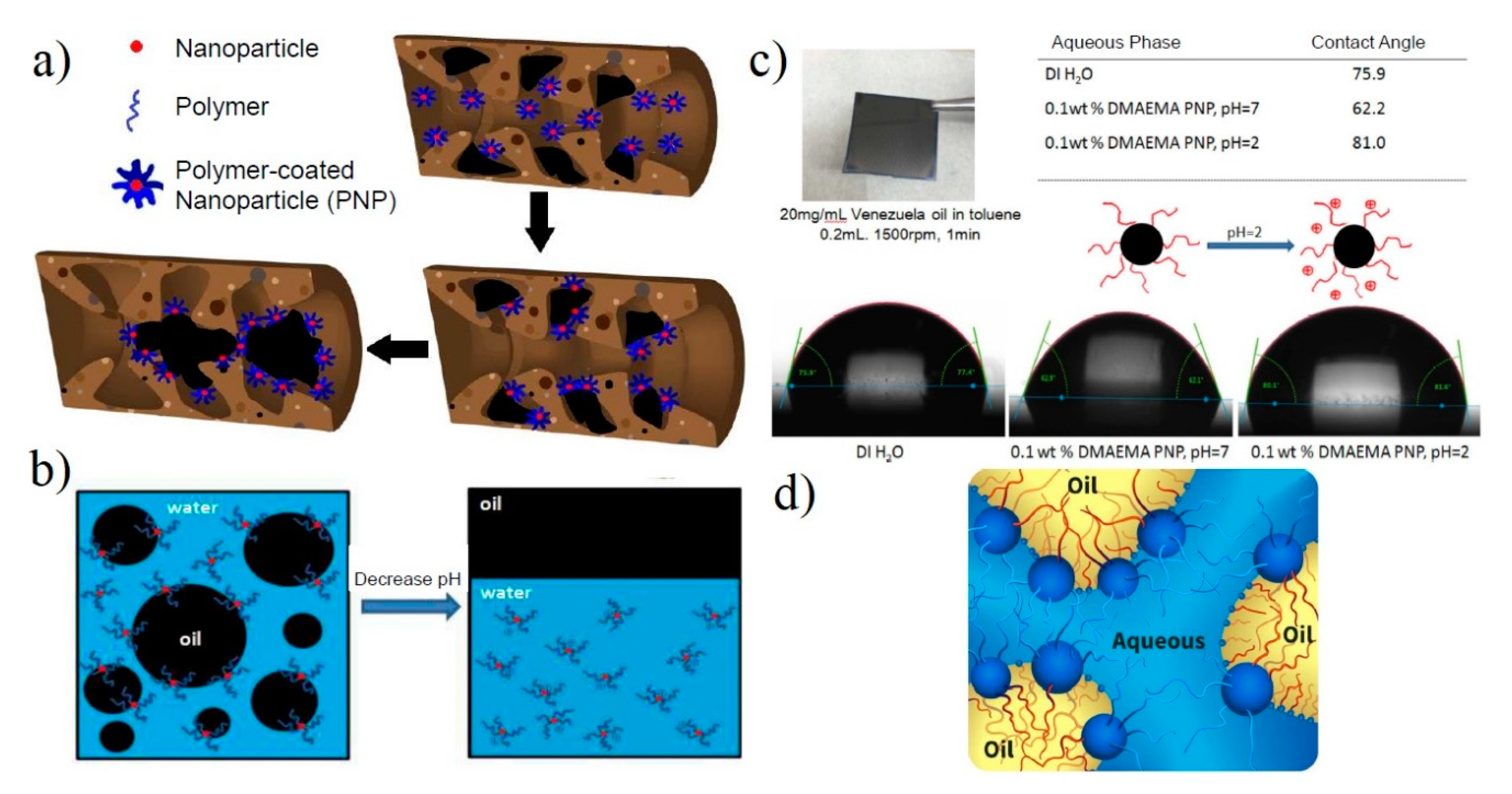

In order to investigate the emulsion stability and polymer solutions in reservoir conditions, several NP-modified polymers have been developed by researchers. Wang et al.[36] focused on the effect of Na–montmorillonite (Na–Mt) particles and hydrolyzed polyacrylamide (HPAM) on emulsion stability. They also studied the interfacial properties of water–oil, dilatational viscoelasticity, IFT and zeta potentials. The results indicated that increasing NP concentrations cause a decrease in the IFT and zeta potential of oil drops and increases the dilatational viscoelasticity. With increasing NP concentrations, dilatational viscoelasticity and IFT were increased, while zeta potential became stable after 250 mg/L concentration. Actually, in the heavy oil reservoir, polymer-coated nanoparticles can change the pH conditions of the reservoir and cause recovery of heavy oil, which is shown in Figure 3.

Figure 3. Schematic of (a) the use of polymer-coated NP additives to recover heavy oil trapped in porous media, (b) the demulsification of oil-in-water emulsions with changes in solution pH, (c) wettability alteration by polymer-coated NPs [37] and (d) schematic of oil–water microemulsion phases with polymer-coated NP additives [38].

Figure 3. Schematic of (a) the use of polymer-coated NP additives to recover heavy oil trapped in porous media, (b) the demulsification of oil-in-water emulsions with changes in solution pH, (c) wettability alteration by polymer-coated NPs [37] and (d) schematic of oil–water microemulsion phases with polymer-coated NP additives [38].

A comprehensive laboratory study on hydrophilic silica dioxide NPs for EOR objectives was carried out at various wettability levels and temperatures of reservoirs (oil-wet, intermediate-wet and water-wet) by Hendraningrat et al. [39]. Relationships between the temperature, initial wettability and additional oil recovery and the nanofluid flooding (nano-EOR) process were investigated. Experimental results have shown that NPs have stable conditions at high temperatures and avoid the aggregation of particles in porous media. Collectively, their results reviewed nanofluid properties for EOR purposes in a wide range of reservoir conditions.

Recently, some researchers have conducted systematic research about the performance of NPs on surfactant flooding. Zargartalebi et al. [40] studied surfactant flooding with nanoparticles. The results indicated that NPs could improve oil recovery and surfactant flooding in equal NP and surfactant concentrations. In addition, hydrophobic NP-modified surfactants were more efficient than hydrophilic NP-modified surfactants.

In another work, a novel polymer nanocomposite was synthesized by nano-SiO2 and free radical polymerization for use in a polymer flooding system. Oil displacement efficiency, mobility control ability, salt tolerance, temperature tolerance, viscoelasticity and rheological properties were checked under various conditions. The experimental results showed that polymer nanocomposite as a chemical agent has excellent performance for mobility control ability, temperature tolerance and rheological properties for polymer flooding [41][42].

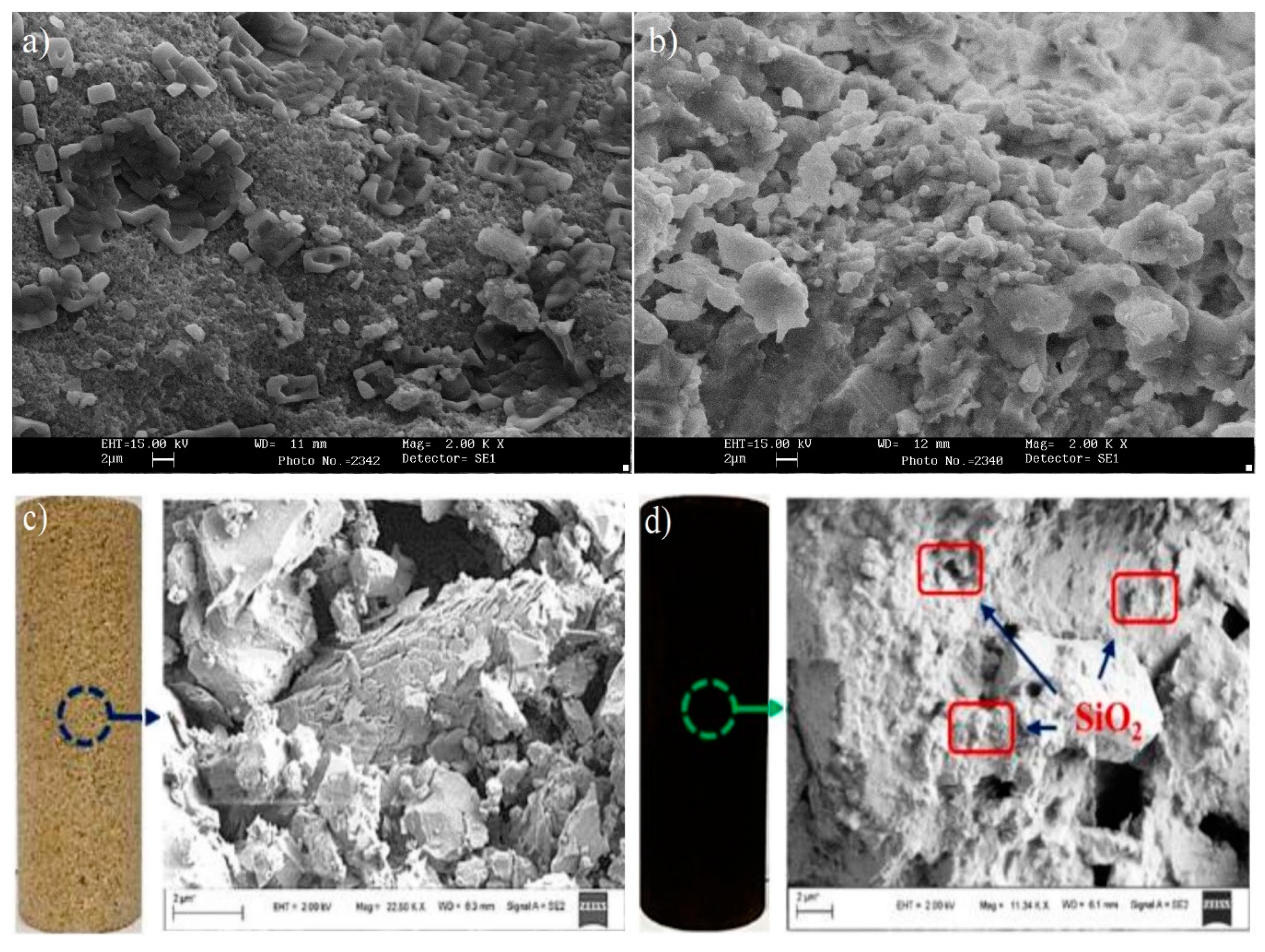

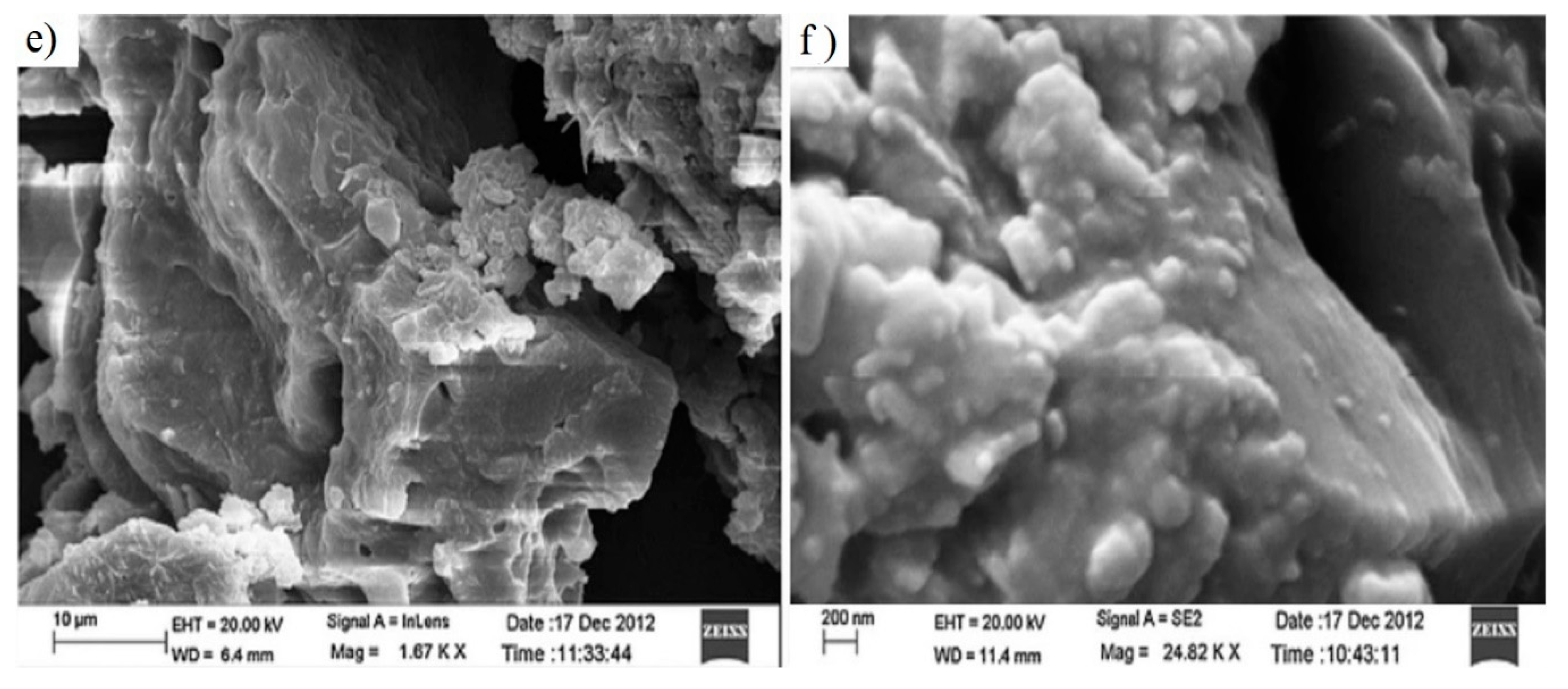

Hendraningrat [43] also showed that polymeric nanospheres have great potential to recover trapped residual oil from porous media. His study showed that NPs could reduce water permeability and mobility ratio, so polymer solutions move to bypassed oil zones (unswept areas) and cause improved oil recovery. In addition, NPs play a key role in changing oil displacement mechanisms and wettability alteration. The results of flooding with NPs indicated that higher concentrations of NPs increase the recovery of oil more than normal polymer flooding (Figure 5a–d) [44][45]. However, high concentrations of NPs have a low effect on the viscosity and IFT, as well having a negative effect on reservoir permeability due to the blocking of porous media (Figure 4c,d).

Figure 4. SEM images of sand samples with (a) 0.45 wt.% and (b) 0.90 wt.% clay NPs after polymer (c) Core sample before surfactant–polymer NP flooding, (d) deposition of NPs on the core sample after surfactant–polymer NP flooding [45]; (e,f) SEM images of core plug after flooding with NPs [33].

Figure 4. SEM images of sand samples with (a) 0.45 wt.% and (b) 0.90 wt.% clay NPs after polymer (c) Core sample before surfactant–polymer NP flooding, (d) deposition of NPs on the core sample after surfactant–polymer NP flooding [45]; (e,f) SEM images of core plug after flooding with NPs [33].

Some works indicated that hydrophilic silica nanoparticles were distributed through reservoir porous media. According to some research, the concentration of silica NPs should not be more than 0.1 wt.%. This is because the subject can have different effects on EOR. In addition, a high concentration of NPs necessarily result in high oil recovery. However, even a high concentration can decrease residual oil saturation by 2–13% [13]. In a research study, the performance of nano hydrophilic metal oxide was investigated as a polymeric nanofluid for oil recovery by adding polyvinylpyrrolidone. Between NPs, TiO2 has better performance in polymer flooding and wettability alteration in comparison to silica-based nanofluid [39].

Silica NPs distribute into water-wet porous media but do not move with oil in sandstone channels. Silica NPs with 600 ppm HPAM can, in this system, decrease residual oil saturation by around 20% [21]. Furthermore, propanol and SiO2 NPs are suitable combinations for oil recovery of around 88% by changing wettability and reducing IFT [46]. Therefore, this subject indicates that NPs can significantly reduce trapped oil if NPs are injected into porous media[46].

The results show that NPs with a 0.1 wt.% concentration cause improved rheological properties in the polymer at a low shear rate (pseudo-plasticity behavior). NPs also cause more enhanced viscosity in nanosuspensions than polymer solutions. In fact, nanosuspensions are a suitable option as they can be applied instead of polymeric solutions to EOR [47].

This entry is adapted from the peer-reviewed paper 10.3390/pr8091073

References

- Aliabadian, E.; Sadeghi, S.; Moghaddam, A.R.; Maini, B.B.; Chen, Z.; Sundararaj, U. Application of graphene oxide nanosheets and HPAM aqueous dispersion for improving heavy oil recovery: Effect of localized functionalization. Fuel 2020, 265, 116918.

- Miranda, C.R.; De Lara, L.S.; Tonetto, B.C. Stability and Mobility of Functionalized Silica Nanoparticles for Enhanced Oil Recovery Applications, SPE 157033-MS. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012.

- Roustaei, A.; Saffarzadeh, S.; Mohammadi, M. An evaluation of modified silica nanoparticles’ effciency in enhancing oil recovery of light and intermediate oil reservoirs. Egypt. J. Pet. 2013, 22, 427–433.

- Ju, B.; Fan, T.; Ma, M. Enhanced oil recovery by flooding with hydrophilic nanoparticles. China Particuol. 2006, 4, 41–46.

- Nezhad, S.S.K.; Cheraghian, G.; Roayaei, E.; Tabatabaee, H.; Karambeigi, M.S. Improving heavy oil recovery in the polymer flooding process by utilizing hydrophilic silica nanoparticles. Energy Sources Part A Recover. Util. Environ. Eff. 2017, 1, 1–10.

- Huang, B.; Wang, C.; Zhang, W.; Fu, C.; Liu, H.; Wang, H. Study on the Stability of Produced Water from Alkali/Surfactant/Polymer Flooding under the Synergetic Effect of Quartz Sand Particles and Oil Displacement Agents. Processes 2020, 8, 315.

- Cheraghian, G.; Nezhad, S.S.K. Improvement of heavy oil recovery and role of nanoparticles of clay in the surfactant flooding process. Pet. Sci. Technol. 2016, 34, 1397–1405.

- Torsater, O.; Engeset, B.; Hendraningrat, L.; Suwarno, S. Improved Oil Recovery by Nanofluids Flooding: An Experimental Study. In Proceedings of the SPE Kuwait International Petroleum Conference and Exhibition, Kuwait City, Kuwait, 10–12 December 2012.

- Hendraningrat, L.; Li, S.; Torsæter, O. Enhancing oil recovery of low-permeability berea sandstone through optimized nanoûuids concentration. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 2–4 July 2013.

- Cheraghian, G.; Wu, Q.; Mostofi, M.; Li, M.-C.; Afrand, M.; Sangwai, J.S. Effect of a novel clay/silica nanocomposite on water-based drilling fluids: Improvements in rheological and filtration properties. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 339–350.

- Cheraghian, G.; Hemmati, M.; Bazgir, S. Application of TiO2 and fumed silica nanoparticles and improve the performance of drilling fluids. AIP Conf. Proc. 2014, 1590, 266–270.

- Cheraghian, G. Application of Nano-Particles of Clay to Improve Drilling Fluid. Int. J. Nanosci. Nanotechnol. 2017, 13, 177–186.

- Engeset, B. The Potential of Hydrophilic Silica Nanoparticles for EOR Purposes: A Literature Review and an Experimental Study. Master’s Thesis, Norwegian University of Science and Technology, Department of Petroleum Engineering and Applied Geophysics, Trondheim, Norway, 2012.

- Cheraghian, G.; Tardasti, S. Improved Oil Recovery by the Efficiency of Nano-particle in Imbibition Mechanism. In Proceedings of the 74th EAGE Conference and Exhibition Incorporating (EUROPEC 2012), Copenhagen, Denmark, 4–7 July 2012.

- Cheraghian, G. A New Thermal Method Concept for IOR from Oil Reservoir Using Optimized In-situ Combustion. In Proceedings of the 78th EAGE Conference and Exhibition, Vienna, Austria, 30 May–2 June 2016.

- Kanj, M.; Funk, J.J.; Al-Yousif, Z. Nanofluid Coreflood Experiments in the ARAB-D. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, Al-Khobar, Saudi Arabia, 9–11 May 2009.

- Yuan, W.; Liu, X.; Wei, H.; Liu, J.; Yang, H.; Hu, S.; Li, Y.; Wang, D. Research and application effect of polymeric microsphere in Wen-10 of Sinopec Zhongyuan Oil ûeld. Inner Mong. Petrochem. 2010, 12, 122–126.

- Li, X.; Ying, Z.; Jia, Y.; Liu, X.; Yang, T.; Ma, L. Application of nanosphere deep proûle control and displacement technology in Chanqing oilûeld. Oil Field Chem. 2012, 29, 13–16.

- Tian, Q.Y.; Wang, L.; Tang, Y.; Liu, C.; Ma, C.; Wang, T. Research and Application of Nano Polymer Microspheres Diversion Technique of Deep Fluid. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, SPE 156999-MS, Noordwijk, The Netherlands, 12–14 June 2012.

- Shokrlu, Y.H.; Babadagli, T. Effects of Nano-Sized Metals on Viscosity Reduction of Heavy Oil/Bitumen During Thermal Applications. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010.

- Skauge, T.; Hetland, S.; Spildo, K.; Skauge, A. Nano- Sized Particles for EOR, SPE 129933. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010.

- Cheraghian, G. Thermal Resistance and Application of Nanoclay on Polymer Flooding in Heavy Oil Recovery. Pet. Sci. Technol. 2015, 33, 1580–1586.

- Cheraghian, G. Nanokomposit stabilisiert Bohrflüssigkeiten. Keram. Z. 2019, 71, 25.

- Cheraghian, G. Improved Heavy Oil Recovery by Nanofluid Surfactant Flooding—An Experimental Study. In Proceedings of the 78th EAGE Conference and Exhibition, Vienna, Austria, 30 May–2 June 2016.

- Nezhad, S.S.K.; Cheraghian, G. Mechanisms behind injecting the combination of nano-clay particles and polymer solution for enhanced oil recovery. Appl. Nanosci. 2015, 6, 923–931.

- Cheraghian, G.; Hemmati, M.; Masihi, M.; Bazgir, S. An experimental investigation of the enhanced oil recovery and improved performance of drilling fluids using titanium dioxide and fumed silica nanoparticles. J. Nanostruct. Chem. 2013, 3, 78.

- Le, N.Y.T.; Pham, D.K.; Le, K.H.; Nguyen, P.T. Design and screening of synergist ic blends of SiO2 nanoparticles and surfactants for enhanced oil recovery in high-temperature reservoirs. J. Adv. Nat. Sci. 2011, 2, 35013–35019.

- Afolabi, R.O. Enhanced oil recovery for emergent energy demand: Challenges and prospects for a nanotechnology paradigm shift. Int. Nano Lett. 2019, 9, 1–15.

- Mohajeri, M.; Hemmati, M.; Shekarabi, A.S. An experimental study on using a nanosurfactant in an EOR process of heavy oil in a fractured micromodel. J. Pet. Sci. Eng. 2015, 126, 162–173.

- Cheraghian, G.; Hendraningrat, L. A review on applications of nanotechnology in the enhanced oil recovery part A: Effects of nanoparticles on interfacial tension. Int. Nano Lett. 2016, 6, 129–138.

- Cheraghian, G.; Nezhad, S.K. Experimental Investigation of Polymer Solutions Used in Enhanced Oil Recovery-Thermal properties Improved by Nanoclay. In Proceedings of the 77th EAGE Conference and Exhibition, Madrid, Spain, 1–4 June 2015.

- Cheraghian, G. Synthesis and properties of polyacrylamide by nanoparticles, effect nanoclay on stability polyacrylamide solution. Micro Nano Lett. 2017, 12, 40–44.

- Ehtesabi, H.; Ahadian, M.M.; Taghikhani, V. Enhanced Heavy Oil Recovery Using TiO2 Nanoparticles: Investigation of Deposition during Transport in Core Plug. Energy Fuels 2015, 29, 1–8.

- Shah, R.D. Application of Nanoparticle Saturated Injectant Gases for EOR of Heavy Oils. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009; Society of Petroleum Engineers (SPE): Richardson, TX, USA, 2009.

- Kanj, M.; Rashid, H.; Giannelis, E. Industry First Field Trial of Reservoir Nanoagents. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 25–28 September 2011; Society of Petroleum Engineers (SPE): Richardson, TX, USA, 2011.

- Wang, Y.; Lu, F.; Li, Y.; Wu, T.; Sun, D.; Zhang, G.; Huang, X.; Wang, G. Effects of Na–montmorillonite particles on the emulsification stability of polymer flooding produced water. Colloids Surf. A Physicochem. Eng. Asp. 2012, 410, 125–129.

- Qi, L.; Song, C.; Wang, T.; Li, Q.; Hirasaki, G.J.; Verduzco, R. Polymer-Coated Nanoparticles for Reversible Emulsification and Recovery of Heavy Oil. Langmuir 2018, 34, 6522–6528.

- Qi, L.; ShamsiJazeyi, H.; Ruan, G.; Mann, J.A.; Lin, Y.-H.; Song, C.; Ma, Y.; Wang, L.; Tour, J.M.; Hirasaki, G.J.; et al. Segregation of Amphiphilic Polymer-Coated Nanoparticles to Bicontinuous Oil/Water Microemulsion Phases. Energy Fuels 2017, 31, 1339–1346.

- Hendraningrat, L.; Torsæter, O. Metal oxide-based nanoparticles: Revealing their potential to enhance oil recovery in different wettability systems. Appl. Nanosci. 2015, 5, 181–199.

- Zargartalebi, M.; Kharrat, R.; Barati, N. Enhancement of surfactant flooding performance by the use of silica nanoparticles. Fuel 2015, 143, 21–27.

- Kim, B.-J.; Kang, K.-S. Fabrication of a Crack-Free Large Area Photonic Crystal with Colloidal Silica Spheres Modified with Vinyltriethoxysilane. Cryst. Growth Des. 2012, 12, 4039–4042.

- Ye, Z.; Qin, X.; Lai, N.; Peng, Q.; Li, X.; Li, C. Synthesis and Performance of an Acrylamide Copolymer Containing Nano-SiO2 as Enhanced Oil Recovery Chemical. J. Chem. 2013, 2013, 1–10.

- Hendraningrat, L.; Zhang, J. Polymeric nanospheres as a displacement fluid in enhanced oil recovery. Appl. Nanosci. 2015, 5, 1009–1016.

- Cheraghian, G.; Nezhad, S.S.K. Effect of Nanoclay on Heavy Oil Recovery During Polymer Flooding. Pet. Sci. Technol. 2015, 33, 999–1007.

- Saha, R.; Uppaluri, R.V.S.; Tiwari, P. Impact of Natural Surfactant (Reetha), Polymer (Xanthan Gum), and Silica Nanoparticles to Enhance Heavy Crude Oil Recovery. Energy Fuels 2019, 33, 4225–4236.

- Joonaki, E.; Ghanaatian, S. The Application of Nanofluids for Enhanced Oil Recovery: Effects on Interfacial Tension and Coreflooding Process. Sci. Technol. 2014, 32, 2599–2607.

- Maghzi, A.; Mohebbi, A.; Kharrat, R.; Ghazanfari, M.H. An Experimental Investigation of Silica Nanoparticles Effect on the Rheological Behavior of Polyacrylamide Solution to Enhance Heavy Oil Recovery. Sci. Technol. 2013, 31, 500–508.