Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Materials Science, Biomaterials

When nanoparticles and nanofibers are combined, the composite material can perform more functions, such as photothermal, magnetic response, biosensing, antibacterial, drug delivery and biosensing.

- polymer composites

- nanoparticle

- polymer blends

1. Introduction

COVID-19 has contributed to a worldwide healthcare crisis resulting in several hundreds of thousands of deaths over recent years and complications that can lead to severe pneumonia [1,2]. In synergy with Polymer Engineering, Bioengineering, and Advanced Manufacturing, the mRNA vaccine was successfully developed and blocked the further spread of the virus on a large scale [3,4]. The mRNA-1273 vaccine approved for use under urgent circumstances has the potential to be unsafe for delivery, being inherently unstable while the large density of negative charges makes it difficult to cross cell membranes [5,6], and the latest research uses polymer-based composites as carriers for effective vaccine delivery [7].

In medical applications, polymers with superior biocompatibility are often used to not produce antibody reactions or even stimulate inflammation in contact with the human body [8,9,10]. Synthetic polymers include: polycaprolactone (PCL), poly (vinyl alcohol) (PVA), polylactide (PLA) and poly (lactic-co-glycolic acid) (PLGA) [11,12]; natural polymers include: Chitosan (polysaccharide), cellulose (polysaccharide), gelatin (protein), silk proteins (proteins) [13], etc. In biomedical applications, natural polymers are often perceived as relatively safe, biocompatible and degradable polymers [14]. Cellulose is a linear polysaccharide, the main component of the cell wall, which is currently the most used in biological applications from bacteria [15]. Taokaew et al. composite nanofibers based on bacterial cellulose with Garcinia mangostana peel extract exhibited potent bacterial inhibition against Gram-positive bacteria while treating the membranes with MCF-7 breast cancer cells for 48 h, only 5% of the cancer cells remained viable [16]. The protein class of silk fibroin, unlike other natural polymers, has outstanding elasticity and strength, which is of interest in tissue engineering applications [17,18].

The advantages of synthetic polymers over natural polymers are their stability, superior mechanical properties and degradability. PCL is an aliphatic semicrystalline polymer with hexanoic acid formed by esterolysis [19], which can be excreted through the digestive system, thus making it biocompatible, biodegradable, non-toxic and popular in medical applications, such as drug delivery, wound plug dressings and stents. The use of PCL scaffolds for tissue engineering has been reported in detail by Janmohammadi et al. [20]. Zavan and co-works prepared a bilayer fibrous scaffold with the outer layer of PCL exhibiting the best in vitro response to fibroblasts and weak adhesion to cellular tissues due to the hydrophobicity of PCL to cellular tissues, while the inner layer used gelatin-modified PCL to significantly promote gene expression in endothelial cells [21].

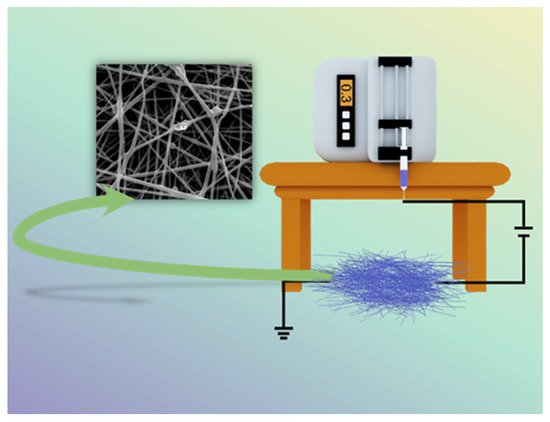

Nanoscale polymers have a wide range of uses in various fields, especially in medical applications, where the electrospinning process (Figure 1) is one of the most convenient ways to prepare nanofiber membranes (1–100 nm) directly and continuously [22,23,24,25,26]. Laboratory electrospinning setup generally has three components: a high voltage electrostatic generator (1–30 kv), a spinning head and a collector (opposite charge target) for the process of producing various continuous nanofiber assemblies with controlled morphology and dimensions from polymer solutions or melts under a high voltage electric field [27,28,29]. The development of the electrospinning (ES) process was a somewhat difficult journey. In the 16th century, William Gibert discovered a conical droplet formed when charged amber approached water droplets. Micro-droplets are also ejected from the conical droplets. The beginning of electrospinning technology is recognized to be in 1934, when Anton Formalas invented a device to prepare polymer fibers by electrostatic force action, presenting for the first time how a polymer solution could form the jet between electrodes. Subsequent years of intermittent patent publication have not attracted much attention from researchers. In 1990, Reneker’s research team at the Acolon University, USA, went deeper into the electrospinning (ES) process and applications, with ES of various organic polymer solutions into fibers, ES process is rapidly becoming a research hotspot, entering a new era of vigorous development [30,31].

Figure 1. Schematic diagram of electrospinning setup.

To prepare the desired nanofibers, the electrospinning process usually requires setting parameters, the main influencing factors being the system (nature of the polymer, solution viscosity, conductivity and surface tension) [32], process parameters (voltage, receiving distance and flow rate) [33] and environmental factors (temperature and humidity) [34].

Synthetic polymers have modifiable mechanical properties, but the hydrophobic nature contributes to an absence of cell adhesion and the onset of inflammation, which is usually modified by natural polymers. One problem that most natural polymers suffer from is the deficiency of certain mechanical properties [48]. To combine the advantages of various polymers and overcome their limitations, the desired properties have been achieved using blends of these polymers instead of using single polymers by optimizing the ratio between the components of the blend. During drug release, the hydrophobic properties of the polymer seriously affect the release performance of the loaded drug. Huo and co-workers used PCL blended with gelatin to effectively improve the hydrophobic properties of the composite fiber. Drug release demonstrated that the increased PCL content made the composite fiber more hydrophobic, which belonged to the slow release of artemisinin (ART) and enhanced the therapeutic effect [49]. Chen et al. improved the defect of gelatin’s poor hemostasis ability for large wounds by co-mixing sodium alginate, which can form a gel on the wound surface, and achieved hemostasis of rat wounds in only 1.53 min [50].

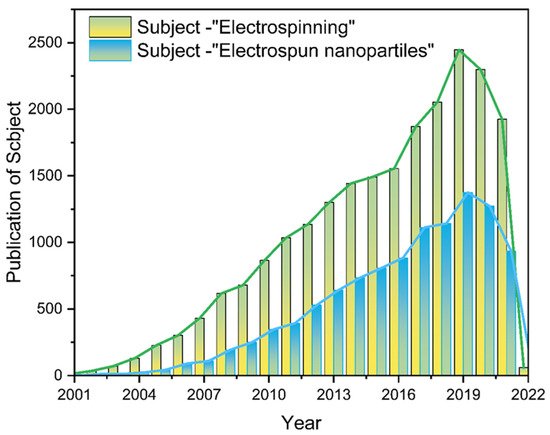

Nanofiber membranes are prepared by the ES process of polymers, and the application scenario is constrained to fiber scaffolds [51,52,53]. Researchers are not satisfied with this single role, so various functional nanofiber membranes have been prepared by ES in combination with multifunctional materials, among which NNHs show great potential to combine the advantages of nanoparticles with the properties of polymers. Additionally, the is a wide range of application scenarios [51,52,53,54,55,56,57,58]. Of interest is that as with decades of research, the number of electrospun nanoparticle articles published occupies half the number of electrostatic spinning (Figure 2). It shows the pivotal position of NNHs.

Figure 2. The literature search statistics of “electrostatic spinning” and “electrospun nanoparticles” on the “Web of Science” platform, respectively.

Multiple nanoparticles have been successfully prepared into nanofibers, which mainly include: metal [59], metal oxide [60] and polymer nanoparticles (NPs) [61,62]. The presence of NPs in polymer solution is uniformly dispersed and will be randomly distributed on the surface or inside the nanofibers (NFs). Therefore, the co-blending of NPs with polymer solutions is the most common form. During the process of electrospinning the mixture into fibers, the homogeneity of NPs in the polymer solution and the interfacial interaction between nanoparticles and polymer solution significantly affect the performance of NNHs. To attenuate the effects of the above factors, the NPs can be mixed by physical mixing methods (stirring and sonication), by dissolving the NPs and polymer in different solvents separately or adding a certain amount of surface activator. The electrospun fiber precursor working solution can effectively reduce the phenomenon of nanoparticle agglomeration and even blockage of the spinning heads after mixing uniformly [63,64,65]. Secondly, other processes combined with ES technology can also effectively load NPs into NFs. For instance, the modification of NFs by plasma technology. This methodology promotes the interaction between NPs and easily loads NPs on the nanofiber surface [66]. The electrospray [67] or magnetron sputtering [68] technology allows the uniform spraying of NPs on the fiber surface. The single-fluid ES process requires mixed solutions with a certain viscosity and dispersion. Otherwise, a non-spinnable or agglomerative phenomenon will occur. Multi-fluid dynamics have been studied for many years. The design of the spinneret is especially important. The morphological structure of the nanofibers is similar to the spinneret structure [69]. Multi-fluid dynamics ES processes often require only one fluid available for spinning to form nanofibers [70]. Zheng et al. used TiO2 suspension as the sheath layer and PEO as the core layer, which perfectly avoided the enrichment of TiO2NPs using a modified coaxial electrospinning process, and the uniform TiO2NPs on the nanofiber surface enhanced the absorption of UV light [71]. The NPs are loaded in nanofibers based on the above single-step process, and if the NPs are not well dispersed in the working solution, many self-assembly strategies are available to grow NPs in the fibers by initiation effects in the precursor solution, including: in situ synthesis [72], hydrothermal-assistance [73] and calcination [74].

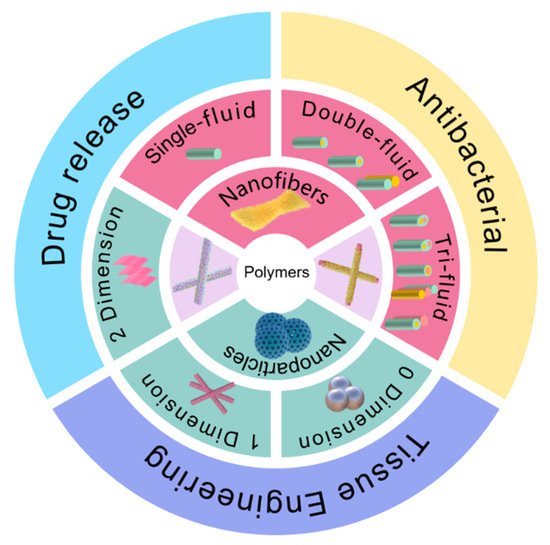

NNHs prepared by combining the characteristics of biocompatible polymers and multifunctional nanoparticles are already practical in medical applications [75,76]. The objective of this review is to investigate the preparation of nanofiber and nanoparticle hybrids in-depth by combining different processes with ES; concentrate on the most recent breakthroughs of NNHs in the medical area (Figure 3); and provide clear concepts for research workers in material preparation and application.

Figure 3. Electrospun fiber and NPs structures and their hybrids in medical direction.

2. The Methods for Creating Polymer-Based Nanofiber-Nanoparticle Hybrids (NNHs)

2.1. Overlapping of Electrospinning and Other Techniques

ES is a top-down molding process for the direct and continuous preparation of nanofibers. NNHs in the preparation of NPs in the spinning precursor solution, due to a certain stability, will not form a homogeneous solution in organic solvents. In addition to the large-scale manufacturing of NNHs, other technologies are often used in further combination with ES.

AgNPs in PCL nanofibers suffer from inhomogeneous dispersion and irregular ion release. To address this problem, Valerini and co-workers employed the magnetron sputtering technique to sputter Ag targets onto the surface of PCL nanofibers at a low power of 500 w. SEM images of PCL NFs after Ag magnetron sputtering show higher contrast. Composite NFs with 22 nm size AgNPs were deposited on the surface. Although the Ag content was only 0.1 wt.%, the PCL-Ag nanofibers showed a faster and stronger antibacterial effect by depositing all AgNPs on the nanofiber surface by magnetron sputtering technique [77]. Immersion of nanofibers (NFs) in NPs suspension loaded with NPs is the simplest approach; however, significant rejection occurs due to the different hydrophilic properties of NPs and NFs, leading to ineffective results. Liu et al. introduced oxygen-containing polar functional groups to the surface of PLLA membranes by a facile plasma technique. Negatively charged pPLLA membranes, impregnated in AgNPs solution, were well aggregated with NPs on the fiber surface driven by electrostatic interactions [78]. Electrospray, a sister technology to electrospun fibers, is commonly employed to generate NPs [79]. Fahimirad and co-workers sprayed chitosan NPs loaded with curcumin onto the surface of PCL/chitosan/curcumin nanofibers by electrospray, which showed no significant change in nanofiber diameter. While effectively promoting the swelling ability and degradation rate of nanofibers, the composite fibers healed 98.5% of the wounds infected by MRSA through wound closure experiments [80].

2.2. Encapsulating Nanoparticles in the Working Fluids

The presence of NPs necessarily affects the spinnability and composite fiber morphology during the preparation of NNHs. NPs appear agglomerated in the working solution, and needle blocking may occur during ES, or the NPs will not appear uniformly on the fibers. These issues can lead to reduced mechanical properties and loss of functional sites in composite fiber membranes. There are three ways to deal with them to avoid a similar situation: (1) disperse NPs uniformly in the working solution by physical methods such as stirring; (2) separately dissolve NPs and polymers in different solvents; (3) modify them using surfactants to promote uniform dispersion. With different natures of nanoparticles and polymer solutions in the mixing process, there is a large interfacial force, and the mixture can be added to a quantitative amount of surfactant, promoting the orderly arrangement of nanoparticles no longer agglomeration. Karagoz and co-workers took this approach by adding a quantitative amount of Triton x-100 (surfactant) to a mixture of ZnO nanorods and DMF, sonicated for 20 min, then added the polymer under rapid stirring until complete dissolution. Fiber diameters were uniformly distributed, and no beads were observed [81].

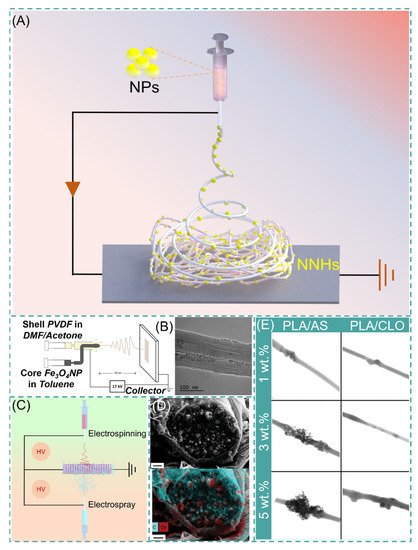

2.3. Formation of NNHs in the Single-Step Process

With a precursor working solution using suitable solvent and proper dispersion, the NPs are uniformly dispersed in the working solution, which requires only a single-step process to form NNHs by adjusting the ES process parameters (Figure 4A). Lopresti et al. incorporated silica (AS) or clay (CLO) NPs into 10% PLA solution and gathered them by a cylindrical grounded drum at 15 KV. The phenomenon of particle aggregation or clustering was evident with the increase in NPs content of the composite fibers (Figure 4E). Moreover, the composites with a certain number of added NPs exhibited brittleness, but bone cells diffused faster on the composites with higher particle content [82]. Abdelaziz and co-workers encapsulated silver nanoparticles (AgNPs) and hydroxyapatite (HANPs) in PCL/CA solution. Interestingly, the tensile stress of the composite fibers loaded with 10% HANPs was up to 3.39 MPa, well above that of pure PCL/CA nanofibers, but then the tensile stress of the composite fibers with 20% HANPs dropped sharply to 2.22 MPa, perhaps because the mechanical property change of NNHs with the addition of nanoparticles is a parabolic. This interesting phenomenon could contribute to the reference of optimizing the relationship between NNHs proportioning and mechanical properties [83].

Figure 4. (A) Simple preparation of NNHs based on the single-step process. (B) Schematic diagram of coaxial preparation of NNHs and Transmission Electron Microscopy (TEM), reprinted with permission from Ref. [84]. Copyright 2021 John Wiley and Sons. (C) Schematic diagram of simultaneous electrospinning and electrospraying. (D) Scanning Electron Microscopy (SEM) images of CDP-PVP-PANI fiber cross-sections and Energy dispersive X-Ray spectroscopy map. Reprinted from Ref. [85]. (E) Scanning Transmission Electron Microscopy (STEM) images of PVA/AS or PVA/CLO fibers with different particle concentrations, Reprinted from Ref. [82].

The polymer solution and NPs are divided into different syringes to eliminate the agglomeration of NPs inside the fibers, which are encapsulated in the fibers by coaxial electrospinning or electrospray. Navarro Oliva and co-workers prepared core-shell-structured NNHs by the coaxial electrostatic spinning technique using an Fe3O4 solution as the core layer and a PVDF polymer solution as the shell layer. As shown in Figure 4B, TEM images showed that the NPs were uniformly dispersed inside the fibers without agglomeration [84]. Combining both electrospinning and electrospraying to prepare NNHs is also a convenient method. These two processes are carried out simultaneously, and NPs can be uniformly distributed in the fiber layer (Figure 4C).

The electrospinning process (ESP) has evolved from single-fluid to multi-fluid as research has progressed [86]. Yu’s research team successfully prepared nanofibers with obvious core-shell structures and smoother fiber surfaces by modified tri-axial ESP and achieved intelligent three-stage controlled drug release [87,88]. Pursuing a simple and convenient preparation method, the main preparation method of NNHs is currently the uniaxial ES process. Integrating the preparation of NNHs with more sophisticated ES techniques is a challenge. The incorporation of NPs somewhat reduces the capability of NFs. There are two obvious drawbacks: (1) The addition the NPs reduces the interactions between polymer chains and decreases the mechanical properties of NNHs. (2) NPs are wrapped in fibers and cannot be functionalized. However, Radacsi et al. avoid the defect that NPs are encapsulated by nanofibers and cannot realize the specific surface area enhancement by using cesium dihydrogen phosphate (CDP) for spontaneous nucleation along the solute growth in porous nanofibers; the moist water in the air acts as a solute transport fast channel. Thus, NPs are not only grown inside the fibers but also are uniformly dispersed on the fiber surface. This strategy perfectly avoids the defect that NPs are encapsulated by nanofibers and cannot realize the specific surface area enhancement (Figure 4D) [85].

2.4. The Nanoparticles from Nanofibers through Molecular Self-Assembly

NPs are formed spontaneously by self-assembly strategies [89,90], combining this scheme with ESP, based on post-processing to form NPs spontaneously in fibers, such as in situ synthesis, hydrothermal-assistance and calcination.

2.4.1. In Situ Synthesis

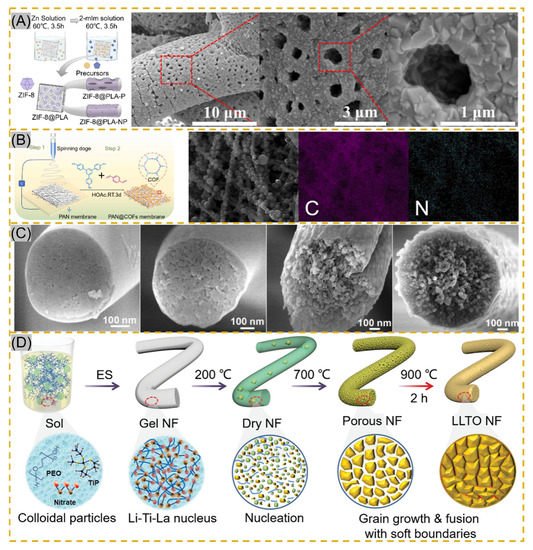

The smooth surface of electrospun fibers and certain stability of the polymer, NPs cannot be perfectly and uniformly attached to the fiber surface by electrostatic adsorption or functional group action. The fiber impregnated with a ligand solution instigates bonding using a reducing agent or other reduction in the composite material to form NPs [91,92]. Lv et al. cross-linked potato starch as a polymer after forming starch fiber mats immersed in AgNO3 solution, and Ag+ was reduced to AgNPs by heating at 60 °C protected from light. The average particle size of AgNPs increased with the concentration of AgNO3, but the particle size decreased significantly and agglomerated together when the concentration reached 100 mg/mL [93]. The technology is also applied to MOF-based nanofibers. Li and co-workers synthesized PW12@UiO-66 crystals in situ on PAA-PVA nanofibers. The surface of the fibers was completely covered by crystals at 12 min of growth, and the MOF crystals were enriched on the surface of NNH but with the disadvantage of random arrangement [94]. Lee and co-workers adopted a hydrodistillation-induced phase separation method to form dense cavities on the surface of PLA nanofibers, followed by uniform growth of ZIF-8 crystals on the porous fiber surface (Figure 5A [95]). Using COF materials with similar properties to MOF, Ma et al. adopted soaking PAN membranes in COF material precursor solutions, where Schiff base condensation occurred at room temperature to form COF spherical particles, and PAN@COF composite fibers showed excellent thermodynamic stability at 300 °C (Figure 5B) [91]. The NNHs prepared by this method, with dense particle aggregation, provide a sufficient number of sites of action that may provide a good solution for the adsorption of tissue fluids or other substances. Similar results from in situ synthesis can be found in Figure 5C [96] and Figure 5D [97].

Figure 5. (A) Schematic of in situ ZIF-8 growth on PLA fibers and Scanning Electron Microscopy (STEM) images of ZIF@PLA-P, reprinted with permission from Ref. [95]. Copyright 2021 ACS Publications. (B) Schematic of PAN@COF synthesis and EDS mapping images reprinted with permission from Ref. [91]. Copyright 2022 Elsevier. (C) Transmission Electron Microscopy images of MBNM films prepared based on different contents of PAA, reprinted with permission from Ref. [96]. Copyright 2021 Elsevier. (D) Schematic of LLTO NF process prepared by electrospinning followed by calcination, reprinted with permission from Ref. [97]. Copyright 2021 John Wiley and Sons.

2.4.2. Calcination

Calcination is another effective method to prepare NNHs. Precursor fibers are prepared by the sol–gel method in combination with ESP, and calcination forms nanoparticles in the fibers [98]. Xie fabricated PVP composite fibers, which were maintained at 800 °C for 30 min, and iron-cobalt (FeCo) alloy nanoparticles (30–50 nm) were uniformly distributed in CNFs (150–300 nm), which achieved electrocatalytic degradation of antibiotics in wastewater [99]. Ding’s research team proposed the use of ball-milling precursor sols to form homogeneous nuclear to precisely control crystal nucleation and growth for the purpose of grain refinement to avoid problems, such as the appearance of impurity phases and crack expansion during the preparation of flexible chalcogenide LLTO nanofibers (Figure 5D). Meanwhile, the soft grain boundary is constructed by adopting 200–900 °C stage calcination, which shows the excellent mechanical properties of flexible electronic fiber films based on perovskite ceramic oxide [92]. Nanofibers obtained by unusual calcination are brittle and inflexible. To reduce such a situation, Shan et al. formed porous structures using the template method with sacrificial PAA heated at 700 °C for 2 h to modulate the PAA concentration driving phase separation during calcination stage pyrolysis (Figure 5C) [91]. Similarly, Li and colleagues inherited the MOF structure in ZIF/PAN-Ni-15 composite nanofibers at the sacrifice of ZIFNPs by calcining at 700 °C for 2 h, followed by annealing to form a rosary morphology in the fibers [74].

2.4.3. Hydrothermal-Assistance

Hydrothermal-assistance is a common method to prepare a variety of inorganic oxide crystals, which is based on the conditions of low temperature and isobaric pressure. The uniform distribution of substances avoids the appearance of impurity phases by means of an aqueous medium, obtaining nanoparticles (such as spheres, cubes, flowers, etc.) with diverse morphologies [100,101,102]. The combination of hydrothermal and ESP for the preparation of multilayer heterostructures provides superior performance at a low cost and is green, easy to operate and well received by researchers. Küçük et al. immersed TiO2 fibers (100–200 nm) in an alkaline Ba (OH)2·8H2O solution by a simple hydrothermal reaction, which unexpectedly transformed the composite fibers into tetragonal crystals, demonstrating that metal oxide nanofibers can also be precursors for the preparation of BaTiO3 crystals [103]. Mukhiya and colleagues grew MOF materials on PAN-prepared carbon nanomats (350 nm). First growth of ZIF-67 crystals was attributed to the hydrothermal reaction of cobalt carbonate hydroxide with 2-methylimidazole. The synthesis of ligands by deprotonated 2-methylimidazole with Co2+ was responsible for the crystals’ second growth. The composite fiber membrane has high specific capacity and excellent service life, with strong advantages in energy storage applications [104]. In terms of the same application, Poudel et al. prepared PAN/PMMA nanofiber membranes using a coaxial ESP and sacrificed the internal PMMA after carbonization to obtain 3D hollow carbon nanofibers (3DHPCNF). By adopting two hydrothermal methods, Fe2O3 was first synthesized on the fiber surface, and then this was used as a precursor to hydrothermally generate ZMALDH@Fe2O3/3DHPCNF with ternary metal salts in an autoclave. The LDH lamellar structure was thinned by changing the content of Zn, and the transformation of nanosheets to nanowires was found at high Zn2+ content, which is a novel top-down way to obtain ternary LDH-electrospun hollow carbon nanofibers, providing a new idea for subsequent design [105].

This entry is adapted from the peer-reviewed paper 10.3390/polym14020351

This entry is offline, you can click here to edit this entry!